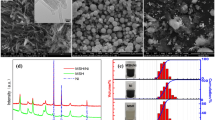

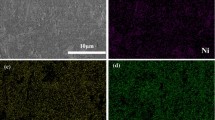

The powders of hBN, SiC, and B4C were employed as the raw ingredients to prepare the B4C–SiC–hBN composite ceramics by a vacuum high-pressure sintering method with hBN and SiC contents in the range of 0, 10, and 20 wt.%, respectively. A pin-on-disc testing equipment was used to assess the tribological properties of B4C–SiC–hBN composite ceramics with various hBN and SiC content when sliding against AISI 347 steel immersed in the emulsion. The experiment’s findings indicate that the sliding COF of the B4C/AISI 347 steel pair marginally drops as the sliding distance increases. Besides, the sliding COF of the B4C–10 wt.% SiC–20 wt.% hBN/AISI 347 steel pair rapidly declines. By tribopairs of B4C–SiC–hBN composite ceramics against AISI 347 steel under the condition of lubrication by water-based emulsion, the steady-state friction may move into a state of mix lubrication as the hBN concentration rises, improving the tribological performance. The steady-state COF considerably decreases to 0.01 from 0.386 as the hBN and SiC concentration is increased to 20 wt.% and 10 wt.% from zero, showing a decreasing trend for both the B4C–SiC–hBN pin and AISI 347 steel disc samples’ COWs. The steady-state friction of tribopairs of B4C–SiC–hBN composite ceramics against AISI 347 steel may enter a state of mixed lubrication in the emulsion. The wear resistance of composite ceramics was improved by the addition of hBN and SiC particles because of their lubricating and reinforcing effects. These findings offer valuable insights into the design and development of advanced composite ceramics for various industrial applications that require improved tribological properties.

Similar content being viewed by others

References

H. Zhu, Y. Niu, C. Lin, L. Huang, H. Ji, and X. Zheng, “Microstructures and tribological properties of vacuum plasma-sprayed B4C–Ni composite coatings,” Ceram. Int., 39, No. 1, 101–110 (2013).

P. Foroughi and Z. Cheng, “Understanding the morphological variation in the formation of B4C via carbothermal reduction reactions,” Ceram. Int., 42, No. 14, 15189–15198 (2016).

S. Kumar, K. Sairam, J.K. Sonber, T.S.R.C. Murthy, V. Reddy, G.V.S. Nageswara Rao, and T. Srinivasa Rao, “Hot-pressing of MoSi2 reinforced B4C composites,” Ceram. Int., 40, No. 10, 16099–16105 (2014).

R. Belon, G. Antou, N. Pradeilles, A. Maître, and D. Gosset, “Mechanical behavior at high temperatures of spark plasma sintered boron carbide ceramics,” Ceram. Int., 43, No. 8, 6631–6635 (2017).

N.K. Sharma, R.K. Misra, and S. Sharma, “Experimental characterization and numerical modeling of thermo-mechanical properties of Al–B4C composites, Ceram. Int., 43, No. 1, 513–522 (2017).

A. Erdemir, C. Bindal, C. Zuiker, and E. Savrun, “Tribology of naturally occurring boric acid films on boron carbide,” Surf. Coat. Technol., 86–87, 507–510 (1996).

Y.G. Gogotsi, A.M. Koval’chenko, and I.A. Kossko, “Tribochemical interactions of boron carbide against steel,” Wear, 154, 133–140 (1992).

K. Umeda, Y. Enomoto, A. Mitsui, and K. Mannami, “Friction and wear of boride ceramics in air and water,” Wear, 169, 63–68 (1993).

A. Erdemir, C. Bindal, and G.R. Fenske, “Formation of ultralow friction surface films on boron carbide,” Appl. Phys. Lett., 68, 1637 (1996).

H. Czichos, D. Klaffke, E. Santner, and M. Woydt, “Advances in tribology: The materials point of view,” Wear, 190, 155–161 (1995).

A. Skopp and M. Woydt, “Ceramic and ceramic composite materials with improved friction and wear properties,” Tribol. Trans., 38, No. 2, 233–242 (1995).

C. Zishan, L. Hejun, F. Qiangang, and Q. Xinfa, “Tribological behaviors of SiC and h-BN composite coating at elevated temperatures,” Tribol. Int., 56, 58–65 (2012).

X. Li, Y. Gao, S. Wei, Q. Yang, and Z. Zhong, “Dry sliding tribological properties of self-mated couples of B4C-hBN ceramic composites,” Ceram. Int., 43, No. 1, 162–166 (2017).

X. Li, Y. Gao, W. Pan, Z. Zhong, L. Song, W. Chen, and Q. Yang, “Effect of hBN content on the friction and wear characteristics of B4C–SiC–hBN ceramic composites under dry sliding conditions,” Ceram. Int., 41, No. 3, 3918–3926 (2015).

X. Li, Y. Gao, Q. Yang, W. Pan, Y. Li, Z. Zhong, and L. Song, “Evaluation of tribological behavior of B4C–hBN ceramic composites under water-lubricated conditions,” Ceram. Int., 41, No. 6, 7387–7393 (2015).

X. Li, Y. Gao, S. Wei, and Q. Yang, “Tribological behaviors of B4C–hBN ceramic composites used as pins or discs coupled with B4C ceramic under dry sliding conditions,” Ceram. Int., 43, No. 1, 1578–1583 (2017).

X. Li, Y. Gao, W. Pan, X. Wang, L. Song, Z. Zhong, and S. Wu, “Fabrication and characterization of B4C-based ceramic composites with different mass fractions of hexagonal boron nitride,” Ceram. Int., 41, No. 1, 27–36 (2015).

K. Nihara, R. Morena, and D.P.H. Hasselman, “Evaluation of Kc of brittle solid by the indention method with low crack-to-indent ratios,” J. Mater. Sci. Lett., 1, No. 1, 13–16 (1982).

Author information

Authors and Affiliations

Corresponding author

Additional information

Published in Poroshkova Metallurgiya, Vol. 62, Nos. 3–4 (550), pp. 78–87, 2023.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Liang, D., Xiong, S. Tribological Properties of B4C–SiC–hBN Composite Ceramics Sliding Against AISI 347 Steel Immersed in Emulsion. Powder Metall Met Ceram 62, 195–202 (2023). https://doi.org/10.1007/s11106-023-00381-6

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-023-00381-6