Introduction

Artificial intelligence (AI) technology is transforming the way engineering designers work, enabling new work models in many aspects of engineering design and manufacturing industries. The advent of digitalization and the Industry 4.0 phenomenon (Lasi et al Reference Lasi, Fettke, Kemper, Feld and Hoffmann2014) has resulted in a substantial increase in AI applications and data to develop new AI-based methods (Lee et al Reference Lee, Davari, Singh and Pandhare2018; Marion and Fixson Reference Marion and Fixson2020; Roh et al Reference Roh, Heo and Whang2021). New digital tools and sensors generate massive data sources and repositories that become readily available for AI solutions (Lee et al Reference Lee, Davari, Singh and Pandhare2018; Marion and Fixson Reference Marion and Fixson2020; Roh et al Reference Roh, Heo and Whang2021). Such AI-based applications and data have also found a way into the field of engineering design, making it an important platform for the development and application of AI in this digital economy (Lee et al Reference Lee, Davari, Singh and Pandhare2018; Marion and Fixson Reference Marion and Fixson2020; Roh et al Reference Roh, Heo and Whang2021). Knowledge of AI, machine learning, and data science have been effectively implemented to develop tools and frameworks that support engineers in their design tasks. AI-based methods, especially machine learning, have been utilized for rapid design data learning and processing (Sim and Duffy Reference Sim and Duffy1998; Saridakis and Dentsoras Reference Saridakis and Dentsoras2008). These advances in digital tools have led computers to effectively automate several engineering design tasks that were traditionally performed by humans. As such, the growth in AI capabilities coincides with a digital transformation in the engineering design industry.

The availability of engineering design data and the development of state-of-the-art AI-based methods have, together, led to the emergence of diverse literature focused on the application of AI-based methods for analyzing or automating different engineering design tasks. If one took all these developments at face value, one might conclude that we are on the cusp of fully automated AI engineering design. But the broader literature on AI capabilities makes it clear that this simply is not true (Frank et al Reference Frank, Autor, Bessen, Brynjolfsson, Cebrian, Deming, Feldman, Groh, Lobo, Moro, Wang, Youn and Rahwan2019). Considering this shift in how and what work humans and AI do in the engineering design process, it is important to reflect on the current prevalence and applications of AI in the field of engineering design. As engineering design is a complex process that includes multiple design tasks to be carefully and sequentially processed, we require a stage-by-stage categorization of the design process, followed by a mapping of AI-based methods to appropriate design stages. This mapping of AI methods across different design stages could potentially be important for designers and researchers to assess, select and then effectively implement appropriate AI-based methods for tasks in specific design stages in their research.

Previous literature studies on engineering design and AI have discussed function modeling related to AI (Erden et al Reference Erden, Komoto, Van Beek, D'Amelio, Echavarria and Tomiyama2008), the impact of Industry 4.0 on the product design process (Pereira Pessôa and Jauregui Becker Reference Pereira Pessôa and Jauregui Becker2020), design requirements elicitation (Cheligeer et al Reference Cheligeer, Huang, Wu, Bhuiyan, Xu and Zeng2022), and the AI methods used in the data-driven design-by-analogy process (Jiang et al Reference Jiang, Hu, Wood and Luo2022). In addition, certain literature studies focus on applications of specific AI-based methods such as soft computing techniques (Saridakis and Dentsoras Reference Saridakis and Dentsoras2008), deep learning-based generative models (Regenwetter et al Reference Regenwetter, Nobari and Ahmed2022), and natural language processing (NLP) (Siddharth et al Reference Siddharth, Blessing and Luo2022) toward engineering design. However, a study pertaining to the focus of state-of-the-art AI methods in the stages of the engineering design process and how these methods support these design stages is lacking.

To address this gap, we present a focused literature review that classifies the applications of AI solutions to the engineering design process. Through our literature review study, we address the following key research questions:

-

RQ-1: Which AI-based methods are commonly applied in each engineering design stage?

-

RQ-2: Why are AI-based methods prevalent in certain engineering design stages?

-

RQ-3: How do AI-based methods support designers in each engineering design stage?

By addressing these objectives, our stage-by-stage categorization of the AI-based design literature offers insights regarding the nature of the AI-based methods that focus on specific stages of the engineering design process and why researchers may have focused the application of certain AI methods on these specific stages. Our study highlights seven AI-based methods, which are agent-based modeling, deep learning, machine learning, NLP, network theory, probabilistic modeling, and optimization algorithms, that are mapped to the engineering design stages and describe which AI-based methods are commonly used in each stage. An understanding of the distribution of AI-based research works could illuminate high-value opportunities for design researchers to explore if AI-based methods could support the design tasks in the under-served stages.

The rest of the paper is organized as follows. In the section “Background”, we present a background focusing on the engineering design process and the importance of AI in engineering design. In the section “Methodology for this literature review”, we present the methods used in this work to conduct a focused literature review followed by a classification of the AI-based design literature in different stages of the engineering design process. Finally, we present our findings and discuss how these findings address the three research questions in the section “Findings and discussion”. In the section “Conclusion”, we present our conclusion and future directions.

Background

The engineering design process

Design is, fundamentally, one of the most important aspects of engineering and is the primary way in which engineers contribute to society (Dym et al Reference Dym, Agogino, Eris, Frey and Leifer2005; Daly et al Reference Daly, Adams and Bodner2012). The engineering design process requires a combination of knowledge and skills of humans, including fundamental subject matter expertise (in physics, chemistry, computation, optimization, etc.) as well as problem-solving and creativity. The role that humans play in this process has been the focus of significant research, in particular with regards to topics such as creativity (Hsiao and Chou Reference Hsiao and Chou2004), empathy (Kouprie and Visser Reference Kouprie and Visser2009; Zhou et al Reference Zhou, Phadnis and Olechowski2021), intuition (Durling Reference Durling1999; Taura and Nagai Reference Taura and Nagai2017), experience (Cross Reference Cross2004; Atman et al Reference Atman, Adams, Cardella, Turns, Mosborg and Saleem2007), and collaboration (McComb et al Reference McComb, Cagan and Kotovsky2015, Reference McComb, Cagan and Kotovsky2017). Furthermore, engineering design is a complex process (Kossiakoff et al Reference Kossiakoff, Sweet, Seymour and Biemer2011; Ulrich and Eppinger Reference Ulrich and Eppinger2012). It consists of multiple stages, each containing a variety of unique tasks that advance the design toward a completed system. These tasks require specialized skills and knowledge gained through years of study or work – often exceeding the experience of a single designer. Lastly, the design process is rarely linear: a design might iterate through a number of these stages before progressing forward. Acknowledging this complexity, Dym et al (Reference Dym, Little and Orwin2013) summarized this process into five stages which are apt for our literature analysis. We review these five stages as follows:

1) Problem Definition: The design objectives, constraints, functions, and other information are identified during the problem definition stage to establish a list of customer, client, or end-user requirements. Designers rely on empathy to understand the customer's requirements, existing product reviews, and responses, which help the designers translate them to design parameters and requirements (Kouprie and Visser Reference Kouprie and Visser2009). In this way, a detailed and precise list of requirements, statements, objectives, constraints, and functions obtained in this stage are input to the subsequent conceptual design stage.

2) Conceptual Design: In this stage, the requirements obtained from the previous stage are translated into engineering design specifications used to benchmark potential designs. Designers harness their creativity and intuition gained from their experience in the conceptual design stage to assist ideation process to generate novel design alternatives (Parmee and Bonham Reference Parmee and Bonham2000; Badke-Schaub and Eris Reference Badke-Schaub, Eris, Chakrabarti and Blessing2014; Sarkar and Chakrabarti Reference Sarkar and Chakrabarti2014). Through this ideation process, multiple design alternatives are generated according to the engineering design specifications that suitably satisfy customer's requirements, objectives, constraints, and desired functions. These multiple design concepts are input to the next design stage for modeling, evaluation, and analysis.

3) Preliminary Design: In this stage, the alternate design concepts are modeled by estimating the design requirements’ size and major attributes. Designers utilize computer-aided design (CAD) software for modeling the design concepts for effective visualization. Through such CAD-enabled features and visualizations, designers are able to harness their creativity to generate design models (Robertson et al Reference Robertson, Walther and Radcliffe2007; Chang et al Reference Chang, Chien, Lin, Chen and Hsieh2016). These models are tested and evaluated based on the performance and function requirements of the customer. This process mainly leverages computational tools such as CAD and simulation software for quick and effective analysis of the design concepts. After the analysis, designers use their decision-making skills to select the proper designs suitable to the requirements.

4) Detailed Design: In this stage, from the evaluations in the previous stage, the selected design is articulated in a detailed manner. To optimize the design, the designers use the procedures expressed in specific rules, formulas, and algorithms found in design codes, handbooks, databases, and catalogues. Using their decision-making skills and methods (Arroyo et al Reference Arroyo, Tommelein and Ballard2015), the designers finalize an apt design with relevant details to be communicated in the next stage.

5) Design Communication: In this final stage of the engineering design process, the final design with its details is documented and communicated in the form of reports, drawings, manufacturing specifications, and prototypes. Designers leverage their creative thinking to design prototypes and rely on empathy to effectively communicate the prototypes and final designs to customers and stakeholders (Fonseca et al Reference Fonseca, Jorge, Gomes, Gonçalves and Vala2009; Lim et al Reference Lim, Kim, Jo and Woo2012; Wang and Liou Reference Wang and Liou2018; Lee and Park Reference Lee and Park2021). The entire design process is also documented since it may prove beneficial for future reference. The design communication process can also help obtain feedback from customers and stakeholders to modify the design further and provide their final approval.

Artificial intelligence algorithms and the design process

While the goal of engineering design work remains constant over time, the nature of engineering work is transforming, driven partly by the increased availability of data and various AI algorithms. Machine learning, deep learning, and NLP are some of the most widely used AI-based methods for processing and interpreting myriad data types, including applications ranging from product recommendation (Sharma et al Reference Sharma, Sharma, Garg and Sharma2021), machine vision (Golnabi and Asadpour Reference Golnabi and Asadpour2007), and language translation (Hirschberg and Manning Reference Hirschberg and Manning2015), respectively. Classical machine learning is the most commonly used tool for large-scale data processing and learning features and patterns in data through statistical analysis (Jordan and Mitchell Reference Jordan and Mitchell2015). Classical machine learning algorithms such as decision trees, naïve-Bayes, support vector machines, K-nearest neighbors, and regression methods have been useful for effectively classifying, predicting, and clustering data (Russell and Norvig Reference Russell and Norvig2010). Deep learning, a subset of machine learning algorithms, leverages artificial neural networks to process, interpret and even generate data expressed in images, 3D models, and videos (Deng and Yu Reference Deng and Yu2013; Lecun et al Reference Lecun, Bengio and Hinton2015). Compared to the classic machine learning algorithms, deep learning algorithms require fewer human interventions and can automatically learn and extract features from large-scale data, providing results with high accuracy and hence suitability for complex data processing such as machine vision, audio processing, and generative models. NLP involves text-based data, bridging the gap between “computer” language and “human” language through knowledge representation to access, store, and analyze information expressed in a natural language (Chowdhury Reference Chowdhury2003; Hirschberg and Manning Reference Hirschberg and Manning2015). NLP has been used with machine learning or deep learning algorithms for applications such as chatbots, sentiment analysis, autocorrect, and machine translation (Hirschberg and Manning Reference Hirschberg and Manning2015). Although these three methods are widely used, other AI-based methods, such as agent-based modeling, network/graph theory, probabilistic methods, and optimization algorithms, are also being utilized for tasks involving data processing, automation, and optimization. Agent-based modeling involves the development of a computational agent or agents along with an environment where the agent or multiple agents interact with the environment to achieve certain outcomes (Crooks and Heppenstall Reference Crooks, Heppenstall, Heppenstall, Crooks, See and Batty2012). Network/graph theory involves the study of interactions or relations between discrete objects represented in the form of graphs (Borgatti and Halgin Reference Borgatti and Halgin2011; West Reference West2001). Probabilistic methods, which include Hidden Markov models (Eddy Reference Eddy2004), Bayesian frameworks (MacKay Reference MacKay1992), and Gaussian models (Schulz et al Reference Schulz, Speekenbrink and Krause2018), are used to estimate the likelihood of events/states based using probability theory and statistical modeling of available data. Optimization algorithms, such as genetic algorithm, Bayesian optimization, and multiscale topology optimization, are used to achieve the best solution iteratively within given constraints (Arora Reference Arora2015).

Since the advent of Industry 4.0, myriad industries have begun incorporating AI tools to expedite data processing and decision-making for complex tasks (Li et al Reference Li, Hou, Yu, Lu and Yang2017; Lee et al Reference Lee, Davari, Singh and Pandhare2018). With the shift to digital tools, sensors, and big data accessible through cyber-physical systems, vast amounts of design knowledge, previous product designs, customer reviews, and manufacturing capabilities are available to assist design engineers in accelerating the product design process (Marion and Fixson Reference Marion and Fixson2020). The availability of rich and diverse design data in open repositories has led to the emergence of literature reflecting novel AI applications in each stage of the engineering design process (Johri Reference Johri2020). As such, a literature study highlighting different AI methodologies mapped to the five engineering design stages could motivate researchers, engineers, and engineering aspirants to recognize the potential of utilizing AI-based methods. Moreover, such motivation could further inspire the development of new methodologies to synthesize or analyze designs on the different stages of the engineering design process.

Methodology for this literature review

We conducted a literature review of 108 research works that used AI-based methods and tools in the engineering design process. This literature review was done in a focused manner (Huelin et al Reference Huelin, Iheanacho, Payne and Sandman2015) to identify and understand the trend of AI-based methods in different stages of engineering design. This section describes how we obtained and assessed the literature pertaining to AI-based methods across different stages of the engineering design process. The overview of the literature review methodology is depicted in Figure 1 and described in the following subsections.

Figure 1. Framework used for literature search and review.

Obtaining search words for the literature review

The engineering design stages described by Dym et al summarized the engineering design process (Dym et al Reference Dym, Little and Orwin2013) into five stages, namely: (1) Problem Definition, (2) Conceptual Design, (3) Preliminary Design, (4) Detailed Design, and (5) Design Communication. Based on these definitions and the authors’ expertise in engineering design, a group of search words was compiled that represented the aspects of the engineering design process and would assist in the literature search. Next, five AI-based search words were selected that broadly represent the field of AI. The two sets of search words that represented engineering design and AI are listed in Table 1.

Table 1. Lists of search words used for the literature review

Searching the literature

Using combinations of the engineering design search words with AI search words in Table 1, the literature was searched through Google Scholar and the University of Toronto Libraries with consolidated access to databases such as Scopus, IEEE Xplore, Science Direct, and Web of Science. Only peer-reviewed research papers from conference proceedings or journals were considered for this literature review. The research papers obtained through this search underwent a manual assessment, which involved scrutinizing the abstracts and methods section of the research papers, to select those that accurately represented applications of AI-based methods in engineering design. Below are the exclusion criteria for manual scrutinization:

1) Papers with the absence of a concrete AI-based method for processing design tasks;

2) Papers from non-peer-reviewed publications;

3) Papers that review AI-based methods in fields other than engineering design;

4) Papers that used AI-based methods in the engineering design context for supplementary design aspects, such as evaluating the designer's experience or communication, rather than processing design tasks.

The 108 papers considered for this literature study comprised research works published in peer-reviewed journals and conference proceedings such as the American Society of Mechanical Engineers (ASME), Journal of Mechanical Design, Artificial Intelligence in Design and Manufacturing (AI EDAM), ASME International Design Engineering Technical Conference (IDETC) proceedings, and others, and were observed to be dated from 1998 to 2022. The list of these 108 papers is provided in Appendix 1. These 108 papers can be considered a representative sample of AI-based design research, as they cover a wide range of AI applications in design tasks across the engineering design process and provide an in-depth understanding of how and why these AI-based methods are applied in these stages.

Mapping the literature to the engineering design stages

The 108 papers were thoroughly reviewed and mapped to the engineering design stages based on their respective methodologies and research objectives. The purpose of mapping the research works to the engineering design stages was to assess the major areas of the engineering design process where AI methods are focused and possible research gaps to be explored. We analyzed each paper to assess the stage, or stages, of the engineering process in which the particular AI-based method was used. First, we categorized the engineering design task that the AI-based method targeted. Then, we matched this engineering design task to the definitions of the engineering design stages (highlighted in the section “The engineering design process”) and categorized that paper accordingly.

Summarizing the AI-based research works in engineering design stages

After mapping the 108 papers to the respective engineering design stages, we extracted and summarized the following information for each paper:

• The AI-based method used in the paper.

• The purpose of applying the AI-based method in the paper.

Reviewing the papers, we observed seven AI-based methods used to process design tasks. We list these seven AI-based methods as follows:

1) Agent-based modeling

2) Deep learning

3) Machine learning

4) Network/graph theory

5) NLP

6) Optimization algorithms

7) Probabilistic methods

In addition, we also observed the purpose of applying AI-based methods in each paper and, with that information, summarized how these methods support designers in each design stage. By summarizing this information, we highlight and discuss the findings corresponding to RQ-1, RQ-2, and RQ-3 in the following section.

Findings and discussion

The growth of digitalization and AI-based methods has naturally motivated designers to apply such methods toward improving the design tasks throughout the process. However, the engineering design process is complex and includes several unique tasks to be meticulously planned and processed across different stages. Hence, it is important to explore the different AI-based methods through stage-wise categorization of the engineering design process and understand how these methods support designers in each stage. Such AI-based methods mapped to respective design stages will potentially guide us to understand, select, and then effectively implement appropriate AI-based methods for appropriate tasks in specific stages in the design process. In addition, understanding the prevalence of AI-based methods though the design stage-wise categorization can provide high-value opportunities for design researchers to focus their efforts on the under-served stages and assess if AI-based methods can be suitably implemented to improve the design tasks in those stages.

Through a stage-by-stage view of the engineering design process, our study describes how AI tools are applied for tasks involving specific stages of the overall design process. We observe a distribution of AI-based methods across the design stages, which we conjecture to be attributed to the nature of design tasks involved in these stages and the availability of design data repositories that make it ideal for applying data-driven AI methods. As a further contribution, we present which specific AI methods are most often implemented in each design stage and the reason for their applications.

In this section, we present and discuss our findings corresponding to the three research objectives stated in the section “Introduction”. First, we summarize the AI-based methods used in each of the five stages and highlight some key works to address RQ-1. Next, we address RQ-2 by discussing the observed prevalence of certain AI-based methods in different design stages. Finally, we highlight how the applications of these AI-based methods support designers in each stage, answering RQ-3.

Mapping AI-based methods to the engineering design stages

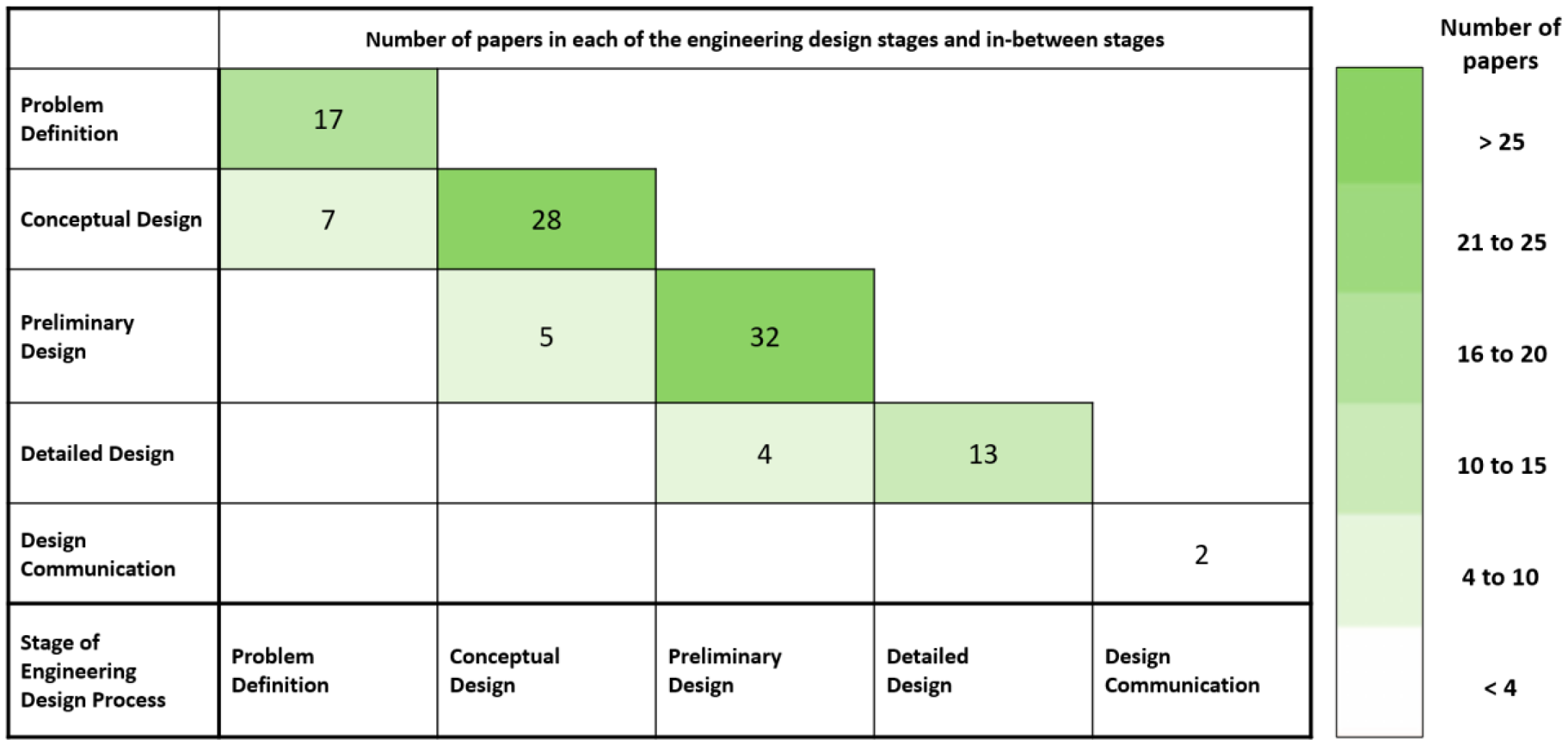

We address RQ-1 by highlighting the results of the literature review mapped to the five engineering design stages, as depicted in Figure 2. Of the 108 papers considered in this literature review, 97 papers were observed as directly related to only one of the five engineering design stages and 16 papers mapped to three transitions between engineering design stages. We observe that most of the papers reviewed in this literature study are concentrated in the middle stages, that is, preliminary design (32) and conceptual design stages (28), followed by problem definition (17), detailed design (13), and lastly, design communication stage (2). In comparison, 16 papers were mapped to three transition engineering design stages, that is, problem definition–conceptual design (7), conceptual design–preliminary design (5), and preliminary design–detailed design (4).

Figure 2. Number of papers in literature review mapped to the five engineering design stages.

After mapping the 108 papers to their respective engineering design stages, we categorized them into seven AI-based methods, as shown in Table 2. Furthermore, we summarized the purpose for which the AI-based methods were applied in each paper and supported their respective engineering design stage/stages. We also provide a stage-wise distribution of the papers according to the AI-based method employed within the respective papers in Table 3.

Table 2. Summary of AI methods and their purpose corresponding to the engineering design stages (Refer to Appendix 1 for mapping of codes to papers)

Table 3. Stage-wise distribution of the AI papers according to the AI-based methods applied in them

From Table 3, we can observe that deep learning is the most commonly used AI-based method across the design stages, followed by machine learning and NLP. Next, we highlight our findings on the AI-based methods commonly used in each engineering design stage, thereby addressing RQ-1. In addition, we give examples of AI-based methods in each stage and summarize their applications in each of the five engineering design stages.

AI in problem definition

As discussed in the section “Obtaining search words for the literature review”, during problem definition, the customer requirements are identified and clarified into a detailed and interpretable list of design objectives, constraints, functions, and other information for producing design concepts. This stage mostly involves data in a textual or natural language format. The research works mapped to this stage of the engineering design process often used NLP tools to translate the requirements into the required data for the conceptual design stage (15 out of 17 papers). Second, we also observed that four machine learning methods had been used in customer reviews, ratings, and design requirements analyses (Suryadi and Kim Reference Suryadi and Kim2019; Hein et al Reference Hein, Kames, Chen and Morkos2021; Lin and Kim Reference Lin and Kim2021; Saidani et al Reference Saidani, Kim and Yannou2021). Further, two deep learning methods were used along with NLP for design-requirement-extraction through semantic analysis (Wu et al Reference Wu, Hong, Feng, Li, Lou and Tan2022) and automatic extraction of functional requirements (Akay et al Reference Akay, Yang and Kim2021); two network theory methods for requirements-identification (Sen and Summers Reference Sen and Summers2013) and customer segmentation (Park and Kim Reference Park and Kim2021); and one probabilistic method that used Latent Dirichlet allocation (LDA) to identify and generate latent topic for managing design requirements (Chen et al Reference Chen, Mullis and Morkos2021).

Linking the problem definition stage to the conceptual design stage, Kop and Mayr (Reference Kop and Mayr1998) have introduced an intermediate stage called conceptual predesign to provide an effective transition between user requirements and conceptual design. In this intermediate stage, Kop and Mayr (Reference Kop and Mayr1998) used NLP techniques to automate the process of generating the predesign scheme from the users’ requirements expressed in natural language, thereby providing an effective interface between users and designers.

AI in conceptual design

The conceptual design stage focuses on analyzing, ideating, and generating design concepts based on the design information from the problem definition stage. From Tables 2 and 3, we observe that many papers (28 out of 108 papers) in our sample focus on this stage of the engineering design process and each of the seven types of AI-based methods observed in this study is observed to be applied in this stage. In the conceptual design stage, researchers often used NLP (8 out of 28 papers) and deep learning (11 out of 28 papers) to translate design requirements to specifications, ideate designs and generate alternative design concepts for further analysis. In addition to these methods, we observed: three agent-based modeling methods applied to facilitate ideation (Maier et al Reference Maier, Zurita, Starkey, Spillane, Menold and McComb2020), to transfer design strategies from human to computer (Raina, Cagan et al Reference Raina, Cagan and McComb2019), and to generate concepts from standard grammatic representations and abstract designer heuristics (Puentes et al Reference Puentes, McComb and Cagan2018); three machine learning methods for recommending design features (Yao et al Reference Yao, Moon and Bi2017), evaluating design features (Vasantha et al Reference Vasantha, Purves, Quigley, Corney, Sherlock and Randika2022), and clustering designs with common structures (Vasantha et al Reference Vasantha, Purves, Quigley, Corney, Sherlock and Randika2021); two probabilistic methods applied jointly with agent-based modeling for transfer learning (Raina, Cagan et al Reference Raina, Cagan and McComb2019) and Bayesian networks and N-grams for feature evaluation (Vasantha et al Reference Vasantha, Purves, Quigley, Corney, Sherlock and Randika2022); two network/graph theory methods for analyzing design functions (Song et al Reference Song, Luo and Wood2018) and for providing design stimuli for effective design ideation (Luo et al Reference Luo, Sarica and Wood2021); one topology optimization algorithm for aiding concept generation (Fujita et al Reference Fujita, Minowa, Nomaguchi, Yamasaki and Yaji2021); and two new automation frameworks for reusing common features in 3D CAD models (Vasantha et al Reference Vasantha, Purves, Quigley, Corney, Sherlock and Randika2021) and automating concept generation from high-level functional description of the product (Kurtoglu et al Reference Kurtoglu, Swantner and Campbell2010). We also observed certain works that leverage AI-based methods for the collective generation of design alternatives, generally done in the conceptual design stage and subsequent modeling or evaluation processed in the preliminary design stage. For example, Lee et al (Reference Lee, Park, Jo, Kim, Lee and Lee2022) used a deep generative framework in the conceptual design to generate 2D tire tread patterns per required tire performance. In another example, Jeon et al (Reference Jeon, Lee, Hahm and Suh2016) effectively used NLP to extract concepts from design concepts, followed by retrieving CAD model corresponding to the design concepts.

AI in preliminary design

Most AI-based works in this literature review (32 out of 108 papers) are focused on the preliminary design stage for the engineering design process, as indicated in Figure 2. As previously discussed, this stage includes design generation and evaluation. We observed that most of the research works mapped to this stage utilized machine learning (11 out of 32 papers) and deep learning (19 out of 32 papers) algorithms as their AI-based methodologies. In this stage, most machine learning algorithms have been used for design evaluation, whereas most deep learning algorithms have been used for design generation. We further elaborate on these applications and the potential reason why researchers have focused their AI on this design stage in the section “Conclusion”. In addition to such works, we observed that: two papers have applied NLP for processing texts to model generation (Friedrich et al Reference Friedrich, Mendling and Puhlmann2011) and topic extraction for subsequent design performance prediction (Ball and Lewis Reference Ball and Lewis2020); two papers have used probabilistic modeling for generating aerodynamic designs (Ghosh et al Reference Ghosh, Anantha Padmanabha, Peng, Andreoli, Atkinson, Pandita, Vandeputte, Zabaras and Wang2021) and evaluating the environmental impact of designs (Ferrero et al Reference Ferrero, Hoyle and DuPont2021); one paper used network theory-based surrogate modeling for evaluating trusses (Whalen and Mueller Reference Whalen and Mueller2022); and one paper used the Jaya algorithm as the optimization method for generating a set optimal number of design solutions (Khan and Awan Reference Khan and Awan2018).

In the Preliminary Design–Detailed Design transition stage, we observe that AI-based methods (Oh et al Reference Oh, Jung, Kim, Lee and Kang2019; Xiong et al Reference Xiong, Duong, Wang, Park, Ge, Raghavan and Rosen2019; Zhang et al Reference Zhang, Yang, Jiang, Nigam, Yamakawa, Furuhata, Shimada and Kara2019; Kallioras and Lagaros Reference Kallioras and Lagaros2020) are used for design synthesis (Preliminary Design) followed by design optimization (Detailed Design), as indicated in Table 2.

AI in detailed design

The primary purpose of the detailed design stage is to conduct design optimizations for obtaining a final design solution suitable to user requirements. Our literature review revealed that researchers mainly used machine learning and deep learning algorithms for design optimization in this phase. In addition to these, we also observed: four optimization methods, which used a multi-objective genetic algorithm for optimal material selection (Zhou et al Reference Zhou, Yin and Hu2009) and simulation-based optimization (Owoyele et al Reference Owoyele, Pal and Torreira2021), Gaussian process regression for topology optimization (Najmon et al Reference Najmon, Valladares and Tovar2021), and Bayesian optimization for improving geometric parameters (Coulter et al Reference Coulter, Wang and Huang2022); one probabilistic method involving multiscale Gaussian process for multi-physics simulation-based optimization (Sarkar et al Reference Sarkar, Mondal, Joly, Lynch, Bopardikar, Acharya and Perdikaris2019); and one novel framework for modeling detailed design knowledge using a structural-behavior-function (SBF) model and a genetic programming approach (Chen et al Reference Chen, Huang, Xie and Zhang2013).

AI in design communication

The design communication stages involve the documentation of the design in the form of reports and manufacturing specifications, along with the creation of prototypes to effectively communicate the design with stakeholders, customers, and production teams. This limited literature includes research works that use machine learning for aesthetic feedback (Tsai et al Reference Tsai, Hung and Hung2007) and deep learning-based holistic styling analysis for generating different appearances/styles for a design (Ranscombe et al Reference Ranscombe, Kinsella and Blijlevens2017).

The prevalence of AI algorithms across engineering design stages

We address RQ-2 by assessing the prevalence of AI methodologies in different stages of the engineering design process. Our main finding is that work on AI-based methods is not uniformly distributed across stages of the engineering design process. As displayed in Figure 2, we observe that most AI-based papers focus on the conceptual and preliminary design stages. In contrast, we observe fewer AI-based research papers in the design communication and transition between stages. We offer four reasons for this, based on the strengths of AI tools and propensities of design-AI researchers: (1) a natural inclination for targeting computational support toward the effort-intensive and iterative design tasks in the conceptual and preliminary design stages, (2) access to easily available open repositories containing design data on the conceptual and preliminary design stages, (3) a perceived lack of AI-compatible computationally intensive tasks in design communication stage, and (4) a tendency of design researchers to focus on processing designs tasks in one particular design stage effectively rather than across multiple stages. We elaborate on these potential reasons and present insights behind the observed distribution of AI-based research works across the five design stages.

We observed that most AI-based methods focus on conceptual and preliminary design stages. This echoes Luo's (Reference Luo2022) taxonomy of data-driven approaches in the design space of the data-driven innovation process, as evidenced by the prevalence of generative design-based deep learning and supervised machine learning methods for design generation and evaluation in these stages. One reason for this finding is the attractive promise of data-driven AI algorithms as assistants for designers in quick and effective, effort-intensive, iterative design tasks such as ideating, generating, and evaluating design concepts and models. Traditionally, these stages rely on the designer's knowledge, experience, creativity, and decision-making skills to iteratively process, generate, and evaluate multiple design concepts to achieve a creative and innovative solution. Despite recent advances in AI, computational systems are far from accurately replicating a designer's creativity and heuristics. So, it was surprising to observe the application of most AI-based methods in these stages. However, on closer inspection of these AI-based research works, we observed that AI algorithms mainly support designers by automating or analyzing certain design tasks within these stages. Such AI-enabled automation or analysis of design tasks provides quick and effective computation support to designers, who can then focus their creative and decision-making skills toward generating novel design concepts and models. In addition, AI algorithms backed by computationally powerful processors can provide rapid processing and analysis of design data for quick iterations, thereby contributing to improved design process efficiency. Thus, we observe most AI-based research works that effectively assist designers in saving time and effort toward the tasks in the conceptual and preliminary design stages.

Another possible reason for most AI-based methods being applied in the conceptual and preliminary design stages can be the availability of open repositories containing design data for analysis and design generation. As observed from Table 2, the majority of the AI-based methods used in these stages are NLP, machine learning, and deep learning algorithms. The development and application of NLP methods are highly dependent on the availability of textual data. On the other hand, machine learning and deep learning algorithms applied in these stages have used supervised learning models such as neural networks, support vector machines, and decision trees, which require large-scale data for effective training and testing of the models. Furthermore, unsupervised learning methods such as clustering require large-scale data use to establish relevant patterns and relations between different design variables. As such, the availability of open repositories for developing AI-based methods is crucial to analyze textual data, training supervised learning models for effective prediction and classification, and establishing patterns using unsupervised learning methods. Such availability of design data in open repositories could be why most AI-based research works, such as NLP, deep learning, and machine learning, are focused on the conceptual design and the preliminary stages (Dym et al Reference Dym, Little and Orwin2013).

Further, the results indicate fewer AI-based contributions in the design communication stage compared to other stages. In fact, it can be observed that no papers implement an AI-based methodology to streamline design communication with its preceding stages effectively. Once the final design is selected in the detailed design stage, designers document the entire process and create prototypes to communicate the final design to the customers and stakeholders. Most design tasks in the previous stages, such as requirements analysis, design generation, evaluation, and optimization, are highly iterative and data-intensive. In contrast, researchers may have perceived the design communication stage involving design documentation and communication as less computationally compatible than the tasks involved in the previous stages. Hence, researchers may have opted to focus the development of AI algorithms on the computationally intensive stages (that is, from problem definition to detailed design) for rapid processing and evaluation of designs. In addition, all the data used as inputs or obtained as outputs in the design stages, such as design requirements, design concepts, 2D sketches, or 3D models, are readily available in digital formats such as text files, CAD files, images, and video recordings. This data, obtained throughout the design process, can be easily compiled, requiring less computation effort for final documentation. Thus, the lack of computationally intensive tasks involved in the Detailed Design–Design Communication transition stage and the design communication stage could be a reason for the lack of AI methods implemented in these stages.

Lastly, the application of AI algorithms to design is a relatively new endeavor. As such, automating tasks within a stage might be a more obvious target than those between stages. From Table 2, we also observe that certain AI-based research works focus on three transition stages: problem definition–conceptual design, conceptual design–preliminary design, and preliminary design–detailed design. Such AI-based research works are observed to support designers in processing and completing the design tasks across two engineering design stages together. Compared to the papers mapped to a single design stage, we observe fewer papers mapped to the transition between stages. The overall design process is complex, iterative, and sequential, such that the inputs of certain design tasks can be highly dependent on the output of its preceding stage; for example, design concepts and attributes generated in the conceptual design stage are used to develop and evaluate 3D CAD models in the preliminary design stage. Thus, designers must have focused their efforts on effectively automating such complex tasks and thereby used AI algorithms to focus on one stage rather than the transitions.

The insights gathered from this literature regarding the prevalence of AI algorithms applied across the different stages of the engineering design process highlight high-value opportunities for researchers to develop and implement AI methods toward the under-served design stages. As indicated before, design data in various formats, processed throughout the design process, is easily accessible for building an automated documentation method. Such a method could highlight potential opportunities for the applications of text-based AI methods leveraging NLP and deep learning techniques for effectively recording, documenting, and captioning the designs and prototypes throughout the design process. Furthermore, the lack of AI focus in the transition stages could indicate a potential gap for researchers to explore and apply more AI solutions that provide effective design processing across multiple design stages with the potential goal of improving design process efficiency and effectiveness.

AI's support to human designers

Here, we address RQ-3 by describing how AI methods support designers in each stage of the engineering design process. Our analysis showed that AI algorithms support designers’ abilities across the design process: understanding the design problem and requirements, generating design concepts and models, selecting the best option, and assisting designers in prototyping their selection. In each case, designers relied on AI's ability to efficiently process large amounts of data. We summarize the designer and AI contributions to the engineering design stages in Table 4 and expand on them below.

Table 4. Contribution of human designer and AI in each stage of the engineering design process

a This column represents the human designer's contribution to the design process (as discussed in the section “Background”).

b This column represents the AI support to the design process as observed from the 108 papers in this literature study.

First, AI algorithms can process large amounts of data containing user reviews and requirements to extract useful design information to help designers understand the problem. In the problem definition stage, as customer reviews or requirements data are often available in a textual or natural language format, most research works used NLP techniques to process or analyze them. NLP techniques (Chowdhury Reference Chowdhury2003; Hirschberg and Manning Reference Hirschberg and Manning2015) have proven to be effective in encoding and processing large-scale textual data to perform operations such as text mining (Tucker and Kim Reference Tucker and Kim2011; Zhang et al Reference Zhang, Fan, Zhang, Wang and Fan2021), semantic analysis (Wu et al Reference Wu, Hong, Feng, Li, Lou and Tan2022), sentiment analysis (Suryadi and Kim Reference Suryadi and Kim2019), topic extraction (Ayoub et al Reference Ayoub, Zhou, Xu and Yang2019), and text summarization (Hou et al Reference Hou, Yannou, Leroy and Poirson2019). These analyses can be beneficial for understanding the key customer and design requirements and can, therefore, assist human designers translating such requirements to apt design parameters such as form, function, and aesthetics.

Second, AI algorithms can effectively analyze large-scale data to assist designers with design ideation and concept generation. In the conceptual design stage, designers utilize their knowledge and data to generate design concepts according to the requirements and constraints. As described earlier, this process is highly iterative in which the designers use their creativity, experience, and intuition to develop novel and creative design concepts. From our literature review results, researchers employed deep learning and NLP methods in this phase. Deep learning techniques such as neural networks and autoencoders have been effective in generating and analyzing large-scale data (Deng and Yu Reference Deng and Yu2013; Lecun et al Reference Lecun, Bengio and Hinton2015). Hence, deep learning methods are used in the conceptual design stage for tasks such as predicting function from design forms (Dering and Tucker Reference Dering and Tucker2017), testing design repository attributes (Williams et al Reference Williams, Meisel, Simpson and McComb2019), design synthesis for exploration (Chaudhari et al Reference Chaudhari, Kumar and Selva2021), and generating design concepts (Lopez et al Reference Lopez, Miller and Tucker2018; Fujita et al Reference Fujita, Minowa, Nomaguchi, Yamasaki and Yaji2021; Nurizada and Purwar Reference Nurizada and Purwar2021). Similar to the previous stage, design data is often available in textual format, which makes it apt for researchers to apply NLP methods for supporting the design ideation process toward concept generation (Chen et al Reference Chen, Wang, Dong, Shi, Han, Guo, Childs, Xiao and Wu2019; He et al Reference He, Camburn, Liu, Luo, Yang and Wood2019; Liu et al Reference Liu, Wang, Li and Liu2020; Sarica et al Reference Sarica, Song, Luo and Wood2020). In this literature, researchers employed NLP-based methodologies for analyzing text for Kansei Engineering and design automation (Chiu and Lin Reference Chiu and Lin2018), design function processing (Yamamoto et al Reference Yamamoto, Taura, Ohashi and Yamamoto2009), and semantic processing for retrieving CAD models from design documents (Jeon et al Reference Jeon, Lee, Hahm and Suh2016). Additionally, Lee et al (Reference Lee, McAdams and Morris2017) have used machine learning techniques and NLP to explore and categorize potential design solutions for bioinspired conceptual design. Further, Wang et al (Reference Wang, Mo and Tseng2018) used NLP with deep learning techniques to effectively map customer requirements and design parameters from online product review data. This way, deep learning and NLP methods can assist designers in effective design data analysis, ideation process, and even concept generation.

Third, AI algorithms can effectively assist designers with automating the design-model generation and subsequent evaluation as per the design's requirements. In the preliminary design stage, design models are generated from the concepts, which are then evaluated to select the best designs. We observe most research works in this literature use deep learning methods for design generation and machine learning methods for design evaluations. Deep learning algorithms such as generative adversarial networks (GANs) (Goodfellow et al Reference Goodfellow, Pouget-Abadie, Mirza, Xu, Warde-Farley, Ozair, Courville and Bengio2020) and autoencoders (Bank et al Reference Bank, Koenigstein and Giryes2020) can effectively be used to encode the data in which they are trained and generate new data, and hence are applied to generate designs in 2D (Quan et al Reference Quan, Li and Hu2018; Raina, McComb et al Reference Raina, McComb and Cagan2019), 3D (Khan and Awan Reference Khan and Awan2018; Shu et al Reference Shu, Cunningham, Stump, Miller, Yukish, Simpson and Tucker2020), and point cloud (Achlioptas et al Reference Achlioptas, Diamanti, Mitliagkas and Guibas2018; Krahe et al Reference Krahe, Bräunche, Jacob, Stricker and Lanza2020) formats. With such capabilities, GANs have also been leveraged for data-driven generative design models (Li et al Reference Li, Xie and Sha2021), synthesizing designs with interpart dependencies (Chen and Fuge Reference Chen and Fuge2019), generating 3D designs for physics-based simulations (Zhang et al Reference Zhang, Yang, Jiang, Nigam, Yamakawa, Furuhata, Shimada and Kara2019), and generate designs based on class, characteristics, and dimensions conditions (Krahe et al Reference Krahe, Bräunche, Jacob, Stricker and Lanza2020). Such effective utilization of GANs has also been applied to generating designs for topological optimization of designs conducted in the subsequent detailed stage (Oh et al Reference Oh, Jung, Kim, Lee and Kang2019; Kallioras and Lagaros Reference Kallioras and Lagaros2020). Since most of the data in the preliminary design stage are represented in the form of an image or 3D design model, researchers have leveraged deep learning algorithms to predict a design's performance based on an image (Khanolkar et al Reference Khanolkar, Abraham, McComb and Basu2020) and a 3D model (McComb Reference McComb2019), and predict energy for a given building design (Geyer and Singaravel Reference Geyer and Singaravel2018). Similarly, machine learning methods such as neural networks, decision trees, K-nearest neighbors, and support vector machines can perform quick and accurate evaluations through regression, classification, or clustering (Mitchell and Mitchell Reference Mitchell and Mitchell1997; Jordan and Mitchell Reference Jordan and Mitchell2015). In such manner, machine learning algorithms are used for design cost evaluation (Bodendorf and Franke Reference Bodendorf and Franke2021), design time prediction (Yan and Xu Reference Yan and Xu2007), predicting energy performance (Geyer and Singaravel Reference Geyer and Singaravel2018), and analyzing CAD geometries (Bickel et al Reference Bickel, Sauer, Schleich and Wartzack2020). As such, deep learning and machine learning algorithms provide quick and accurate automation to model, process and evaluate designs and could assist designers in decision-making to select proper designs.

Similarly, AI algorithms can help designers optimize the designs and assist in finalizing the solution. In the detailed design stage, designers use their knowledge and experience to optimize the designs from the previous stage. In this stage, machine learning algorithms have been used for applications such as multi-objective optimization for selecting suitable material for sustainable products (Zhou et al Reference Zhou, Yin and Hu2009), simulation-driven design optimization of internal combustion engines (Owoyele et al Reference Owoyele, Pal and Torreira2021), design optimization for maximizing the flexibility of design and minimizing the cost (Bhosekar and Ierapetritou Reference Bhosekar and Ierapetritou2020), and product portfolio design optimization for maximizing company profit without violating customer product performance expectations (Tucker and Kim Reference Tucker and Kim2009). Similarly, deep learning algorithms have been used for 3D functional design optimizations (Zhang et al Reference Zhang, Yang, Jiang, Nigam, Yamakawa, Furuhata, Shimada and Kara2019), design optimization using reinforcement learning (Yonekura and Hattori Reference Yonekura and Hattori2019), and conducting effective and accurate data-driven decision-making processes for complex product designs (Lai et al Reference Lai, Fu, Yu, Lan and Yang2021). Such AI methods can assist designers in processing and optimizing designs, ultimately developing the best design by utilizing the design knowledge stored in AI-compatible digital format.

Lastly, AI algorithms can be helpful in assisting designers by documenting and communicating their final designs effectively. Once the design is optimized, the designers document their design and create prototypes for effective presentation and communication with the stakeholders, users, and subsequent manufacturing departments in the design communication stage. In this stage, designers have used AI algorithms for aesthetics and styling for effective design documentation.

Conclusion

In summary, our focused literature review revealed that engineering design research has recognized the potential for AI-based methods to advance this important endeavor. Our literature review included 108 papers, which represent an apt sample of research works that leveraged AI-based methods applied toward design tasks across the five design stages. The AI-based methods, highlighted in the 108 papers, focused on different design stages and aimed to improve the engineering design process by automating or augmenting certain design tasks, such as mapping customer reviews to design requirements, generating design models and concepts, and analyzing designs. Our literature review provides a stage-by-stage distribution of the 108 AI-based design research papers by mapping the AI-based method in each paper to the appropriate engineering design stages based on their design-based application. We observed that within the 108 papers, deep learning is the most commonly used among the seven AI-based methods. Based on the nature of design tasks in different stages and the data processing capabilities of neural networks, deep learning could be seen as a popular AI tool across the engineering design field. In particular, we found that conceptual design and preliminary design stages, which leverage human creativity and collaboration, have been the focus of AI-based engineering design research. We also found that fewer AI-based engineering design works apply to the design communication and transition stages. In addition, we observed that researchers used all seven AI-based methods in their respective works in the conceptual design stage, potentially signaling the wide range of current AI capabilities and future novel AI-based methods that could be applied to assist the designers in this stage. In this literature study, we also observed that the AI-based methods supported designers in each stage by generating, analyzing, and optimizing design data, concepts, and models.

The stage-by-stage distribution of AI-based research works could illuminate opportunities for researchers to focus on developing new AI methods in the under-served stages to see if AI solutions could apply. Understanding which and how AI-based methods support designers in specific design tasks in each stage could inspire researchers to implement similar methods for processing certain design tasks in specific stages for their respective research. Thus, our literature review analysis reveals insights and opportunities to explore AI applications in other design process steps and continue leveraging the work toward human–AI collaboration in the engineering design stages. Such insights can help integrate the technical benefits of AI combined with the non-technical skills of humans to potentially improve the efficiency and effectiveness of the engineering design process.

This literature review was conducted via a focused search, where our main contribution was categorizing 108 research works into the five stages of the engineering design process. As a next step, a systematic literature review way reveals additional sources, which we expect to follow the same trends and categories presented here. Such a systematic literature study could also present emerging topics such as multi-modal learning and human–AI collaboration, which can provide a better understanding of the state-of-the-art in the engineering design field. As the scope of this review was limited to the application of AI methods in the design process, this future work could focus on in-depth analyses of AI-based methods, highlighting their capabilities, limitations, and level of human interaction (or complete human replacement). Future work could also investigate the literature that leverages AI to evaluate the designer's experience and interaction during the engineering design process (Behoora and Tucker Reference Behoora and Tucker2015; Ferguson et al Reference Ferguson, Cheng, Adolphe, Van de Zande, Wallace and Olechowski2022). Such literature focussing on the use of AI for enhancing design and designer experience could further solidify the growing importance of AI in engineering design and call for the inclusion or expansion of AI education in engineering design.

Funding

This work is co-funded by the Social Sciences and Humanities Research Council – Knowledge Synthesis Grant: Skills and Work in the Digital Economy

Pranav Milind Khanolkar is a PhD candidate in the Department of Mechanical & Industrial Engineering at the University of Toronto. He holds a Master's degree in Industrial Engineering from The Pennsylvania State University and Bachelor's degree in Mechanical Engineering from University of Mumbai. At Penn State, he worked as a Graduate Research Assistant in THRED Group, with his research focused towards application of deep learning for structural analyses. His research interests involve applications of AI algorithms for automating product design processes and understanding how industries decide and implement apt automation algorithms for their product design processes.

Ademir Vrolijk, PhD, is a Senior Policy Advisor for the Government of Canada's Privy Council Office (PCO). In this role, he is responsible for measuring, analyzing, and reporting on the immediate and long-term outcomes of the multi-million dollar innovation challenges run by PCO's Impact Canada team. Before joining this team, Dr. Vrolijk was a Postdoctoral Fellow at Ready Lab at the University of Toronto. He was also a Visiting Fellow at the Laboratory for Innovation Sciences at Harvard (LISH) at Harvard University – a centre of excellence for open innovation. Dr. Vrolijk holds a PhD in Systems Engineering from The George Washington University and a Bachelor of Aerospace Engineering from Carleton University.

Alison Olechowski, PhD, PEng, is an Assistant Professor in the Department of Mechanical & Industrial Engineering at the University of Toronto. She completed her PhD at the Massachusetts Institute of Technology (MIT) studying product development decision-making. Dr. Olechowski completed her BSc (Engineering) at Queen's University and her MS at MIT, both in Mechanical Engineering. Her current research focuses on engineering design; in particular, her group investigates how new technologies can best be used to improve the process and outputs of engineering design and new product development. Current areas of focus include computer-aided design and model-based systems engineering tools.

Appendix 1: The following table contains the list of research papers selected for literature review and their mapping to corresponding to the stages of the engineering design process

Problem Definition (PD), Conceptual Design (CD), Preliminary Design (PDes), Detailed Design (DD), Design Communication (DC)