Abstract

The efficient characterization of material properties of porous multi-phase sintered steels by instrumental indentation is still an open question. To the authors’ knowledge, so far only a characterization of single-phase porous sintered steel by nanoindenation has been reported in literature. This paper for the first time offers a study about the applicability of microindentation techniques for characterizing the matrix material in a multi-phase sintered steel. This preliminary study is motivated by the relatively wide availability of necessary equipment, and simplicity of material identification procedures.

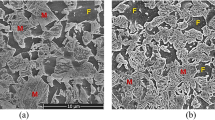

Herein, a dual-phase ferrite/bainite Astaloy steel with 9% porosity is studied. Various commonly used methods for the reconstruction of stress–strain curves from microindentation data are considered, whereby both Vickers and spherical tips are used. In addition, some homogeneous solid materials are investigated to better asses the performance of applied identification procedures. Two approaches for the mesoscale identification of the considered sintered steel are attempted. The first one is based on the identification of individual material phases, while in the other one the homogenization of the metallic matrix is adopted. To assess the reliability of obtained parameters, the direct numerical simulation of representative volume elements of realistic steel microstructure subjected to uniaxial tension is conducted. Numerical results are compared with the data from the macroscopic uniaxial tensile test.

The obtained results indicate that microindentation is adequate for the identification of elastic properties of individual material phases, but results for local plastic parameters are largely inconclusive and a further analysis is needed, focusing on applying smaller forces and investigating the influence of pores on identification results. Nevertheless, it seems that macroscopic stress–strain curves could be captured more accurately by the methodology based on the matrix homogenization if relatively large indentation forces are applied.

Similar content being viewed by others

Data Availability

Data sharing not applicable.

References

Brecher C, Löpenhaus C, Schroers M, Frech T (2017) Scholzen: Optimization of NVH behavior of gears by alternative gear materials. In: International Conference on Gears 2017 2 Bände. VDI Verlag GmbH, Düsseldorf, pp. 539–552. https://doi.org/10.51202/9783181022948

Dudrova E, Kabátova M (2016) A review of failure of sintered steels: Fractography of static and dynamic crack nucleation, coalescence, growth and propagation. Powder Metall 59:148–167. https://doi.org/10.1080/00325899.2016.1145786

Doroszko M, Seweryn A (2021) Numerical modelling of the mesofracture process of sintered 316L steel under tension using microtomography. Eng Fracture Mechanics 255:107965. https://doi.org/10.1016/j.engfracmech.2021.107965

Doroszko M, Seweryn A (2020) Pore-scale numerical modelling of large deformation behaviour of sintered porous metals under compression using computed microtomography. Mech Mater 141:103259. https://doi.org/10.1016/j.mechmat.2019.103259

Doroszko M, Seweryn A (2015) Modeling of the tension and compression behavior of sintered 316L using micro computed tomography. Acta Mech. Autom 9:70–74. https://doi.org/10.1515/ama-2015-0012

Madej L, Legwand A, Mojzeszko M, Chraponski J, Roskosz S, Cwajna J (2018) Experimental and numerical two- and three-dimensional investigation of porosity morphology of the sintered metallic material. Arch Civ Mech Eng 18:1520–1534

Scherff F, Gola J, Scholl S et al (2021) Numerical simulation of dual-phase steel based on real and virtual three-dimensional microstructures. Continuum Mech Thermodyn 33:1989–2006. https://doi.org/10.1007/s00161-021-00980-x

Tomić Z, Gubeljak N, Jarak T, Polančec T, Tonković Z (2022) (2022) Micro - and macromechanical properties of sintered steel with different porosity. Scr Mater 217:114787. https://doi.org/10.1016/j.scriptamat.2022.114787

Tomić Z, Jarak T, Lesičar T, Gubeljak N, Tonković Z (2023) Modelling of Fatigue Microfracture in Porous Sintered Steel Using a Phase-Field Method. Materials 16(11):4174. https://doi.org/10.3390/ma16114174

Ishikawa N, Yasuda K, Sueyoshi H, Endo S, Ikeda H, Morikawa T, Higashida K (2015) Microscopic deformation and strain hardening analysis of ferrite–bainite dual-phase steels using micro-grid method. Acta Materialia. 97:257–268. https://doi.org/10.1016/j.actamat.2015.06.037

Sun X, Choi KS, Liu WN, Khaleel MA (2009) Predicting failure modes and ductility of dual phase steels using plastic strain localization. Int J Plasticity 25(10):1888–1909. https://doi.org/10.1016/j.ijplas.2008.12.012

Qiao G-Y, Zhao Z-T, Shi X-B, Shan Y-Y, Gu Y, Xiao F-R (2021) Effect of Bainite to Ferrite Yield Strength Ratio on the Deformability of Mesostructures for Ferrite/Bainite Dual-Phase Steels. Materials 14(18):5352. https://doi.org/10.3390/ma14185352

Zhou J, Gokhale AM, Gurumurthy A, Bhat SP (2015) Realistic microstructural RVE-based simulations of stress–strain behavior of a dual-phase steel having high martensite volume fraction. Materials Sci Eng: A 630:107–115. https://doi.org/10.1016/j.msea.2015.02.017

Zhao Z, Wang X, Qiao G, Zhang S, Liao B, Xiao F (2019) Effect of bainite morphology on deformation compatibility of mesostructure in ferrite/bainite dual-phase steel: Mesostructure-based finite element analysis. Mater Des 180:107870. https://doi.org/10.1016/j.matdes.2019.107870

Basantia SK, Bhattacharya A, Khutia N et al (2021) Plastic Behavior of Ferrite-Pearlite, Ferrite-Bainite and Ferrite–Martensite Steels: Experiments and Micromechanical Modelling. Met Mater Int 27:1025–1043. https://doi.org/10.1007/s12540-019-00519-5

Uchic MD, Shade PA, Dimiduk DM (2009) Plasticity of micrometerscale single crystals in compression. Annu Rev Mater Res 39:361–386

Gianola DS, Eberl C (2009) Micro- and nanoscale tensile testing of materials. JOM 3:24–35

Magagnosc DJ, Ligda JP, Sano T, Schuster BE (2018) Femtosecond laser machining of micro-tensile specimens for high throughput mechanical testing. In: Starman L, Hay J (eds) Micro and Nanomechanics, vol 5. Conference Proceedings of the Society for Experimental Mechanics Series. Springer, Cham, pp 7–9https://doi.org/10.1007/978-3-319-63405-0_2

Voyiadjis G, Yaghoobi M (2019) Size effects in plasticity: from macro to nano, 1st edn. Academic Press, Elsevier Inc.

Durst K, Göken M, Pharr GM (2008) Indentation size effect in spherical and pyramidal indentations. J Phys D Appl Phys 41:74005. https://doi.org/10.1088/0022-3727/41/7/074005

Bushby AJ, Dunstan DJ (2004) Plasticity size effects in nanoindentation. J Mater Res 19:13. https://doi.org/10.1557/jmr.2004.19.1.137

Oliver WC, Pharr GM (1992) An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J Mater Res 7:1564–1583. https://doi.org/10.1557/JMR.1992.1564

Giannakopoulos AE, Suresh S (1999) Determination of elastoplastic properties by instrumented sharp indentation. Scr Mater 40:1191–1198

Dao M, Chollacoop N, Van Vliet KJ, Venkatesh A, Suresh S (2001) Computational modeling of the forward and reverse problems in instrumented sharp indentation. Acta Mater 49:3899–3918

Bucaille JL, Stauss S, Felder E, Michler J (2003) Determination of plastic properties of metals by instrumented indentation using different sharp indenters. Acta Mater 51:1663–1678

Pathak S, Kalidindi SR (2015) Spherical nanoindentation stress–strain curves. Mater Sci Eng R Reports 91:1–36. https://doi.org/10.1016/j.mser.2015.02.001

Mesarovic D, Fleck NA (1999) Spherical indentation of elastic-plastic solids. Proc R Soc a-Mathematical Phys Eng Sci 455:2707–2728

Herbert EG, Pharr GM, Oliver WC, Lucas BN, Hay JL (2001) On the measurement of stress–strain curves by spherical indentation. Thin Solid Films 398–399:331–5. https://doi.org/10.1016/S0040-6090(01)01439-0

Herbert EG, Oliver WC, Pharr GM (2006) On the measurement of yield strength by spherical indentation. Philos Mag 86:5521–39. https://doi.org/10.1080/14786430600825103

Ruiz-Moreno A, Hähner P, Fumagalli F, Haiblikova V, Conte M, Randall N (2020) Stress−strain curves and derived mechanical parameters of P91 steel from spherical nanoindentation at a range of temperatures. Mater Des 194:108950. https://doi.org/10.1016/j.matdes.2020.108950

Pathak S, Shaffer J, Kalidindi SR (2009) Determination of an effective zero-point and extraction of indentation stress-strain curves without the continuous stiffness measurement signal. Scr Mater 60:439–42. https://doi.org/10.1016/j.scriptamat.2008.11.028

Donohue BR, Ambrus A, Kalidindi SR (2012) (2012) Critical evaluation of the indentation data analyses methods for the extraction of isotropic uniaxial mechanical properties using finite element models. Acta Mater 60:3943–52. https://doi.org/10.1016/j.actamat.2012.03.034

Cuervo-Basurto A, Narvaez-Tovar CA, Rodriguez-Baracaldo R (2022) Assessment of microindentation method in the characterization of DP600 response using phases distribution and a specific shape parameter along RVEs and FEM simulation approaches. J App Res Technol 20:686–702. https://doi.org/10.22201/icat.24486736e.2022.20.6.1121

Cheng G, Choi KS, Hu X, Sun X (2016) Determining individual phase properties in a multi-phase Q&P steel using multi-scale indentation tests. Mater Sci Eng A 652:384–95. https://doi.org/10.1016/j.msea.2015.11.072

Shen Y-L, Guo YL (2001) Indentation modelling of heterogeneous materials. Model Simul Mater Sci Eng 9:391–8. https://doi.org/10.1088/0965-0393/9/5/304

Pöhl F, Huth S, Theisen W (2013) Finite element method-assisted acquisition of the matrix influence on the indentation results of an embedded hard phase. Mater Sci Eng A 559:822–8. https://doi.org/10.1016/j.msea.2012.09.029

Heidari M, Karimzadeh A, Ayatollahi MR, Yahya MY (2021) Effects of particle distribution and calculation method on results of nano-indentation technique in heterogeneous nanocomposites-experimental and numerical approaches. Int J Solids Struct. 225:111054. https://doi.org/10.1016/j.ijsolstr.2021.111054

Kannan R, Wang Y, Nouri M, Li D, Li L (2018) Materials Science & Engineering A Instrumented indentation study of bainite / martensite duplex microstructure. Mater Sci Eng A 713:1–6

Madej L, Legwand A, Setty M et al (2022) Evaluation of capabilities of the nanoindentation test in the determination of flow stress characteristics of the matrix material in porous sinters. Archiv Civ Mech Eng 22:21. https://doi.org/10.1007/s43452-021-00343-y

Abaqus Analysis User's Guide (2014) vol 4. Dassault Systems Simulia Corp., Providence, RI, USA

Gu W, Yao Z (2011) Evaluation of surface cracking in micron and sub-micron scale scratch tests for optical glass BK7. J Mech Sci Technol 25:1167. https://doi.org/10.1007/s12206-011-0306-2

Calcutt V (2001) Introduction to copper: fact sheets. Copper Development Association Inc. https://www.copper.org/publications/newsletters/innovations/2001/08/intro_fac.html. Accessed 13 Oct 2022

Copper Alloy 110/C110/C11000 Electrolytic Tough Pitch (ETP) (2022) Basic Copper. https://basiccopper.com/copper-c110-alloy-electrolytic-tough-pitch.html. Accessed 13 Oct 2022

Tran HS, Bouffioux C, Dedry O, Rojas-Ulloa C, Duchêne L, Mertens A et al (2022) Identification of a soft matrix-hard inclusion material by indentation. Int J Mech Sci 235:107723. https://doi.org/10.1016/j.ijmecsci.2022.107723

Tabor D (1951) The Hardness of Metals, 1st edn. Oxford University Press, Londkon

Zhang T, Wang S, Wang W (2019) A comparative study on uniaxial tensile property calculation models in spherical indentation tests (SITs). Int J Mech Sci 155:159–69. https://doi.org/10.1016/j.ijmecsci.2019.02.044

Bruns S, Petho L, Minnert C, Michler J, Durst K (2020) Fracture toughness determination of fused silica by cube corner indentation cracking and pillar splitting. Mater Des 186:108311. https://doi.org/10.1016/j.matdes.2019.108311

Torres-Torres D, Muñoz-Saldaña J, De Guevara L, Hurtado-Macías A, Swain MV (2010) Geometry and bluntness tip effects on elastic-plastic behaviour during nanoindentation of fused silica: Experimental and FE simulation. Model Simul Mater Sci Eng 18:075006. https://doi.org/10.1088/0965-0393/18/7/075006

Shuman DJ, Costa ALM, Andrade MS (2007) Calculating the elastic modulus from nanoindentation and microindentation reload curves. Mater Charact 58:380–9. https://doi.org/10.1016/j.matchar.2006.06.005

Ghassemi-Armaki H, Mass R, Baht SP, Sriram S, Greer JR, Kumar RS (2014) Deformation response of ferrite and martensite in a dual-phase steel. Acta Mater 62:197–211

Tao P, Gong J, Wang Y, Jiang Y, Li Y, Cen W (2018) Characterization on stress-strain behavior of ferrite and austenite in a 2205 duplex stainless steel based on nanoindentation and finite element method. Results Phys 11:377–84. https://doi.org/10.1016/j.rinp.2018.06.023

Ternero F, Rosa LG, Urban P, Montes JM, Cuevas FG (2021) Influence of the Total Porosity on the Properties of Sintered Materials—A Review. Metals 11(5):730. https://doi.org/10.3390/met11050730

Manoylov AV, Borodich FM, Evans HP (2013) Modelling of elastic properties of sintered porous materials. Proc R Soc A Math Phys Eng Sci 469:20120689. https://doi.org/10.1098/rspa.2012.0689

Acknowledgements

This work has been fully supported by Croatian Science Foundation under the project “Multiscale Numerical Modelling and Experimental Investigation of Aging Processes in Sintered Structural Components” (MultiSintAge, PZS-1 2019-02-4177).

Funding

This work has been supported by Croatian Science Foundation under project “Multiscale Numerical Modelling and Experimental Investigation of Aging Processes in Sintered Structural Components” (MultiSintAge, PZS-1 2019-02-4177).

Author information

Authors and Affiliations

Contributions

Zoran Tomić: Conceptualization, Methodology, Investigation, Experimental investigation, Numerical calculation, Results preparation, Writing – original draft, Tomislav Jarak: Conceptualization, Methodology, Investigation, Supervision, Writing – original draft, review & editing, Benjamin Pavlović: Investigation, Numerical calculation, Results preparation, Zdenko Tonković: Supervision, Resources, Writing – review & editing.

Corresponding author

Ethics declarations

Conflict of Interest

All authors declare that they have no known competing financial interests or personal relationships that are relevant to the content of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Tomić, Z., Jarak, T., Pavlović, B. et al. On Extracting Stress–Strain Curves of Porous Multi-Phase Sintered Steels by Microindentation. Exp Tech (2023). https://doi.org/10.1007/s40799-023-00684-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40799-023-00684-8