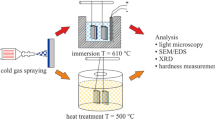

The structure of a copper–zinc coating deposited onto steel 40Kh at 450°C by the method of gas-dynamic spraying of a mechanical mixture of copper, zinc and corundum particles with 2-mm displacement of the sprayer nozzle is studied. The coated specimens are heat treated in a furnace at 420 – 430°C for at most 180 min. The structure and the chemical composition of the coating are studied by the methods of x-ray diffraction phase analysis and microscopic spectrum analysis. It is shown that the spraying is accompanied by diffusion of copper into zinc, which yields an electron-type solid solution based on Cu5Zn8 (a γ-phase). After the heat treatment at 420 – 430°C for 180 min the coating contains a solid solution of zinc in copper (an α-phase) and an electron-type solid solution based on CuZn (a γ′-phase). The chemical and phase compositions of the coating correspond to duplex brass L65.

Similar content being viewed by others

Notes

Here and below in the article the contents of the elements and of the phases is given in mass percent.

References

B. N. Efremov, Brasses from Phase Constitution to Structure and Properties [in Russian], INFRA-M, Moscow (2016), 314 p.

Wenyuan China, Yuan Yuan, Xu dong Saya, et al., “Tribological behavior of the low-pressure cold sprayed (Cu – 5Sn)/Al2O3–Ag solid-lubricating coating in artificial seawater,” Surf. Coat. Technol., 403, 1 – 10 (2020). https://doi.org/10.1016/j.surfcoat.2020.126359

Qin Chen, Min Yu, Kai Ca, and Hui Chen, “Thermal conductivity and wear resistance of cold-sprayed Cu-ceramic phase composite coating,” Surf. Coat. Technol., 434, 1 – 14 (2022). https://doi.org/10.1016/j.surfcoat.2022.128135

Kostoula I. Triantou, Dimitris I. Pantelis, Vincent Guipont, and Michel Jeandin, “Microstructure and tribological behavior of copper and composite copper + aluminum cold sprayed coatings for various alumina contents,” Wear, 336 – 337, 96 – 107 (2015). https://doi.org/10.1016/j.wear.2015.05.003

Stephan Theimer, et al., “Adhesion of cold sprayed brass coatings for lead-free bearings,” in: Int. Thermal Spray Conf. ITSC, May 7 – 10, 2019, Orlando, Florida.

V. E. Arkhipov, T. I. Murav’eva, M. S. Pugachev, and I. V. Shkaley, “Effect of process parameters of gas-dynamic spraying on structural and phase transformations in a “brass” type coating,” Uproch. Tekhnol. Pokr., 16(12), 554 – 560 (2020).

B. S. Bokshtein, Diffusion in Metals [in Russian], Metallurgiya, Moscow (2019), 248 p.

V. E. Arkhipov, T. I. Murav’eva, M. S. Pugachev, and O. O. Shcherbakova, “Structural and phase transformations in a coating based on copper and zinc particles deposited by gas-dynamic spraying,” Metalloved. Term Obrab Met., No. 4, 32 – 36 (2020).

B. Ya. Sachek, A. M. Mezrin, V. E. Arkhipov, and A. F. Londarskii, “Surface modification of tribological assemblies by spraying of metallic coatings as a means for raising their fretting resistance,” Trenie Iznos, 39(4), 24 – 28 (2018).

DIMET. Application of Technology and Equipment [electronic resource], http://www.dimet-r.narod.ru/ (accessed 31.01.2023).

The work has been performed with partial support of a state assignment (No. 123021700050-1, Microscope Researches).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 7, pp. 3 – 7, July, 2023.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Arkhipov, V.E., Murav’eva, T.I., Moskvitin, G.V. et al. Effect of Heat Treatment on the Phase Composition of Copper-Zinc Coating on Steels. Met Sci Heat Treat 65, 395–399 (2023). https://doi.org/10.1007/s11041-023-00945-8

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11041-023-00945-8