Abstract

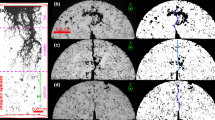

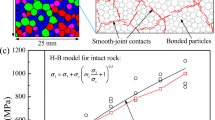

Dissolution pores have a notable impact on the mechanical behavior of rock masses. Understanding the mechanisms by which dissolution pores influence the mechanics of rock is crucial for various engineering projects, including slope and foundation stability and related disaster mechanisms. Dissolved pores can be divided into two main types: honeycomb- and wormhole-like pores. In this study, a random algorithm was used to create discrete-element rock samples with different dissolution pore structures. Two characteristic dissolution parameters (rate of dissolution(k) and dissolution density coefficient (u)) were defined. They were used to describe the dissolution characteristics. We analyzed the internal stress, uniaxial compressive strength, crack propagation, and failure mode characteristics of the dissolved rock samples during the loading process. The results showed that rocks with different dissolution pore structures exhibit distinct mechanical behavior. Wormhole-like porous rock samples have higher uniaxial compressive strength and strength variability due to their different stresses. Furthermore, the uniaxial compressive strength of the dissolved rock is a function of the characteristic dissolution parameters. The deformation process of the porous dissolution sample was divided into four stages: (1) elastic deformation, (2) unstable fracture development, (3) post-peak strain softening, and (4) failure. Cracks in honeycomb-like dissolution rock were mainly initiated at the pore poles, and the failure mode was a shear failure, whereas cracks in the wormhole-like dissolution rock were mainly initiated at the pore poles and sidewalls, and the failure was rock crushing failure.

Similar content being viewed by others

References

Chen D, Yi C (2017) Study on roof safe thickness of rock foundation with Karst cave and karst cave-surrounding rock stability. IOP Conf Ser Mater Sci Eng 224(1):012058. https://doi.org/10.1088/1757-899X/224/1/012058

Leng D, Shi W, Liang F, Li H, Yan L (2023) Stability and deformation evolution analysis of karstified slope subjected to underground mining based on Hoek-Brown failure criterion. Bull Eng Geol Env 82(5):17. https://doi.org/10.1007/s10064-023-03211-6

Zhang L, Fu H, Wu J, Zhang X, Zhao D (2021) Effects of karst cave shape on the stability and minimum safety thickness of tunnel surrounding rock. Int J Geomech 21(9):04021150. https://doi.org/10.1061/(ASCE)GM.1943-5622.0002054

Wang X, Xiao Y, Shi W, Ren J, Liang F, Lu J, Li H, Yu X (2022) Forensic analysis and numerical simulation of a catastrophic landslide of dissolved and fractured rock slope subject to underground mining. Landslides 19(5):1045–1067. https://doi.org/10.1007/s10346-021-01842-y

Xin L, Mingzhou B, Zijun W, Pengxiang L, Hai S, Ye Z (2021) Dynamic response and stability analysis of high-speed railway subgrade in Karst areas. IEEE Access 9:129188–129206. https://doi.org/10.1109/ACCESS.2021.3113706

Asadizadeh M, Hossaini M, Moosavi M, Masoumi H, Ranjith P (2019) Mechanical characterisation of jointed rock-like material with non-persistent rough joints subjected to uniaxial compression. Eng Geol 260:105224. https://doi.org/10.1016/j.enggeo.2019.105224

Fan X, Kulatilake P, Chen X (2015) Mechanical behavior of rock-like jointed blocks with multi-non-persistent joints under uniaxial loading: a particle mechanics approach. Eng Geol 190:17–32. https://doi.org/10.1016/j.enggeo.2015.02.008

Wu T, Gao Y, Zhou Y, Li J (2020) Experimental and numerical study on the interaction between holes and fissures in rock-like materials under uniaxial compression. Theoret Appl Fract Mech 106:102488. https://doi.org/10.1016/j.tafmec.2020.102488

Yousif OS, Karakouzian M, Rigby DB (2021) Impacts of void existence on mechanical behavior of tuff-like lithophysal material. Rock Mech Rock Eng 54(3):1315–1330. https://doi.org/10.1007/s00603-020-02322-w

Xie S, Shao J, Xu W (2011) Influences of chemical degradation on mechanical behaviour of a limestone. Int J Rock Mech Min Sci 48(5):741–747. https://doi.org/10.1016/j.ijrmms.2011.04.015

Li H, Yang D, Zhong Z, Sheng Y, Liu X (2018) Experimental investigation on the micro damage evolution of chemical corroded limestone subjected to cyclic loads. Int J Fatigue 113:23–32. https://doi.org/10.1016/j.ijfatigue.2018.03.022

Lin Y, Zhou K, Li J, Ke B, Gao R (2020) Weakening laws of mechanical properties of sandstone under the effect of chemical corrosion. Rock Mech Rock Eng 53(4):1857–1877. https://doi.org/10.1007/s00603-019-01998-z

Luo T, Fan G, Guo B, Zhang S (2021) Experimental study on the influence of hydro-chemical erosion on morphology parameters and shear properties of limestone fractures. Acta Geotech 16(12):3867–3880. https://doi.org/10.1007/s11440-021-01365-9

Al NahariAlhashmi Z, Blunt M, Bijeljic B (2016) The impact of pore structure heterogeneity, transport, and reaction conditions on fluidfluid reaction rate studied on images of pore space. Transp Porous Media 115(2):215–237. https://doi.org/10.1007/s11242-016-0758-z

Liu M, Mostaghimi P (2017) Pore-scale simulation of dissolution-induced variations in rock mechanical properties. Int J Heat Mass Transf 111:842–851. https://doi.org/10.1016/j.ijheatmasstransfer.2017.04.049

He P, Kulatilake P, Yang X, Liu D, He M (2018) Detailed comparison of nine intact rock failure criteria using polyaxial intact coal strength data obtained through PFC 3D simulations. Acta Geotech 13(2):419–445. https://doi.org/10.1007/s11440-017-0566-9

Wong R, Lin P (2015) Numerical study of stress distribution and crack coalescence mechanisms of a solid containing multiple holes. Int J Rock Mech Min Sci 79:41–54. https://doi.org/10.1016/j.ijrmms.2015.08.003

Yang J, Weizhong C, Diansen Y, Yuan J (2015) Numerical determination of strength and deformability of fractured rock mass by FEM modeling. Comput Geotech 64:20–31. https://doi.org/10.1016/j.compgeo.2014.10.011

Zhang C, Tu S, Bai Q (2018) Evaluation of pore size and distribution impacts on uniaxial compressive strength of lithophysal rock. Arab J Sci Eng 43(3):1235–1246. https://doi.org/10.1007/s13369-017-2810-x

Cheng Y, Jiao Y, Tan F (2019) Numerical and experimental study on the cracking behavior of marble with En-Echelon flaws. Rock Mech Rock Eng 52(11):4319–4338. https://doi.org/10.1007/s00603-019-01849-x

Xie L, Jin P, Su T, Li X, Liang Z (2020) Numerical simulation of uniaxial compression tests on layered rock specimens using the discrete element method. Comput Part Mech 7(4):753–762. https://doi.org/10.1007/s40571-019-00307-3

Zhang S, Wang X, Wang C (2017) Effects of pore structure and its development degree on dissolution rock mechanical characteristics. J Tianjin Univ Sci Technol 50(10):1018–1028. https://doi.org/10.11784/tdxbz201611016. (In Chinese)

Wu S, Xu X (2016) A study of three intrinsic problems of the classic discrete element method using flat-joint model. Rock Mech Rock Eng 49(5):1813–1830. https://doi.org/10.1007/s00603-015-0890-z

Chen P (2017) Effects of microparameters on macroparameters of flat-jointed bonded-particle materials and suggestions on trial-and-error method. Geotech Geol Eng 35(2):663–677. https://doi.org/10.1007/s10706-016-0132-5

Xu X, Wu S, Gao Y, Xu M (2016) Effects of micro-structure and micro-parameters on Brazilian tensile strength using flat-joint model. Rock Mech Rock Eng 49(9):3575–3595. https://doi.org/10.1007/s00603-016-1021-1

Potyondy D (2017) Simulating perforation damage with a flat-jointed bonded-particle material. 51st US Rock Mechanics/Geomechanics Symposium.

Yang X, Qiao W (2018) Numerical investigation of the shear behavior of granite materials containing discontinuous joints by utilizing the flat-joint model. Comput Geotech 104:69–80. https://doi.org/10.1016/j.compgeo.2018.08.014

Potyondy D (2013) PFC3D flat joint contact model version 1. Itasca Consulting Group, Minneapolis

Itasca C (2014) PFC (particle flow code in 2 and 3 dimensions), version 5.0 [User’s manual]. Numer Anal Methods Geomech 32(6):189–213

Elkhoury JE, Ameli P, Detwiler RL (2013) Dissolution and deformation in fractured carbonates caused by flow of CO2-rich brine under reservoir conditions. Int J Greenhouse Gas Control 16:S203–S215. https://doi.org/10.1016/j.ijggc.2013.02.023

Garcia-Rios M, Luquot L, Soler JM, Cama J (2015) Influence of the flow rate on dissolution and precipitation features during percolation of CO2-rich sulfate solutions through fractured limestone samples. Chem Geol 414:95–108. https://doi.org/10.1016/j.chemgeo.2015.09.005

Luquot L, Rodriguez O, Gouze P (2014) Experimental characterization of porosity structure and transport property changes in limestone undergoing different dissolution regimes. Transp Porous Media 101(3):507–532. https://doi.org/10.1007/s11242-013-0257-4

Wang X, Lei Q, Lonergan L, Jourde H, Gosselin O, Cosgrove J (2017) Heterogeneous fluid flow in fractured layered carbonates and its implication for generation of incipient karst. Adv Water Res 107:502–516. https://doi.org/10.1016/j.advwatres.2017.05.016

Lin J, Chen H, Liu L, Zhang R (2020) Impact of particle size ratio on the percolation thresholds of 2D bidisperse granular systems composed of overlapping superellipses. Phys A Stat Mech Appl 544:123564. https://doi.org/10.1016/j.physa.2019.123564

Chen P (2017) Effects of microparameters on macroparameters of flat-jointed bonded-particle materials and suggestions on trial-and-error method. Geotech Geol Eng 35:663–677. https://doi.org/10.1007/s10706-016-0132-5

Ford D, Williams PD (2013) Karst hydrogeology and geomorphology. John Wiley & Sons

Jordan G, Rammensee W (1998) Dissolution rates of calcite (1014) obtained by scanning force microscopy: Microtopography-based dissolution kinetics on surfaces with anisotropic step velocities. Geochim Cosmochim Acta 62(6):941–947. https://doi.org/10.1016/S0016-7037(98)00030-1

Han T, Shi J, Chen Y, Cao X (2018) Quantifying microstructural damage of sandstone after hydrochemical corrosion. Int J Geomech 18(10):04018121. https://doi.org/10.1061/(ASCE)GM.1943-5622.0001237

Zhu W, Baud P, Wong TF (2010) Micromechanics of cataclastic pore collapse in limestone. J Geophys Res Solid Earth 115:B04405. https://doi.org/10.1029/2009JB006610

Acknowledgements

The National Natural Science Foundation of China (Grant No. 42067046). The National Key R&D Program of China (2022YFC3003300) and Science and Technology Planning Project of Guizhou Province, China (Grant Nos. QKHJC-ZK[2021]YB228, QKHJC-ZK[2022]YB075).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Leng, D., Shi, W., Liang, F. et al. Numerical analysis of the influence of dissolution pore structure on mechanical behavior of rock mass. Comp. Part. Mech. (2023). https://doi.org/10.1007/s40571-023-00697-5

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40571-023-00697-5