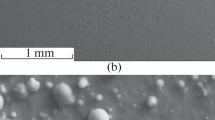

Ultrahigh-temperature ceramics (UHTC) have a wide range of applications, particularly in supersonic aircraft vehicles. However, the production of UHTCs with predetermined mechanical parameters is relevant. The paper analyzes the structurization trends and their influence on the properties of film coatings from transition metal nitrides and borides synthesized by ion-plasma and magnetron sputtering methods. Under optimal deposition energy conditions, the films show general regularities in their formation, such as the presence of a columnar (fibrous) structure and growth texture. The average grain size varies from 18–20 nm to 60–80 nm, depending on the deposition parameters and method. The films demonstrate excellent mechanical properties, including hardness, elastic modulus, recoverable elastic indicators under load, etc. Growth directions <111> and <100> are observed for transition metal carbide and nitride coatings, while growth in direction <0001> is typical of transition metal diborides. The identified trends will allow realistic computer modeling of the film formation process, using predetermined film properties and optimal sputtering parameters to promote excellent mechanical characteristics of the surface. A thermodynamic model describing the formation of nuclei for a typical film in the environment of atoms randomly deposited onto the substrate is proposed. The critical radius for nucleus growth and, accordingly, for film crystallization is analytically estimated. The influence of Gibbs energy changes on the crystallization process is discussed within the model.

Similar content being viewed by others

References

V.G. Samsonov, Nitrides [in Russian], Kyiv (1969), p. 380.

G.V. Samsonov and B.A. Kovenskaya, “The electronic structure of boron compounds,” in: Boron and Refractory Borides, Springer Berlin Heidelberg, Heidelberg, Berlin (1977), pp. 5–18.

G.V. Samsonov and B.A. Kovenskaya, “II. The nature of the chemical bond in borides,” in: Boron and Refractory Borides, Springer Berlin Heidelberg, Heidelberg, Berlin (1977), pp. 19–30.

W.G. Fahrenholtz, G.E. Hilmas, I.G. Talmy, and J.A. Zaykoski, “Refractory diborides of zirconium and hafnium,” J. Am. Ceram. Soc., 90, No. 5, 1347–1364 (2007).

H. Holleck, “Material selection for hard coatings,” J. Vac. Sci. Technol. A, 4, No. 6, 2661–2669 (1986).

H. Holleck and V. Schier, “Multilayer PVD coatings for wear protection,” Surf. Coat. Technol., 76–77,\ No. 1, 328–336 (1995).

A.D. Pogrebnjak and A.A. Goncharov, “Structural features of formed coatings and films of refractory compounds,” Metallof. Noveish. Tekhnol., 38, No. 9, 1145–1166 (2016).

A.I. Bazhin, A.A. Goncharov, A.D. Pogrebnyak, V.A. Stupak, and S.A. Goncharova, “Superhardness effect in transition-metal diborides films,” Phys. Met. Metall., 117, 594–601 (2016).

A. Pogrebnjak, A. Goncharov, A. Yunda, I. Shelest, A. Swic, and I. Lebedynskyi, “Structural features of the formation of multicomponent and high-entropy transition metal nitride films,” High Temp. Mater. Proc. Int. Quart. High-Technol. Plasma Proc., 22, No. 1, 7–15 (2018).

A.A. Goncharov, “Physical processes of the formation of structure and properties of films of transitionmetal diborides,” Phys. Met. Metall., 111, 314–324 (2011).

M.El. Garah, P. Briois, and F. Sanchette, “Recent progress on high-entropy films deposited by magnetron sputtering,” Crystals, 12, 335–355 (2022).

J. Li, Y. Huang, X. Meng, and Y. Xie, “A review on high entropy alloys coatings: Fabrication processes and property assessment,” Adv. Eng. Mater., 21, 1900343–1900343-27 (2019).

M. Magnuson, L. Hultman, and H. Högberg, “Review of transition-metal diboride thin films,” Vacuum, 196, 110567–110567-138 (2021).

A.A. Onoprienko and V.I. Ivashchenko, “Solid solutions in films of ternary carbides and nitrides of groups IV–VI transition metals: Structure and properties (Review),” J. Superhard Mater., 43, No. 4, 231–247 (2021).

J. Musil, P. Banoch, and P. Zeman, “Hard nanocomposite coatings. Present status and trends, Chapter 1,” in: Plasma Surface Engineering and Its Practical Applications, Research Signpost Publisher, Kerala (2007), pp. 1–34.

P.H. Mayrhofer, F. Kunc, J. Musil, and C. Mitterer, “A comparative study on reactive and non-reactive unbalanced magnetron sputter deposition of TiN coatings,” Thin Sol. Films, 415, No. 1–2, 151–159 (2002).

C. Mitterer, P.H. Mayrhofer, and J. Musil, “Thermal stability of PVD hard coatings,” Vacuum, 71, No. 1–2, 279–284 (2003).

P.H. Mayrhofer, G. Tischler, and C. Mitterer, “Microstructure and mechanical/thermal properties of Cr–N coatings deposited by reactive unbalanced magnetron sputtering,” Surf. Coat. Technol., 142–144, 78–84 (2001).

P.H. Mayrhofer, C. Mitterer, and J. Musil, “Structure–property relationships in single- and dual-phase nanocrystalline hard coatings,” Surf. Coat. Technol., 174–175, 725–731 (2003).

J. Musil and H. Polakova, “Hard nanocomposite Zr–Y–N coatings, correlation between hardness and structure,” Surf. Coat. Technol., 127, No. 1, 99–106 (2000).

A.D. Pogrebnjak, O.V. Sobol, V.M. Beresnev, P.V. Turbin, G.V. Kirik, N.A. Makhmudov, M.V. Il'yashenko, A.P. Shypylenko, M.V. Kaverin, M.Yu. Tashmetov, and A.V. Pshyk, “Phase composition, thermal stability, physical and mechanical properties of superhard on base Zr–Ti–Si–N nanocomposite coatings,” Ceram. Eng. Sci. Proc., 31, No. 7, 127–138 (2010).

A.D. Pogrebnjak, I.V. Yakushchenko, A.A. Bagdasaryan, O.V. Bondar, R. Krause-Rehberg, G. Abadias, P. Chartier, K. Oyoshi, Y. Takeda, V.M. Beresnev, and O.V. Sobol, “Microstructure, physical and chemical properties of nanostructured (Ti–Hf–Zr–V–Nb)N coatings under different deposition conditions,” Mater. Chem. Phys., 147, 1079–1091 (2014).

A.D. Pogrebnjak, “Hard and superhard nanostructured and nanocomposite coatings,” in: Nanomaterials- Based Coatings: Fundamentals and Applications, Elsevier (2019), pp. 237–337.

A.D. Pogrebnjak, A.A. Bagdasaryan, V.M. Beresnev, U.S. Nyemchenko, V.I. Ivashchenko, Ya.O. Kravchenko, Z.H.K. Shaimardanov, S.V. Plotnikov, and O. Maksakova, “The effects of Cr and Si additions and deposition conditions on the structure and properties of the (Zr–Ti–Nb)N coatings,” Ceram. Int., 43, No. 1, 771–782 (2017).

A.D. Pogrebnjak, I.V. Yakushchenko, O.V. Bondar, O.V. Sobol’, V.M. Beresnev, K. Oyoshi, H. Amekura, and Y. Takeda, “Influence of implantation of Au-ions on the microstructure and mechanical properties of the nanostructured multielement (TiZrHfVNbTa)N coating,” Phys. Sol. State, 57, 1559–1564 (2015).

A.D. Pogrebnjak, M.V. Kaverin, and V.M. Beresnev, “Influence of the phase and elemental compositions and defect structure on the physicomechanical properties and tribotechnical characteristics of nanostructural Ti–Hf–Si–N coatings,” Tech. Phys., 59, 85–92 (2014).

A.D. Pogrebnjak, A.P. Shpak, V.M. Beresnev, D.A. Kolesnikov, Yu.A. Kunitskii, O.V. Sobol, V.V. Uglov, F.F. Komarov, A.P. Shypylenko, N.A. Makhmudov, A.A. Demyanenko, V.S. Baidak, and V.V. Grudnitskii, “Effect of thermal annealing in vacuum and in air on nanograin sizes in hard and superhard coatings Zr–Ti–Si–N,” J. Nanosci. Nanotechnol., 12, No. 12, 9213–9219 (2012).

S.-C. Liang, Z.-C. Chang, D.-C. Tsai, Y.-C. Lin, H.-S. Sung, M.-J. Deng, and F.-S. Shieu, “Effects of substrate temperature on the structure and mechanical properties of (TiVCrZrHf)N coatings,” Appl. Surf. Sci., 257, No. 17, 7709–7713 (2011).

C. Mitterer, P.H. Mayrhofer, M. Beschliesser, P. Losbichler, P. Warbichler, F. Hofer, P.N. Gibson, W. Gissler, H. Hruby, J. Musil, and J. Vlček, “Microstructure and properties of nanocomposite Ti–B–N and Ti–B–C coatings,” Surf. Coat. Technol., 120–121, 405–411 (1999).

P.H. Mayrhofer, C. Mitterer, J.G. Wen, J.E. Greene, and I. Petrov, “Self-organized nanocolumnar structure in superhard TiB2 thin films,” Appl. Phys. Lett., 86, No. 13, 131909–131909-3 (2005).

F. Kunc, J. Musil, P.H. Mayrhofer, and C. Mitterer, “Low-stress superhard TiB films prepared by magnetron sputtering,” Surf. Coat. Technol., 174–175, 744–753 (2003).

P.H. Mayrhofer and M. Stoiber, “Thermal stability of superhard Ti–B–N coatings,” Surf. Coat. Technol., 201, No. 13, 6148–6153 (2007).

M. Berger, L. Karlsson, M. Larsson, and S. Hogmark, “Low stress TiB2 coatings with improved tribological properties,” Thin Solid Films, 401, No. 1–2, 179–186 (2001).

M. Berger, E. Coronel, and E. Olsson, “Microstructure of d.c. magnetron sputtered TiB2 coatings,” Surf. Coat. Technol., 185, No. 2–3, 240–244 (2004).

M. Mikula, B. Grančič, V. Buršı́ková, A. Csuba, M. Držı́k, Š. Kavecký, A. Plecenik, and P. Kúš, “Mechanical properties of superhard TiB2 coatings prepared by DC magnetron sputtering,” Vacuum, 82, No. 2, 278–281 (2007).

M. Mikula, B. Grančič, T. Roch, T. Plecenik, I. Vávra, E. Dobročka, A. Šatka, V. Buršı́ková, M. Držı́k, M. Zahoran, A. Plecenik, and P. Kúš, “The influence of low-energy ion bombardment on the microstructure development and mechanical properties of TiBx coatings,” Vacuum, 85, No. 9, 866–870 (2011).

F. Lofaj, T. Moskalewicz, G. Cempura, M. Mikula, J. Dusza, and A. Czyrska-Filemonowicz, “Nanohardness and tribological properties of nc-TiB2 coatings,” J. Eur. Ceram. Soc., 33, No. 12, 2347–2353 (2013).

K.P. Budna, P.H. Mayrhofer, I. Neidhardt, É. Hegedűs, I. Kovács, L. Tóth, B. Pécz, and C. Mitterer, “Effect of nitrogen-incorporation on structure, properties and performance of magnetron sputtered CrB2,” Surf. Coat. Technol., 202, No. 13, 3088–3093 (2008).

K.L. Dahm, L.R. Jordan, J. Haase, and P.A. Dearnely, “Magnetron sputter deposition of chromium diboride coatings,” Surf. Coat. Technol., 108–109, 413–418 (1998).

D.V. Shtansky, F.V. Kiryukhantsev-Korneev, A.N. Sheveiko, I.A. Bashkova, O.V. Malochkin, E.A. Levashov, N.B. D'yakonova, and I.V. Lyasotsky, “Structure and properties of Ti–B–N, Ti–Cr–B–(N), and Cr–B–(N) coatings deposited by magnetron sputtering of targets prepared by self-propagating hightemperature synthesis,” Phys. Solid State, 47, 252–262 (2005).

M. Audronis, P.J. Kelly, R.D. Arnell, A. Leyland, and A. Matthews, “The structure and properties of chromium diboride coatings deposited by pulsed magnetron sputtering of powder targets,” Surf. Coat. Technol., 200, No. 5–6, 1366–1371 (2005).

M. Audronis, P.J. Kelly, A. Leyland, and A. Matthews, “Microstructure of direct current and pulse magnetron sputtered Cr–B coatings,” Thin Solid Films, 515, No. 4, 1511–1516 (2006).

É. Hegedűs, I. Kovács, B. Pécz, L. Tóth, K.P. Budna, and C. Mitterer, “Transmission electron microscopy of nanocomposite Cr single bond B–N thin films,” Vacuum, 82, No. 2, 209–213 (2007).

K.P. Budna, I. Neidhardt, P.H. Mayrhofer, and C. Mitterer, “Synthesis–structure–property relations for Cr–B–N coatings sputter deposited reactively from a Cr–B target with 20 at.% B,” Vacuum, 82, No. 8, 771–776 (2008).

S. Zhang, Z. Wang, P. Guo, P. Ke, M. Odén, and A. Wang, “Temperature induced superhard CrB2 coatings with preferred (001) orientation deposited by DC magnetron sputtering technique,” Surf. Coat. Technol., 322, 134–140 (2017).

M. Samuelsson, J. Jensen, U. Helmersson, L. Hultman, and H. Högberg, “ZrB2 thin films grown by high power impulse magnetron sputtering from a compound target,” Thin Solid Films, 526, 163–167 (2012).

L. Tengdelius, J. Birch, J. Lu, L. Hultman, U. Forsberg, E. Janzén, and H. Högberg, “Magnetron sputtering of epitaxial ZrB2 thin films on 4H-SiC(0001) and Si(111),” Phys. Status Solidi A, 211, No. 3, 636–640 (2014).

L. Tengdelius, M. Samuelsson, J. Jensen, J. Lu, L. Hultman, U. Forsberg, E. Janzén, and H. Högberg, “Direct current magnetron sputtered ZrB2 thin films on 4H-SiC(0001) and Si(100),” Thin Solid Films, 550, 285–290 (2014).

L. Tengdelius, G. Greczynski, M. Chubarov, J. Lu, U. Forsberg, L. Hultman, E. Janzén, and H. Högberg, “Stoichiometric, epitaxial ZrB2 thin films with low oxygen-content deposited by magnetron sputtering from a compound target: Effects of deposition temperature and sputtering power,” J. Cryst. Growth, 430, 55–62 (2015).

L. Tengdelius, J. Lu, U. Forsberg, L. Li, E. Janzén, and H. Högberg, “ZrB2 thin films deposited on GaN(0001) by magnetron sputtering from a ZrB2 target,” J. Cryst. Growth, 453, 71–76 (2016).

E. Broitman, L. Tengdelius, U.D. Hangen, J. Lu, L. Hultman, and H. Högberg, “High-temperature nanoindentation of epitaxial ZrB2 thin films,” Scr. Mater., 124, 117–120 (2016).

A.A. Goncharov, S.N. Dub, A.V. Agulov, and V.V. Petukhov, “Structure, composition, and mechanical properties of thin films of transition metals diborides,” J. Superhard Mater., 37, 422–428 (2015).

A.A. Goncharov, A.N. Yunda, H. Komsta, and P. Rogalski, “Effect of structure on physicomechanical properties of transition metals diboride films,” Acta Phys. Pol. A, 132, No. 2, 270–273 (2017).

A.A. Goncharov, V.A. Konovalov, S.N. Dub, V.A. Stupak, and V.V. Petukhov, “Structure, composition, and physicomechanical characteristics of tantalum diboride films,” Phys. Met. Metall., 107, 285–290 (2009).

A.A. Goncharov, S.N. Dub, and A.V. Agulov, “Structure, composition, and physicomechanical characteristics of HfB2 and Hf–B–N films,” Phys. Met. Metall, 114, 95–101 (2013).

A.A. Goncharov, V.A. Konovalov, G.K. Volkova, and V.A. Stupak, “Size effect on the structure of nanocrystalline and cluster films of hafnium diboride,” Phys. Met. Metall., 108, 368–373 (2009).

V. Buranich, A. Pogrebnjak, P. Budzynski, I. Shelest, A. Prószyński, D. Chocyk, A. Goncharov, and A. Yunda, “Mechanical and tribological characterization of nanostructured HfB2 films deposited from compound target,” SN Appl. Sci., 2, 563 (2020).

A.A. Goncharov, V.V. Petukhov, D.N. Terpii, and P.I. Ignatenko, “Composition of thin films obtained by the reaction method on substrates of tantalum and tungsten,” Metallofiz. Noveish. Tekhnol., 27, No. 7, 865–872 (2005).

S. Yakovin, A. Zykov, S. Dudin, A. Goncharov, and I. Shelest, “Plasma assisted deposition of TaB2 coatings by magnetron sputtering system,” Probl. Atom. Sci. Technol., 107, No. 1, 187–190 (2017).

A. Mockute, J. Palisaitis, B. Alling, P. Berastegui, E. Broitman, L.-Å. Näslund, N. Nedfors, J. Lu, J. Jensen, L. Hultman, J. Patscheider, U. Jansson, P.O.Å. Persson, and J. Rosen, “Age hardening in (Ti1−xAlx)B2+∆ thin films,” Scr. Mater., 127, 122–126 (2017).

P.H. Mayrhofer, A. Kirnbauer, Ph. Ertelthaler, and C.M. Koller, “High-entropy ceramic thin films. A case study on transition metal diborides,” Scr. Mater., 149, 93–97 (2018).

A. Kirnbauer, A. Wagner, V. Moraes, D. Primetzhofer, M. Hans, J.M. Schneider, P. Polcik, and P.H. Mayrhofer, “Thermal stability and mechanical properties of sputtered (Hf, Ta, V, W, Zr)-diborides,” Acta Mater., 200, 559–569 (2020).

A.A. Goncharov, G.K. Volkova, V.A. Konovalov, and V.V. Petukhov, “Substrate effect on the orientation and structure of thin films produced by rf magnetron sputtering of tantalum diboride targets,” Metallof. Noveish. Tekhnol., 28, No. 12, 1621–1628 (2006).

P.H. Mayrhofer, C. Mitterer, L. Hultman, and H. Clemens, “Microstructural design of hard coatings,” Progr. Mater. Sci., 51, 1032–1114 (2006).

A.A. Goncharov, A.N. Yunda, A.V. Zykov, V.I. Farenik, I.V. Shelest, and V.V. Buranich, “Analysis of synthesis condition of hard tantalum diboride coatings in magnetron sputtering systems,” J. Surf. Phys. Eng., 2, No. 2–3, 105–114 (2017).

A.A. Goncharov, A.V. Zykov, A.N. Yunda, I.V. Shelest, and V.V. Buranich, “Effect of energy factors on the structure and substructure characteristics of hafnium diboride films deposited by rf magnetron sputtering,” Metallophys. Adv. Technol., 42, No. 6, 815–827 (2020).

B. Bakhit, J. Palisaitis, Z. Wu, M.A. Sortica, D. Primetzhofer, O.Å. Persson, J. Rosen, L. Hultman, I. Petrov, J.E. Greene, and G. Greczynski, “Age hardening in superhard ZrB2-rich Zr1–xTaxBy thin films,” Scr. Mater., 191, 120–125 (2021).

A.V. Khomenko, D.S. Troshchenko, and L.S. Metlov, “Effect of stochastic processes on structure formation in nanocrystalline materials under severe plastic deformation,” Phys. Rev. E, 100, 022110–022110-12 (2019).

A.V. Khomenko and I.A. Lyashenko, “Melting of ultrathin lubricant film due to dissipative heating of friction surfaces,” Techn. Phys., 52, No. 9, 1239–1243 (2007).

J.W. Christian, The Theory of Transformations in Metals and Alloys, Elsevier Ltd (2002), p. 1198.

A.V. Khomenko, I.A. Lyashenko, and L.S. Metlov, “Phase dynamics and kinetics of severe plastic deformation,” Metallofiz. Novejsh. Tekhnol., 30, No. 6, 859–872 (2008).

A.A. Goncharov, A.V. Agulov, V.A. Stupak, and V.V. Petukhov, “Structure and composition of hafnium diboride films,” Inorg. Mater., 47, No. 6, 592–596 (2011).

Acknowledgments

The research was funded by the Ministry of Education and Science of Ukraine under Project ‘Mechanisms for Forming and Modeling the Structural State of Refractory Films with Predictable Mechanical Characteristics’ (No. 0122U000776) and Scholarship for Outstanding Researchers Threatened by the Military Conflict in Ukraine (Slovakia, 09I03-03-V01-00028, (2023‒2026)).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Poroshkova Metallurgiya, Vol. 62, Nos. 5–6 (551), pp. 60–76, 2023.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Goncharov, O.A., Kolinko, I.S., Kornich, G.V. et al. Structural Characteristics and Their Influence on the Properties of Transition Metal Nitride and Boride Films (Overview). Powder Metall Met Ceram 62, 312–325 (2023). https://doi.org/10.1007/s11106-023-00395-0

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-023-00395-0