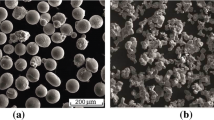

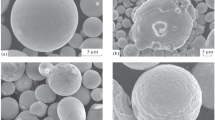

The paper presents the results of structural studies and assessment of the level of bending strength of an alloy based on nickel aluminide (VKNA-1V) obtained by spark plasma sintering of mechanically activated powders of the initial components at different sintering conditions. Sintering temperature was the main variable parameter (range: 1,100 to 1,250°C). It has been established that when the sintering temperature exceeds 1,200°C, the formation of a liquid phase occurs. X-ray diffraction analysis of the studied materials revealed Ni3Al as the main phase. The recommended sintering conditions required to obtain a dense, low-defect billet made of VKNA-1V alloy include sintering at 1,150°C for 5 min under a pressure of 40 MPa. This type of material has an increased level of bending strength at room temperature (σbend = 1,640 MPa) and a microhardness equal to 650 HV.

Similar content being viewed by others

References

N. A. Nochovnaya, O. A. Bazyleva, D. E. Kablov, and P. V. Panin, Intermetallic Alloys based on Titanium and Nickel [in Russian], VIAM, Moscow (2018).

P. Jozwik, W. Polkowski, and Z. Bojar, “Applications of Ni3Al based intermetallic alloys – current stage and potential perceptivities,” Materials, 8, 2537-2568 (2015); https://doi.org/10.3390/ma8052537.

O. A. Bazyleva, E. G. Arginbaeva, and E. Yu. Turenko, “High-temperature intermetallic alloys for gas turbine engine components,” Aviatsionnye Materialy i Tekhnologii, No. 3, 26–31 (2013).

Ye. N. Kablov, O. G. Ospennikova, and O. A. Bazyleva, “Materials for high-temperature loaded components of gas turbine engines,” Vestn. MGTU im. N. E. Baumana, Ser. Mashinostroyeniye, Metallurgiya, No. SP2, 13–19 (2011).

O. G. Ospennikova, O. A. Bazyleva, E. G. Arginbaeva, et al., “Development of intermetallic nickel alloys and composite materials based on them,” Vestn. MGTU im. N. E. Baumana, Ser. Mashinostroyeniye, No. 3, 75–89 (2017).

D. V. Dudina, Modern Methods of Powder Sintering. Specifics of Structure Formation in Sintered Materials [in Russian], NGTU, Novosibirsk (2020).

M. Tokita, “Trends in advanced SPS (Spark Plasma Sintering) systems and technology,” J. Soc. Powd. Tech. Japan, 30, No. 11, 790–804 (1993).

L. Shevtsova, V. Mali, A. Bataev, et al., “Microstructure and mechanical properties of materials obtained by spark plasma sintering of Ni3Al–Ni powder mixtures,” Mat. Sci. and Eng. A, 773, Art. 138882 (2020); https://doi.org/10.1016/j.msea.2019.138882.

P. Mardiha, A. Bahrami, and A. Mohammadnejad, “Towards a high strength ductile Ni/Ni3Al/Ni multilayer composite using spark plasma sintering,” Sci. Sintering, 51, 401–408 (2019); https://doi.org/10.2298/SOS1904401M.

10 L. I. Shevtsova, “Structure and mechanical properties of Ni3Al intermetallic compound obtained by spark plasma sintering of mechanically activated Ni–Al powder mixture,” Obrabotka Metallov (Tekhnologiya, Oborudovaniye, Instrumenty), No. 3(64), 21–27 (2014).

N. Frage, S. Kalabukhov, A. Wagner, and E.B. Zaretsky, “High temperature dynamic response of SPS-processed Ni3Al,” Intermetallics, 102, 26–33 (2018).

J. Meng, C. Jia, and Q. He, “Effect of mechanical alloying on structure and property of Ni3Al by spark plasma sintering,” Powder Metallurgy, 51, 227–230 (2008).

T. S. Ogneva, I. A. Bataev, V. I. Mali, et al., “Effect of sintering pressure and temperature on structure and properties of Ni–Al metal-intermetallic composites produced by SPS,” Materials Characterization, 180, 111415 (2021); https://doi.org/10.1016/j.matchar.2021.111415.

L. I. Shevtsova, M. A. Korchagin, M. A. Yesikov, et al., “Structure and properties of Ni3Al intermetallic compound formed by SPS sintering of powder mixtures prepared by various methods,” Metallurg, No. 11, 56–61 (2021); https://doi.org/10.52351/00260827_2021_11_56.

A. Mohammadnejad, A. Bahrami, M. Sajjadi, et al., “Microstructure and mechanical properties of spark plasma sintered nanocrystalline Ni3Al–xB (0.0 < x < 1.5 at.%),” Alloy, Mater. Today Communications, 17, 161–168 (2018).

16 O. A. Bazyleva, I. Yu. Yefimochkin, E. G. Arginbaeva, et al., “Composite material based on oxide-reinforced VKNA-type intermetallic alloy,” Perspektivnye Materialy, No. 10, 19–27 (2020).

S. A. Oglezneva, M. N. Kachenyuk, A. A. Smetkin, and V. B. Kulmeteva, “Binder composition for a gradient material with heat-protective properties formed by spark plasma sintering,” Tsvetnye Metally, No. 9 (945), 53–59 (2021).

L. I. Shevtsova, M. A. Yesikov, V. A. Lozhkin, et al., “Structure and strength properties of compacted materials obtained by sintering powders of nickel aluminide grades PN85Yu15 and PN75Yu23V (VKNA) using the SPS method,” Metallurg, No. 8, 61–67 (2022); https://doi.org/10.52351/00260827_2022_08_61.

N. N. Trofimenko, I. Yu. Yefimochkin, I. V. Osin, and R. M. Dvoretskov, “Studying the possibility of producing a high-entropy VNbMoTaW alloy by mixing elemental powders with subsequent compaction using hybrid spark plasma sintering,” Aviatsionnye Materialy i Tekhnologii, No. 2 (55), 12–20 (2019).

I. Yu. Yefimochkin, B. V. Shchetanov, S. V. Paegle, and R. M. Dvoretskov, “Studying the specifics of mechanical alloying during in-situ synthesis of composites based on refractory metals,” Trudy VIAM, No. 4 (64), 38–50 (2018).

O. A. Bazyleva, E. G. Arginbaeva, M. V. Unchikova, and Yu. V. Kostenko, “Effect of high-temperature annealing on the structure and properties of alloys based on the Ni3Al intermetallic compound,” Vestn. MGTU im. N. E. Baumana, Ser. Mashinostroyeniye, No. 1, 112–122 (2016); https://doi.org/10.18698/0236-3941-2016-1-112-122.

V. Yu. Filimonov, M. A. Korchagin, E. V. Smirnov, et al., “Kinetics of mechanically activated high temperature synthesis of Ni3Al in the thermal explosion mode,” Intermetallics, 19, 1–8 (2010); https://doi.org/10.1016/j.intermet.2010.11.028.

GOST 20018-74: Sintered Solid Alloys. Method for Determining Density [in Russian], valid from Jan. 01, 1976 to Jan. 01, 1991, Izd. Standartov, Moscow, 11 p.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallurg, Vol. 67, No. 8, pp. 63–70, August, 2023.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Shevtsova, L.I. Investigation of the VKNA-1V Alloy Obtained by SPS Method with a Preliminary Mechanical Activation of Powders. Metallurgist 67, 1146–1157 (2023). https://doi.org/10.1007/s11015-023-01606-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11015-023-01606-0