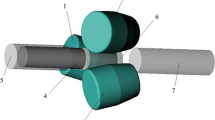

Computer simulation of the processes of three- and four-roller screw rolling was performed using the QForm finite element analysis computing environment with a constant and variable friction factor for roll–billet pairs. Simulation results at a constant friction factor showed that in the longitudinal section of the billet after four-roller rolling, the average value of the accumulated deformation is higher compared to three-roller rolling, and the deformation penetrates deep into the billet. The results also showed that four-roller rolling proceeds faster than three-roller rolling with a constant and variable friction factor. An analysis of the estimated speed of the billet movement during three- and four-roller rolling revealed that the return to a stable process after a sharp decrease in speed occurs faster in four-roller screw rolling than in three-roller rolling due to insufficient friction between the roll and the billet.

Similar content being viewed by others

References

S. Dobatkin, S. Galkin, Yu. Estrin, V. Serebryany, M. Diez, N. Martynenko, E. Lukyanova, and V. Perezhogin, “ Grain refinement, texture, and mechanical properties of a magnesium alloy after radial-shear rolling,” J. Alloys Compd., 774, 969–979 (2019).

B. Karpov, P. Patrin, S. Galkin, E. Kharitonov, and I. Karpov, “Alloy VT-8 bars with controlled structure for small diameter radialshear rolling of titanium ingots (< 200 mm),” Metallurgist, 61, No. 9–10, 884–890 (2018).

S. P. Galkin, B. A. Romantsev, D. X. Ta, and Yu. V. Gamin, “ Resource-saving technology for production of round bars from used shaft of rolling railroad stock,” Chern. Metally, Issue 4, 20–27 (2018).

Yu. Gamin, T. Akopyan, A. Koshmin, A. Dolbachev, and A. Goncharuk, “ Microstructure evolution and property analysis of commercial pure Al alloy processed by radial-shear rolling,” Arch. Civ. Mech. Eng., 20, Art. No. 143 (2020).

Yu. Gamin, A. Koshmin, A. Dolbachev, S. Galkin, A. Aleschenko, and M. Kadach, “Studying the influence of radial-shear rolling on thermal deformation conditions of A1050 Processing,” Russ, J. Non-Ferr. Metals, 61, No. 6, 646–657 (2020).

A. Stefanik, P. Szota, S. Mroz, and H. Dyja, “ Application of the three-high skew rolling to magnesium rods production,” Mater. Testing, 58, No. 5, 438–441 (2016).

A. Stefanik, P. Szota, S. Mroz, T. Bajor, and S. Boczkal, “ Influence of the deformation method on the microstructure changes in AZ31 magnesium alloy round rods obtained by the rolling process,” Key Eng. Mater., 716, 864–870 (2016).

Li Wang Ya, A. Molotnikov, M. Diez, R. Lapovok, Kim Hyoun-Ee, Tao Wang Jing, and Yu. Estrin, “Gradient structure produced by three roll planetary milling: Numerical simulation and microstructural observations,” Mater. Sci. Eng., A., 639, 165–172 (2014).

S. P. Galkin, B. A. Romantsev, and E. A. Kharitonov, “Implementation of the innovative potential of the universal method of radial shear rolling,” Chern. Metally, No. 1, 23–28 (2015).

Z. Pater, “A comparative analysis of forming railway axles in 3- and 4-roll rolling mills,” Materials, 13, No. 14, 3084 (2020).

B. A. Romantsev, A. V. Goncharuk, N. M. Vavilkin, and S. V. Samusev, Pipe Production [in Russian], 2nd ed., cor. and add., ID MISIS, Moscow (2011).

B. A. Romantsev, I. N. Potapov, A. V. Goncharuk, and V. A. Popov, Production of Hollow Profiled Billets [in Russian], NPO Inform TEI, Moscow (1992).

P. K. Teterin, Theory of Screw Rolling [in Russian], Metallurgiya, Moscow (1973).

B. A. Romantsev, B. Kh. Chan, M. M. Skripalenko, M. N. Skripalenko, A. A. Gartvig, and Yu. A. Gladkov, “ Investigation of the screw rolling process in a four-roller stand by simulation,” Metallurg, No. 7, 15–20 (2018).

B. A. Romantsev, Ba Hui Chan, M. M. Skripalenko, M. N. Skripalenko, Yu. A. Gladkov, and S. A. Odnokozova, “Simulation of the process of screw piercing in a four-roll stand,” Stal’, No. 8, 32–35 (2018).

M. M. Skripalenko, Ch. B. Khui, B. A. Romantsev, S. P. Galkin, and S. V. Samusev, “ Investigation of the characteristics of the stress-strain state of billets with different schemes of screw rolling using computer simulation,” Stal’, No. 2, 35–39 (2019).

V. S. Komlev, B. A. Romantsev, M. M. Skripalenko, and V. S. Yusupov, “Advantages of the new four-roll mill compared to existing screw rolling equipment based on computer simulation,” in: in the book Modern Materials and Advanced Production Technologies (SMPPT-2019), Abstracts of Reports at the Int. Scientific-Conf. (2019), pp. 46–47.

V. S. Komlev, V. S. Yusupov, V. A. Andreev, B. A. Romantsev, M. M. Skripalenko, A. S. Budnikov, and R. D. Karelin, Patent RU 2722952 C1 IPC B21B 19/00, No. 2019119313 decl. 06/20/2019; publ. 06/05/2020, Bull. No. 16.

B. A. Romantsev, M. M. Skripalenko, V. S. Yusupov, and V. A. Andreev, “ Evaluation of the stress-strain state in the processes of piercing based on computer simulation,” Tyazhel. Mashinostr., No. 5–6, 46–49 (2020).

V. S. Yusupov, B. A. Romantsev, M. M. Skripalenko, V. A. Andreev, A. V. Erokhin, A. A. Myshechkin, and A. E. Kasumov, “Simulation of characteristics of the stress-strain state of billets in the processes of screw rolling,” Stal’, No. 6, 17–19 (2021).

B. A. Romantsev, V. A. Andreev, V. S. Yusupov, and M. M. Skripalenko, Patent RU 2764066 C2 IPC V21V 19/02, Screw Rolling Mill, No. 2020115423, submitted 05/06/2020; publ. 01/13/2022, Bull. No. 2.

B. A. Romantsev, M. M. Skripalenko, Ba Hui Chan, M. N. Skripalenko, Yu. A. Gladkov, and A. A. Gartwig, “Computer simulation of billet piercing in a four-roll screw rolling mill,” Metallurg, No. 9, 19–24 (2017).

M. M. Skripalenko, Ba Hui Chan, B. A. Romantsev, M. N. Skripalenko, and A. A. Sidorov, Simulation in DEFORM-3 of the Piercing Process in a Four-Roll Mill, Engineering Systems-2017 [in Russian], Proc. Int. Forum, Moscow, April 11–12, 169–176 (2017).

B. A. Romantsev, M. M. Skripalenko, and Ba Hui Chan, Patent RU 2635685 C1 IPC V21V 19/04, The Method of Piercing in a Screw Rolling Mill, Publ. 11/15/2017, Bull. No. 32.

A. V. Vlasov, S. A. Stebunov, S. A. Evsyukov, N. V. Biba, and A. A. Shitikov, Finite Element Modeling of Technological Processes of Forging and Bulk Forming [in Russian], Izd. MGTU im. N. E. Baumana, Moscow (2019).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallurg, Vol. 67, No. 7, pp. 102–107, July, 2023.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Skripalenko, M.M., Romantsev, B.A., Gartvig, A.A. et al. Simulation of Screw Rolling Processes at Constant and Variable Friction Along the Contact Surface Between Roll and Billet. Metallurgist 67, 1021–1028 (2023). https://doi.org/10.1007/s11015-023-01592-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11015-023-01592-3