The method of orientation microscopy (EBSD) is used to study the structural and textural states of samples of low-carbon low-alloy steel of type 06G2MB subjected to thermomechanical controlled processing (TMCP) by five pilot routes differing in the finishing hot-rolling temperature and in the intensity of the controlled cooling. The interrelation between the processing parameters, the structure and the mechanical properties of the samples is determined. It is shown that the TMCP route with the finishing hot-rolling temperature close to A3 and maximum cooling intensity is the most optimal treatment.

Similar content being viewed by others

References

I. I. Mazur, et al., Safety of Russia. Legal, Socioeconomic and Scientific-Engineering Aspects, in 60 Vols., Vol. 20, Safety of Pipeline Transportation [in Russian], ed. by M. A. Makhutov, Znanie, Moscow (2002), 749 p.

E. A. Telegin, et al., Safety of Russia. Legal, Socioeconomic and Scientific-Engineering Aspects. Energy Safety (FEC and the State) [in Russian], ed. by M. A. Makhutov, Znanie, Moscow (2000), 302 p.

Y. D. Morozov,M. Y. Matrosov, A. B. Arabei, and S. Y. Nastich, “New generation of high-strength tube steels with a ferrite-bainite structure,” Metallurgist, 52(7 – 8), 450 – 456 (2008). https://doi.org/10.1007/s11015-008-9080-5

D. J. Stolheim, “Recent alloying schemes and practice of production of high-strength steels for cross-country oil and gas pipelines. Part I,” Metallurg, No. 11, 35 – 66 (2013).

V. I. Il’inskii, P. P. Stepanov, L. I. Efron, et al., “Experience of mastering plate production of strength category SAWL 450 for deep-water pipes at the Vyksa metallurgical plant 5000 mill,” Metallurgist, 58(1 – 2), 38 – 42 (2014). https://doi.org/10.1007/s11015-014-9865-7

S. Yu. Nastich, V. A. Kornilov, Yu. D. Morozov, et al., “New steels for pipelines of strength classes K54-K60 (X70): production experience at OAO MMK,” Steel in Translation, 39, 5, 431 – 436 (2009). https://doi.org/10.3103/S0967091209050179

Cl. Petersen, K. Corbett, D. Fairchild, et al., “Improving long-distance gas transmission economics. X120 development over-view,” in: Proc. 4th Int. Pipeline Conf., Ostend (2004), pp. 3 – 29.

K. Hulka and F. Heistercamp, “Tendencies in development of steels for large-diameter pipes,” Stal’, No. 10, 62 – 67 (1997).

Yu. D. Morozov, S. Yu. Nastich, and O. N. Chevskaya, “Obtaining high-quality properties of rolled material for large-diameter pipes based on formation of ferrite-bainite microstructure,” Metallurgist, 52(1 – 2), 21 – 28 (2008). https://doi.org/10.1007/s11015-008-9003-5

M. Yu. Matrosov, A. A. Kichkina, A. A. Efimov, et al., “Simulating structure-forming processes in tube steels during controlled rolling with accelerated cooling,” Metallurgist, 51(7 – 8), 367 – 376 (2007). https://doi.org/10.1007/s11015-007-0068-3

S. Y. Nastich, Y. D. Morozov, M. Y. Matrosov, et al., “Assimilation of production in an MMK 5000 mill of thick-rolled sheet from low-alloy steels with improved strength and cold resistance properties,” Metallurgist, 55(11 – 12), 810 – 818 (2012). https://doi.org/10.1007/s11015-012-9507-x

A. B. Arabey, “Development performance specifications for the metal of cross-country gas pipelines,” Izv. Vysh. Uchebn. Zaved., Chern. Metall., No. 7, 3 – 10 (2010).

I. Yu. Pyshmintsev, V. I. Stolyarov, A. M. Gervas’ev, et al., “Special features of structure and properties of pilot batches of pipes of strength category K65 (X80) manufactured for complex testing,” Nauka Tekh. Gaz. Prom-sti, No. 1, 56 – 61 (2009).

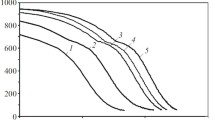

S. I. Platov, S. M. Gorbatyuk, M. L. Lobanov, et al., “Mathematical model of the accelerated cooling of metal in thick-plate hot rolling,” Metallurgist, 66(3 – 4), 642 – 648 (2022). https://doi.org/10.1007/s11015-022-01348-5

GOST 1497–84. Metals. Methods of Tensile Tests [in Russian], Standartinform, Moscow (2008), 22 p.

GOST 9454–78. Metals. Methods of Testing for Impact Bending at Low, Room and Elevated Temperatures [in Russian], Izd. Standartov, Moscow (1994), 26 p.

M. L. Lobanov, V. A. Khotinov, S. V. Danilov, et al., “Tensile deformation and fracture behavior of API-5L X70 line pipe steel,” Materials, 15(2), 501 (2022).

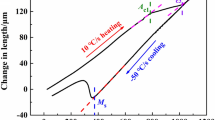

M. L. Lobanov, S. V. Danilov, V. I. Pastukhov, et al., “Effect of cooling rate on the structure of low-carbon low-alloy steel after thermomechanical controlled processing,” Metal Sci. Heat Treat., 61(1 – 2), 32 – 38 (2019). https://doi.org/10.1007/s11041-019-00373-7

I. L. Yakovleva, N. A. Tereshchenko, and N. V. Urtsev, “Observation of the martensitic-austenitic component in the structure of low-carbon low-alloy pipe steel,” Phys. Met. Metallogr., 121, 4, 352 – 358 (2020). https://doi.org/10.1134/S0031918X20040171

M. L. Lobanov, G. M. Rusakov, A. A. Redicul’tsev, et al., “Investigation of special misorientations in lath martensite of low-carbon steel using the method of orientation microscopy,” Phys. Met. Metallogr., 117, 254 – 259 (2016).

G. M. Rusakov, M. L. Lobanov, A. A. Redikul’tsev, and A. S. Belyaevskikh, “Special misorientations and textural heredity in the commercial alloy Fe – 3% Si,” Phys. Met. Metallogr., 115, 775 – 785 (2014).

B. Hutchinson, L. Ryde, E. Lindh, and K. Tagashira, “Texture in hot rolled austenite and resulting transformation products,” Mater. Sci. Eng. A, 257, 9 – 17 (1998).

X. Yang, Y. Xu, X. Tan, and D.Wu, “Influences of crystallography and delamination on anisotropy of Charpy impact toughness in API X100 pipeline steel,” Mater. Sci. Eng. A, 607, 53 – 62 (2014).

M. L. Lobanov, Y. N. Loginov, S. V. Danilov, et al., “Effect of hot rolling on the structure and texture condition of plates of the Al – Si – Mg alloy system,” Metal. Sci. Heat Treat., 60(5 – 6), 322 – 328 (2018). https://doi.org/10.1007/s11041-018-0279-1

M. Hölscher, D. Raabe, and K. Lucke, “Relationship between rolling textures and shear textures in f.c.c. and b.c.c. metals,” Acta Metall. Mater., 42(3), 879 – 886 (1994).

W. Gong, Y. Tomota, A. M. Paradowska, et al., “Effects of ausforming temperature on bainite transformation, microstructure and variant selection in nanobainite steel,” Acta Mater., 61, 4142 – 4154 (2013).

I. Sabirov, I. De Diego-Calderon, J. M. Molina-Aldareguia, et al., “Microstructural design in quenched and partitioned (Q&P) steels to improve their fracture properties,” Mater. Sci. Eng. A, 657, 136 – 146 (2016)

F. J. Humphreys and M. Hatherly, Recrystallization and Related Annealing Phenomena, ELSEVIER Ltd., Oxford (2004), 574 p.

The work has been financed by Grant No. 23-29-00615 of the Russian Scientific Foundation, https://rscf.ru/project/23-29-00615/.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 8, pp. 26 – 34, August, 2023.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Lobanov, M.L., Platov, S.I., Zorina, M.A. et al. Effect of Controlled Thermomechanical Processing Routes on the Structural and Textural States of Low-Carbon Low-Alloy Steel. Met Sci Heat Treat 65, 485–493 (2023). https://doi.org/10.1007/s11041-023-00959-2

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11041-023-00959-2