Abstract

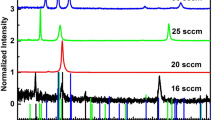

Copper films with a thickness varying from 6 nm to 100 nm are prepared by magnetron sputtering. The films are characterized by homogeneous and fine-grained microstructure. The X-ray diffraction data confirm formation of a copper fcc phase orientated predominantly in the (111) direction. Depending on the growth conditions, the size of Cu grains in the films varies from 7 nm to 20 nm. The refractive index of the films increases from 0.52 to 1.22 with decreasing copper film thickness. The transmittance of the films decreases as their thickness increases from 6 nm to 62 nm, and the transparency of the films with the same thickness decreases with increasing sputtering power and decreasing argon flow rate. The surface resistivity of the films decreases from 8.89±0.06 Ω/sq to 1.47±0.01 Ω/sq as their thickness increases from 20 nm to 70 nm.

Similar content being viewed by others

REFERENCES

J. R. Davis. ASM Specialty Handbook: Copper and Copper Alloys. ASM International, 2001.

J. Sarkar. Sputtering Materials for VLSI and Thin Film Devices. William Andrew, 2014, Chap. 5: Sputtering targets and thin films for integrated circuits, 291-416. https://doi.org/10.1016/b978-0-8155-1593-7.00005-9

Y. Cao, Y. Xia, B. Duan, W. Mu, X. Tan, and H. Wu. Microstructure evolution and anti-wear mechanism of Cu film fabricated by magnetron sputtering deposition. Mater. Lett., 2022, 315. https://doi.org/10.1016/j.matlet.2022.131941

H.-W. Kim. Recent trends in copper metallization. Electronics, 2022, 11, 2914. https://doi.org/10.3390/electronics11182914

H. Li, P. Wei, D. Gao, and G. Wang. In situ Raman spectroscopy studies for electrochemical CO2 reduction over Cu catalysts. Curr. Opin. Green Sustain. Chem., 2022, 34, 100589. https://doi.org/10.1016/j.cogsc.2022.100589

Y. Yin, W. Jing, F. Wang, Y. Liu, and L. Guo. Electro-reduced copper on polymeric C3N4 for photocatalytic reduction of CO2. Carbon, 2023, 214, 118317. https://doi.org/10.1016/j.carbon.2023.118317

S. Rtimi, D. D. Dionysiou, S. C. Pillai, and J. Kiwi. Advances in catalytic/photocatalytic bacterial inactivation by nano Ag and Cu coated surfaces and medical devices. Appl. Catal., B, 2019, 240, 291-318. https://doi.org/10.1016/j.apcatb.2018.07.025

A. Radisic, O. Lühn, H. G. G. Philipsen, Z. El-Mekki, M. Honore, S. Rodet, S. Armini, C. Drijbooms, H. Bender, and W. Ruythooren. Copper plating for 3D interconnects. Microelectron. Eng., 2011, 88, 701-704. https://doi.org/10.1016/j.mee.2010.06.030

S. Lim, D. Han, H. Kim, S. Lee, and S. Yoo. Cu-based multilayer transparent electrodes: A low-cost alternative to ITO electrodes in organic solar cells. Sol. Energy Mater. Sol. Cells, 2012, 101, 170-175. https://doi.org/10.1016/j.solmat.2012.01.016

P. Xiong, Y. Liu, T. Ding, P. Chen, H. Wang, and Y. Duan. Transparent electrodes based on ultrathin/ultra smooth Cu films produced through atomic layer deposition as new ITO-free organic light-emitting devices. Org. Electron., 2018, 58, 18-24. https://doi.org/10.1016/j.orgel.2018.03.036

V. N. Vertoprakhov and S. A. Krupoder. Preparation of thin copper films from the vapour phase of volatile copper(I) and copper(II) derivatives by the CVD method. Usp. Khim., 2000, 69, 1149-1177. https://doi.org/10.1070/rc2000v069n12abeh000572

A. M. Willcocks, T. Pugh, J. A. Hamilton, A. L. Johnson, S. P. Richards, and A. J. Kingsley. CVD of pure copper films from novel iso-ureate complexes. Dalton Trans., 2013, 42, 5554-5565. https://doi.org/10.1039/c3dt00104k

S. Walke, M. B. Mandake, M. Naniwadekar, R. W. Tapre, T. Ghosh, and Y. Qureshi. A review on copper chemical vapour deposition. Mater. Today Proc., 2023. https://doi.org/10.1016/j.matpr.2022.12.140

N. Bahlawane, P. A. Premkumar, F. Reilmann, K. Kohse-Höinghaus, J. Wang, F. Qi, B. Gehl, and M. Bäumer. CVD of conducting ultrathin copper films. J. Electrochem. Soc., 2009, 156, D452. https://doi.org/10.1149/1.3205478

J. L. Hodgkinson, D. Massey, and D. W. Sheel. The deposition of copper-based thin films via atmospheric pressure plasma-enhanced CVD. Surf. Coatings Technol., 2013, 230, 260-265. https://doi.org/10.1016/j.surfcoat.2013.06.053

V. Krisyuk, L. Aloui, N. Prud′Homme, S. Sysoev, F. Senocq, D. Saḿlor, and C. Vahlas. CVD of pure copper films from amidinate precursor. Electrochem. Solid-State Lett., 2011, 14, D26. https://doi.org/10.1149/1.3526142

K. Bernal Ramos, M. J. Saly, and Y. J. Chabal. Precursor design and reaction mechanisms for the atomic layer deposition of metal films. Coord. Chem. Rev., 2013, 257, 3271-3281. https://doi.org/10.1016/j.ccr.2013.03.028

Z. Li, A. Rahtu, and R. G. Gordon. Atomic layer deposition of ultrathin copper metal films from a liquid copper(I) amidinate precursor. J. Electrochem. Soc., 2006, 153, C787. https://doi.org/10.1149/1.2338632

O. Stenzel, S. Wilbrandt, S. Stempfhuber, D. Gäbler, and S.-J. Wolleb. Spectrophotometric characterization of thin copper and gold films prepared by electron beam evaporation: Thickness dependence of the drude damping parameter. Coatings, 2019, 9, 181. https://doi.org/10.3390/coatings9030181

J. Vancea, F. Hofmann, and H. Hoffmann. Grain size-dependent Hall coefficient in polycrystalline copper films. J. Phys. Condens. Matter, 1989, 1, 7419-7424. https://doi.org/10.1088/0953-8984/1/40/015

B. Im, S. Kim, and S.-H. Kim. Nucleation-controlled growth of Cu thin films electrodeposited directly on ALD Ru diffusion barrier in additive-free electrolyte for Cu interconnect. Microelectron. Eng., 2023, 275, 111991. https://doi.org/10.1016/j.mee.2023.111991

A. I. Vorobjova, V. A. Labunov, E. A. Outkina, and D. V. Grapov. Metallization of vias in silicon wafers to produce three-dimensional microstructures. Russ. Microelectron., 2021, 50, 8-18. https://doi.org/10.1134/s1063739721010108

D. Meng, Y. G. Li, Z. T. Jiang, and M. K. Lei. Stick-climb-slip induced damage mode in Cu/Si(100) thin films deposited by modulated pulsed power magnetron sputtering during scratch. Vacuum, 2020, 174, 109233. https://doi.org/10.1016/j.vacuum.2020.109233

D. Meng, Y. G. Li, Z. T. Jiang, and M. K. Lei. Scratch behavior and FEM modelling of Cu/Si(100) thin films deposited by modulated pulsed power magnetron sputtering. Surf. Coatings Technol., 2019, 363, 25-33. https://doi.org/10.1016/j.surfcoat.2019.02.008

M. V. Shandrikov, I. D. Artamonov, A. S. Bugaev, E. M. Oks, K. V. Oskomov, and A. V. Vizir. Deposition of Cu-films by a planar magnetron sputtering system at ultra-low operating pressure. Surf. Coatings Technol., 2020, 389, 125600. https://doi.org/10.1016/j.surfcoat.2020.125600

B. L. Zhu, C. H. Yi, X. Zhao, J. M. Ma, J. Wu, and X. W. Shi. Improvement of transparent conductive properties of Cu films by introducing H2 into deposition atmosphere during RF magnetron sputtering. Superlattices Microstruct., 2020, 145, 106628. https://doi.org/10.1016/j.spmi.2020.106628

B. Giroire, M. Ali Ahmad, G. Aubert, L. Teule-Gay, D. Michau, J. J. Watkins, C. Aymonier, and A. Poulon-Quintin. A comparative study of copper thin films deposited using magnetron sputtering and supercritical fluid deposition techniques. Thin Solid Films, 2017, 643, 53-59. https://doi.org/10.1016/j.tsf.2017.09.002

S. K. Mukherjee, L. Joshi, and P. K. Barhai. A comparative study of nanocrystalline Cu film deposited using anodic vacuum arc and dc magnetron sputtering. Surf. Coatings Technol., 2011, 205, 4582-4595. https://doi.org/10.1016/j.surfcoat.2011.03.119

K. Mech, R. Kowalik, and P. Żabiński. Cu thin films deposited by DC magnetron sputtering for contact surfaces on electronic components. Arch. Metall. Mater., 2011, 56, 903-908. https://doi.org/10.2478/v10172-011-0099-4

Z. A. Ansari, K. Hong, and C. Lee. Structural and electrical properties of porous silicon with rf-sputtered Cu films. Mater. Sci. Eng. B, 2002, 90, 103-109. https://doi.org/10.1016/S0921-5107(01)00917-5

E. Shahriari and M. Ghasemi Varnamkhasti. Nonlinear optical and electrical characterization of nanostructured Cu thin film. Superlattices Microstruct., 2014, 75, 523-532. https://doi.org/10.1016/j.spmi.2014.08.001

K.-Y. Chan and B.-S. Teo. Atomic force microscopy (AFM) and X-ray diffraction (XRD) investigations of copper thin films prepared by dc magnetron sputtering technique. Microelectronics J., 2006, 37, 1064-1071. https://doi.org/10.1016/j.mejo.2006.04.008

K.-Y. Chan, T.-Y. Tou, and B.-S. Teo. Thickness dependence of the structural and electrical properties of copper films deposited by dc magnetron sputtering technique. Microelectronics J., 2006, 37, 608-612. https://doi.org/10.1016/j.mejo.2005.09.016

D. L. Ma, P. P. Jing, Y. L. Gong, B. H. Wu, Q. Y. Deng, Y. T. Li, C. Z. Chen, Y. X. Leng, and N. Huang. Structure and stress of Cu films prepared by high power pulsed magnetron sputtering. Vacuum, 2019, 160, 226-232. https://doi.org/10.1016/j.vacuum.2018.11.039

H.-D. Liu, Y.-P. Zhao, G. Ramanath, S. Murarka, and G.-C. Wang. Thickness dependent electrical resistivity of ultrathin (< 40 nm) Cu films. Thin Solid Films, 2001, 384, 151-156. https://doi.org/10.1016/S0040-6090(00)01818-6

X. Cui, D. A. Hutt, and P. P. Conway. Evolution of microstructure and electrical conductivity of electroless copper deposits on a glass substrate. Thin Solid Films, 2012, 520, 6095-6099. https://doi.org/10.1016/j.tsf.2012.05.068

B. H. Wu, J. Wu, F. Jiang, D. L. Ma, C. Z. Chen, H. Sun, Y. X. Leng, and N. Huang. Plasma characteristics and properties of Cu films prepared by high power pulsed magnetron sputtering. Vacuum, 2017, 135, 93-100. https://doi.org/10.1016/j.vacuum.2016.10.032

V. A. Vdovin, V. G. Andreev, P. S. Glazunov, I. A. Khorin, and Y. V. Pinaev. Optical coefficients of nanoscale copper films in the range of 9-11 GHz. Opt. Spectrosc., 2019, 127, 907-913. https://doi.org/10.1134/S0030400X19110274

E. D. Palik. Handbook of Optical Constants of Solids, Vol. 1. Academic Press, 1985. https://doi.org/10.1016/C2009-0-20920-2

W. S. M. Werner, K. Glantschnig, and C. Ambrosch-Draxl. Optical constants and inelastic electron-scattering data for 17 elemental metals. J. Phys. Chem. Ref. Data, 2009, 38, 1013-1092. https://doi.org/10.1063/1.3243762

M. A. Ordal, R. J. Bell, R. W. Alexander, L. L. Long, and M. R. Querry. Optical properties of fourteen metals in the infrared and far infrared: Al, Co, Cu, Au, Fe, Pb, Mo, Ni, Pd, Pt, Ag, Ti, V, and W. Appl. Opt., 1985, 24, 4493. https://doi.org/10.1364/ao.24.004493

J. M. Elazar, A. B. Djurišić, A. D. Rakić, and M. L. Majewski. Optical properties of metallic films for vertical-cavity optoelectronic devices. Appl. Opt., 1998, 37(22), 5271-5283. https://doi.org/10.1364/ao.37.005271

H.-J. Hagemann, W. Gudat, and C. Kunz. Optical constants from the far infrared to the X-ray region: Mg, Al, Cu, Ag, Au, Bi, C, and Al2O3. J. Opt. Soc. Am., 1975, 65, 742. https://doi.org/10.1364/josa.65.000742

P. B. Johnson and R. W. Christy. Optical constants of the noble metals. Phys. Rev. B, 1972, 6, 4370-4379. https://doi.org/10.1103/PhysRevB.6.4370

Inorganic Crystal Structure Database. Germany: FIZ Karlsruhe, https://icsd.products.fiz-karlsruhe.de/.

M. M. Shehata, A. M. Abdelreheem, S. A. Waly, and A. H. Ashour. Cu and Ag nanoparticles films deposited on glass substrate using cold cathode ion source. J. Inorg. Organomet. Polym. Mater., 2017, 27, 720-727. https://doi.org/10.1007/s10904-017-0515-y

A. A. Solovyev, V. A. Semenov, V. O. Oskirko, K. V. Oskomov, A. N. Zakharov, and S. V. Rabotkin. Properties of ultra-thin Cu films grown by high power pulsed magnetron sputtering. Thin Solid Films, 2017, 631, 72-79. https://doi.org/10.1016/j.tsf.2017.04.005

Funding

The study was funded by the Russian Science Foundation (project No. 23-79-00026, https://rscf.ru/project/23-79-00026/) using facilities of the Shared Research Center “National Center of Investigation of Catalysts” at Boreskov Institute of Catalysis, Siberian Branch of Russian Academy of Sciences.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors of this work declare that they have no conflicts of interests.

Additional information

Russian Text © The Author(s), 2023, published in Zhurnal Strukturnoi Khimii, 2023, Vol. 64, No. 12, 121572.https://doi.org/10.26902/JSC_id121572

Publisher’s Note. Pleiades Publishing remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sulyaeva, V.S., Shayapov, V.R., Syrokvashin, M.M. et al. Nano-Sized Copper Films Prepared by Magnetron Sputtering. J Struct Chem 64, 2438–2450 (2023). https://doi.org/10.1134/S0022476623120156

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0022476623120156