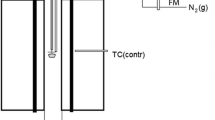

The density and surface tension of homogeneous molten slags from the joint smelting of nickel saprolite and copper pyrite ores have been experimentally assessed (maximum bubble pressure method) using model samples of iron-containing slage (8.9 wt.% CaO + 11.8 wt.% MgO + 12.5 wt.% Al2O3 + 47.4 wt.% SiO2 + 13.3 wt.% FeO + 5.0 wt.% Fe2O3) and iron-free slag (12.5 wt.% CaO + 16.0 wt.% MgO + 9.4 wt.% Al2O3 + 58.3 wt.% SiO2), which represent the composition and structure of real prototypes in the temperature ranges of 1550–1300°C and 1550–1400°C, respectively. A decrease in temperature leads to an increase in the density and surface tension of these slags in the ranges of 1.85–2.21 and 2.23–2.29 g·cm–3 and 144–250 and 340–345 mN·m–1, respectively. The structural changes after the change over from the former composition to the latter one are due to the decrease in basicity from 0.7 to 0.6 and the replacement of Fe2+ by Ca2+ and Mg2+. The latter factor makes the major contribution to the increase of the characteristics themselves and their temperature coefficients (from –0.0015 to –0.0004 g·cm–3·°C–1 and from –0.4 to –0.1 mN·m–1·°C–1, respectively). The regression analysis of the experimental data was performed to obtain empirical models that accurately predict the density and surface tension of real slags from the smelting of copper and nickel raw materials in the temperature range considered. The results obtained can be used in developing and improving metallurgical technologies and in the glass and ceramic industries.

Similar content being viewed by others

References

I. D. Reznik, S. I. Sobol’, and V. M. Khudyakov, Cobalt [in Russian], Vol. 1, Mashinostroenie, Moscow (1995).

M. E. Schlesinger, M. J. King, K. C. Sole, and W. G. Davenport, Extractive Metallurgy of Copper, Elsevier, Amsterdam, Boston, Heidelberg, London, New York, Oxford, Paris, San Diego, San Francisco, Singapore, Sydney, Tokyo (2011).

P. Meshram, Abhilash, and B. D. Pandey, “Advanced review on extraction of nickel from primary and secondary sources,” Mineral Process. Extract. Metallurgy Rev., 40, No. 3, 157–193 (2018).

F. K. Crundwell, M. S. Moats, V. Ramachandran, T. G. Robinson, and W. G. Davenport, Extractive Metallurgy of Nickel, Cobalt and Platinum-Group Metals, Elsevier, Oxford (2011).

J. G. Dunn and S. A. A. Jayaweera, “ Effect of heating rate on the TG curve during the oxidation of nickel sulphide concentrates,” Thermochimica Acta, 61, 313–317 (1983).

S. M. Kozhakhmetov, S. A. Kvyatkovsky, M. K. Sultanov, Z. K. Tulegenova, and A. S. Semenova, “Processing of oxidized copper ores and sulfide copper concentrates from the Aktogay deposite by pyrometallurgical methods,” Compl. Use Miner. Resours., No. 3, 54–62 (2018).

E. N. Selivanov, A. M. Klyushnikov, and R. I. Gulyaeva, “Use of quartz-containing materials as fluxes in copper smelting production,” Metallurgist, 61, No. 1-2, 155–161 (2017).

E. N. Selivanov, R. I. Gulyaeva, and A. M. Klyushnikov, “Studying the structure and phase composition of copper and cobalt sulfide ores from the Dergamysh deposit,” Tsvetn. Metally, No. 3 (879), 13–17 (2016).

E. N. Selivanov, A. M. Klyushnikov, and R. I. Gulyaeva, “Application of sulfide copper ores oxidizing roasting products as sulfidizing agent during melting nickel raw materials to matte,” Metallurgist, 63, No. 7-8, 83–90 (2019).

A. M. Klyushnikov, R. I. Gulyaeva, E. N. Selivanov, and S. M. Pikalov, “Kinetics and mechanism of oxidation for nickel- containing pyrrhotite tailings,” Int. J. Mineral. Metallurg. Mater., 28, No. 9, 1469–1477 (2021).

A. M. Klyushnikov and E. N. Selivanov, “Thermodynamic modeling of the joint processing of oxidized nickel ores and sulfide copper-bearing ores,” Butlerov Communic., 49, No. 1, 34–42 (2017).

A. M. Klyushnikov and G. I. Mal’tsev, “Optimizing the conversion of the matte of the joint smelting of oxidized nickel and copper sulfide ores through thermodynamic modeling,” Izv. VUZov: Tsvetn. Metallurg., 28, No. 6, 12–21 (2022).

A. Klyushnikov, R. Gulyaeva, and S. Pikalov, “ Cold crystallization kinetics of slag from the joint smelting of oxidized nickel and sulfide copper ores,” J. Therm. Analys. Calorimetry, 117, 12165–12176 (2022).

L. Muhmood and S. Seetharaman, “ Density measurements of low silica CaO–SiO2–Al2O3 slags,” Metallurg. Mater. Trans. B, 41, 833–840 (2010).

R. Rajavaram, H. Kim, C. Hoon Lee, W. S. Cho, C. Hwan Lee, and J. Lee, “Effect of Al2O3 concentration on density and structure of (CaO–SiO2)–xAl2O3 slag,” Metallurg. Mater. Trans. B, 48, 1595–1601 (2017).

H. Taniguchi, “ Densities of melts in the system CaMgSi2O6–CaAl2Si2O8 at low and high pressures, and their structural significance,” Contribution to Mineralogy and Petrology, 103, 325–334 (1989).

P. Vadasz, M. Havlik, and V. Danek, “ Density and surface tension of the systems CaO–FeO–Fe2O3–MgO, CaO–FeO–Fe2O3–ZnO and CaO–Fe2O3–Cu2O,” Centr. Europ. J. Chem., 4, 174–193 (2006).

J. F. Xu, K. Wan, J. Y. Zhang, J. Chang, L. Tang, and K. C. Chou, “ Measuring and modeling of density for selected CaO–MgO– Al2O3–SiO2 slag with low silica,” J. Iron and Steel Res. Int., 19, No. 7, 26–32 (2012).

J. F. Xu, K. Wan, J. Y. Zhang, Y. Chen, and M. Q. Sheng, “ Measuring and modelling of density for selected CaO–Al2O3–MgO slags,” The Journal of The Southern African Institute of Mining and Metallurgy, 115, 767–772 (2015).

Slag Atlas, Committee for Fundamental Metallurgy of the Verin Deutscher Eisenhürrenleute, Verlag Stahleisen, Düsseldorf (1981).

A. V. Vanyukov and V. Ya. Zaitsev, Mattes and Slags of Nonferrous Metallurgy [in Russian], Metallurgiya, Moscow (1969).

J. F. Xu, J. Y. Zhang, D. Chen, M. Q. Sheng, and W. P. Weng, “Effects of MgO content and CaO/Al2O3 ratio on surface tension of calcium aluminate refining slag,” J. of Central South University, 23, 3079–3084 (2016).

S. Vargas, F. J. Frandsen, and K. Dam-Johansen, “ Rheological properties of high-temperature melts of coal ashes and other silicates,” Progress in Energy and Combustion Science, 27, 237–429 (2001).

P. P. Arsent’ev., V. V. Yakovlev, M. G. Krasheninnikov, L. A. Pronin, and E. S. Filippov, Physical and Chemical Methods for Studying Metallurgical Processes [in Russian], Metallurgiya, Moscow (1988).

P. P. Arsent’ev, S. N. Paderin, G. V. Serov, D. I. Ryzhonkov, M. G. Krasheninnikov, and N. B. Kazakov, Experimental Studies on the Theory of Metallurgical Processes [in Russian], Metallurgiya, Moscow (1989).

B. V. Linchevskii, Methods of Metallurgical Experiment, Mir, Moscow (1982).

Acknowledgments

The study was carried out in compliance with the governmental task to the Institute of Metallurgy, Ural Division of the Russian Academy of Sciences (state registration No. 122020100404–2).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallurg, Vol. 67, No. 7, pp. 59–66, July, 2023

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Klyushnikov, A.M., Chentsov, V.P., Agafonov, S.N. et al. Density and Surface Tension of Slags from the Joint Smelting of Nickel Saprolite and Copper Pyrite Ores. Metallurgist 67, 965–975 (2023). https://doi.org/10.1007/s11015-023-01586-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11015-023-01586-1