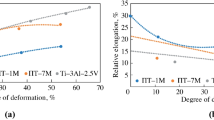

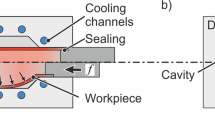

The article provides systematization and comparative analysis of data for structural and phase states and set of physical and mechanical properties formed in deformable tube semi-finished products. Analysis includes various stages of obtaining hot-extruded tubes of titanium alloys PT-1M, PT-7M, Ti–3Al–2.5V. The relationship between characteristics of macro-, microstructure, parameters of the phases formed with spread of hardness values in the original hot-forged tube billets is established. Physical simulation of hot deformation processes of alloys with varying temperature and upsetting deformation rate is conducted. Recommendations for extrusion temperature ranges for each alloy are proposed. These recommendations are based on energy-power parameters of industrial equipment used and restrictions imposed by the structure. Evolution of the structure and change in hardness during expansion of a tube billet made from the alloys investigated are considered. Results of computer simulations of energy-power parameters of tube extrusion and their comparison with industrial experiment data are presented. Features of the structure, texture and their relationship with tube mechanical properties are established.

Similar content being viewed by others

References

D. A. Pumpyanskii, “ Pipelines: selection of its niche. Export vole of seam-free tubes with defining rates,” Metally Evrazy, No. 4, 26–27 (2004).

D. A. Pumpyanskii, “Problems of competitive development of the tube market. Series of scientific works,” UrO RAN, Institute of Economics, Ekaterinburg (2004).

V. G. Smirnov, B. G. Krokhin, and V. S. Kalinin, “Assimilation of the production of high quality tube workpieces (TREX) of titanium alloys for aerospace systems,” Titan, No. 1 (12), 36–39 (2003).

D. A. Pumpyanskii, A. G. Illarionov, F. V. Vodolazskii, Ya. I. Kosmatskii, and A. A. Popov, “Promising titanium alloys for preparing cold-worked tubes,” Metallurg, No. 1, 3748 (2023)https://doi.org/10.52351/00260827_2023_01_37

A. G. Illarionov, Ya. I. Kosmatskii, E. A. Filyaeva, F. V. Vodolazskii, and N. A. Barannikova, “Experimental determination of temperature parameters for evaluating the possibility of preparing hot-extruded tubes of alloy Ti–3Al–2.5V,” Metallurg., No. 9, 83–87 (2017); https://doi.org/10.1007/s11015-017-0396-x.

Ya. I. Kosmatskii, N. V. Fokin, E. A. Filyaeva, and B. V. Barichko, “Study of deformation capacity of titanium alloy Ti–3Al–2.5V and evaluation of the production possibility for manufacturing hot pressed tubes from it,” Titan, No. 2, 18–22 (2016).

I. Yu. Pyshmintsev, Ya. I. Kosmatskii, E. A. Filyaeva, A. G. Illarionov, F. V. Vodolazkii, and N. A. Barannikova, “ Structure and properties of hot-extruded tubes of alloy Ti–3Al–2.5V,” Metallurg., No. 4, 7075 (2018); https://doi.org/10.1007/s11015-018-0671-5.

V. V. Tetyukhin, V. G. Smirnov, A..A. Fyodorov, and A. V. Safianov, “ New titanium alloy development and tube manufacture for offshore oil and gas production,” Titanium 99 Science and Technology, 2, 1119–1124 (1999).

F. V. Vodolazskiy, S. M. Illarionova, N. A. Barannikova, and Ya. I. Kosmatskiy,”Cross-sectional structure and properties of shellbillet of PT-7M titanium alloy after expanding,” Materials Today: Proc., 38, 1799–1803 (2021); https://doi.org/10.1016/j.matpr.2020.08.412.

F. V. Vodolazskiy, E. A. Gornostaeva, and A. G. Illarionov, “Structure and properties of hot-extruded tube of titanium alloy PT7M,” Materials Today: Proc., 19, 2200–2204 (2019); https://doi.org/10.1016/j.matpr.2019.07.378.

V. P. Leonov, L. P. Rtishcheva, V. N. Kopylov, K. G. Martynov, D. A. Negodin, S. V. Zherebtsov, and D. N. Klimenko, “ Study of diffusion process in titanium alloys during hot extrusion of tube workpieces in a copper lubricating layer,” Titan, No. 2(64), 31–43 (2019).

Ya. I. Kosmatskii, B. V. Barichko, N. V. Fokin, and V. D. Nikolenko, “Use of a Gleeble 3800 complex in developing hot extrusion technology and upsetting of tube ends,” Metallurg., No. 4, 36–41 (2021); https://doi.org/10.1007/s11015-021-01170-5.

A. S. Oryshchenko, V. P. Leonov, L. P. Rtishcheva, V. N. Kopylov, and K. G. Martynov, “Contemporary state of production and use of tubes of titanium alloys in atomic power engineering and shipbuilding,” Titan, No. 3(61), 21–32 (2018).

F. V. Vodolazskii, A. G. Illarionov, Yu. N. Loginov, Ya. I. Kosmatskii, and A. Yu. Postylyakov, “ Comparison of the structure and properties of titanium alloy Ti–3Al–2.5V with results of digital process for its extrusion,” MiTOM., No. 8 (806), 41–46 (2022); https://doi.org/10.1007/s11041-022-00831-9.

F. V. Vodolazskiy, N. A. Barannikova, and A. G. Illarionov, “Structure, texture and mechanical properties through the section of the hot-extruded tube of titanium alloy PT-1M,” Materials Science Forum, 989, 139–144 (2020); https://doi.org/10.4028/www.scientific.net/MSF.989.139.

A. G. Illarionov F. V. Vodolazskii, Ya. I. Kosmatskii, and E. A. Gornostaeva, “ Determination of temperature-force parameter required for preparing hot-extruded tubes of titanium alloy PT-1M,” Svet. Met., No. 2, 77083 (2021).

ASTM B338-14. Standard Specification for Seamless and Welded Titanium and Titanium Alloy Tubes for Condensers and Heat Exchangers, ASTM Intern., West Conshohocken, PA (2014); https://doi.org/10.1520/B0338-14.

TU 1-5-132−78. Titanium Alloy Tube Workpieces (1978).

V. K. Aleksandrov, N. F. Anoshkin, A. F. Belov, et al., Titanium Alloy Semifinished Products [in Russian], ONTI VILS, Moscow (1998).

A. A. Il’in, B. A. Kolachev, and I. S. Pol’kin, Titanium Alloys. Composition. Structure. Properties, Handbook [in Russian], VILS Moscow (1009).

D. A. Pumpyanskii, M. G. Stutsa, I. Yu. Pyshmintsev, Ya. I. Kosmatskii, O. V. Varnak, and B. V. Barichko, “Assimilation of production of special forms of tube of ferritic-martensitic steelks taking account of features of the microstructure and properties,” Chernye Metally., No. 11, 41–49 (2022).

GOST 1497−84. Interstate Standard. Metals. Test Methods in Tension, Standartinform, Moscow (2005).

N. F. Anoshkin, E. A. Borisova, G. A. Bochvar, et al., Titanium Alloys. Titanium Alloy Metallography [in Russian], Metallurgiya, Moscow (1980).

A. G. Illarionov, F. V. Vodolazskiy, N. A. Barannikova, Ya. I. Kosmatskiy, and Y. V. Khudorozhkova, “Influence of phase composition on thermal expansion of Ti–0.4Al, Ti–2.2Al–2.5Zr and Ti–3Al–2.5V alloys,” J. Alloys Compounds, 857, Art. 158049 (2021); https://doi.org/10.1016/j.jallcom.2020.158049.

Yu. Tsvikker, Titanium and its Alloys [in Russian], Mir, Moscow (1979).

A. M. Vasserman, V. A., Danilkin, O. S. Korobov, et al., Methods for Monitoring and Studying Nonferrous Alloys: Handbook [in Russian], Metallurgiya, Moscow 91985).

P. I. Polukhin, G. Ya. Gun, and A. M. Galkin, Metal and Alloy Resistance to Plastic Deformation: Handbook [in Russian], Metallurgiya, Moscow (1983)

S. P. Solonina and S. G. Glazunov, High-Strength Titanium Alloys [in Russian], Matallurgiya, Moscow (1976).

L. A. Nikol’skii, S. Z. Figlin, V. V. Boitsov, Yu. G. Kalinin, and A. V. Bakharev, Hot Stamping and Extrusion of Titanium Alloys [in Russian], Mashinostroenie, Moscow (1975).

Ya. I. Kosmatskii, B. V. Barichko, and K. Yu. Panova, Extrusion Process Technology: Teaching Aid [in Russian], Izd. YuUrGU, Chelyabinsk (2011).

B. A. Kolachev, V. A. Elagin, and Vi. Livanov, Material Science and Heat Treatment of Nonferrous Metals and Alloys [in Russian], MiSIS, Moscow (2005).

S. G. Glazunov and V. N. Moiseev, Structural Titanium Alloys [in Russian], Metallurgiya, Moscow (1974).

G. Aurelio, A. Fernandez Guillermet, G. J. Cuello and J. Campo, “Metastable phases in the Ti–V System: Part I. Neutron diffraction study and assessment of structural properties,” Metallurgical and Materials Transactions A, 33A, 1307–1317 (2002).

J. Gokyu, H. Suzuki, and F. Seki, “ Studies on rolled and annealed textures in commercially pure Ti,” J. Inst. Metals. Metallurg. Abstr., 22, 195–196 (1954/55).

C. E. Foney and S. E. Meredith, Ti–3Al–2.5V Seamless Tubing Engineering Guide, Kennewick Wash. USA. Sandvick Special Metals Corp. (1990).

V. I. Polukhin, S. S, Gorelik, and V. K. Vorontsov, Physical Bases of Plastic Deformation [in Russian], Metallurgiya, Moscow (1982).

A. A. Babareko, “Texture of metals alloys,” in: Coll. “Targets of science and technology,” Ser. Metalloved. Term. Obrab., VINITI, Moscow, 13, 79–148 (1980).

TU 14-3-821−79. Seamless Hot-Deformed Tubes of Alloys Based Upon Titanium (1979).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallurg, Vol. 67, No. 8, pp. 30–40, August, 2023.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Pumpyanskiy, D.A., Illarionov, A.G., Vodolazskiy, F.V. et al. Materials Science Aspects of Titanium Tube Production. Part 1. Production of Hot-Extruded Tubes. Metallurgist 67, 1103–1117 (2023). https://doi.org/10.1007/s11015-023-01601-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11015-023-01601-5