Abstract

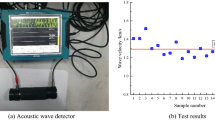

The mechanically over-excavated cavity along the borehole represents an innovative technology designed to enhance permeability in soft coal seams. This study aims to elucidate the complex mechanisms that influence the mechanical properties and crack evolution of over-excavated cavities. Uniaxial compression tests were performed on coal specimens with double over-excavated cavities, and the impact of cavity length–height ratio and shape on mechanical properties and crack evolution was investigated using digital image correlation techniques and acoustic emission (AE) measurements. Discrete element method simulations provided deeper insights into stress evolution and crack behavior around the cavities. The presence of an over-excavated cavity significantly affected the specimen’s mechanical properties, with the effect’s magnitude closely linked to the length–height ratio. As this ratio decreased, the peak stress and elastic modulus of the specimen increased. Specimens containing elliptical cavities demonstrated higher elastic modulus and peak stress compared to those with rectangular cavities of the same length. Crack initiation and propagation displayed distinct features, such as a sudden surge in AE counts and the appearance of strain concentration regions. The failure mode of the specimen was dominated by shear failure combined with tensile failure, and spalling of the specimen appeared as the length–height ratio decreased, indicating stronger damage. Numerical simulations aligned well with experimental findings, revealing tensile and shear cracks as predominant, with failure resulting from crack coalescence. Specimens containing rectangular cavities were more prone to failure than those with elliptical cavities due to stress concentration in corners. The maximum compressive principal stress was concentrated at the tips of the left and right flaws. The release and transfer of stress concentration zones played a pivotal role in influencing the evolution and behavior of cracks, ultimately impacting the overall mechanical response and failure characteristics of the specimen. The research findings provide valuable insights for optimizing the parameters of mechanically over-excavated cavities in coal mines, enhancing performance and safety.

Similar content being viewed by others

References

Xia T, Zhou F, Liu J, Hu S, Liu Y (2014) A fully coupled coal deformation and compositional flow model for the control of the pre-mining coal seam gas extraction. Int J Rock Mech Min 72:138–148

Zhou F, Xia T, Wang X, Zhang Y, Sun Y, Liu J (2016) Recent developments in coal mine methane extraction and utilization in China: a review. J Nat Gas Sci Eng 31:437–458

Zhang R, Cheng Y, Yuan L, Zhou H, Wang L, Zhao W (2019) Enhancement of gas drainage efficiency in a special thick coal seam through hydraulic flushing. Int J Rock Mech Min 124:104085

Zou Q-L, Lin B-Q, Liu T, Zhou Y, Zhang Z, Yan F-Z (2014) Variation of methane adsorption property of coal after the treatment of hydraulic slotting and methane pre-drainage: a case study. J Nat Gas Sci Eng 20:396–406

Liu M, Kong L-A, Hao F-C, Xin X, Wei G, Liu Y (2005) Application of hydraulic flushing technology in severe outburst coal. J China Coal Soc 30(4):451–454

Liu Y, Ren P, Xia S, Sun Y (2009) Analysis of pressure-relief and permeability improvement effect of hydraulic flushing. J Henan Polytech Univ 28(6):695–699

Chang Z, Xi B, Zhao Y, Zhao L (2008) Mechanics of breaking coal by water jet. J China Coal Soc 33(9):983–987

Linghu J, An F, Wang L (2022) Permeability improvement mechanism and application of large-diameter mechanical caving drilling technology for promoting coal gas drainage. Arab J Geosci 15(10):792

Hao C, Cheng Y, Liu H, Wang L, Liu Q (2019) A novel technology for high-efficiency borehole-enlarging to enhance gas drainage in coal seam by mechanical cutting assisted by waterjet. Energy Source Part A Recover Utiliz Environ Effects 44(1):1336–1353

Zhongyi M, Chun L, Mingyao W, Yonglong W (2023) Mechanical behaviour and fracture evolution of coal specimens containing an over-excavated hole: experimental study and numerical modelling. Strain 59(5):e12443

Zhou XP, Zhang JZ, Yang SQ, Berto F (2021) Compression-induced crack initiation and growth in flawed rocks: a review. Fatigue Fract Eng Mater Struct 44(7):1681–1707

Xiong F, Liu X, Zhou X, Lin G, Liu D, Han Y, Xu B, He C, Wang Z (2022) Mechanical behaviours of sandstone containing intersecting fissures under uniaxial compression. J Rock Mech Geotechn Eng 14(2):460–476

Yang S-Q, Jing H-W (2011) Strength failure and crack coalescence behavior of brittle sandstone samples containing a single fissure under uniaxial compression. Int J Fract 168(2):227–250

Wong LNY, Li H-Q (2013) Numerical study on coalescence of two pre-existing coplanar flaws in rock. Int J Solids Struct 50(22):3685–3706

Cao P, Liu T, Pu C, Lin H (2015) Crack propagation and coalescence of brittle rock-like specimens with pre-existing cracks in compression. Eng Geol 187:113–121

Wong LNY, Einstein HH (2009) Crack coalescence in molded gypsum and Carrara marble: Part 1 macroscopic observations and interpretation. Rock Mech Rock Eng 42(3):475–511

Yang S-Q, Huang Y-H, Jing H-W, Liu X-R (2014) Discrete element modeling on fracture coalescence behavior of red sandstone containing two unparallel fissures under uniaxial compression. Eng Geol 178:28–48

Zhao Z, Zhou D (2016) Mechanical properties and failure modes of rock samples with grout-infilled flaws: a particle mechanics modeling. J Nat Gas Sci Eng 34:702–715

Haeri H, Shahriar K, Marji MF, Moarefvand P (2014) Cracks coalescence mechanism and cracks propagation paths in rock-like specimens containing pre-existing random cracks under compression. J Central South Univ 21(6):2404–2414

Zhang JZ, Zhou XP, Zhou LS, Berto F (2019) Progressive failure of brittle rocks with non-isometric flaws: insights from acousto-optic-mechanical (AOM) data. Fatigue Fract Eng Mater Struct 42(8):1787–1802

Miao S, Pan P-Z, Wu Z, Li S, Zhao S (2018) Fracture analysis of sandstone with a single filled flaw under uniaxial compression. Eng Fract Mech 204:319–343

Zhu QQ, Li DY, Han ZY, Li XB, Zhou ZL (2019) Mechanical properties and fracture evolution of sandstone specimens containing different inclusions under uniaxial compression. Int J Rock Mech Min 115:33–47

Wu H, Zhao G, Liang W (2020) Mechanical properties and fracture characteristics of pre-holed rocks subjected to uniaxial loading: a comparative analysis of five hole shapes. Theor Appl Fract Mech 105:102433

Tan L, Zhou Z, Cai X, Rui Y (2022) Analysis of mechanical behaviour and fracture interaction of multi-hole rock mass with DIC measurement. Measurement 191:110794

Liu T, Lin B, Yang W (2017) Mechanical behavior and failure mechanism of pre-cracked specimen under uniaxial compression. Tectonophysics 712–713:330–343

Liu X-R, Yang S-Q, Huang Y-H, Cheng J-L (2019) Experimental study on the strength and fracture mechanism of sandstone containing elliptical holes and fissures under uniaxial compression. Eng Fract Mech 205:205–217

Fan X, Li K, Lai H, Xie Y, Cao R, Zheng J (2018) Internal stress distribution and cracking around flaws and openings of rock block under uniaxial compression: a particle mechanics approach. Comput Geotech 102:28–38

Yao D, Jiang N, Wang X, Jia X, Lv K (2022) Mechanical behaviour and failure characteristics of rocks with composite defects of different angle fissures around hole. Bull Eng Geol Environ 81(7):290

Bai-quan L, Ting L, Quan-le Z, Chuan-jie Z, Fa-zhi Y, Zhen Z (2014) Crack propagation patterns and energy evolution rules of coal within slotting disturbed zone under various lateral pressure coefficients. Arab J Geosci 8(9):6643–6654

Cheng L, Xu J, Peng S, Liu Y, Chen G, Li X, Qin Y (2018) Mesoscopic crack initiation, propagation, and coalescence mechanisms of coal under shear loading. Rock Mech Rock Eng 52(6):1979–1992

Zhang H, Lu C-P, Liu B, Liu Y, Zhang N, Wang H-Y (2020) Numerical investigation on crack development and energy evolution of stressed coal-rock combination. Int J Rock Mech Min 133:104417

Zhang L, Ren T, Li X, Tan L (2021) Acoustic emission, damage and cracking evolution of intact coal under compressive loads: experimental and discrete element modelling. Eng Fract Mech 252:107690

Hao D, Tu S, Zhang C, Tu H (2020) Quantitative characterization and three-dimensional reconstruction of bituminous coal fracture development under rock mechanics testing. Fuel 267:107690

He Z, Gong F, Wu W, Wang W (2021) Experimental investigation of the mechanical behaviors and energy evolution characteristics of red sandstone specimens with holes under uniaxial compression. Bull Eng Geol Env 80(7):5845–5865

Zeng W, Yang S-Q, Tian W-L (2018) Experimental and numerical investigation of brittle sandstone specimens containing different shapes of holes under uniaxial compression. Eng Fract Mech 200:430–450

Zhou Z, Tan L, Cao W, Zhou Z, Cai X (2017) Fracture evolution and failure behaviour of marble specimens containing rectangular cavities under uniaxial loading. Eng Fract Mech 184:183–201

Potyondy DO (2012) A flat-jointed bonded-particle material for hard rock. In: 46th U.S. rock mechanics/geomechanics symposium

Itasca (2019) PFC 6.0 Documentation, user’s guide, itasca consulting group, Inc., Minneapolis, MN, USA

Zhang X-P, Wong LNY (2012) Crack initiation, propagation and coalescence in rock-like material containing two flaws: a numerical study based on bonded-particle model approach. Rock Mech Rock Eng 46(5):1001–1021

Zhang X-P, Wong LNY (2013) Displacement field analysis for cracking processes in bonded-particle model. Bull Eng Geol Env 73(1):13–21

Chen M, Yang S-Q, Ranjith PG, Zhang Y-C (2020) Cracking behavior of rock containing non-persistent joints with various joints inclinations. Theoret Appl Fract Mech 109:102701

Zhao Y, Chen C, Qi Q, Wu S (2022) Rotation and deflection of 3D principal stress axes induced by a prefabricated single flaw in sandstone: a numerical investigation based on DEM. Theor Appl Fract Mech 120:103430

Zhao Y, Li B, Wu S, Chen L (2022) Failure mechanism of brittle rock with 3D parallel preset flaws based on the particle displacement trend method. Theor Appl Fract Mech 117:103193

Zhang X-P, Zhang Q, Wu S (2017) Acoustic emission characteristics of the rock-like material containing a single flaw under different compressive loading rates. Comput Geotech 83:83–97

Chang X, Zhang X, Dang F, Zhang B, Chang F (2022) Failure behavior of sandstone specimens containing a single flaw under true triaxial compression. Rock Mech Rock Eng 55(4):2111–2127

Zhang K, Jiang Z, Liu X, Zhang K, Zhu H (2022) Quantitative characterization of the fracture behavior of sandstone with inclusions: experimental and numerical investigation. Theor Appl Fract Mech 121:103429

Gong F, He Z, Jiang Q (2022) Internal mechanism of reducing rockburst proneness of rock under high stress by real-time drilling pressure relief. Rock Mech Rock Eng 55(8):5063–5081

Acknowledgements

This research was supported by the National Natural Science Funds of China (52074283) and the Research Fund of State and Local Joint Engineering Laboratory for Gas Drainage and Ground Control of Deep Mines (Henan Polytechnic University) (SJF202001).

Author information

Authors and Affiliations

Contributions

ZM was involved in writing and editing, polishing, data collection, software, and application. CL was involved in guide, investigation, funding, data curation, and supervision. MW contributed to direction and supervision.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhongyi, M., Chun, L. & Mingyao, W. Mechanical characteristics and crack evolution in specimens with double over-excavated cavities: experimental and numerical investigations. Comp. Part. Mech. (2024). https://doi.org/10.1007/s40571-023-00702-x

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40571-023-00702-x