Abstract

The traditional ironmaking technologies (including coking, sintering, pelletizing, and BF ironmaking process) are carbon-intensive, which makes the industry a significant contributor to global CO2 emissions. Hydrogen replacement of carbon in steelmaking processes is a sustainable way to reduce CO2 emissions. First, the reduction thermodynamics and kinetics of iron oxide by carbon and hydrogen are compared. Then, the latest researches on different hydrogen reduction technologies in ironmaking industry are compared and analyzed. Based on this, the advantages and problems faced by hydrogen-based reduction over carbon-based reduction are presented. And finally, the possible pathways for the future development of hydrogen metallurgy are proposed, hoping to provide guidance for the hydrogen metallurgy in the steel industry. The reduction product of hydrogen metallurgy is H2O, and has a faster reduction rate than CO reduction. Therefore, hydrogen metallurgy is considered to be an effective way to achieve low-carbon green transformation in the metallurgical industry.

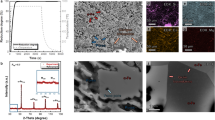

Graphical Abstract

Similar content being viewed by others

References

United States Environmental Protection Agency. Overview of greenhouse gases. https://www.epa.gov/ghgemissions/overview-greenhouse-gases

Calise F, Cappiello FL, Cimmino L, Vicidomini M (2023) Dynamic modelling and energy, economic, and environmental analysis of a greenhouse supplied by renewable sources. Appl Sci 13:1

Sesana E, Gagnon AS, Ciantelli C, Cassar J, Hughes JJ (2021) Climate change impacts on cultural heritage: a literature review. Wiley Interdiscipl Rev 12:e710

Hickmann T, Widerberg O, Lederer M, Pattberg P (2021) The United Nations framework convention on climate change secretariat as an orchestrator in global climate policymaking. Int Rev Adm Sci 87(1):21–38

Verschuuren J (2022) Climate change adaptation under the United Nations Framework Convention on Climate Change and related documents Research handbook on climate change adaptation law. Edward Elgar Publishing, Cheltenham, pp 14–30

Miyamoto M, Takeuchi K (2019) Climate agreement and technology diffusion: impact of the Kyoto protocol on international patent applications for renewable energy technologies. Energy Policy 129:1331–1338

Lawrence MG, Schäfer S, Muri H, Scott V, Oschlies A, Vaughan NE et al (2018) Evaluating climate geoengineering proposals in the context of the Paris agreement temperature goals. Nat Commun 9(1):1–19

Rogelj J, Huppmann D, Krey V, Riahi K, Clarke L, Gidden M et al (2019) A new scenario logic for the Paris agreement long-term temperature goal. Nature 573(7774):357–363

Hall BD, Crotwell AM, Kitzis DR, Mefford T, Miller BR, Schibig MF et al (2021) Revision of the World Meteorological Organization global atmosphere watch (WMO/GAW) CO2 calibration scale. Atmos Meas Tech 14(4):3015–3032

Lei R, Sheng Z, Xunmin O (2023) The carbon reduction potential of hydrogen in the low carbon transition of the iron and steel industry: the case of China. Renew Sustain Energy Rev 171(1):1130261–1130317

International Energy Agency (2020) Hydrogen. https://www.iea.org/reports/iron-and-steel-technology-roadmap

Sun M, Pang K, Barati M, Meng X (2023) Development and problems of fluidized bed ironmaking process: an overview. J Sustain Metall. https://doi.org/10.1007/s40831-023-00746-6

Gu W, Zhao X, Yan X, Wang C, Li Q (2019) Energy technological progress, energy consumption, and CO2 emissions: empirical evidence from China. J Clean Prod 236:117666

Lei W, Xie Y, Hafeez M, Ullah S (2022) Assessing the dynamic linkage between energy efficiency, renewable energy consumption, and CO2 emissions in China. Environ Sci Pollut Res 29(13):19540–19552

Choi J, Kim W, Choi S (2022) The economic effect of the steel industry on sustainable growth in China—a focus on input–output analysis. Sustainability 14:4110

Wulf C, Linssen J, Zapp P (2019) Review of power-to-gas projects in Europe. 12th international renewable energy storage conference: IRES 2018, Dusseldorf, Germany, 13–15 March 2018, 367–378

Rechberger K, Andreas Sasiain C, Wolfmeir A, Harris H (2020) Green hydrogen-based direct reduction for low-carbon steelmaking. Steel Res Int 91(11):202000110

(2023) 2022 Steel Industry Green Development Level Assessment Report by Environmental Engineering Evaluation Center of the Ministry of Ecology and Environment

Yu X, Tan C (2022) China’s pathway to carbon neutrality for the iron and steel industry. Glob Environ Chang 76:102574

Qazi UY (2022) Future of hydrogen as an alternative fuel for next-generation industrial applications. Challenges Expect Opportunities Energies 15(13):4741

Dutta S (2014) A review on production, storage of hydrogen and its utilization as an energy resource. J Ind Eng Chem 20(4):1148–1156

Bailera M, Lisbona P, Pea B, Romeo LM (2021) A review on CO2 mitigation in the iron and steel industry through power to X processes. J CO2 Util 46:101456

As D, Sabrina G, Sven L, Gilles K, Anand A, Miriam V et al (2021) Reduction of CO2 emission from off-gases of steel industry by dry reforming of methane. Angew Chem 60(21):11852–11857

Zhidong T, Qi Z, Yongsheng S, Peng G, Yuexin H (2022) Prospects of green extraction of iron from waste dumped flotation tailings by H2: A pilot case study. J Clean Prod 330(1):1298531–1298612

Chen Y, Zuo H (2021) Review of hydrogen-rich ironmaking technology in blast furnace. Ironmaking Steelmaking 48(6):749–768

Zhang C, Vladislav L, Xu R, Sergey G, Jiao K, Zhang J et al (2022) Blast furnace hydrogen-rich metallurgy-research on efficiency injection of natural gas and pulverized coal. Fuel 311:122412

Rechberger K, Spanlang A, Sasiain Conde A, Wolfmeir H, Harris C (2020) Green hydrogen-based direct reduction for low-carbon steelmaking. Steel Res Int 91:2000110

Wang R, Zhao Y, Babich A, Senk D, Fan X (2021) Hydrogen direct reduction (H-DR) in steel industry—an overview of challenges and opportunities. J Clean Prod 329:129797

Liu W, Zuo H, Wang J, Xue Q, Ren B, Yang F (2021) The production and application of hydrogen in steel industry. Int J Hydrogen Energy 46(17):10548–10569

Badr K (2007) Smelting of iron oxides using hydrogen based plasmas. University of Leoben

Souza Filho IR, Ma Y, Kulse M, Ponge D, Gault B, Springer H et al (2021) Sustainable steel through hydrogen plasma reduction of iron ore: process, kinetics, microstructure, chemistry. Acta Mater 213:116971

Geerdes M, Chaigneau R, Lingiardi O (2020) Modern blast furnace ironmaking: an introduction. Ios Press, New York

Manuel B (2023) Comparing different syngas for blast furnace ironmaking by using the extended operating line methodology. Fuel 333(1):1265331–1265413

Sfi R, Hauke S, Yan M, Ankita M et al (2022) Green steel at its crossroads: Hybrid hydrogen-based reduction of iron ores. J Clean Prod 340(15):1308051–1308115

Jozwiak W, Kaczmarek E, Maniecki T, Ignaczak W, Maniukiewicz W (2007) Reduction behavior of iron oxides in hydrogen and carbon monoxide atmospheres. Appl Catal A 326(1):17–27

Yan M, R. SFI, Xue Z, Supriya N, Pere BV, Guillermo R, et al (2022) Hydrogen-based direct reduction of iron oxide at 700°C: heterogeneity at pellet and microstructure scales. Int J Miner Metall Mater 29(10):1901–1907

Yan M et al (2022) Hierarchical nature of hydrogen-based direct reduction of iron oxides. Scr Mater 1:114571

Zhenxiao X, Zeyi J, Xinru Z, Zhen L, Yuanxiang L, Yewei H et al (2022) The CO2 reduction potential for the oxygen blast furnace with CO2 capture and storage under hydrogen-enriched conditions. Int J Gas Control 121:1

Ea A, Sl T, SeHo K, Baptiste G, Dierk R (2023) The fate of water in hydrogen-based iron oxide reduction. Adv Sci 10(24):e2300626

Spreitzer D, Schenk J (2019) Reduction of iron oxides with hydrogen—a review. Steel Res Int 90(10):1900108

Wei Z, Jing D, Chengzhi L, Xiaobing Y, Zhengliang X, Henrik S (2020) A review on explorations of the oxygen blast furnace process. Steel Res Int 92:1

Ubando AT, Chen WH, Show PL, Ong HC (2020) Kinetic and thermodynamic analysis of iron oxide reduction by graphite for CO2 mitigation in chemical-looping combustion. Int J Energy Res 44(5):3865–3882

Mondal K, Lorethova H, Hippo E, Wiltowski T, Lalvani S (2004) Reduction of iron oxide in carbon monoxide atmosphere—reaction controlled kinetics. Fuel Process Technol 86(1):33–47

Barde AA, Klausner JF, Mei R (2016) Solid state reaction kinetics of iron oxide reduction using hydrogen as a reducing agent. Int J Hydrogen Energy 41(24):10103–10119

Zhang X (2022) Kinetic analysis of iron ore powder reaction with hydrogen-carbon monoxide. J Miner Metall Mater 29:1882–1890

Zuo H-b, Wang C, Dong J-j, Jiao K-x, Xu R-s (2015) Reduction kinetics of iron oxide pellets with H2 and CO mixtures. Int J Miner Metall Mater 22(7):688–696

Aidin H, Niusha N, Mikko I, Timo F (2021) A review on the kinetics of iron ore reduction by hydrogen. Materials 14(24):7540–7540

Li ZZTCWZW (2022) Direct reduction swelling behavior of pellets in hydrogen-based shaft furnaces under typical atmospheres. J Miner Metall Mater 29:1891–1900

Metolina P, Ribeiro TR, Guardani R (2022) Hydrogen-based direct reduction of industrial iron ore pellets: statistically designed experiments and computational simulation. Int J Miner Metall Mater 29:1908–1921

Thomas W, Daniel S, Johannes S (2022) Using iron ore ultra-fines for hydrogen-based fluidized bed direct reduction—a mathematical evaluation. Materials 15:1

Pineau A, Kanari N, Gaballah I (2006) Kinetics of reduction of iron oxides by H2: part I: low temperature reduction of hematite. Thermochim Acta 447(1):89–100

Pineau A, Kanari N, Gaballah I (2007) Kinetics of reduction of iron oxides by H2: Part II. Low temperature reduction of magnetite. Thermochim Acta 456(2):75–88

Ueno H, Endo S, Tomomura S, Ishiwata N (2015) Outline of CO2 ultimate reduction in steelmaking process by innovative technology for cool earth 50 (COURSE50 project). J Jpn Inst Energy 94:1277–1283

Tonomura S (2013) Outline of course 50. Energy Proc 37:7160–7167

Quader MA, Ahmed S, Ghazilla RAR, Ahmed S, Dahari M (2015) A comprehensive review on energy efficient CO2 breakthrough technologies for sustainable green iron and steel manufacturing. Renew Sustain Energy Rev 50:594–614

Zhang N, Zhou P, Choi Y (2013) Energy efficiency, CO2 emission performance and technology gaps in fossil fuel electricity generation in Korea: a meta-frontier non-radial directional distance functionanalysis. Energy Policy 56:653–662

Choi J, Cho H, Yun S, Jang M-G, Oh S-Y, Binns M et al (2019) Process design and optimization of MEA-based CO2 capture processes for non-power industries. Energy 185:971–980

Jeong S-J (2015) System dynamics approach for the impacts of FINEX technology and carbon taxes on steel demand: case study of the POSCO. Int J Precis Eng Manuf Green Technol 2:85–93

Ariyama T, Takahashi K, Kawashiri Y, Nouchi T (2019) Diversification of the ironmaking process toward the long-term global goal for carbon dioxide mitigation. J Sustain Metall 5(3):276–294

Tang J, Chu M-s, Li F, Feng C, Liu Z-g, Zhou Y-s (2020) Development and progress on hydrogen metallurgy. Int J Miner Metall Mater 27(6):713–723

Bhaskar A, Assadi M, Nikpey SH (2020) Decarbonization of the iron and steel industry with direct reduction of iron ore with green hydrogen. Energies 13(3):758

Ren L, Zhou S, Peng T, Ou X (2021) A review of CO2 emissions reduction technologies and low-carbon development in the iron and steel industry focusing on China. Renew Sustain Energy Rev 143:110846

Lin Y, Yang H, Ma L, Li Z, Ni W (2021) Low-carbon development for the iron and steel industry in China and the world: status quo, future vision, and key actions. Sustainability 13:12548

Zhao J, Zuo H, Wang Y, Wang J, Xue Q (2020) Review of green and low-carbon ironmaking technology. Ironmaking Steelmaking 47(3):296–306

Pei M, Petäjäniemi M, Regnell A, Wijk O (2020) Toward a fossil free future with HYBRIT: development of iron and steelmaking technology in Sweden and Finland. Metals 10(7):972

Varling AS, Christensen TH, Bisinella V (2023) Life cycle assessment of alternative biogas utilisations, including carbon capture and storage or utilisation. Waste Manag 157:168

ArcelorMittal (2019) World first for steel: ArcelorMittal investigates the industrial use of pure hydrogen-ArcelorMittal. https://corporate.arcelormittal.com/news-and-media/news/2019/mar/28-03-2019

Langner AL, L (2019) ArcelorMittal (2023) The carbon reduction potential of hydrogen in the low carbon transition of the iron and steel industry: the case of China. Renewable and Sustainable Energy Reviews 171 in Hamburg. https://corporate.arcelormittal.com/news-andmedia/news/2019/sep/16-09-2019

Vaughan A (2019) Zero carbon’s hard problem. New Sci 244(3256):38–41

Kar SK, Sinha ASK, Harichandan S, Bansal R, Balathanigaimani MS (2022) Hydrogen economy in India: a status review. Wiley Interdiscipl Rev 1:e459

Buergler T, Prammer J (2019) Hydrogen steelmaking: technology options and R&D projects. BHM 164(11):447–451

Wang Y, Zuo H, Zhao J (2020) Recent progress and development of ironmaking in China as of 2019: an overview. Ironmaking Steelmaking 47(6):640–649

Li J, Kuang S, Jiao L, Liu L, Zou R, Yu A (2022) Numerical modeling and analysis of hydrogen blast furnace ironmaking process. Fuel 323:1243681–1243716

Nishioka K, Ujisawa Y, Tonomura S, Ishiwata N, Sikstrom P (2016) Sustainable aspects of CO2 ultimate reduction in the steelmaking process (COURSE50 project), part 1: hydrogen reduction in the blast furnace. J Sustain Metall 2(3):200–208

Onoda M, Matsuzaki Y, Chowdhury FA, Yamada H, Goto K, Tonomura S (2016) Sustainable aspects of ultimate reduction of CO2 in the steelmaking process (COURSE50 project), part 2: CO2 capture. J Sustain Metall 2(3):209–215

Junjie Y (2018) Progress and future of breakthrough low-carbon steelmaking technology (ULCOS) of EU. Int J Miner Process Extract Metall 3(2):15–15

Quader MA, Ahmed S, Dawal SZ, Nukman Y (2016) Present needs, recent progress and future trends of energy-efficient ultra-low carbon dioxide (CO2) steelmaking (ULCOS) program. Renew Sustain Energy Rev 55:537–549

Alexandra H, Jan VDS, Dominique S (2012) ULCOS top gas recycling blast furnace. Stahl Undsen 132(4):31–40

World Steel Capacity News (2023) EU commission approves funds for Thyssenkrupp's tkH2Steel Programme. World Steel Capacity News

Peng S, Binglang R, Jingsong W, Guang W, Haibin Z, Qingguo X (2023) Current situation and development prospects of metallurgical by-product gas utilization in China’s steel industry. Int J Hydrogen Energy 48(74):28945–28969

Yichao H, Yinxuan Q, Jian C, Liangyuan H, Edward RT, Victor R et al (2022) Integrating a top-gas recycling and CO2 electrolysis process for H2-rich gas injection and reduce CO2 emissions from an ironmaking blast furnace. Materials 15(6):2008–2008

Michael B, Kyriakos P, Panos S, Spyridon V, Ismael M, Alice P et al (2021) Integration of renewable hydrogen production in steelworks off-gases for the synthesis of methanol and methane. Energies 14(10):2904–2904

Joakim A, Stefan G (2021) A comparison of two hydrogen storages in a fossil-free direct reduced iron process. Int J Hydrogen Energy 46(56):28657–28674

Author information

Authors and Affiliations

Contributions

MS is the corresponding author contributed toward writing—review and editing. KP contributed toward review and editing. MB contributed toward conceptualization and supervision. XM contributed toward review and editing.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

The contributing editor for this article was Yan Ma.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sun, M., Pang, K., Barati, M. et al. Hydrogen-Based Reduction Technologies in Low-Carbon Sustainable Ironmaking and Steelmaking: A Review. J. Sustain. Metall. 10, 10–25 (2024). https://doi.org/10.1007/s40831-023-00772-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40831-023-00772-4