Abstract

In this paper, we present a new optimization method to estimate the parameters and torques of an induction motor (IM). The proposed method is known as the Vortex Search Algorithm (VSA), whose performance is based on the behavior of the vortices created by stirred fluids. This algorithm was compared with other four optimization methods reported in the specialized literature (grasshopper optimization algorithm, particle swarm optimization, salp swarm algorithm and sine cosine algorithm), and its solution quality, precision, and robustness were validated using two test motors. During the tests, we analyzed the minimum error between the estimated values and the values provided by the manufacturer, as well as the global error of each method and their required processing time. The results show that the VSA is an excellent alternative to estimate the parameters of an IM, as it exhibited the best performance when compared to the other optimization methods.

Similar content being viewed by others

1 Introduction

Induction motors (IMs) are electrical machines commonly used in industrial environments and intended to harness the rotary motion they produce. These motors are composed of a stator containing a synchronous machine within a squirrel-cage rotor or winding. Additionally, when compared to other types of motors, IMs require less maintenance (Sakthivel et al. 2010; Martinez-Herrera et al. 2022). Due to the rapid development of semiconductor technologies, motor models, and control methods, IMs are becoming increasingly attractive and popular to perform direct current (DC) motor functions in the field of speed control (Boros and Bodnár 2023), allowing them to be widely employed at the industrial level (Bojoi et al. 2008) and in the growing field of electric mobility (Tousizadeh et al. 2018; Fathy Abouzeid et al. 2020). Thus, there is a significant interest among the scientific community in developing strategies to characterize IMs and thus improve their performance in terms of torque (El Ouanjli et al. 2019; Chasiotis et al. 2022; Younas et al. 2022). For such characterization, an equivalent circuit is often used and modeled mathematically to determine the parameters of the corresponding circuit, such as stator resistance and reactance, rotor resistance and reactance, and magnetizing reactance (Al-Jufout et al. 2018; Carbonieri et al. 2019; Gülbahçe and Karaaslan 2022; Kharlamov et al. 2018; Puri and Chauhan 2022). Estimating the parameters of an IM is important because these parameters can be used to design an appropriate control strategy for speed regulation (Khamehchi et al. 2006; Anagreh and Al-Ibbini 2023).

Notwithstanding, because of the three-phase nature of IMs, it is difficult to get an accurate representation of their dynamic behavior, as in the case of transient state stability (Koubaa 2006). To solve this problem, the parameters of the equivalent circuit of an IM must be determined, with the main challenge being the construction of a mathematical model able to represent its behavior, as there is typically no information available regarding motors in industrial environments (Arslan et al. 2012; Singh 2023). It is, therefore, unusual to find features of IMs using mathematical models for industrial applications (Pustovetov 2016; Akinloye and Obe 2022).

1.1 Induction Motors and Parameter Estimation

One of the techniques used to estimate the parameters of an IM is traditional laboratory testing (Say 1976; Sengamalai et al. 2022), which consists in conducting vacuum tests with the rotor shaft locked. Although this technique is the most widely employed in industrial settings, its manipulation is extremely dangerous, even for skilled workers. Moreover, for health reasons, these tests should be performed at a voltage lower than the operating one, which can affect the results. For this reason, an intelligent IM drive capable of determining the motor parameters while avoiding isolation from its system must be used.

According to the literature reviewed, methodologies other than the traditional ones, such as optimization techniques, have also been employed for IM parameter estimation. For instance, in Koubaa (2006), the least-squares method was used to identify the parameters of a steady-state equivalent circuit. In such study, a linear parameter estimation technique was employed to calculate the rotor resistance, rotor self-inductance, and stator leakage inductance of a three-phase IM. This method, however, requires an average of the estimated values to obtain a linear regression model of the system that fits the approximate motor parameters. Furthermore, it tends to use a considerable amount of memory, thus limiting the number of parameters that can be estimated in the model.

Other techniques that have been used for IM parameter estimation are particle swarm optimization (PSO) and improved particle swarm optimization (IPSO) (Sakthivel et al. 2010). Sakthivel et al. (2010), the authors proposed estimating additional properties of an IM, such as torque, starting current, and peak current, using three methods: PSO, IPSO, and the classical method. Although the results they obtained with the IPSO and PSO methods are interesting, there is no a significant difference when compared to the classical method. In fact, the results of some parameters such as starting torque showed a lower approximation when compared to those obtained with the classical method, which questions the effectiveness of the proposed solutions. The differential evolution (DE) algorithm (Arslan et al. 2012; Subudhi and Jena 2009), has also been employed to estimate the RLC (resistor, inductor, and capacitor) components of the equivalent circuit of a single-phase IM, which correspond to the electrical values of the stator and rotor. This algorithm, however, requires a priori and well-defined knowledge in order to converge in a reasonable time; otherwise, it may not converge at all. Giri et al. (2010), an improved differential evolution algorithm known as differential evolution (DE) with a neighborhood-based mutation scheme showed better performance and approximation when compared to the genetic algorithm (GA) and PSO. Nevertheless, although the proposed algorithm outperformed the GA and PSO, the authors of such paper failed to mention fundamental aspects of the applied methodology, which raises the question of whether the comparison between the methods was fair.

Hybrid genetic algorithms (HGAs) have also been developed for IM parameter estimation (Sundareswaran et al. 2008), with the idea that combining optimization techniques can increase performance in parameter estimation. Nonetheless, despite their outstanding results reported in the literature, these algorithms require a reasonable time for the proposed initial population to converge to a global optimum and thus avoid premature convergence. Similarly, studies carried out using the GA have yielded approximate results (Kampisios et al. 2008), demonstrating that this is an equally applicable optimization technique. However, since this estimation is done during production, the motor can be constantly subjected to variable loads that may be ignored and may modify the steady-state parameters of the circuit; hence, the error in one of the variables reported in the results would be significant.

In addition to the algorithms mentioned above, other techniques such as the Shuffled Frog-Leaping Algorithm (SFLA) and the imperialist competitive algorithm (ICA) (Ojaghi and Mardani 2011) have also been used to estimate the parameters of the equivalent circuit of an steady-state IM. The results obtained with these techniques have proven to be sufficiently close to the reference information in the motor nameplate. Likewise, the ant colony optimization (ACO) method has produced satisfactory results when compared to other algorithms such as the GA and the adaptive genetic algorithm (AGA) (Chen et al. 2008), particularly with a \(50\%\) reduction in processing time. However, the initial conditions for the GA and the AGA were not specified in Chen et al. (2008), making it difficult to establish a baseline from which to compare the selected populations and their effect on the remarkably reduced processing time of the ACO versus that of the other algorithms.

Furthermore, various studies have compared different algorithms previously validated in the literature to see which one performs better. For instance, in Çanakoğlu et al. (2014), the charged system search (CSS), the GA, the DE algorithm, and PSO were employed to estimate classical motor parameters reported in the literature (e.g., torque and peak current), as well as the values of each RLC component of the equivalent circuit. The good results obtained by the CSS when compared to the other algorithms are, however, severely hampered by the processing time it requires to converge.

Kim and Kim (2005), the Dynamic Encoding Algorithm for Searches (DEAS) was used to estimate the parameters of an IM, and its results were compared with those obtained by the continuous time prediction error method and the AGA. The DEAS was found to outperform the other two methods in terms of iterations and processing time. However, due to its nonlinear and parallel-processing nature, this algorithm has a high computational cost. Therefore, it is preferable to use other techniques that produce approximate results but have lower computational costs.

In summary, the different studies applied under the different approaches for parameter estimation of IMs have limitations due to their complexity concerning the mathematical model, as well as the determination of a precise cost function and a validation of results in terms of solution quality and time. In addition, there is no detailed analysis of statistical results or comprehensive demonstration that would allow accurate evaluation of parameter estimation in IMs. To address such limitations, it is proposed the use of an objective function, a specific procedure for the estimation of its parameters, its incorporation from the manufacturer’s data sheet, the implementation of various optimization techniques to determine which technique performs better regarding quality and solution time; finally, a statistical analysis to determine the diversity of the obtained results in each iterative process generated to validate the repeatability of the algorithms and their processing times. For this reason, this paper proposes a methodology to solve the parameter estimation problem in IMs, replicable using open source software; characterized by detailing a precise objective function considering the fundamental parameters for IMs, and the use of the VSA algorithm proposed by Razavi and Sajedi (2019); which is selected for its high performance in solving engineering problems, reported in the industrial and research fields (Liu et al. 2023, 2023; Gong et al. 2023).

1.2 Contributions

Considering that the studies mentioned above present acceptable results but do not provide a detailed description of the applied methodology, the following are the key contributions of this study:

-

A new application for the Vortex Search Algorithm (VSA).

-

A new methodology to solve the IM parameter estimation problem.

-

A clear and detailed methodology with comprehensive considerations to solve the IM parameter estimation problem.

-

Exploration of various optimization techniques, aiming to identify and validate which optimization algorithm provides the optimal results regarding both solution quality and consistency of results for parameter estimation in IMs.

-

Statistical validation through an exhaustive sequence of global iterations for each optimization algorithm (100 global iterations), ensuring the determination of the most efficient technique in terms of solution excellence and speed of convergence in IM parameter estimation.

1.3 Paper Organization

The rest of this paper is organized as follows. Section 2 presents the mathematical formulation of the IM parameter estimation problem, along with its representative model and the constraints considered in this study. Section 3 introduces the proposed optimization technique to solve the IM parameter estimation problem. Section 4 describes the test motors and the considerations of this study, as well as the parameter constraints, specifications, and characteristics of the test motors. Section 5 reports the results obtained by the optimization algorithms. Finally, Sect. 6 draws the conclusions and makes recommendations for future research.

2 Mathematical Formulation

The IM parameter estimation problem is linked to a set of constraints associated with the estimation of the equivalent circuit parameters. These constraints help to determine the best values that fit the equivalent mathematical model of the IM. For such purpose, the equivalent circuit per phase of a three-phase IM is considered, as shown in Fig. 1. The values of each component of the circuit are used to determine the nominal torque (\(T_{n}\)), starting torque (\(T_{st}\)), and maximum torque (\(T_{\max }\)) of the IM. Likewise, the stator resistance and reactance (R1, X1), the rotor resistance and reactance (R2, X2), and the magnetizing reactance \((X_m)\) are estimated using the values of such torques. The actual or starting torque specifications are defined by the manufacturer and can be usually found in the motor nameplate or user manual (Kim and Kim 2005). These torque values, however, are not always accurate; the actual ones may be above or below the initial parameters. Errors in the torque value delivered by IMs can cause different problems, such as (i) harm to the process in which the IM is being used or (ii) internal damage to the IM, thus reducing its lifespan or overall operating capacity. Hence, the importance of properly and accurately calculating the IM parameters. Based on the estimation of the parameters of the single-phase circuit components, the equations below can be used to determine the actual torque values of an IM.

Equations (1)–(3) represent the different torques of the IM, where \(T_n\) denotes the nominal torque; \(T_{st}\), the starting torque; and \(T_{\max }\), the maximum torque that can be obtained from the IM. Each equation consists of different variables, which are calculated using the motor specifications, such as voltage level, power, and number of poles (Sakthivel et al. 2010). Table 1 shows the motor specifications. The equations employed to determine the variables used to calculate the different torques are presented in Çanakoğlu et al. (2014) and are listed below.

In these equations, K represents a constant coefficient; \(\omega _s\) denotes the angular velocity; \(V_{th}\), \(R_{th}\), and \(X_{th}\) are the voltage, the resistance, and the Thevenin’s reactance, respectively; and \(V_s\) is the power supply.

2.1 Objective Function

In this study, the objective function is to minimize the error between the torque values computed based on the parameters estimated by the optimization algorithms.

The equations described above [Eqs. (1)–(3) and (5)] are employed to determine the most accurate values for the stator and rotor resistances and reactances and magnetizing reactance of the IM. The torque values, as well as the error between the estimated torque values and the actual torque values (those provided by the manufacturer), are also calculated using such equations.

The error is calculated by comparing the actual torque (the one provided by the manufacturer) and the torque error computed after estimating the parameters of the IM. The lower the error, the higher the accuracy in the IM parameter estimation.

2.2 Considerations

In order to estimate its parameters and different torque values, the specifications of the IM must be known. Table 1 reports the specifications of the two test motors used in this study.

The actual torque values and the rotor and stator parameters to be estimated must also be known. Hence, the torque values provided by the manufacturers are used as reference. Table 2 shows the actual torque values of Motor 1 and Motor 2, which are used as reference and which allowed us to calculate the error between the actual torque values and those estimated by the optimization algorithms.

3 Proposed Methodology: Vortex Search Algorithm (VSA)

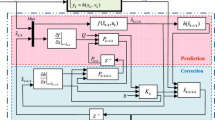

The VSA is a bio-inspired optimization technique used to solve discrete and continuous problems, and its behavior is based on the vortices created by stirred fluids. It has advantages over other optimization methods because it generates candidate solutions around the current best solution using Gaussian distributions that are executed at each iteration process (better exploration and exploitation characteristics). Moreover, the vortices have a variable radius that allows them to explore the solution space (Doğan and Ölmez 2015; Montoya et al. 2019). This behavior can be modeled mathematically, allowing the VSA to be employed as an optimization method. This algorithm can be used, for example, to solve problems such as estimating the parameters of an IM and ensuring an optimal global solution. The next subsections describe the stages followed in this study for the computational development and to find a solution to the IM parameter estimation problem using the VSA (Razavi and Sajedi 2019).

3.1 Generating the Initial Solutions

The VSA works with nonconcentric hyperspheres, with a radius (\(t_{t}\)) that represents the size of the solution space and a center that represents the current best solution. Equation (9) can be used to define the initial values of the hypersphere, where \(x^{\max }\) and \(x^{\min }\) are vectors of size \(1\times d\) that denote the upper and lower limits of the variables associated with the problem, respectively.

3.2 Generating the Set of Candidate Solutions

The set of candidate solutions is represented as C(s) in each iteration process (t). These solutions are generated by a Gaussian distribution using the size of the problem (1xd), where \(C_{n,d}^{t}(s)=\left\{ s_(n,1),~s_(n,2),~\ldots ,~s_(n,d) \right\}\), with n being the number of candidate solutions. Equation (10) is used to create the Gaussian distribution.

Probability distribution \(\varsigma _{(n,d)}^{t}\) is a vector of random values, where \(\mu _{t}\) represents the center of the hypersphere at the current iteration (t), and v is a covariance matrix (Montoya et al. 2019). The radius of the hypersphere is critical in the evolutionary process of the VSA because of its process with random values, which is represented by \(\varsigma _{(n,d)}^{t}=r_{t}rand(n, d)\), where rand(n, d) denotes random numbers in the \([0-1]\) range considering the number of particles (n) and the dimension of the problem (d).

3.3 Selecting the New Center of the Hypersphere

In the iterative process of the VSA, it is necessary to find the center of the hypersphere (the best solution found so far) defined in \(C_{(n,d)}^{t}(s)\), that is, \(\mu _{(t+1)}=s_{{Best}_{(n,d)}}^{t}\). This occurs in the IM parameter estimation problem, where the number of columns (d) corresponds to the number of estimated parameters of the IM equivalent circuit, i.e., the stator resistance and reactance (R1, X1), the rotor resistance and reactance (R2, X2), and the magnetizing reactance (\(X_{m}\)), which are used to calculate the actual values of the starting torque (\(T_{st}\)), nominal torque (\(T_{n}\)), and maximum torque (\(T_{\max }\)).

3.4 Reducing the Radius of the Hypersphere

In a previous study, it was shown that the recommended way to gradually reduce the radius of the hypersphere is to use an exponential version of the gamma functions (Montoya et al. 2019), as shown in Equation (11).

In this equation, \(\theta\) denotes the fitting parameter that governs the rate of reduction of the radius of the hypersphere, and \(t_{\max }\) is the maximum number of iterations (Qyyum et al. 2020).

3.5 Stopping Criteria

Two stopping criteria, which are described below, are employed.

-

The optimization algorithm will end when the incumbent solution to the problem is not updated after n consecutive iterations. In other words, the iterative process finishes when the objective function has reached a given number of iterations (non-improvement counter) and no better solutions to the problem have been found.

-

The computational analysis will end when the optimization algorithm reaches the maximum number of allowable iterations. The iterations of the algorithm are controlled by a counter.

Algorithm 1: VSA

4 Test Motors and Considerations

To validate performance of the optimization and parameter estimation methodology proposed in this study, two induction motors were used as test motors. Their basic characteristics are shown in Table 3.

Certain characteristics of the two test motors must be taken into account. For instance, Motor 1 (Çanakoğlu et al. 2014) is a squirrel-cage motor with a delta configuration, which means that its nominal voltage does not change. Additionally, as shown in Table 4, the starting torque of this motor is lower than its nominal voltage, implying that the motor has a soft starter. As for Motor 2 (Sakthivel et al. 2010), its wye connection must be considered, and calculations must be carefully made because this wye connection implies that its nominal voltage will be divided by the square root of three.

To conduct this study, it was necessary to know the actual R1, X1, R2, X2, and \(X_{m}\) of the motors, as well as their actual \(T_{n}\), \(T_{st}\), and \(T_{\max }\) values, which are provided by the manufacturer and presented in Table 4.

Parameter constraints were also considered in this study, which allow the optimization method to explore a limited region where potential solutions can be found. Such constraints were defined based on the actual values of the parameters. The initial population of solutions is generated randomly, and the next population is generated according to the parameter constraints as shown in Table 5.

4.1 Methods Used for Comparison Purposes

To validate the robustness and the quality of the solution provided by the proposed methodology, it was compared, under the same scenarios and conditions, to the following optimization methods: the Grasshopper Optimization Algorithm (GOA), Particle Swarm Optimization (PSO), the Salp Swarm Algorithm (SSA), and the Sine Cosine Algorithm (SCA). Additionally, in order for each method to obtain the best possible results, each algorithm was tuned using the arithmetic optimization algorithm. This tuning was carried out considering variations in the maximum number of iterations, the maximum number of non-improvement iterations, and the size of the population. Table 6 shows the results of such tuning.

After obtaining the tuning data, the parameters of the two IM were estimated considering the actual values provided by the manufacturer, as well as all the specifications representing the induction motor’s mathematical model, as described in Sect. 2. The next section presents the results of such estimation.

5 Simulations and Results

This section discusses the results obtained by the proposed methodology and the other methods employed to solve the IM parameter estimation problem. To assess the quality of each solution, we compared the actual values and those estimated using the equations governing the IM’s mathematical model. Also, we analyzed the global error of each optimization algorithm, along with the processing time each required to solve the parameter estimation problem. In addition to analyzing the error in the parameters, it is computed the error between the actual torque values and the torque values calculated based on the parameters estimated by each optimization algorithm. Tables 7 and 8 show the results of such analysis, and Table 9 reports the global error and processing time of each optimization method used in this study.

Concerning the results of parameter estimation, Table 7 shows that, in Motor 1, R1 and Xm were the parameters with the highest estimation error, while R2 and X1,X2 were those with the lowest estimation error. Regarding Xm, the GOA and the SSA presented the lowest estimation error. As for R1, the algorithm with the lowest estimation error was the GOA (31.31%). For R1 and Xm, the VSA obtained an estimation error of 50% and 34.55%, respectively. Regarding R1 and Xm in Motor 2, the VSA achieved the best estimation accuracy, with a 4.51% error in estimating R1 and a 14.44% error in estimating Xm. As for R2 in Motor 1, the method with the lowest estimation error was the SSA (0.09%), followed by the VSA, with an error of 0.47%. Regarding X1,X2 in Motor 1, the method with the best estimation accuracy was the VSA, with an error of 0.85%. As for R2 in Motor 2, the SCA achieved the best estimation accuracy, with an error of 0.70%, followed by the VSA, with an error of 0.80%. The estimation accuracy of the SCA was 0.09% better than that of the VSA.

After obtaining the estimated parameters, we calculated the different torques resulting from such parameters. Both the parameters and the torque values provided by the manufacturer must be considered to calculate the error between the values from factory and the values estimated based on the parameters. Table 8 shows the results obtained by each optimization algorithm. Regarding Motor 1, the VSA presented the lowest average error in torque estimation (2.53%), with an estimation error of 0.007, 0.001, and 7.591% for \(T_{n}\), \(T_{st}\), and \(T_{\max }\), respectively. This average error is 0.40% better than that obtained by the other methods. As for Motor 2, the VSA also obtained the lowest average error in torque estimation (0.16%), thus outperforming the GOA, the SCA, the SSA, and PSO by 0.92, 0.83, 0.15, and 1.08%, respectively. According to the results, \(T_{\max }\) in Motor 1 was the torque with the worst estimation accuracy because Motor 1 also presented a poor parameter estimation.

Table 9 shows the results of the objective function \((E_T)\), or the global error of each method, as well as the processing time each required to solve the parameter estimation problem. The method with the best performance in estimating the parameters of Motor 1 was the VSA, followed by PSO and, finally, the SCA. Regarding parameter estimation for Motor 2, the method with the best performance was the VSA, followed by the SCA and, finally, PSO, whereas those with the worst performance were the SSA and the GOA.

The Torque-slip curves in Figs. 2 and 3 were generated using the estimated parameters and torques and then compared with the curve obtained using the actual values provided by the manufacturer. When analyzing the error between the curve generated with the values provided by the manufacturer and the curves obtained with the estimated parameters, we observed that, although the curves were similar, the error in Motor 1 was higher than that in Motor 2. In Motor 1, the method with the highest error was the GOA, and that with the lowest error was the VSA, followed by the SSA. In Motor 2, the method with the highest error was also the GOA, and that with the lowest error was the VSA, followed by the SCA, PSO, and, finally, the SSA.

Figure 4 illustrates the performance of the optimization methods used in this study by comparing the processing time each required to estimate the motor parameters and their global error in the estimation of such parameters. As observed, the VSA had the best performance in Motors 1 and 2. Regarding Motor 1, even though PSO required less processing time than the VSA, its global error in parameter estimation was higher than that of the VSA. As for Motor 2, the VSA and PSO required similar processing times, but the global error of the VSA in parameter estimation was lower.

6 Conclusions

In this study, the VSA was used for the first time to estimate the parameters of the equivalent circuit of an induction motor. The results obtained with the proposed methodology were compared to those obtained with other four metaheuristic optimization methods (GOA, PSO, SCA, and SSA) in two different test motors. The known equivalent circuit parameters and torque-slip characteristics of the coiled rotor (Motor 2) were taken from Sakthivel et al. (2010), and the equivalent circuit parameters of the squirrel-cage motor (Motor 1) were taken from Çanakoğlu et al. (2014).

According to our findings, the VSA proposed in this paper showed the best performance when compared to the other four algorithms reported in the literature to solve the parameter estimation problem. In terms of global error and processing time, it performed well in estimating the parameters of Motors 1 and 2. Additionally, the torque-slip curve obtained with the proposed method presented the lowest error in Motor 1 and Motor 2. Figure 4 shows the performance of the optimization methods in terms of the global error to processing time ratio. From the information in Table 8, we may conclude that errors in parameter estimation directly affect torque estimation, as observed in the estimated \(T_{\max }\) value in Motor 1.

Furthermore, this paper presents a detailed implementation of the VSA, as well as the mathematical model of an induction motor and a proper way to estimate its parameters. Thus, the VSA is considered the most adequate method to solve this kind of problems.

References

Akinloye BO, Obe ES (2022) Performance analysis of single-phase interior permanent magnet synchronous motor. Int J Power Electron Drive Syst 13(2):812

Al-Jufout SA, Al-Rousan WH, Wang C (2018) Optimization of induction motor equivalent circuit parameter estimation based on manufacturer’s data. Energies 11(7):1792

Anagreh Y, Al-Ibbini A (2023) Low cost high performance self-starting sensorless single phase induction motor drive. Int J Power Electron Drive Syst 14(1):123

Arslan M, Çunkaş M, Sağ T (2012) Determination of induction motor parameters with differential evolution algorithm. Neural Comput Appl 21(8):1995–2004

Bojoi R, Guglielmi P, Pellegrino G-M (2008) Sensorless direct field-oriented control of three-phase induction motor drives for low-cost applications. IEEE Trans Ind Appl 44(2):475–481

Boros RR, Bodnár I (2023) Effect of spwm inverter in combination with solar uninterruptible induction motor drive. Energies 16(13):5061

Çanakoğlu Aİ, Yetgin AG, Temurtaş H, Turan M (2014) Induction motor parameter estimation using metaheuristic methods. Turk J Electr Eng Comput Sci 22(5):1177–1192

Carbonieri M, Bianchi N, Alberti L (2019) Induction motor mapping using rotor field-oriented analysis technique. In: IEEE energy conversion congress and exposition (ECCE). IEEE, pp 2321–2328

Chasiotis ID, Karnavas YL, Scuiller F (2022) Effect of rotor bars shape on the single-phase induction motors performance: an analysis toward their efficiency improvement. Energies 15(3):717

Chen Z, Zhong Y, Li J (2008) Parameter identification of induction motors using ant colony optimization. In: IEEE congress on evolutionary computation (IEEE world congress on computational intelligence). IEEE, pp 1611–1616

Doğan B, Ölmez T (2015) A new metaheuristic for numerical function optimization: vortex search algorithm. Inf Sci 293:125–145

El Ouanjli N, Derouich A, El Ghzizal A, Motahhir S, Chebabhi A, El Mourabit Y, Taoussi M (2019) Modern improvement techniques of direct torque control for induction motor drives—a review. Protect Control Mod Power Syst 4(1):1–12

Fathy Abouzeid A, Guerrero JM, Endemaño A, Muniategui I, Ortega D, Larrazabal I, Briz F (2020) Control strategies for induction motors in railway traction applications. Energies 13(3):700

Giri R, Chowdhury A, Ghosh A, Panigrahi BK, Das S (2010) Offline parameter estimation of induction motor using a meta heuristic algorithm. In: International conference on swarm, evolutionary, and memetic computing. Springer, pp 523–530

Gong Y, Zoltán ES, Gyergyák J (2023) A neural network trained by multi-tracker optimization algorithm applied to energy performance estimation of residential buildings. Buildings 13(5):1167

Gülbahçe MO, Karaaslan ME (2022) Estimation of induction motor equivalent circuit parameters from manufacturer’s datasheet by particle swarm optimization algorithm for variable frequency drives

Kampisios K, Zanchetta P, Gerada C, Trentin A, Jasim O (2008) Induction motor parameters identification using genetic algorithms for varying flux levels. In: 13th international power electronics and motion control conference. IEEE, pp 887–892

Khamehchi S et al (2018) Identification of the induction motor parameters at standstill including the magnetic saturation characteristics

Kharlamov V, Moskalev YV, Lysenko V (2018) Connection three-phase winding of the induction motor to a single-phase electrical network. In: Dynamics of systems, mechanisms and machines (dynamics). IEEE, pp 1–4

Kim J-W, Kim SW (2005) Parameter identification of induction motors using dynamic encoding algorithm for searches (DEAS). IEEE Trans Energy Convers 20(1):16–24

Koubaa Y (2006) Application of least-squares techniques for induction motor parameters estimation. Math Comput Model Dyn Syst 12(4):363–375

Liu J, Li H, Li Y, Zhou H (2023) An enhanced vortex search algorithm based on fluid particle density transfer for global and engineering optimization. Appl Soft Comput 135:110024

Liu J.-S, Li H.-R, Li Y, Zhou H (2023) A dynamic vortex search algorithm of flow field attraction for large-scale complex global optimization. Acta Electon Sin 1

Martinez-Herrera AL, Ferrucho-Alvarez ER, Ledesma-Carrillo LM, Mata-Chavez RI, Lopez-Ramirez M, Cabal-Yepez E (2022) Multiple fault detection in induction motors through homogeneity and kurtosis computation. Energies 15(4):1541

Montoya OD, Gil-González W, Grisales-Noreña LF (2019) Vortex search algorithm for optimal power flow analysis in dc resistive networks with cpls. IEEE Trans Circuits Syst II: Express Br 67(8):1439–1443

Ojaghi M, Mardani M (2011) Parameter estimation of induction motor using shuffled frog leaping and imperialistic competitive algorithms. In: 26th international power system conference, pp 1–9

Puri V, Chauhan YK (2022) Offline parameter estimation of a modified permanent magnet generator using GSA and GSA-PSO. Soft Comput 26(13):6333–6345

Pustovetov MY (2016) A mathematical model of the three-phase induction motor in three-phase stator reference frame describing electromagnetic and electromechanical processes. In: Dynamics of systems, mechanisms and machines (dynamics). IEEE, pp 1–5

Qyyum MA, Yasin M, Nawaz A, He T, Ali W, Haider J, Qadeer K, Nizami A-S, Moustakas K, Lee M (2020) Single-solution-based vortex search strategy for optimal design of offshore and onshore natural gas liquefaction processes. Energies 13(7):1732

Razavi SF, Sajedi H (2019) SVSA: a semi-vortex search algorithm for solving optimization problems. Int J Data Sci Analyt 8(1):15–32

Sakthivel V, Bhuvaneswari R, Subramanian S (2010) An improved particle swarm optimization for induction motor parameter determination. Int J Comput Appl 1(2):62–67

Sakthivel V, Bhuvaneswari R, Subramanian S (2010) Multi-objective parameter estimation of induction motor using particle swarm optimization. Eng Appl Artif Intell 23(3):302–312

Say MG (1976) Alternating current machines. Pitman

Sengamalai U, Anbazhagan G, Thamizh Thentral T, Vishnuram P, Khurshaid T, Kamel S (2022) Three phase induction motor drive: a systematic review on dynamic modeling, parameter estimation, and control schemes. Energies 15(21):8260

Singh G (2023) Comparison between two offline artificial intelligence methods for an efficiency estimation of in-service induction motors. IETE J Res 1–9

Subudhi B, Jena D (2009) Differential evolution computation applied to parameter estimation of induction motor

Sundareswaran K, Shyam H, Palani S, James J (2008) Induction motor parameter estimation using hybrid genetic algorithm. In: 2008 IEEE region 10 and the 3rd international conference on industrial and information systems. IEEE, pp 1–6

Tousizadeh M, Che HS, Selvaraj J, Abd Rahim N, Ooi B-T (2018) Performance comparison of fault-tolerant three-phase induction motor drives considering current and voltage limits. IEEE Trans Ind Electron 66(4):2639–2648

Younas MB, Khalid H, Javed A, Yetis H, Goktas T, Arkan M (2022) Performance enhancement of single-phase induction motor using GA based multi-objective optimisation. Int J Electron 109(9):1473–1492

Funding

Open Access funding provided by Colombia Consortium.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Montano, J., Garzón, O.D., Herrera-Jaramillo, D.A. et al. Estimating the Parameters of a Three-Phase Induction Motor using the Vortex Search Algorithm. Iran J Sci Technol Trans Electr Eng 48, 337–347 (2024). https://doi.org/10.1007/s40998-023-00673-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40998-023-00673-y