Abstract

Coal gangue (CG) is an environmental waste that faces an urgent demand for disposal in China. The utilization of CG in construction materials has broad application prospects and gained increasing interest. However, the poor compatibility of polycarboxylate superplasticizer (PCE) with CG powder hinders its efficiency in a wide range of applications. Here, this paper attempts to improve the compatibility of PCE with CG powder in cement paste based on the regulation of aggregation and the adsorption behavior of PCE. Dynamic light scattering (DLS) and fluorescence spectroscopy tests were carried out to understand the improved mechanism. The results indicated that the addition of CG powder increases the ionic strengths of the cement liquid phase, which makes PCE tend to aggregate at a lower concentration compared with no CG powder introduction. Adding (CH3COO)2Cu is beneficial for enhancing the workability of cement paste by reducing PCE aggregation while maintaining the compressive strength of cement specimens. Therefore, (CH3COO)2Cu extra addition can be regarded as an effective and sustainable way to improve the workability of cement paste with CG powder.

Graphical abstract

Similar content being viewed by others

Data availability

Data will be made available on request.

References

International Energy Agency Statistics. 2023. Tracking Clean Energy Progress 2023. Available at: https://www.iea.org/reports/tracking-clean-energy-progress-2023. Accessed 15 June 2023.

Li, H., Zheng, F., and Wang, J. 2020. Facile preparation of zeolite-activated carbon composite from coal gangue with enhanced adsorption performance. Chemical Engineering Journal 390: 124513. https://doi.org/10.1016/j.cej.2020.124513.

Zhou, C., Liu, X., Zhao, Y., et al. 2021. Recent progress and potential challenges in coal upgrading via gravity dry separation technologies. Fuel 305: 121430. https://doi.org/10.1016/j.fuel.2021.121430.

Zhang, L., Zhang, W., Li, M., et al. 2022. Coal fly ash reinforcement for the property enhancement of crude glycerol-based polyurethane foam composites. Waste Disposable and Sustainable Energy 4: 271–282. https://doi.org/10.1007/s42768-022-00112-4.

Stracher, G.B., and Taylor, T.P. 2004. Coal fires burning out of control around the world: Thermodynamic recipe for environmental catastrophe. International Journal of Coal Geology 59: 7–17. https://doi.org/10.1016/j.coal.2003.03.002.

Yao, C., Shen, Z., Wang, Y., et al. 2023. Tracing and quantifying the source of heavy metals in agricultural soils in a coal gangue stacking area: Insights from isotope fingerprints and receptor models. Science of The Total Environment 863: 160882. https://doi.org/10.1016/j.scitotenv.2022.160882.

Li, J., Wang, W., Xu, D., et al. 2020. Preparation of sulfoaluminate cementitious material using harmful titanium gypsum: Material properties and heavy metal immobilization characteristics. Waste Disposable and Sustainable Energy 2: 127–137. https://doi.org/10.1007/s42768-020-00038-9.

Li, J., and Wang, J. 2019. Comprehensive utilization and environmental risks of coal gangue: A review. Journal of Cleaner Production 239: 117946. https://doi.org/10.1016/j.jclepro.2019.117946.

Zhang, J., Chen, T., and Gao, X. 2021. Incorporation of self-ignited coal gangue in steam cured precast concrete. Journal of Cleaner Production 292: 126004. https://doi.org/10.1016/j.jclepro.2021.126004.

Huang, G., Ji, Y., Li, J., et al. 2018. Improving strength of calcinated coal gangue geopolymer mortars via increasing calcium content. Construction and Building Materials 166: 760–768. https://doi.org/10.1016/j.conbuildmat.2018.02.005.

Liu, C., Deng, X., Liu, J., et al. 2019. Mechanical properties and microstructures of hypergolic and calcined coal gangue based geopolymer recycled concrete. Construction and Building Materials 221: 691–708. https://doi.org/10.1016/j.conbuildmat.2019.06.048.

Mao, N., Wu, D., Chen, K., et al. 2023. Combining experiments and molecular dynamics simulations to investigate the effects of water on the structure and mechanical properties of a coal gangue-based geopolymer. Construction and Building Materials 389: 131556. https://doi.org/10.1016/j.conbuildmat.2023.131556.

Cheng, Y., Shen, H., and Zhang, J. 2023. Understanding the effect of high-volume fly ash on micro-structure and mechanical properties of cemented coal gangue paste backfill. Construction and Building Materials 378: 131202. https://doi.org/10.1016/j.conbuildmat.2023.131202.

Zhang, S., Cao, M., Zhang, K., et al. 2023. Wrapped coal gangue aggregate enhancement ITZ and mechanical property of concrete suitable for large-scale industrial use. Journal of Building Engineering 72: 106649. https://doi.org/10.1016/j.jobe.2023.106649.

Qiu, J., Cheng, K., Zhang, R., et al. 2022. Study on the influence mechanism of activated coal gangue powder on the properties of filling body. Construction and Building Materials 345: 128071. https://doi.org/10.1016/j.conbuildmat.2022.128071.

Wu, D., Chen, T., Hou, D., et al. 2023. Utilization of coal gangue powder to improve the sustainability of ultra-high performance concrete. Construction and Building Materials 385: 131482. https://doi.org/10.1016/j.conbuildmat.2023.131482.

Dong, Z., Xia, J., Fan, C., et al. 2015. Activity of calcined coal gangue fine aggregate and its effect on the mechanical behavior of cement mortar. Construction and Building Materials 100: 63–69. https://doi.org/10.1016/j.conbuildmat.2015.09.050.

Guan, X., Qiu, J., Song, H., et al. 2019. Stress–strain behaviour and acoustic emission characteristic of gangue concrete under axial compression in frost environment. Construction and Building Materials 220: 476–488. https://doi.org/10.1016/j.conbuildmat.2019.06.008.

Guan, X., Chen, J., Zhu, M., et al. 2021. Performance of microwave-activated coal gangue powder as auxiliary cementitious material. Journal of Materials Research and Technology 14: 2799–2811. https://doi.org/10.1016/j.jmrt.2021.08.106.

Wang, A., Liu, P., Mo, L., et al. 2022. Mechanism of thermal activation on granular coal gangue and its impact on the performance of cement mortars. Journal of Building Engineering 45: 103616. https://doi.org/10.1016/j.jobe.2021.103616.

Zhang, Y., and Ling, T.-C. 2020. Reactivity activation of waste coal gangue and its impact on the properties of cement-based materials – a review. Construction and Building Materials 234: 117424. https://doi.org/10.1016/j.conbuildmat.2019.117424.

Qin, L., Mao, X., Gao, X., et al. 2022. Performance degradation of CO2 cured cement-coal gangue pastes with low-temperature sulfate solution immersion. Case Studies in Construction Materials 17: e01199. https://doi.org/10.1016/j.cscm.2022.e01199.

Qin, L., and Gao, X. 2019. Properties of coal gangue-Portland cement mixture with carbonation. Fuel 245: 1–12. https://doi.org/10.1016/j.fuel.2019.02.067.

Zhao, J., Liu, Q., Long, B., et al. 2023. Utilization of coal gangue power generation industry by-product CFA in cement: Workability, rheological behavior and microstructure of blended cement paste. Fuel 345: 128185. https://doi.org/10.1016/j.fuel.2023.128185.

Marchon, D., Sulser, U., Eberhardt, A., et al. 2013. Molecular design of comb-shaped polycarboxylate dispersants for environmentally friendly concrete. Soft Matter 9: 10719. https://doi.org/10.1039/c3sm51030a.

Zhang, J., Ye, H., Gao, X,. Wu, W. 2022. Adsorption and desorption of polycarboxylate ether superplasticizer in fresh cementitious materials blended with mineral admixtures. Journal of Materials Research and Technology 17: 1740–1751. https://doi.org/10.1016/j.jmrt.2022.01.145.

Gelardi, G., Mantellato, S., Marchon, D., et al. 2016. Chemistry of chemical admixtures. In Science and Technology of Concrete Admixtures, pp. 149–218. Amsterdam: Elsevier. https://doi.org/10.1016/B978-0-08-100693-1.00009-6.

Lv, D., Liu, Q., Wang, C., et al. 2022. Imparting pH and temperature dual-responsiveness in a micellar solution of cationic surfactants by introducing a hydrotrope. Soft Matter 18: 5249–5260. https://doi.org/10.1039/D2SM00509C.

Xie, Z., Tian, Y., Li, Y., Hu, J. 2023. Understanding the temperature-dependent workability of cement paste with polycarboxylate superplasticizer. Journal of Building Engineering 107408. https://doi.org/10.1016/j.jobe.2023.107408.

Su, T., Wang, Q., and Lu, J. 2023. Effect of NaOH content on the fluidizing effect of PCEs with different structures in NaOH-activated slag. Cement and Concrete Research 166: 107112. https://doi.org/10.1016/j.cemconres.2023.107112.

Qian, Y., Lesage, K., El Cheikh, K., et al. 2018. Effect of polycarboxylate ether superplasticizer (PCE) on dynamic yield stress, thixotropy and flocculation state of fresh cement pastes in consideration of the critical micelle concentration (CMC). Cement and Concrete Research 107: 75–84. https://doi.org/10.1016/j.cemconres.2018.02.019.

Tian, Y., Xie, Z., Xue, K., et al. 2023. The role of coal gasification slag in cement paste with and without polycarboxylate superplasticizer and its rheology. Construction and Building Materials 373: 130852. https://doi.org/10.1016/j.conbuildmat.2023.130852.

Huang, X., Cao, M., Wang, J., et al. 2006. Controllable organization of a carboxylic acid type gemini surfactant at different pH values by adding copper(ii) ions. The Journal of Physical Chemistry B 110: 19479–19486. https://doi.org/10.1021/jp0630121.

State Administration for Market Regulation of China. 2020. Common portland cement. GB175-2020. Beijing, China: Standardization Administration of China.

National Development and Reform Commission (NDRC) of China. 2008. Test method for compatibility of cement and water-reducing agent. JC/T 1083. Beijing, China: NDRC.

General Administration of Quality Supervision, Inspection and Quarantine of China. 2012. Methods for testing uniformity of concrete admixture. GB/T 8077. Beijing, China: Standardization Administration of China.

Xie, Z., Yuan, Q., Yao, H., et al. 2023. Understanding the impact of polyacrylamide molecular weight on the workability of cement paste. Cement and Concrete Composites 142: 105171. https://doi.org/10.1016/j.cemconcomp.2023.105171.

Huang, T., Yuan, Q., Zuo, S., et al. 2022. New insights into the effect of gypsum on hydration and elasticity development of C3S paste during setting. Cement and Concrete Research 159: 106860. https://doi.org/10.1016/j.cemconres.2022.106860.

Huang, T., Yuan, Q., Zuo, S., et al. 2022. Physio-chemical effects on the temperature-dependent elasticity of cement paste during setting. Cement and Concrete Composites 134: 104769. https://doi.org/10.1016/j.cemconcomp.2022.104769.

Zuo, S., Yuan, Q., Huang, T., et al. 2023. Rheology and air entrainment of fresh Portland cement mortars in simulated low air pressure environments. Cement and Concrete Composites 135: 104848. https://doi.org/10.1016/j.cemconcomp.2022.104848.

Yuan, Q., Xie, Z., Yao, H., et al. 2022. Effect of polyacrylamide on the workability and interlayer interface properties of 3D printed cementitious materials. Journal of Materials Research and Technology 19: 3394–3405. https://doi.org/10.1016/j.jmrt.2022.06.093.

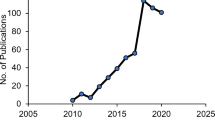

Lei, L., Hirata, T., and Plank, J. 2022. 40 years of PCE superplasticizers - History, current state-of-the-art and an outlook. Cement and Concrete Research 157: 106826. https://doi.org/10.1016/j.cemconres.2022.106826.

Bessaies-Bey, H., Baumann, R., Schmitz, M., et al. 2015. Effect of polyacrylamide on rheology of fresh cement pastes. Cement and Concrete Research 76: 98–106. https://doi.org/10.1016/j.cemconres.2015.05.012.

Yang, J., Huang, H., Zhu, L., et al. 2019. Effect of β-cyclodextrin, alcohol and temperature on the aggregation transitions of cationic/cationic surfactant systems. Colloids and Surfaces A: Physicochemical and Engineering Aspects 582: 123855. https://doi.org/10.1016/j.colsurfa.2019.123855.

Plank, J., and Sachsenhauser, B. 2009. Experimental determination of the effective anionic charge density of polycarboxylate superplasticizers in cement pore solution. Cement and Concrete Research 39: 1–5. https://doi.org/10.1016/j.cemconres.2008.09.001.

Huang, B., Hu. X., Fu, C., et al. 2019. Molecular morphology and viscoelasticity of ASP solution under the action of a different medium injection tool. Polymers 11: 1299. https://doi.org/10.3390/polym11081299.

Jin, J., Qin, Z., Lü, X., et al. 2022. Rheology control of self-consolidating cement-tailings grout for the feasible use in coal gangue-filled backfill. Construction and Building Materials 316: 125836. https://doi.org/10.1016/j.conbuildmat.2021.125836.

Funding

This article is funded by National Key R&D Program of China, No. 2022YFB2602604, Qiang Yuan, Systematic Project of Guangxi Key Laboratory of Disaster Prevention and Engineering Safety, No. 2022ZDK027, Yi Tian.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Xie, Z., Li, Y., Sun, D. et al. An alternative approach to improve the compatibility of PCE in cement paste blend with coal gangue powder. Waste Dispos. Sustain. Energy 6, 139–150 (2024). https://doi.org/10.1007/s42768-023-00174-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42768-023-00174-y