Abstract

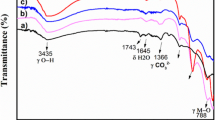

Cu–Ni/SiO2 catalysts were prepared by coprecipitation method and used in the dehydrogenation reaction of secondary butyl alcohol to methyl ethyl ketone (MEK). The crystal structure, reduction characteristics, element valence state and dispersibility of the catalysts were investigated using X-ray diffraction (XRD), hydrogen temperature-programmed reduction (H2-TPR), inductively coupled plasma optical emission spectrometry (ICP-OES), X-ray photoelectron spectroscopy (XPS), X-ray Auger electron spectroscopy (XAES) and high resolution transmission electron microscopy (HRTEM). The role of Ni component in the dehydrogenation reaction of secondary butyl alcohol was analyzed. The results showed that the conversion of secondary butyl alcohol increased to over 99% when using the Cu–Ni/SiO2 catalyst. The addition of nickel component to Cu/SiO2 inhibited the agglomeration of copper nanoparticles. The interaction between copper and nickel was strengthened due to the formation of the Cu–Ni compound. This resulted in change to the valence state and improved the dispersion of copper species on the catalyst surface. The Cu+/(Cu+ + Cu0) ratio increased with the addition of nickel component to Cu/SiO2, which may be responsible for the enhancement of the secondary butyl alcohol conversion. However, the addition of the nickel component increased the reduction temperature of the catalysts and deteriorated their reduction characteristics, which leads to insufficient reduction, resulting in a high content of Cu+ species remaining in the catalyst. Therefore, side reactions can occur, which are detrimental to the selectivity and yield of MEK. The selectivity to MEK can reach 98% with the Cu/SiO2 catalyst, whereas that for the Cu–Ni/SiO2 catalyst was 97%.

Similar content being viewed by others

REFERENCES

Halawy, S., Mohamed, M., and Abdelkader, A., Arab. J. Chem., 2018, vol. 11, p. 991. https://doi.org/10.1016/j.arabjc.2018.03.023

Segovia-Hernández, J., Sanchez-Ramirez, E., and Ramirez-Marquez, C., Improvements in Bio-Based Building Blocks Production Through Process Intensification and Sustainability Concepts, Elsevier, 2022. p. 181. https://doi.org/10.1016/B978-0-323-89870-6.00004-4

Sun, Y., Ni, L., and Maria, P., J. Loss. Prevent. Proc., 2020, vol. 66, p. 1. https://doi.org/10.1016/j.jlp.2020.104177

Qiao, Z., Chin. J. Chem. Eng., 2006, vol. 14, p. 676. https://doi.org/10.1016/s1004-9541(06)60134-1

Torres-Vinces, L., Contraras-Zarazua, G., and Huerta-Rosas, B., Chem. Eng. Technol., 2020, vol 43, p. 1433. https://doi.org/10.1002/ceat.201900664

Lambert, S., Cellier, C., and Ferauche, F., Catal. Commun., 2007, vol. 8, p. 2032. https://doi.org/10.1016/j.catcom.2007.04.004

Wang, B., Jin, M., and An, H., Catal. Lett., 2020, vol. 150, p. 56. https://doi.org/10.1007/s10562-019-02908-2

Hu, Y.-F., Cai, J., and Jiang, G.-S., Adv. Mater. Res., 2013, vol. 750, p. 1773. https://doi.org/10.4028/www.scientific.net/AMR.750-752.1773

Geravand, E., Shariatinia, Z., and Yaripour, F., Korean J. Chem. Eng., 2015, vol. 32, p. 2418. https://doi.org/10.1007/s11814-015-0087-x

Vedyagin, A., Kotolevich, Y., and Tsyrul’nikov P., Int. J. Nanotechnol., 2016, vol. 13, p. 185. https://doi.org/10.1504/IJNT.2016.074533

Shelepova, E., Ilina, L., and Vedyagin, A., React. Kinet. Mech. Catal., 2017, vol. 120, p. 449. https://doi.org/10.1007/s11144-016-1135-1

Ponomareva, E., Krasnikova, I., and Egorova, E., React. Kinet. Mech. Catal., 2017, vol. 122, p. 399. https://doi.org/10.1007/s11144-017-1220-0

Zhao, Y., Kong, L., and Xu, Y., Ind. Eng. Chem. Res., 2020, vol. 59, p. 12381. https://doi.org/10.1021/acs.iecr.0c01619

Ye, C.-L., Cui, L., and Zhang, J.-L., Fuel. Process. Technol., 2016, vol. 143, p. 219. https://doi.org/10.1016/j.fuproc.2015.12.003

Zhao, Y., Zhang, H., and Xu, Y., J. Energy. Chem., 2020, vol. 49, p. 248. https://doi.org/10.1016/j.jechem.2020.02.038

Ren, Z., Younis, M.-N., and Li, C., RSC Adv., 2020, vol. 10, p. 5590. https://doi.org/10.1039/c9ra08780j

Zhang, L., Jiang, M., and Zhang, Y., Russ. J. Phys. Chem., 2023, vol. 97, p. 603. https://doi.org/10.1134/s0036024423040209

Xia, Z.-J., and Han, F., Catal. Commun., 2017, vol. 90, p. 39. https://doi.org/10.1016/j.catcom.2016.10.036

Zhao, Y., Zhao, S., and Geng Y., Catal. Today, 2016, vol. 276, p. 28. https://doi.org/10.1016/j.cattod.2016.01.053

Zhang, J., Kong, L., and Chen, Y., Front. Chem. Sci. Eng., 2021, vol. 15, p. 666. https://doi.org/10.1007/s11705-020-1982-1

Zheng, Y., Wang, J., and Li, D., J. Energy. Inst., 2021, vol. 97, p. 58. https://doi.org/10.1016/j.joei.2021.04.008

Huang, S., Xu. H., and Li, H., Fuel. Process. Technol., 2021, vol. 218, p. 106858. https://doi.org/10.1016/j.fuproc.2021.106858

Miao, C., Zhou, G., and Chen, S., Renewably Energy, 2020, vol. 153, p. 1439. https://doi.org/10.1016/j.renene.2020.02.099

Li, S., Han, X., and An, H., Kinet. Catal., 2021, vol. 62, p. 632. https://doi.org/10.1134/S0023158421050025

Yin, A., Chao, W., and Guo, X., J. Catal., 2011, vol. 280, p. 77. https://doi.org/10.1016/j.jcat.2011.03.006

Cai, B., Zhou, X.C., and Miao, Y.-C., ACS Sustainable Chem. Eng., 2016, vol. 5, p. 1322. https://doi.org/10.1021/acssuschemeng.6b01677

Wu, Q., Eriksen, W.L., and Duchstein, L., Catal. Sci. Technol., 2014, vol. 4, p. 378. https://doi.org/10.1039/c3cy00546a

Rao, T., Suchada, S., and Choi, C., Energy Convers. Manage., 2022, vol. 265, p. 115736. https://doi.org/10.1016/j.enconman.2022.115736

Morales, M., Conesa, J., and Galvin, A., Catal. Today, 2023. https://doi.org/10.1016/j.cattod.2023.01.028

Funding

This work was supported by the Funds of Liaoning Provincial Department of Education (nos. LJKMZ20220764, LJ2019001), the Funds of Liaoning Province Applied Basic Research Program Project (no. 2023JH2/101300006), Liaoning BaiQianWan Talents Program (2020B085) and by Shenyang Science and Technology Bureau (no. RC190323).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflicts of interest.

Additional information

Abbreviations and notation: ACF, activated carbon fibrous; ASC, aspen wood char; CNF, carbon nanofibers; MEK, methyl ethyl ketone; XRD, X-ray diffraction; H2-TPR, hydrogen temperature-programmed reduction; ICP-OES, inductively coupled plasma optical emission spectrometry; XPS, X-ray photoelectron spectroscopy; XAES, X-ray Auger electron spectroscopy; HRTEM, high resolution transmission electron microscopy; X, conversion; Y, yield; S, selectivity.

Rights and permissions

About this article

Cite this article

Zhang, L., Xue, Y. & Zhang, Y. Cu–Ni/SiO2 Catalysts for Dehydrogenation Reaction of Secondary Butyl Alcohol. Kinet Catal 64, 872–881 (2023). https://doi.org/10.1134/S0023158423930031

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0023158423930031