Abstract

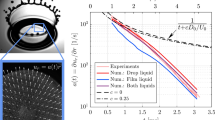

The results of studies concerning the effect of ultrasonic impact parameters exerted on the characteristics of a formed aerosol are presented. Based on high-speed filming performed under spraying a drop of a model liquid, a qualitative description of changes in the aerosol parameters is given depending on the viscosity of the liquid and the amplitude of ultrasonic oscillations. In the course of computer processing of video fragments, the aerosol concentration, the average size of the droplets, and their motion velocity have been determined.

Similar content being viewed by others

REFERENCES

P. Bleys and J. P. Kruth, B. Lauwers, et al., “Surface and sub-surface quality of steel after EDM,” Adv. Eng. Mater. 8, 15–25 (2006).

V. A. Aleksandrov, S. K. Sundukov, D. S. Fatyukhin, et al., “Ultrasonic methods for improving object surface quality prepared by corrosion-resistant steel powder selective laser melting,” Met. Sci. Heat Treat. 60, 381–386 (2018).

D. S. Fatyukhin, “Change in the surface roughness of machine parts under the influence of ultrasonic liquid processing,” Vestn. Mosk. Avtomob.-Dorozh. Gos. Tekh. Univ., No. 4, 30–35 (2010).

T. Zlamal, I. Mrkvica, T. Szotkowski, et al., “The influence of surface treatment of PVD coating on its quality and wear resistant,” Coatings 9, 439 (2019).

S. Pal Dey and S. C. Deevi “Single layer and multilayer wear resistant coatings of (Ti,Al) N: A review,” Mater. Sci. Eng., A 342, 58–79 (2003).

P. G. Grutzmacher, S. Suarez, A. Tolosa, et al., “Superior wear-resistance of Ti3C2T X multilayer coatings,” ACS nano 15, 8216–8224 (2021).

D. Ebert and B. Bhushan, “Transparent, superhydrophobic, and wear-resistant coatings on glass and polymer substrates using SiO2, ZnO, and ITO nanoparticles,” Langmuir 28, 11391–11399 (2012).

D. S. Fatyukhin, R. I. Nigmetzyanov, V. M. Prikhodko, et al., “A comparison of the effects of ultrasonic cavitation on the surfaces of 45 and 40Kh steels,” Metals 12, 138 (2022).

V. M. Prikhod’ko, R. I. Nigmetzyanov, S. K. Sundukov, et al., “Innovative technological processes using ultrasound,” Naukoemkie Tekhnol. Mashinostr., No. 7, 11–14 (2017).

A. Szewczak and M. Szelag, “Modifications of epoxy resins and their influence on their viscosity,” IOP Conf. Ser.: Mater. Sci. Eng. 471 022038 (2019).

P. K. Ghosh, K. Kumar, P. Preeti, et al., “Superior dissimilar adhesive joint of mild steel and aluminium using UDM processed epoxy based TiO2 nano-filler composite adhesive,” Composites, Part B 99, 224–234 (2016).

V. V. Kartashova and N. I. Baurova, “A study of the properties of polymer coatings based on an organosilicon material,” Polym. Sci., Ser. D 15, 374–378 (2022).

V. V. Kartashova and N. I. Baurova, “A study of the performance characteristics of coatings used for treating inner surfaces of road-machine working tools,” Polym. Sci., Ser. D 12, 435–439 (2019).

Q. Ye and K. Pulli, “Numerical and experimental investigation on the spray coating process using a pneumatic atomizer: influences of operating conditions and target geometries,” Coatings 7, 13 (2017).

E. A. Zverev and V. Skeeba, N. Martyushev, et al., “Integrated quality ensuring technique of plasma wear resistant coatings,” Key Eng. Mater. 736, 132–137 (2017).

M. E. Bahrololoom and R. Sani, “The influence of pulse plating parameters on the hardness and wear resistance of nickel-alumina composite coatings,” Surface Coat. Technol. 192, 154–163 (2005).

S. Sundukov, R. Nigmetzyanov, V. Prikhodko, et al., “Sequential treatment of steel surfaces by nitriding and ultrasonic hardening,” Key Eng. Mater. 910, 484–489 (2022).

S. K. Sundukov, R. I. Nigmetzyanov, and D. S. Fatyukhin, “Structure of the weld formed during the application of ultrasonic vibrations,” Russ. Metall. 2021, 1667–1672 (2021).

T. J. Mason, “Use of ultrasound in chemical synthesis,” Ultrasonics 24, 245–253 (1986).

Funding

The work was financially supported by the Russian Science Foundation, project no. 21-19-00660, https://rscf.ru/project/21-19-00660/.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors of this work declare that they have no conflicts of interest.

Additional information

Translated by O. Polyakov

Publisher’s Note.

Pleiades Publishing remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Nigmetzyanov, R.I., Sundukov, S.K., Sukhov, A.V. et al. The Effect of Liquid Viscosity on Aerosol Parameters upon Ultrasonic Spraying. Polym. Sci. Ser. D 16, 978–983 (2023). https://doi.org/10.1134/S1995421223040238

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1995421223040238