Abstract

Both piezoelectricity and self-Fenton catalysis are effective ways to degrade water pollution, but little research has combined them to construct a more efficient water pollution treatment method. Here, a Fe-doped SnS2 (Sn1-xFexS2) piezoelectric self-Fenton system was constructed, which shows superior water treatment performance. The best piezoelectric properties of the Sn0.97Fe0.03S2 system were verified by degrading rhodamine B (RhB). The toxicity analysis of degradation intermediates and solutions confirmed that the toxicity of RhB decreased after degradation. In addition, Kelvin probe force microscopy and photoelectrochemical analysis confirmed the better piezoelectric properties of Sn0.97Fe0.03S2. It has demonstrated the enhancement of systematic piezoelectricity by Fe lattice defects and the formation of self-Fenton by Fe as an active center in the degradation of RhB. In this work, an efficient piezoelectric and self-Fenton technology is constructed to remove organic pollutants from water, which is significant for developing water treatment technology.

Similar content being viewed by others

Introduction

Currently, organic pollutants are widely distributed in the aquatic environment and represent a major challenge for water pollution treatment1,2,3. Due to their complex structure, more toxic intermediate products may be generated in the degradation process, which elevates the treatment requirements of organic polluted wastewater4,5. Advanced oxidation technology produces reactive oxygen species (ROS), which can effectively decompose organic molecules into several non-toxic small molecules and meet the requirements of organic water pollution treatment6,7. Among them, piezoelectric catalysis can use external mechanical energy, including ultrasonic cavitation, vortex-induced shear force, and physical bending deformation, to induce charge separation and generate ROS for the degradation of organic pollutants without the need for additional chemical reagents or light and electricity8,9. SnS2, a typical layered transition metal disulfide (TMD) compound, has been widely used in piezoelectric catalytic energy conversion due to its high specific surface area, surface-to-atom ratio, and multiple reaction sites10,11,12. For example, Yang et al. applied the synthesised SnS2 to a piezoelectric nanogenerator device that converts ambient mechanical energy into electrical energy, and the maximum instantaneous power of the SnS2 piezoelectric nanogenerator reached 2 pW at 0.6% strain13. Tian et al. investigate the piezocatalytic performance of SnS2 for environmental remediation, and the synthesised SnS2/CNFs piezoelectric catalyst could remove 10 mg L−1 of bisphenol A in two hours14. However, the susceptibility of SnS2 to electron-hole (e−-h+) complexation limits its application in the piezoelectric degradation of organic pollutants.

Due to charge polarisation, piezoelectric materials with non-centrosymmetric crystal structures can spontaneously or non-spontaneously generate internal electric fields, thus effectively reducing electron-hole pair complexation to improve catalytic performance15,16,17. Therefore, changing the symmetric crystal structure of SnS2 by doping may be an effective way to enhance its piezoelectric properties. For example, the photocatalytic degradation performance of SnS2 can be effectively improved by Ag or Cu doping18. It is well known that H2O2 can be produced from an aqueous solution under ultrasonic conditions. Interestingly, SnS2 can also produce high concentrations of H2O2 under piezoelectric conditions18. However, the high concentration of H2O2 produced is usually hard to directly participate in the reaction unless a Fenton system is constructed to convert the H2O2 to ROS19. H2O2 can be activated to produce hydroxyl radical (·OH) with metal ions catalysis20. From this perspective, constructing a Fenton piezoelectric system can effectively enhance the catalytic degradation performance of SnS2. The utilisation of H2O2 in the Fenton system usually requires the addition of Fe2+ and the system must be carried out under acidic conditions, which limits the application of the Fenton system21. The self-Fenton system has recently been used for water environment remediation, which not only effectively utilizes H2O2 to produce ROS to degrade pollutants, but also overcomes the above drawbacks22,23. Hence, constructing a piezoelectric self-Fenton system based on SnS2 may be helpful in improving the efficiency of water pollution treatment.

In our work, we constructed the Fe-doped SnS2 self-Fenton piezoelectric catalytic system. The effect of Fe doping on its crystal structure and the piezoelectric response was clarified through a series of characterizations, and the degradation performance of rhodamine B (RhB) was investigated. The structural characteristics of RhB were analyzed using the Fukui function, and the degradation pathway of RhB was inferred based on the degradation products. At the same time, the toxicity of the intermediate products was predicted by ECOlogical Structure Activity Relationships (ECOSAR) and the toxicity changes before and after degradation were tested using zebrafish. Then, the mechanism of piezoelectric degradation of RhB was deeply understood by DFT calculation. Finally, we proposed a piezoelectric-automaton catalytic mechanism for the Fe-doped SnS2 system by combining electron spin resonance (ESR), H2O2 production performance, and free radical analysis.

Results and discussion

Catalysts characterization

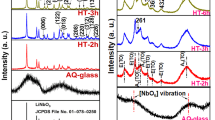

The XRD pattern of SnS2 and Sn1-xFexS2 shows the characteristic peaks of SnS2 (JCPDS NO. 01-1010), and along with the increase in the amount of Fe, the crystalline planes such as (001) and (101) weaken, indicating that Fe is doped by these crystalline planes (Fig. 1a). Meanwhile, the A1g vibrational peak of the Raman spectrum does not change significantly, indicating that Sn0.97Fe0.03S2 maintains the original structure of SnS2 (Fig. 1b). In addition, the peaks in the full spectrum of XPS correspond to all elements of SnS2 and Sn0.97Fe0.03S2 (Supplementary Fig. 1). The binding energy migration of the high-resolution XPS spectra Sn and S indicates that Fe alters the interfacial charge transfer (Supplementary Fig. 2). Two spin orbits for Fe 2p3/2 and Fe 2p1/2 were present in the Fe 2p area, as shown in Fig. 1c, and they were accompanied by satellite peaks with energies of 716 and 735.6 eV, respectively. The peaks could be deconvolved into the Fe2+ peaks at 714.8 and 730 eV and Fe3+ peaks at 716 and 732.9 eV24. The SEM (Supplementary Figs. 3, 4) and TEM (Fig. 1d, e, h–k) images show that both SnS2 and Sn1-xFexS2 are flower spheres composed of nanosheets. In addition, a comparison of their lattice spacing shows that the peak height of Sn1-xFexS2 is more variable. As shown in Fig. 1f, j, there is a slight difference in the lattice spacing between the (001) crystal faces of SnS2 and Sn1-xFexS2, which coincides with the XRD results, with the (001) crystal face shifted to the right. At the same time, the spacing of the contrasting (101) crystal faces also changes (Fig. 1g, k). Moreover, the contrast height reveals that some spacing peaks are missing and the lattice spacing decreases and increases of Sn1-xFexS2, which may be related to the S defect25. Based on the above results, we can confirm that lattice distortion and surface defects occur in Sn1-xFexS2 after Fe doping26,27. The changes in the crystal structure of the material were analyzed by selected electron diffraction (SAED). As shown in Supplementary Fig. 5, spotty concentric rings in the recorded SAED patterns reveal the polycrystalline nature of SnS2 and Sn0.97Fe0.03S2. The drawing image of HAADF-STEM elements shows that Sn and S form flower, and Fe is evenly distributed on the surface (Fig. 1l), which shows that Fe is evenly doped in SnS2 nano-flower spheres.

The XRD patterns of SnS2 and Sn1-xFexS2 system (a), the Raman of SnS2 and Sn0.97Fe0.03S2 (b) and Fe 2p high-resolution XPS spectra of Sn0.97Fe0.03S2 (c), the TEM and HRTEM images of SnS2 (d–g) and Sn0.97Fe0.03S2 (h–k) and the lattice spacing was beneath of position 1 and 2, HAADF-STEM elemental mapping images (l) of Sn0.97Fe0.03S2. The scale bars in d–l represent 1 µm, 100 nm, 2 nm, 2 nm, 1 µm, 200 nm, 2 nm, 2 nm and 2.5 µm, respectively.

The effect of Fe on the piezoelectric response of the Sn1-xFexS2 system was studied by a piezoelectric response force microscope (PFM). As seen in Fig. 2a, b, d, e, there are significant piezoelectric correlations and phase differences in SnS2 and Sn0.97Fe0.03S2 nanosheets. In addition, the typical piezoelectric response amplitude butterfly loop and phase lag loop in Fig. 2c, f confirm exactly the significant piezoelectric response. Varying the phase of the hysteresis line under a reversing field of ±1.5 V, the maximum amplitudes of SnS2 and Sn0.97Fe0.03S2 are approximately 70 pm and 150 pm, respectively. In addition, the piezoelectric coefficient calculated by the method of28 shows that the d33 values for Sn0.97Fe0.03S2 (108 pm V−1) are approximately 2.28 times larger than that of SnS2 (46.7 pm V−1). To further confirm the piezoelectric properties of the system, the piezoelectric potential distribution of SnS2 was simulated through the finite element method using COMSOL Multiphysics29. As the pressure gets higher, the surface piezoelectric potential of the material gets stronger (Fig. 2g–l), showing a linear relationship.

PFM test of amplitude image (a, d), phase image (b, e) and phase hysteresis loop and amplitude butterfly loop (c, f) of SnS2 and Sn0.97Fe0.03S2, respectively; COMSOL simulated piezoelectric potential distribution on the surface of SnS2 under the cavitation pressures of 1 MPa (g), 5 MPa (h), and 10 MPa (i). The scale bars in a, b represent 1 µm, and in d, e represent 600 nm.

Piezocatalytic activity

The degradation performance of the SnS2 and Sn1-xFexS2 system on RhB is shown in Fig. 3a. The piezoelectric performance is significantly improved after introducing Fe, with Sn0.97Fe0.03S2 showing the best performance, removing 83% within 10 min and 95.4% within 30 min of the contaminant. And it can be seen in the blank control that RhB was not significantly degraded without the addition of catalyst (Supplementary Fig. 6), indicating that RhB degradation is mainly a function of piezoelectric catalysis. The degradation performance decreased after 10–30 min, which may be because a large number of intermediate products produced in the later stage of degradation are also preparing for simultaneous degradation30. Meanwhile, when the Fe content improved, the piezoelectric performance weakened, which may be due to the masking effect of excess Fe31. The degradation curves are consistent with the primary degradation kinetics (Supplementary Fig. 7), and the rate constant of Sn0.97Fe0.03S2 for RhB is 14 times more than that of the monomer SnS2 (Fig. 3b). As for the piezoelectric performance at different power levels, the higher the power, the better the performance (Fig. 3c). The degradation rate at 100 W being is 7.5 times than at 40 W (Supplementary Fig. 8). As shown in Fig. 3d, the piezoelectric properties remain essentially unabated after four cycles of degradation. Moreover, it was found that the positions and intensities of the XRD diffraction peaks of Sn0.97Fe0.03S2 remained basically unchanged by analyzing the samples after cycling (Supplementary Fig. 9), indicating that Sn0.97Fe0.03S2 has a good stability. On this basis, the scavenging experiment of active species was carried out to analyze the free radical changes during degradation (Fig. 3e). TEOA, tert-butanol and argon (Ar) were used to capture h+, ·OH and ·O2−, respectively. According to the k value, the contribution rate of free radicals is calculated, and the specific calculation process is in the SM. It was found that h+ (86.7%), ·OH (94.2%) and ·O2− (90.7%) could all play important role in the degradation of RhB, with ·OH playing the most crucial role (Fig. 3f).

The removal rate (a) and kinetic rate constant (b) of RhB by SnS2 and Sn1-xFexS2 system, different power (c) and 4 cycles (d) degradation performance of Sn0.97Fe0.03S2, the degradation curves (e) and the kinetic rate constant (f) of RhB in active species scavenging experiment. Piezocatalytic properties experimental conditions: [RhB] = 20 mg L–1, [SnS2 and Sn1-xFexS2] = 0.3 g L–1, initial pH = 7.0, and T = 25 °C. The center of the data point is the mean of the two sets of data, and error bars represent the standard deviation of the two sets of data.

The molecular structure of RhB was analyzed by DFT calculations (Fig. 4). The surface electron cloud distribution of RhB shows that the carboxyphenyl and epoxypentenyl groups have negative potentials in the vicinity (Fig. 4b). At the same time, highest occupied molecular orbital (HOMO) and lowest occupied molecular orbital (LUMO) also confirmed that these carboxyphenyl and epoxypentenyl groups are electron-rich regions and carboxyphenyl has a large electronegativity (Fig. 4c, d). Furthermore, the reactive sites of RhB and the active species in the degradation process were analyzed through Hirschfeld charges and Fukui indices (Supplementary Table 1). Typically, higher values of f+, f−, and f0 indicate that the site is more susceptible to attack by the active species during the reaction process32. In particular, the sites with high f+ values are susceptible to ·O2− attack, while the sites with high f− values are easily attacked by h+ or ·OH33,34. As shown in Fig. 4e, condensed double descriptor (CDD) plots show the distribution of nucleophilic and pro-potential sites. Here, the C11 was the most vulnerable site of RhB and the two N atoms (N18, N21) are also potential sites of attack (Supplementary Table 1). As a result, the carboxyphenyl group in the RhB molecule and the ethyl on the N are easily removed. On this basis, the degradation products of RhB were analyzed by LC-MS/MS (Supplementary Fig. 10). RhB has a molecular mass (m/z) of 479, but usually exists at m/z = 444 due to ionization of Cl−. The presumed degradation product pathway is shown in Fig. 4f. RhB is gradually broken down into smaller molecules through deethylation and carboxyphenyl. This is consistent with the results of the DFT calculations. Eventually, the products of m/z = 163 can be further broken down into H2O and CO2.

Toxicity assessment

The toxicological changes during the degradation of RhB were analyzed by combining chemical and biological methods. Firstly, the toxicity of RhB and its degradation intermediate products to fish, daphnia, and green algae was inferred from ECOSAR35. There was no significant difference in the toxicity of the two structures of RhB (Supplementary Table 2). As shown in Fig. 5a, b, the acute and chronic toxicity of the three organisms showed a similar pattern, with the toxicity of P1 and P2 gradually decreasing, the toxicity of P3 and P4, and RhB equal, and the toxicity of P5 lowest. Thus, the toxicity of the degraded products of RhB was reduced. Meanwhile, the toxicity of the degradation solutions was analyzed by acute exposure to zebrafish embryos. The mean scores of hatching rate and mortality with standard deviations were calculated for expose group and the one-way analysis of variance was applied to determine whether there were any statistically significant differences between the means of these scores. As shown in Fig. 5c, the hatching rate and mortality of zebrafish embryos showed a similar pattern, with RhB being the most toxic and the degradation solution becoming less toxic as the degradation progressed. In addition, the behaviour of 120 hpf zebrafish was analyzed, with the specific trajectories shown in Fig. 5g. Trajectories of zebrafish can be divided into slow (green) and fast (red) swimming trajectories. As shown in Fig. 5d, the slow swimming distance of the RhB exposed group was irregular, while the slow swimming distance of the other exposed groups remained around 20 mm. The fast swimming (Fig. 5e) and total swimming (Fig. 5f) distances showed a more active pattern in dark conditions, which is more consistent with the habits of zebrafish36,37. At the same time, the fast swimming in the RhB-exposed group also showed no regularity, and the swimming distance was smaller than the slow swimming. These results suggest that the zebrafish exposed to RhB solution were not active, but the swimming activity of zebrafish basically recovered to the level of the blank control group after 30 min of degradation. Thus, a combination of chemical analysis and biological experiments confirmed that the toxicity of RhB was significantly reduced through the degradation of the Fe-doped SnS2 piezoelectric self-Fenton system.

The acute toxicity (a) and chronic toxicity (b) of RhB and its intermediates via ECOSAR program in Sn0.97Fe0.03S2, zebrafish 120 hpf survival rate and 72 hpf hatchability (c), slow (d), fast (e), and total (f) swimming distance per minute for 20 min, swimming trajectory in 20 min alternating light and dark (g). Toxicity experimental conditions: initial pH = 7.0, and T = 28 °C. One-way analysis of variance and Tukey’s test were used to assess the differences between experimental groups, and Dunnett’s test was used to test whether this difference was statistically significant, *above bars in Fig. 5c indicates significant differences (*p < 0.05, **p < 0.01). The center of the data point is the mean of the two sets of data, and error bars represent the standard deviation of the two sets of data.

Piezoelectric charge transport

The built-in electric field is a major influence on charge transport. The surface potentials of SnS2 and Sn0.97Fe0.03S2 were therefore observed by Kelvin probe force microscopy (KPFM). As shown in Fig. 6a–f, the Sn0.97Fe0.03S2 system has a more substantial surface potential than SnS2, elevating from 96 mV to 165 mV. Therefore, the lattice distortion of the Sn0.97Fe0.03S2 system can construct a stronger built-in electric field thus accelerating the charge transfer of the system38,39. Then the charge transfer differences between the systems of SnS2 and Sn0.97Fe0.03S2 were analyzed by electrochemical experiments. As shown in Fig. 6g, SnS2 can produce a transient current response under piezoelectric conditions, indicating that the catalyst can be excited to produce charge transfer under piezoelectric conditions. Sn0.97Fe0.03S2 has a stronger transient current response, which indicates that Sn0.97Fe0.03S2 has a faster charge transfer ability. Meanwhile, the Sn0.97Fe0.03S2 system has a higher current density than SnS2 (Fig. 6h). Compared with SnS2, the arc radius of Nyquist plots in Fig. 6i of the Sn0.97Fe0.03S2 is smaller, indicating that its smaller impedance value and the charge transmission obstruction40. Therefore, the lattice distortion after the introduction of Fe enhances the internal charge polarization of the Sn0.97Fe0.03S2 system, effectively accelerates the charge transfer, reduces the complexation of electron-hole pairs, and further improves the piezoelectric properties.

Geometry optimization and electronic structure

The structural changes of the SnS2 and Sn0.97Fe0.03S2 systems analyzed by DFT calculations are presented in Fig. 7a. The doping of Fe atoms changes the electron density distribution on the surface of SnS2, with more electrons concentrated in the region of Fe atoms. The structural optimization of the two systems is shown in Fig. 7b, where a lattice distortion can be seen in the Sn0.97Fe0.03S2 system. Fe can replace Sn to bind to sulfur, but creates sulfur vacancies, thus changing the charge distribution of the system. On this basis, the changes in bond angle and bond length of the two systems are resolved (Fig. 7c, d). Compared with the SnS2, the bond angle decreases and the bond length increases in the Sn0.97Fe0.03S2, especially the S-Sn-S and Sn-S-Sn angles, and Fe-S4 bond length changes the most. This is mainly due to the formation of distortions in the lattice space caused by S vacancies, which leads to a non-uniform distribution of charges16,41. Therefore, the S vacancy lattice distortion produced by Fe doping can endow charge polarization of Sn0.97Fe0.03S2 with higher piezoelectric properties.

Piezoelectric catalysis mechanism

Catalyst-pollutant interface interactions and charge transfer mechanisms of piezoelectric catalysts were explored by DFT calculations. The difference in adsorption energy (Eads) between RhB and the two catalysts is shown in Supplementary Table 3. After Fe doping, Sn0.97Fe0.03S2 has a stronger Eads to RhB than SnS2, which indicates that RhB binds more tightly to Sn0.97Fe0.03S2, which is favorable for charge transfer at the catalyst-pollutant interface and avoids charge recombination (Fig. 8a, b). Interfacial charge transport was further investigated in Fig. 8c, d. There is a stronger electron aggregation and depletion at the Sn0.97Fe0.03S2-interface than at the SnS2-interface, which suggests that more charge transfer to the pollutant for redox reaction in the Sn0.97Fe0.03S2-RhB system. In particular, there is a significant electron accumulation and depletion in the Fe region, further suggesting that Fe is the active site for the catalytic degradation of RhB42,43. The Bader charge analysis revealed the charges of −0.878e and −0.708e for Sn0.97Fe0.03S2 and SnS2, respectively. Compared with SnS2, the interface between Sn0.97Fe0.03S2 and RhB can accept more electrons for Fe valence consumption44. Moreover, the Fe valence change can promote the generation of free radicals in the Sn0.97Fe0.03S2 system.

The free radicals produced by SnS2 and Sn0.97Fe0.03S2 in the process of piezoelectric catalysis were analyzed by ESR. As shown in Fig. 9a–c, under ultrasound conditions, the Sn0.97Fe0.03S2 system can produce more ·O2−, h+, and ·OH than SnS2, thus enhancing the piezoelectric-catalyzed degradation of RhB. It was found that ·OH dominated the RhB degradation process, while the performance did not decrease significantly after h+ capture (Fig. 3e, f). Therefore, we infer that there are other ways to generate ·OH besides the conversion of OH− by h+. On this basis, the H2O2-producing performance of the two catalysts was investigated in Fig. 9d, and it is interesting to note that the SnS2 system can produce H2O2, but no H2O2 was detected in the Sn0.97Fe0.03S2 system. Meanwhile, the content of ·OH in the piezoelectric system was quantitatively analyzed by fluorescence intensity test45,46. Moreover, through the contribution rate of free radicals in Fig. 3f, we can also see that ·OH play the most important role in the system. The ·OH in the Sn0.97Fe0.03S2 system was about twice as much as that in SnS2 due to the self-Fenton decomposition H2O2 by Sn0.97Fe0.03S2 (Fig. 9e). The piezoelectric effect can be explained in two main ways: the energy band theory and the shielding charge effect theory47,48,49. The lattice distortion produced by S defects due to Fe doping inside the material can modulate the energy band structure of Sn1-xFexS2 to make it more easily excited by mechanical forces and induce potential gradients, thus facilitating the separation and transfer of carriers. The shielding charge effect theory plays a role on the outside of the material50. Firstly, through theoretical calculations, it is found that the material itself possesses the property of easier adsorption of RhB, and then the opposite charge can be adsorbed to the surface of the material through the polarization of the material, and these external charges can participate in the RhB degradation process faster. Based on the above results, a possible piezocatalytic degradation mechanism of RhB by Sn0.97Fe0.03S2 is proposed in Fig. 9f. The polarization of Fe not only enhances the piezoelectric properties of the Sn0.97Fe0.03S2 system, but also inhibits the electron-hole pair recombination and accelerates the charge transfer. Therefore, Sn0.97Fe0.03S2 system produces·O2− from e− and O2 and ·OH from OH− and h+ under piezoelectric action. Moreover, Sn0.97Fe0.03S2 piezoelectric catalysis can also produce a higher concentration of H2O2, and more ·OH can be generated from the self-Fenton system through Fe valence construction51. These free radicals can participate in the degradation process of RhB, especially ·OH.

The ESR spectra of DMPO-·O2– (a), TEMPO-h+ (b) and DMPO-·OH (c) H2O2 generation (d), and the ·OH concentration (e) of SnS2 and Sn0.97Fe0.03S2, and the mechanism of RhB degradation by the free radicals (f). H2O2 and ·OH generation experimental conditions: [Sn0.97Fe0.03S2] = 0.3 g L–1, initial pH = 7.0, and T = 25 °C. The center of the data point is the mean of the two sets of data, and error bars represent the standard deviation of the two sets of data.

In this work, we constructed lattice-deficient Sn1-xFexS2 piezoelectric catalysts with a significantly improved piezoelectric response. As confirmed by RhB degradation experiments, the piezoelectric degradation performence of Sn0.97Fe0.03S2 were remarkable enhancement and had good cycling performance. Combining intermediate product analysis and biotoxicity test verified the significant toxicity reduction after RhB degradation. On this basis, DFT calculation confirms the generation of lattice defects and the improvement of piezoelectric properties of Sn0.97Fe0.03S2 system, and self-Fenton can be realized by valence state transformation of Fe as the active center. In addition to the production of ·O2− from e– as well as O2 and ·OH from OH– and h+ in the Sn0.97Fe0.03S2 system under piezoelectric action, produced H2O2 can accelerate RhB degradation and detoxification through the self-Fenton system. In this work, we construct the Sn1-xFexS2 piezoelectric self-Fenton system, which enhances the removal and detoxification of organic pollution and provides a new idea for developing efficient water pollution treatment technology.

Methods

Chemicals

Tin tetrachloride pentahydrate (SnCl4⋅5H2O), ferric sulfate nonahydrate (Fe2(SO4)3⋅9H2O), Horseradish Peroxidase, terephthalic acid, 2-hydroxyter-ephthalic acid, N, N-diethyl-p-phenylenediamine sulfate, thioacetamide (CH4N2S, TAA), and RhB were purchased from Shanghai Aladdin Biochemical Technology Co., Ltd. (Shanghai, China). Triethanolamine (TEOA), absolute ethanol, sodium hydroxide and tert-butanol were purchased from Nanjing Chemical Reagent Co., Ltd. (Nanjing, China). All materials and reagents were used without further purification. Water was produced by high quality ultra-pure water purification system.

Synthesis of Sn1-xFexS2

Briefly, 8 mmol CH4N2S and 2 mmol SnCl4⋅5H2O were dissolved in 78 mL ethanol. Then X mmol Fe2(SO4)3⋅9H2O was dissolved in 2 mL ultra-pure water and added in to the above solution. The mixed solution was then hydrothermally treated at 180 ◦C for 18 h. After the reaction, the powder was collected and washed three times with deionized water and ethanol. When X was 0.02, 0.06, 0.1, and 0.2 mmol, Sn0.99Fe0.01S2, Sn0.97Fe0.03S2, Sn0.95Fe0.05S2, and Sn0.97Fe0.03S2 were generated, respectively. Meanwhile, SnS2 was synthesized without adding Fe2(SO4)3⋅9H2O.

Measurement of piezocatalytic activities

The piezocatalytic activities of the catalysts synthesized were investigated by the removal of RhB in an ultrasonic cleaner (40 kHz, 100 W). The 15 mg catalyst samples were dispersed in 50 mL RhB solution (20 mg L−1). Prior to the degradation, the mixture was stirred for 1 h in dark to reach a level of adsorption equilibrium. All experiments were carried out in ultrasonic equipment, and the temperature of the reaction suspension was kept at about 25°C. At intervals of 10 minutes, 3 mL aliquots were extracted from the reaction suspension. The concentration of RhB was determined by a Shimadzu UV-3600 spectrofluorometer at 554 nm.

Characterization and toxicity assessment experiment

The theoretical calculations were carried out on VASP and Gaussian 09 and Multiwfn 3.8(dev) program. The ECOSAR toxicity of RhB and its degradation products was evaluated by EPIWEB 4.1. Specific testing instruments, H2O2 production, hydroxyl radical production, electrochemical experiments and zebrafish exposure experiments can be seen in Supplementary Supplemental Material (Supplementary Method 1–6).

Data availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

Eliasson, J. The rising pressure of global water shortages. Nature 517, 6–6 (2015).

Porwal, C., Chauhan, V. S. & Vaish, R. Parametricstudy of visible light active Bi2ZnB207 photocatalyst for dyedegradation. Surf. Interfaces 36, 102636 (2023).

Hong, Y. et al. Rational design 2D/3D MoS2/In2O3 composites for great boosting photocatalytic H2 production coupled with dye degradation. J. Taiwan Inst. Chem. E. 146, 104862 (2023).

Porwal, C., Sharma, M., Vaish, R. & Chauhan, V. S. Piezocatalysis dye degradation using SrO-Bi2O3-B2O3 glass-ceramics. ACS Appl. Eng. Mater. 1, 295–303 (2022).

Jiang, R. et al. Insights into a CQD-SnNb2O6/BiOCl Z-scheme system for the degradation of benzocaine: Influence factors, intermediate toxicity and photocatalytic mechanism. Chem. Eng. J. 374, 79–90 (2019).

Porwal, C., Gaur, A., Chauhan, V. S. & Vaish, R. Photocatalytic dye degradation using lithium borate-bismuth tungstate glass-ceramics. Ceram. Int. 49, 32808–32815 (2023).

Jiang, R. et al. Facet-dependent photoactivity of Mn3O4/BiOCl for naproxen detoxication: Strengthening effect of Mn valence cycle. Appl. Catal. B: Environ. 299, 120672 (2021).

Wen, Y. et al. Two birds with one stone: Cobalt-do** induces to enhanced piezoelectric property and persulfate activation ability of ZnO nanorods for efficient water purification. Nano Energy 107, 108173 (2023).

Mahapatra, S. D. et al. Piezoelectric materials for energy harvesting and sensing applications: Roadmap for future smart materials. Adv. Sci. 8, 2100864 (2021).

Wang, Y. et al. Piezoelectric responses of mechanically exfoliated two-dimensional SnS2 nanosheets. ACS Appl. Mater. Inter. 12, 51662–51668 (2020).

Cao, V. A. et al. Enhanced piezoelectric output performance of the SnS2/SnS heterostructure thin-film piezoelectric nanogenerator realized by atomic layer deposition. ACS Nano 15, 10428–10436 (2021).

Hu, J., Guo, X. W., Zhang, Y. C. & Zhang, F. Review on the advancement of SnS2 in the photocatalysis. J. Mater. Chem. A 11, 7331–7343 (2023).

Yang, P. K. et al. Tin disulfide piezoelectric nanogenerators for biomechanical energy harvesting and intelligent human-robot interface applications. Nano Energy 75, 104879 (2020).

Tian, W. et al. Efficient piezocatalytic removal of BPA and Cr (VI) with SnS2/CNFs membrane by harvesting vibration energy. Nano Energy 86, 106036 (2021).

Jarkov, V., Allan, S. J., Bowen, C. & Khanbareh, H. Piezoelectric materials and systems for tissue engineering and implantable energy harvesting devices for biomedical applications. Int. Mater. Rev. 67, 683–733 (2022).

Ok, K. M., Chi, E. O. & Halasyamani, P. S. Bulk characterization methods for non-centrosymmetric materials: second-harmonic generation, piezoelectricity, pyroelectricity, and ferroelectricity. Chem. Soc. Rev. 35, 710–717 (2006).

Zelenovskii, P. S. et al. 2D layered dipeptide crystals for piezoelectric applications. Adv. Funct. Mater. 31, 2102524 (2021).

Tian, W. et al. Enhanced piezocatalytic activity in ion-doped SnS2 via lattice distortion engineering for BPA degradation and hydrogen production. Nano Energy 107, 108165 (2023).

Cheng, H. et al. Accelerated Fe (III)/Fe (II) cycle for rapid elimination of Rhodamine B by a novel Mo2C co-catalytic Fe2+/H2O2 system. J. Clean. Prod. 393, 136354 (2023).

Zhang, M. H., Dong, H., Zhao, L., Wang, D. X. & Meng, D. A review on Fenton process for organic wastewater treatment based on optimization perspective. Sci. Total Environ. 670, 110–121 (2019).

Deng, F. et al. Critical review on the mechanisms of Fe2+ regeneration in the electro-Fenton process: Fundamentals and boosting strategies. Chem. Rev. 123, 4635–4662 (2023).

Wang, F. et al. Unprecedentedly efficient mineralization performance of photocatalysis-self-Fenton system towards organic pollutants over oxygen-doped porous g-C3N4 nanosheets. Appl. Catal. B: Environ. 312, 121438 (2022).

Xu, J. et al. Highly efficient Fe (III)‐initiated self‐cycled Fenton system in piezo‐catalytic process for organic pollutants degradation. Angew. Chem. Int. Ed. 135, e202307018 (2023).

Shi, Z., Li, M., Sun, J. & Chen, Z. Defect engineering for expediting Li–S chemistry: strategies, mechanisms, and perspectives. Adv. Energy Mater. 11, 2100332 (2021).

Liang, Q., Zhang, Q., Zhao, X., Liu, M. & Wee, A. T. Defect engineering of two-dimensional transition-metal dichalcogenides: applications, challenges, and opportunities. ACS Nano 15, 2165–2181 (2021).

Tian, B. et al. Doping engineering to modulate lattice and electronic structure for enhanced piezocatalytic therapy and ferroptosis. Adv. Mater. 35, 2304262 (2023).

Fu, C. et al. Dual-defect enhanced piezocatalytic performance of C3N5 for multifunctional applications. Appl. Catal. B: Environ. 323, 122196 (2023).

Su, Y. et al. High-performance piezoelectric composites via β phase programming. Nat. Commun. 13, 4867 (2022).

Vajdi, M., Moghanlou, F. S., Sharifianjazi, F., Asl, M. S. & Shokouhimehr, M. A review on the Comsol Multiphysics studies of heat transfer in advanced ceramics. J. Compos. compd. 2, 35–43 (2020).

Jiang, R. et al. The bonding and intercalation efficacy of polyethyleneimine enhanced BiOBr semiconductor-organic framework degradation and detoxification of bisphenol AF. Sep. Purif. Technol. 320, 124134 (2023).

Li, J. et al. Influence of phase transitions on electrostrictive and piezoelectric characteristics in PMN–30PT single crystals. ACS Appl. Mater. Interf. 13, 38467–38476 (2021).

Bince, S., Dindorkar, S. S. & Yadav, A. Computational analysis of substituent effect on indole derivatives as potential antibacterial agents. Chem. Phys. Impact 5, 100088 (2022).

Belenguer, A. M., Michalchuk, A. A., Lampronti, G. I. & Sanders, J. K. Using solid catalysts in disulfide‐based dynamic combinatorial solution‐and mechanochemistry. ChemSusChem 15, e202102416 (2022).

Xie, Z. H. et al. Effects of molecular structure on organic contaminants’ degradation efficiency and dominant ROS in the advanced oxidation process with multiple ROS. Environ. Sci. Technol. 56, 8784–8795 (2022).

Jiang, R., Lu, G., Zhou, R., Dang, T. & Wang, M. Degradation and detoxification of propranolol by a molecular intercalation bismuth oxychloride semiconductor-organic framework. Chem. Eng. J. 423, 130222 (2021).

Zhou, R. et al. Neurotoxicity of polystyrene nanoplastics with different particle sizes at environment-related concentrations on early zebrafish embryos. Sci. Total Environ. 872, 162096 (2023).

Jiang, R. et al. Insight into the degradation process of functional groups modified polystyrene microplastics with dissolvable BiOBr-OH semiconductor-organic framework. Chem. Eng. J. 470, 144401 (2023).

Lechaptois, L., Prado, Y. & Pluchery, O. KPFM visualisation of the Schottky barrier at the interface between gold nanoparticles and silicon. Nanoscale 15, 7510–7516 (2023).

Singh, H. H. & Khare, N. KPFM study of flexible ferroelectric polymer/water interface for understanding the working principle of liquid–solid triboelectric nanogenerator. Adv. Mater. Interfaces 8, 2100032 (2021).

Li, F. et al. Ecotoxicological QSAR modelling of the acute toxicity of fused and non-fused polycyclic aromatic hydrocarbons (FNFPAHs) against two aquatic organisms: Consensus modelling and comparison with ECOSAR. Aquat. Toxicol. 255, 106393 (2023).

Shepelin, N. A. et al. Interfacial piezoelectric polarization locking in printable Ti3C2Tx MXene-fluoropolymer composites. Nat. Commun. 12, 3171 (2021).

Ran, L. et al. Engineering single-atom active sites on covalent organic frameworks for boosting CO2 photoreduction. J. Am. Chem. Soc. 144, 17097–17109 (2022).

Huang, W. et al. Ligand modulation of active sites to promote electrocatalytic oxygen evolution. Adv. Mater. 34, 2200270 (2022).

Menga, D. et al. Resolving the dilemma of Fe–N–C catalysts by the selective synthesis of tetrapyrrolic active sites via an imprinting strategy. J. Am. Chem. Soc. 143, 18010–18019 (2021).

Zhao, H., Gao, J., Zhou, W., Wang, Z. & Wu, S. Quantitative detection of hydroxyl radicals in Fenton system by UV-vis spectrophotometry. Anal. Methods 7, 5447–5453 (2015).

Lin, J. et al. Functional carbon nitride materials in photo‐Fenton‐like catalysis for environmental remediation. Adv. Funct. Mater. 32, 2201743 (2022).

Porwal, C. et al. Piezocatalytic dye degradation using Bi2O3-ZnO-B2O3 glass-nanocomposites. J. Mater. Res. Technol. 21, 2028–2037 (2022).

Yang, D., Zhang, R., Gai, S. & Yang, P. The fundamental and application of piezoelectric materials for tumor therapy: recent advances and outlook. Mater. Horiz. 10, 1140–1184 (2023).

Porwal, C., Verma, S., Chauhan, V. S. & Vaish, R. Bismuth zinc borate-Polyacrylonitrile nanofibers for photo-piezocatalysis. J. Ind. Eng. Chem. 124, 358–367 (2023).

Wang, R., Zhou, T., Zhang, X. & Liu, L. Force-responsive antibiofouling strategy based on the ultrasound-controlled piezoelectric effect. Appl. Surf. Sci. 603, 154467 (2022).

Li, R. et al. Carbon vacancies in porous g-C3N4 nanosheets induced robust H2O2 production for highly efficient photocatalysis-self-Fenton system for metronidazole degradation. Chem. Eng. J. 464, 142584 (2023).

Acknowledgements

This study was supported by the National Natural Science Foundation of China (Grant 52200193, 42177353), China Postdoctoral Science Foundation (2023T160185), Jiangsu Funding Program for Excellent Postdoctoral Talent (2022ZB190).

Author information

Authors and Affiliations

Contributions

R.J.: Methodology, Software, Validation, Funding acquisition, Visualization, Writing—original draft. G.L.: Conceptualization, Supervision, Methodology, Validation, Validation, Formal analysis, Writing—review & editing. M.W.: Formal analysis, Writing—review & editing. Y.C.: Formal analysis, Writing—review & editing. J.L.: Conceptualization, Writing—review & editing. Z.Y.: Supervision, Validation. H.X.: Software, Calculation.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Jiang, R., Lu, G., Wang, M. et al. Lattice distortion SnS2 piezoelectric self-Fenton system for efficient degradation and detoxification of pollutants. npj Clean Water 6, 79 (2023). https://doi.org/10.1038/s41545-023-00293-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41545-023-00293-3