Abstract

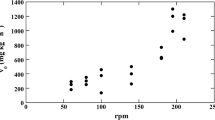

The new kinetically limited linear driving force (KLLDF) model was assessed against the traditional LDF model in the prediction of twelve different ternary and quaternary experimental breakthrough curves. These breakthrough curves comprised mixtures of CO2, N2 and CH4 in He adsorbed on carbon molecular sieve MSC 3 K 172 and were conducted at various pressures (30, 50 and 100 psia) and at ambient temperature. The LDF and KLLDF models were implemented in the dynamic adsorption process simulator (DAPS) with the loading dependent LDF mass transfer coefficients and the single gas equilibrium adsorption isotherms measured independently with gravimetric uptake experiments. To make the comparison between the LDF and the KLLDF models as fair as possible, they utilized the same set of thermodynamic and kinetic parameters in DAPS, with no adjustments to any of them. Both the LDF and KLLDF models provided reasonable predictions of the experimental breakthrough curves and in-bed temperature histories, with general trends of no CH4 uptake, gradual N2 uptake and fast CO2 uptake. However, the KLLDF model always provided better predictions, especially when CO2 was present. The results revealed that the traditional LDF model led to depressed adsorbed phase loadings of CO2, thereby underpredicting its breakthrough time in all cases. This depression stemmed from the equilibrium loading in the LDF driving force of the LDF model depending on the gas phase partial pressure of each component outside the pore structure. In contrast, the KLLDF model corrects this issue by making the equilibrium loading in its LDF driving force dependent on the actual loading of each component inside the pore structure. In conjunction with the mixed gas extended Langmuir model, the KLLDF model is perhaps the more appropriate model to use instead of the LDF model for any multicomponent adsorbate-adsorbent systems, whether diffusion limited or not, since it reduces to the LDF model for systems that do not exhibit significant diffusional limitations.

Similar content being viewed by others

Data availability

The data sets in this work are available in functional form only via the constants listed in Table 2 and the corresponding equations in the text.

Abbreviations

- \({b}_{k,i}\) :

-

Affinity parameter of component i on a site with energy level k, \({\mathrm{kPa}}^{-1}\)

- \({b}_{i}^{T}\) :

-

Toth affinity parameter of component i, \({\mathrm{kPa}}^{-1}\)

- \({b}_{{0}_{k,i}}\) :

-

Pre-exponential factor or adsorption entropy of component i on a site with energy level k, \({\mathrm{kPa}}^{-1}\)

- \({b}_{o,i}^{T}\) :

-

Toth pre-exponential factor or adsorption entropy of component i, \({\mathrm{kPa}}^{-1}\)

- \({B}_{k,i}\) :

-

Ek,i/R, \({\mathrm{K}}\)

- c v :

-

Valve coefficient

- \({C}_{{p}_{g,j}}\) :

-

Gas phase heat capacity of component \(j\), \(\mathrm{kJ }{\mathrm{mol}}^{-1} {\mathrm{K}}^{-1}\)

- \({C}_{{p}_{a,j}}\) :

-

Adsorbed phase heat capacity of component \(j\), \(\mathrm{kJ }{\mathrm{mol}}^{-1} {\mathrm{K}}^{-1}\)

- \({C}_{p,g}\) :

-

Gas-phase heat capacity, \(\mathrm{kJ }{\mathrm{mol}}^{-1} {\mathrm{K}}^{-1}\)

- \({C}_{{p}_{p}}\) :

-

Adsorbent heat capacity, \(\mathrm{kJ }{\mathrm{mol}}^{-1} {\mathrm{K}}^{-1}\)

- \({C}_{{p}_{w}}\) :

-

Wall heat capacity, \(\mathrm{kJ kg }{\mathrm{K}}^{-1}\)

- \({C}_{T}\) :

-

Total gas phase concentration,\({\mathrm{mol m}}^{-3}\)

- \({E}_{k,i}\) :

-

Adsorption energy of component i on a site with energy level k, \(\mathrm{kJ }{\mathrm{mol}}^{-1}\)

- F:

-

Molar gas flow rate through the valve, SLPM

- \({h}_{wi}\) :

-

Inside wall heat transfer coefficient, \(\mathrm{kW }{\mathrm{m}}^{-2} {\mathrm{K}}^{-1}\)

- \({h}_{wo}\) :

-

Outside wall heat transfer coefficient, \(\mathrm{kW }{\mathrm{m}}^{-2} {\mathrm{K}}^{-1}\)

- \({\Delta H}_{i}\) :

-

Isosteric heat of adsorption of component \(i\), \(\mathrm{kJ }{\mathrm{mol}}^{-1}\)

- \({k}_{o,i}\) :

-

LDF mass transfer fitting parameter of component \(i\), \({\mathrm{s}}^{-1}\)

- \({k}_{1,i}\) :

-

LDF mass transfer fitting parameter of component \(i\), \(\mathrm{kg }{\mathrm{mol}}^{-1}\)

- \({k}_{2,i}\) :

-

LDF mass transfer fitting parameter of component \(i\), \(\mathrm{kg }{\mathrm{mol}}^{-1}\)

- \({k}_{i}\) :

-

LDF mass transfer coefficient of component \(i\), \({\mathrm{s}}^{-1}\)

- k w :

-

Wall thermal conductivity, \(\mathrm{kW }{\mathrm{m}}^{-1} {\mathrm{K}}^{-1}\)

- l(i,j) :

-

Energy level of component j corresponding to the same site as the high energy site (site 1) of component i.

- m(i,j) :

-

Energy level of component j corresponding to the same site as the low energy site (site 2) of component i

- m a :

-

Mass of adsorbent, kg

- M g :

-

Average molecular weight of gas phase, kg mol−1

- \({n}_{o,i}\) :

-

Initial adsorbed phase loading of a pressure step, mol kg–1

- \({n}_{f,i}\) :

-

Final adsorbed phase loading of a pressure step, mol kg–1

- \({n}_{i,ave}\) :

-

Average adsorbed phase loading of \({n}_{o,i}\) and \({n}_{f,i}\), mol kg–1

- \({n}_{1,i}^{*}\) :

-

Equilibrium adsorbed phase loading of component i on site 1 in the gas mixture, mol kg–1

- \({n}_{2,i}^{*}\) :

-

Equilibrium adsorbed phase loading of component i on site 2 in the gas mixture, mol kg–1

- \({n}_{i}^{P}\) :

-

Single (pure) gas equilibrium adsorbed phase loading of component i, mol kg–1

- \({n}_{k,i}^{P}\) :

-

Single (pure) gas equilibrium adsorbed phase loading of component i on a site with energy level k, mol kg–1

- \({n}_{i}\) :

-

Adsorbed phase loading of component i inside the pore structure, mol kg–1

- \({n}_{i}^{T}\) :

-

Toth adsorbed phase loading of component \(i\), mol kg–1

- \({n}_{k,i}\) :

-

Adsorbed phase loading of component i on a site with energy level k, mol kg–1

- \({\mathrm{n}}_{k,i}^{*}\) :

-

Equilibrium adsorbed phase loading of component i on a site with energy level k, mol kg–1

- \({n}_{i}^{s,T}\) :

-

Toth adsorbed phase saturation capacity of component i, mol kg–1

- \({n}_{k,i}^{s}\) :

-

Adsorbed phase saturation capacity of component \(i\) on a site with energy level k, \(\mathrm{mol }{\mathrm{kg}}^{-1}\)

- \(N\) :

-

Number of components in the gas mixture

- \(P\) :

-

Absolute pressure, \(\mathrm{kPa}\)

- P F :

-

Feed pressure, kPa

- P I :

-

Initial pressure, kPa

- P + :

-

Pressure downstream of valve, \(\mathrm{kPa}\)

- \({P}_{-}\) :

-

Pressure upstream of valve, \(\mathrm{kPa}\)

- \({P}_{i}\) :

-

Partial pressure of component i, \(\mathrm{kPa}\)

- \({r}_{p}\) :

-

Radius of adsorbent pellet, \(\mathrm{m}\)

- \({r}_{bi}\) :

-

Inner radius of bed, \(\mathrm{m}\)

- \({r}_{bi}\) :

-

Outer radius of bed, \(\mathrm{m}\)

- R :

-

Universal gas constant, \(\mathrm{J }{\mathrm{mol}}^{-1} {\mathrm{K}}^{-1}\)

- S g :

-

Specific gravity of gas relative to air at 1 atm and 21.45 °C

- S i :

-

Representative of the rate of change of the adsorbed phase loading, \(\mathrm{kg }{{s}^{-1}\mathrm{ m}}^{-3}\)

- \({t}_{i}\) :

-

Toth model parameter for component \(i\)

- \({t}_{o}\) :

-

Initial time corresponding to initial equilibrium loading \({n}_{o,i}\), \(\mathrm{s}\)

- t :

-

Time coordinate, s

- \(T\) :

-

Temperature, K

- \({T}_{-}\) :

-

Temperature upstream of valve

- T I :

-

Initial temperature, K

- \({T}_{o}\) :

-

Ambient temperature, K

- \({T}_{w}\) :

-

Temperature of the wall, K

- \(v\) :

-

Interstitial velocity, \(\mathrm{m }{\mathrm{s}}^{-1}\)

- \({v}_{I}\) :

-

Initial interstitial velocity, \(\mathrm{m }{\mathrm{s}}^{-1}\)

- y i :

-

Mole fraction of component i

- \(z\) :

-

Number of experimental data points or spatial coordinate

- \(\alpha\) :

-

LDF kinetic fitting parameter, \(\mathrm{kg }{\mathrm{mol}}^{-1}\)

- δ :

-

Column wall thickness, m

- \({\varepsilon }_{p}\) :

-

Porosity of particle

- \({\varepsilon }_{b}\) :

-

Porosity of bed

- \({\mu }_{g}\) :

-

Viscosity of gas phase, \(\mathrm{N s }{\mathrm{m}}^{-2}\)

- \({\rho }_{p}\) :

-

Density of particle, \(\mathrm{kg }{\mathrm{m}}^{-3}\)

- \({\rho }_{w}\) :

-

Density of wall, \(\mathrm{kg }{\mathrm{m}}^{-3}\)

References

Sircar, S., Hufton, J.R.: Intraparticle adsorbate concentration profile for linear driving force model. AIChE J. 46, 659–660 (2000)

Sircar, S., Hufton, J.R.: Why does the linear driving force model for adsorption kinetics work? Adsorption 6, 137–147 (2000)

Yang, R.T.: Gas Separation by Adsorption Processes. Butterworths, Boston (1987)

Ruthven, D.M.: Principles of Adsorption and Adsorption Processes. John Wiley and Sons, New York (1984)

Adegunju, S.A., Ebner, A.D., Ritter, J.A.: Kinetically limited linear driving force model for diffusion-based adsorptive separations. Ind. Eng. Chem. Res. 61, 17615–17630 (2022)

Sircar, S.: Linear-driving-force model for non-isothermal gas adsorption kinetics. J. Chem. Soc. Faraday Trans. I(79), 785–796 (1983)

O’koye, I.P., Benham, M., Thomas, K.M.: Adsorption of gases and vapors on carbon molecular sieves. Langmuir 13, 4054–4059 (1997)

Reid, C.R., Thomas, K.M.: Adsorption of gases on a carbon molecular sieve used for air separation: linear adsorptives as probes for kinetic selectivity. Langmuir 15, 3206–3218 (1999)

Qinglin, H., Sundaram, S.M., Farooq, S.: Revisiting transport of gases in the micropores of carbon molecular sieves. Langmuir 19, 393–405 (2003)

De-Xin, Z., Zhi-Jing, X., Zhen, F.: Prediction of breakthrough curves of oxygen-nitrogen co-adsorption system on molecular sieves. Gas Sep. Purif. 2, 184–189 (1988)

Malek, A., Farooq, S.: Kinetics of hydrocarbon adsorption on activated carbon and silica gel. AIChE J. 43, 761–776 (1997)

Aguilera, P.G., Gutiérrez Ortiz, F.J.: Prediction of fixed-bed breakthrough curves for H2S adsorption from biogas: importance of axial dispersion for design. Chem. Eng. J. 289, 93–98 (2016)

Kapoor, A., Yang, R.T.: Kinetic separation of methane-carbon dioxide mixture by adsorption on molecular sieve carbon. Chem. Eng. Sci. 44, 1723–1733 (1989)

Farooq, S., Ruthven, D.M.: A comparison of linear driving force and pore diffusion models for a pressure swing adsorption bulk separation process. Chem. Eng. Sci. 45, 107–115 (1990)

Ruthven, D.M., Farooq, S.: Air separation by pressure swing adsorption. Gas Sep. Purif. 4, 141–148 (1990)

Ritter, J.A., Yang, R.T.: Pressure swing adsorption: experimental and theoretical study on air purification and vapor recovery. Ind. Eng. Chem. Res. 30, 1023–1032 (1991)

Fatehi, A.I., Loughlin, K.F., Hassan, M.M.: Separation of methane-nitrogen mixtures by pressure swing adsorption using a carbon molecular sieve. Gas Sep. Purif. 9, 199–204 (1995)

Liu, Y., Holland, C.E., Ritter, J.A.: Solvent vapor recovery by pressure swing adsorption—III: comparison of simulation with experiment for the butane–activated carbon system. Sep. Sci. Tech. 34, 1545–1576 (1999)

Yoshida, M., Ritter, J.A., Kodama, A., Goto, M., Hirose, T.: Simulation of an enriching reflux PSA process with parallel equalization for concentrating a trace component in air. Ind. Eng. Chem. Res. 45, 6243–6250 (2006)

Qinglin, H., Farooq, S., Karimi, I.A.: Prediction of binary gas diffusion in carbon molecular sieves at high pressure. AIChE J. 50, 351–367 (2004)

Adegunju S.A., Amalraj, P.B.C.A., Holland, C.E., Ebner A.D., Ritter, J.A.: Assessment of the new kinetically limited LDF model for diffusion limited separations by PSA. Ind. Eng. Chem. Res. (2023)

Mohammadi, N., Hossain, M.I., Ebner, A.D., Ritter, J.A.: New pressure swing adsorption cycle schedules for producing high-purity oxygen using carbon molecular sieve. Ind. Eng. Chem. Res. 55, 10758–10770 (2016)

Brown, P.N., Hindmarsh, A.C., Petzold, L.R.: Using krylov methods in the solution of large-scale differential-algebraic systems. SIAM J. Stat. Comp. 15, 1467–1488 (1994)

Ritter, J.A., Shubhra, J.B., Ebner, A.D.: On the use of the dual-process langmuir model for correlating unary equilibria and predicting mixed-gas adsorption equilibria. Langmuir 27, 4700–4712 (2011)

Bhadra, S.J., Ebner, A.D., Ritter, J.A.: On the use of the dual process Langmuir model for predicting unary and binary isosteric heats of adsorption. Langmuir 28, 6935–6941 (2012)

Funding

The authors gratefully acknowledge financial support provided over many years by both the NASA Marshall Space Flight Center and the Separations Research Program at UT-Austin.

Author information

Authors and Affiliations

Contributions

Each author has contributed equally to various sections of this work and each author has read, reviewed and approved of this work.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare they have no conflicts of interest.

Ethical approval

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Adegunju, S.A., Amalraj, P.B.C.A., Holland, C.E. et al. Assessment of the new kinetically limited linear driving force model for predicting diffusion limited adsorption breakthrough curves. Adsorption 30, 57–77 (2024). https://doi.org/10.1007/s10450-023-00434-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10450-023-00434-7