Abstract

Phase transformations in materials systems can be tracked using atomic force microscopy (AFM), enabling the examination of surface properties and macroscale morphologies. In situ measurements investigating phase transformations generate large datasets of time-lapse image sequences. The interpretation of the resulting image sequences, guided by domain-knowledge, requires manual image processing using handcrafted masks. This approach is time-consuming and restricts the number of images that can be processed. In this study, we developed an automated image processing pipeline which integrates image detection and segmentation methods. We examine five time-series AFM videos of various fluoroelastomer phase transformations. The number of image sequences per video ranges from a hundred to a thousand image sequences. The resulting image processing pipeline aims to automatically classify and analyze images to enable batch processing. Using this pipeline, the growth of each individual fluoroelastomer crystallite can be tracked through time. We incorporated statistical analysis into the pipeline to investigate trends in phase transformations between different fluoroelastomer batches. Understanding these phase transformations is crucial, as it can provide valuable insights into manufacturing processes, improve product quality, and possibly lead to the development of more advanced fluoroelastomer formulations.

Similar content being viewed by others

References

Nguyen-Tri P, Ghassemi P, Carriere P, Nanda S, Assadi AA, Nguyen DD (2020) Recent applications of advanced atomic force microscopy in polymer science: a review. Polymers 12(5):1142

Binnig G, Quate CF, Gerber C (1986) Atomic force microscope. Phys Rev lett 56(9):930

Maiti M, Bhowmick AK (2006) New insights into rubber-clay nanocomposites by AFM imaging. Polymer 47(17):6156–6166

Ornaghi FG, Bianchi O, Ornaghi HL Jr, Jacobi MA (2019) Fluoroelastomers reinforced with carbon nanofibers: a survey on rheological, swelling, mechanical, morphological, and prediction of the thermal degradation kinetic behavior. Polym Eng Sci 59(6):1223–1232

Ameduri B, Boutevin B, Kostov G (2001) Fluoroelastomers: synthesis, properties and applications. Prog Polym Sci 26(1):105–187

Améduri B (2020) The promising future of fluoropolymers. Macromol Chem Phys 221(8):1900573. https://doi.org/10.1002/macp.201900573

Hobbs JK, Farrance OE, Kailas L (2009) How atomic force microscopy has contributed to our understanding of polymer crystallization. Polymer 50(18):4281–4292. https://doi.org/10.1016/j.polymer.2009.06.021

Wang Y, Yao Q, Kwok JT, Ni LM (2020) Generalizing from a few examples: a survey on few-shot learning. ACM Comput Surv CSUR 53(3):1–34

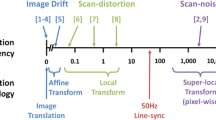

Gaponenko I, Tückmantel P, Ziegler B, Rapin G, Chhikara M, Paruch P (2017) Computer vision distortion correction of scanning probe microscopy images. Sci Rep 7(1):669

Wang Y, Lu T, Li X, Wang H (2018) Automated image segmentation-assisted flattening of atomic force microscopy images. Beilstein J Nanotechnol 9(1):975–985

Shorten C, Khoshgoftaar TM (2019) A survey on image data augmentation for deep learning. J Big Data 6(1):1–48

Giergiel M, Zapotoczny B, Czyzynska-Cichon I, Konior J, Szymonski M (2022) AFM image analysis of porous structures by means of neural networks. Biomed Signal Process Control 71:103097. https://doi.org/10.1016/j.bspc.2021.103097

Ge M, Su F, Zhao Z, Su D (2020) Deep learning analysis on microscopic imaging in materials science. Materials Today Nano 11:100087. https://doi.org/10.1016/j.mtnano.2020.100087

Redmon J, Divvala S, Girshick R, Farhadi A (2016) You only look once: unified, real-time object detection. In: Proceedings of the IEEE conference on computer vision and pattern recognition, pp 779–788

Chen L-C, Papandreou G, Kokkinos I, Murphy K, Yuille AL (2018) Deeplab: semantic image segmentation with deep convolutional nets, Atrous convolution, and fully connected CRFS. IEEE Trans Pattern Anal Mach Intell 40(4):834–848. https://doi.org/10.1109/TPAMI.2017.2699184

Wang Y, Yao Q (2019) Few-shot learning: a survey. CoRR arXiv: 1904.05046

LeCun Y, Bengio Y, Hinton G (2015) Deep learning. Nature 521(7553):436–444

Mandelkern L, Martin G, Quinn F Jr (1957) Poly-(vinylidene fluoride), and their copolymers. J Res Natl Bur Stand 58(3):137

Ameduri B (2009) From vinylidene fluoride (VDF) to the applications of VDF-containing polymers and copolymers: recent developments and future trends. Chem Rev 109(12):6632–6686

Kelly K, Brown G, Anthony S (2020) Quantifying CTFE content in FK-800 using ATR-FTIR and time to peak crystallization. Int J Polym Anal Charact 25(8):621–633. https://doi.org/10.1080/1023666X.2020.1827859

Willey TM, DePiero SC, Hoffman DM (May 2009) A comparison of new TATBs, FK-800 binder and LX-17-like PBXs to legacy materials. Technical report LLNL-CONF-412929, Lawrence Livermore National Lab. (LLNL), Livermore, CA (United States). https://www.osti.gov/biblio/966908 Accessed 2021-12-14

Orme CA (2018) Progress summary: developing experimental methods to quantify the degree of crystallinity in fluoropolymer binders. Tech Rep Lawrence Livermore Nat Lab. https://doi.org/10.2172/1476198

Cady W, Caley L (1977) Properties of Kel F-800 polymer. Technical report UCRL-52301, Lawrence Livermore National Lab. (LLNL), Livermore CA, USA. https://doi.org/10.2172/5305005. http://www.osti.gov/servlets/purl/5305005/ Accessed 2021-11-08

Crist B, Schultz JM (2016) Polymer spherulites: a critical review. Prog Polym Sci 56:1–63. https://doi.org/10.1016/j.progpolymsci.2015.11.006

Su Y, Liu G, Xie B, Fu D, Wang D (2014) Crystallization features of normal alkanes in confined geometry. Accounts Chem Res 47(1):192–201. https://doi.org/10.1021/ar400116c

George L (2011) HBase the definitive guide. O’Reilly, Sebastopol, CA. http://shop.oreilly.com/product/0636920014348.do Accessed 2013-04-18

Harris PA, Taylor R, Thielke R, Payne J, Gonzalez N, Conde JG (2009) Research electronic data capture (redcap)-a metadata-driven methodology and workflow process for providing translational research informatics support. J Biomed Inform 42(2):377–381. https://doi.org/10.1016/j.jbi.2008.08.010

Girshick R (2015) Fast r-cnn. In: 2015 IEEE International conference on computer vision (ICCV), pp 1440–1448. https://doi.org/10.1109/ICCV.2015.169

Redmon J, Farhadi A (2018) Yolov3: An incremental improvement. CoRR arXiv:1804.02767

Wang CY, Liao HYM, Yeh IH, Wu YH, Chen PY, Hsieh JW (2019) CSPNet: A new backbone that can enhance learning capability of CNN. 2020 IEEE/CVF Conference on Computer Vision and Pattern Recognition Workshops (CVPRW)

He K, Zhang X, Ren S, Sun J (2014) Spatial pyramid pooling in deep convolutional networks for visual recognition. In: Computer vision—ECCV 2014, pp 346–361. Springer, Berlin. https://doi.org/10.1007/978-3-319-10578-9_23

Liu S, Qi L, Qin H, Shi J, Jia J (2018) Path aggregation network for instance segmentation. In: 2018 IEEE/CVF Conference on Computer Vision and Pattern Recognition, pp 8759–8768. Salt Lake City, UT. https://doi.org/10.1109/CVPR.2018.00913

Misra D (2020) Mish: A self regularized non-monotonic activation function

Wang CY, Bochkovskiy A, Liao HYM (2022) YOLOv7: Trainable bag-of-freebies sets new state-of-the-art for real-time object detectors

Long J, Shelhamer E, Darrell T (2015) Fully convolutional networks for semantic segmentation. In: 2015 IEEE Conference on computer vision and pattern recognition (CVPR), pp 3431–3440. https://doi.org/10.1109/CVPR.2015.7298965

Chen LC, Papandreou G, Schroff F, Adam H (2017) Rethinking Atrous convolution for semantic image segmentation. arXiv preprint arXiv:1706.05587

Yu F, Koltun V (2015) Multi-scale context aggregation by dilated convolutions. arXiv preprint arXiv:1511.07122

Russell BC, Torralba A, Murphy KP, Freeman WT (2008) Labelme: a database and web-based tool for image annotation. Int J Comput Vision 77(1):157–173

Ester M, Kriegel HP, Sander J, Xu X (1996) A density-based algorithm for discovering clusters in large spatial databases with noise. In: Proceedings of the second international conference on knowledge discovery and data mining. KDD’96, pp 226–231. AAAI Press, Pomona

Schubert E, Sander J, Ester M, Kriegel HP, Xu X (2017) DBSCAN revisited, revisited: why and how you should (still) use DBSCAN. ACM Trans Database Syst TODS 42(3):1–21. https://doi.org/10.1145/3068335

Avrami M (2004) Kinetics of phase change I general theory. J Chem Phys 7(12):1103–1112. https://doi.org/10.1063/1.1750380

Long Y, Shanks RA, Stachurski ZH (1995) Kinetics of polymer crystallisation. Prog Polym Sci 20(4):651–701. https://doi.org/10.1016/0079-6700(95)00002-W

Everingham M, Van Gool L, Williams CK, Winn J, Zisserman A (2010) The pascal visual object classes (VOC) challenge. Int J Comput Vis 88:303–338

Goodfellow I, Bengio Y, Courville A (2016) Deep learning. MIT Press, Cambridge. http://www.deeplearningbook.org

Rezatofighi H, Tsoi N, Gwak J, Sadeghian A, Reid I, Savarese S (2019) Generalized intersection over union: a metric and a loss for bounding box regression. In: Proceedings of the IEEE/CVF conference on computer vision and pattern recognition, pp 658–666

Bradski G (2000) The opencv library. Dr Dobb’s J Softw Tools Prof Program 25(11):120–123

Cantor B (2020) The Avrami equation: phase transformations. In: Cantor, B. (ed.) The equations of materials, pp. 180–206. Oxford University Press, Oxford. https://doi.org/10.1093/oso/9780198851875.003.0009

Acknowledgements

This material is based upon research in the Materials Data Science for Stockpile Stewardship Center of Excellence (MDS3−COE), and supported by the Department of Energy’s National Nuclear Security Administration under Award Number(s) DE-NA0004104. CO acknowledges useful discussions with En Ju Cho, Chami Swaminathan, Xiaojie Xu, and James Lewicki. Work performed by CO was under the auspices of the U.S. Department of Energy by Lawrence Livermore National Laboratory under Contract DE-AC52- 07NA27344. This work made use of the High Performance Computing Resource in the Core Facility for Advanced Research Computing at Case Western Reserve University.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interest.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Lu, M., Venkat, S.N., Augustino, J. et al. Image Processing Pipeline for Fluoroelastomer Crystallite Detection in Atomic Force Microscopy Images. Integr Mater Manuf Innov 12, 371–385 (2023). https://doi.org/10.1007/s40192-023-00320-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40192-023-00320-8