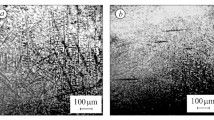

High-entropy coatings produced by electron-beam deposition of multicomponent Al‒Ni‒Co‒Fe‒Cr‒Ti‒Bx (x = 0, 0.25, 0.5, and 1 mol) powder mixtures onto steel substrates in vacuum were examined. The effect of boron content on the phase composition, structure, and strength properties of the AlNiCoFeCrTiBx coatings was studied employing X-ray diffraction, microstructural analysis, and micromechanical tests. The AlNiCoFeCrTi and AlNiCoFeCrTiB0.25 coatings showed a typical dendritic and interdendritic structure and consisted of two substitutional solid solutions with a body-centered cubic (bcc) structure, differing in lattice parameters. An increase in the boron content to 0.5 mol changed the phase composition and led to the formation of in-situ titanium diboride TiB2 as fine inclusions and chromium boride Cr2B as elongated inclusions in the coatings besides the two bcc solid solutions (bcc1 and bcc2). When 1 mol of boron was added, the coatings remained four-phase, while the amount and sizes of TiB2 and Cr2B inclusions increased. Moreover, with 1 mol of boron, the ratio between the bcc1 and bcc2 phases increased toward bcc2 because of the removal of chromium and titanium atoms. Mechanical tests showed that the microhardness and yield stress of the AlNiCoFeCrTiBx coatings produced by electron-beam deposition increased by 1.6 times when boron content raised to 1 mol: from 8.8 and 2.4 GPa for the AlNiCoFeCrTi coatings to 14.2 and 4 GPa for the AlNiCoFeCrTiB coatings. The significant enhancement in the strength indicators (hardness and yield stress) of the high-entropy coatings with greater boron content could be attributed to the solid-solution strengthening effect of interstitial boron atoms and to the strengthening effect of boride phase inclusions.

Similar content being viewed by others

References

B. Murty, Jien-Wie Yeh, S. Ranganathan, and P. Bhattacharjee, High Entropy Alloys, 2nd ed., Elsevier (2019), https://doi.org/10.1016/c2017-0-03317-7.

D.B. Miracle and O.N. Senkov, “A critical review of high entropy alloys and related concepts,” Acta Mater., 122, 448–511 (2017), https://doi.org/https://doi.org/10.1016/j.actamat.2016.08.081.

Y. Zhang, High-Entropy Materials, Springer, Singapore (2019). https://doi.org/https://doi.org/10.1007/978-981-13-8526-1.

Y.F. Ye, Q. Wang, J. Lu, C.T. Liu, and Y. Yang, “High-entropy alloy: challenges and prospects,” Mater. Today, 19, 349–362 (2016), https://doi.org/https://doi.org/10.1016/j.mattod.2015.11.026.

J. Chen, X. Zhou, W. Wang, B. Liu, Y. Lv, W. Yang, D. Xu, and Y. Liu, “A review on fundamental of high entropy alloys with promising high–temperature properties,” J. Alloys Compd., 760, 15–30 (2018), https://doi.org/https://doi.org/10.1016/j.jallcom.2018.05.067.

X. Yan and Y. Zhang, “Functional properties and promising applications of high entropy alloys,” Scr. Mater., 187, 188–193 (2020), https://doi.org/https://doi.org/10.1016/j.scriptamat.2020.06.017.

E.P. George, D. Raabe, and R.O. Ritchie, “High-entropy alloys,” Nat. Rev. Mater., 4, 515–534 (2019), https://doi.org/https://doi.org/10.1038/s41578-019-0121-4.

A. Fu, Y. Cao, Z. Xie, J. Wang, and B. Liu, “Microstructure and mechanical properties of Al–Fe–Co–Cr–Ni high entropy alloy fabricated via powder extrusion,” J. Alloys Compd., 943, 169052 (2023), https://doi.org/https://doi.org/10.1016/j.jallcom.2023.169052.

W. Lu, W. Guo, Z. Wang, J. Li, F. An, G. Dehm, D. Raabe, C.H. Liebscher, and Z. Li, “Advancing strength and counteracting embrittlement by displacive transformation in heterogeneous high-entropy alloys containing sigma phase,” Acta Mater., 246, 118717 (2023), https://doi.org/https://doi.org/10.1016/j.actamat.2023.118717.

M.J. Chae, H. Lee, A. Sharma, and B. Ahn, “Effect of light (X = Mg, Si) and heavy (X = Zn) metals on the microstructural evolution and densification of AlCuFeMnTi-X high-entropy alloy processed by advanced powder metallurgy,” Powder Metall., 64, 228–234 (2021), https://doi.org/https://doi.org/10.1080/00325899.2021.1909212.

J. Li, Y. Huang, X. Meng, and Y. Xie, “A review on high entropy alloys coatings: fabrication processes and property assessment,” Adv. Eng. Mater., 21, 1900343 (2019), https://doi.org/https://doi.org/10.1002/adem.201900343.

A. Sharma, “High entropy alloy coatings and technology,” Coatings, 11, 372 (2021), https://doi.org/https://doi.org/10.3390/coatings11040372.

D.V. Hushchyk, A.I. Yurkova, V.V. Cherniavsky, I.I. Bilyk, and S.O. Nakonechnyy, “Nanostructured AlNiCoFeCrTi high-entropy coating performed by cold spray,” Appl. Nanosci., 10, 4879–4890 (2020), https://doi.org/https://doi.org/10.1007/s13204-020-01364-4.

W. Li, P. Liu, and P.K. Liaw, “Microstructures and properties of high-entropy alloy films and coatings: a review,” Mater. Res. Lett., 6, 199–229 (2018), https://doi.org/https://doi.org/10.1080/21663831.2018.1434248.

V.F. Gorban, S.O. Firstov, M.O. Krapivka, A.V. Samelyuk, and D.V. Kurylenko, “Influence of various factors on the properties of solid-soluble high-entropy alloys based on BCC and FCC phases,” Mater. Sci., 58, 135–140 (2022), https://doi.org/https://doi.org/10.1007/s11003-022-00641-7.

Z. Li, C.C. Tasan, H. Springer, B. Gault, and D. Raabe, “Interstitial atoms enable joint twinning and transformation induced plasticity in strong and ductile high-entropy alloys,” Sci. Rep., 7, 40704 (2017), https://doi.org/https://doi.org/10.1038/srep40704.

Z. Lei, X. Liu, Y. Wu, H. Wang, S. Jiang, S. Wang, X. Hui, Y. Wu, B. Gault, P. Kontis, D. Raabe, L. Gu, Q. Zhang, H. Chen, H. Wang, J. Liu, K. An, Q. Zeng, T.-G. Nieh, and Z. Lu, “Publisher Correction: Enhanced strength and ductility in a high-entropy alloy via ordered oxygen complexes,” Nature, 565, E8 (2018), https://doi.org/https://doi.org/10.1038/s41586-018-0834-3.

H. Luo, W. Lu, X. Fang, D. Ponge, Z. Li, and D. Raabe, “Beating hydrogen with its own weapon: Nanotwin gradients enhance embrittlement resistance of a high-entropy alloy,” Mater. Today, 21, 1003–1009 (2018), https://doi.org/https://doi.org/10.1016/j.mattod.2018.07.015.

J.Y. Aguilar-Hurtado, A. Vargas-Uscategui, D. Zambrano-Mera, and R. Palma-Hillerns, “The effect of boron content on the microstructure and mechanical properties of Fe50–XMn30Co10Cr10BX (x = 0, 0.3, 0.6 and 1.7 wt.%) multi-component alloys prepared by arc-melting,” Mater. Sci. Eng. A, 748, 244–252 (2019), https://doi.org/https://doi.org/10.1016/j.msea.2019.01.088.

L. Guirong, G. Lipeng, W. Hongming, L. Ming, W. Changwen, W. Haoran, Y. Yuwei, R. Wenxiang, and L. Jiaqi, “Effects of boron on microstructure and properties of microwave sintered FeCoNi1.5CuY0.2 highentropy alloy,” J. Alloys Compd., 866, 157848 (2021), https://doi.org/https://doi.org/10.1016/j.jallcom.2020.157848.

B. Xin, A. Zhang, J. Han, J. Zhang, and J. Meng, “Enhancing mechanical properties of the boron doped Al0.2Co1.5CrFeNi1.5Ti0.5 high entropy alloy via tuning composition and microstructure,” J. Alloys Compd., 896, 162852 (2022), https://doi.org/https://doi.org/10.1016/j.jallcom.2021.162852.

X. Gao, L. Wang, N. Guo, L. Luo, G. Zhu, C. Shi, Y. Su, and J. Guo, “In-situ development of MB2 and their effect on microstructure and mechanical properties of refractory Hf0.5Mo0.5NbTiZr high entropy alloy matrix composites,” Int. J. Refract. Met. Hard Mater., 96, 105473 (2021), https://doi.org/https://doi.org/10.1016/j.ijrmhm.2021.105473.

C. Zhang, G.J. Chen, and P.Q. Dai, “Evolution of the microstructure and properties of laser-clad FeCrNiCoBx high-entropy alloy coatings,” Mater. Sci. Technol., 32, 1666–1672 (2016), https://doi.org/https://doi.org/10.1080/02670836.2015.1138035.

F. Chang, B. Cai, C. Zhang, B. Huang, S. Li, and P. Dai, “Thermal stability and oxidation resistance of FeCrxCoNiB high-entropy alloys coatings by laser cladding,” Surf. Coat. Technol., 359, 132–140 (2019), https://doi.org/https://doi.org/10.1016/j.surfcoat.2018.12.072.

D. Liu, J. Zhao, Y. Li, W. Zhu, and L. Lin, “Effects of boron content on microstructure and wear properties of FeCoCrNiBx high-entropy alloy coating by laser cladding,” Appl. Sci., 10, 49 (2019),

26. A. Takeuchi and A. Inoue, “Calculations of mixing enthalpy and mismatch entropy for ternary amorphous alloys,” Mater. Trans. JIM, 41, 1372–1378 (2000), https://doi.org/https://doi.org/10.2320/matertrans1989.41.1372.

27. A. Takeuchi and A. Inoue, “Classification of bulk metallic glasses by atomic size difference, heat of mixing and period of constituent elements and its application to characterization of the main alloying element,” Mater. Trans., 46, 2817–2829 (2005), https://doi.org/https://doi.org/10.2320/matertrans.46.2817.

28. S. Schiller, U. Heisig, and S. Panzer, Electron-Beam Technology [Russian translation], Energiya, Moscow (1980), p. 528.

29. T. Yu, H. Wang, K. Han, and B. Zhang, “Microstructure and wear behavior of AlCrTiNbMo high-entropy alloy coating prepared by electron beam cladding on Ti600 substrate,” Vacuum, 199, 110928 (2022), https://doi.org/https://doi.org/10.1016/j.vacuum.2022.110928.

B.A. Galanov, Yu.V. Milman, S.I. Chugunova, and I.V. Goncharova, “Investigation of mechanical properties of high-hardness materials by indentation,” Superhard Mater., No. 3, 23–35 (1999).

D. Tabor, The Hardness of Metals, Oxford University Press (2000), p. 175, https://archive.org/details/TaborHardnessOfMetals/page/n1/mode/2up.

B.D. Cullity and S.R. Stock, Elements of X-Ray Diffraction, 3rd ed., Pearson Education Limited (2014), p. 654, ISBN 10: 1-292-04054-8. ISBN 13: 978-1-292-04054-7.

33. J.-W. Yeh, S.-Y. Chang, Y.-D. Hong, S.-K. Chen, and S.-J. Lin, “Anomalous decrease in X-ray diffraction intensities of Cu–Ni–Al–Co–Cr–Fe–Si alloy systems with multi-principal elements,” Mater. Chem. Phys., 103, 41–46 (2007), https://doi.org/https://doi.org/10.1016/j.matchemphys.2007.01.003.

34. G.V. Samsonov, T.I. Serebryakova, and V.A. Neronov, Borides [in Russian], Atomizdat, Moscow (1975), p. 376.

35. B. Yang, L. Ma, and P. Zhao, “Effect of boron on the microstructure and mechanical properties of as-cast and annealed CrFeNi medium-entropy alloys,” Mater. Sci. Eng. A, 863, 144524 (2023), https://doi.org/https://doi.org/10.1016/j.msea.2022.144524.

R.W. Cahn and P. Haasen, Physical Metallurgy, 3rd ed., North-Holland (1983).

V.S. Zolotarevskii, Mechanical Properties of Metals [in Russian], 3rd ed., MISIS, Moscow (1998), p. 400, ISBN: 5-87623-017-0.

38. J.P. Hirth and M. Cohen, “On the strength-differential phenomenon in hardened steel,” Metall. Mater. Trans., 1, 3–8 (1970), https://doi.org/https://doi.org/10.1007/bf02819235.

39. R.P. Reed, “Nitrogen in austenitic stainless steels,” JOM, 41, 16–21 (1989), https://doi.org/https://doi.org/10.1007/bf03220991.

Acknowledgments

This research has been supported by the National Research Fund of Ukraine (Grant No. 2020.02/0108) and the Ministry of Education and Science of Ukraine (Project No. 0121U109789).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Poroshkova Metallurgiya, Vol. 62, Nos. 5–6 (551), pp. 77–93, 2023

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Nakonechnyi, S.O., Yurkova, A.I., Loboda, P.I. et al. The Effect of Boron Content on the Structure and Mechanical Properties of Electron-Beam High-Entropy AlNiCoFeCrTiB Coatings. Powder Metall Met Ceram 62, 326–338 (2023). https://doi.org/10.1007/s11106-023-00396-z

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-023-00396-z