Abstract

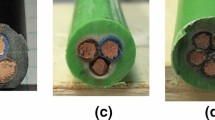

Electrical cables are one of the main fire hazards in nuclear power plants (NPPs) and in many other industrial sectors. To assess the potential damages of the cable fires, models are required to forecast the fire spread over multiple cable trays and the resulting heat release rate. A new test device, called CISCCO, was developed to conduct flame spread experiments on a preheated horizontal cable layer to support the development and validation of the models. The characteristics of the CISCCO device are first presented before the description of four series of experiments that first investigated the temperature dependence of the flame spread velocity. The series involved a cable layer composed of either a polyvinyl chloride (PVC)-based cable, named PVC cable or a halogen free flame retardant (HFFR) poly(ethylene–vinyl acetate)/polyethylene-based cable, labelled HFFR cable. Temperature measurements performed in the solid phase (cable outer sheath) and in the gas phase (above the cable layer) allowed to assess the preheated cable layer temperature and the flame spread velocity. A first attempt of flame heat flux measurements was also conducted in this work. All series highlighted a temperature dependence of the flame spread velocity according to experimental power laws. The flame spread velocities were measured higher for the PVC cable (0 to 5.5 mm/s) than for the HFFR cable (0 to 1.5 mm/s) while the related preheated cable temperatures suitable for spreading were measured lower for the former (170 to 250°C) than for the latter (280 to 370°C). Finally, one of the four test series that used the PVC cable and implemented heat release rate measurements, revealed that the cable fire growth rate is also temperature dependent according to a power law and is linearly correlated to the flame spread velocity.

Similar content being viewed by others

Notes

Given the maximal extraction flow rate of 3000 m3/h and the hood diameter of 1.5 m, the maximal average air velocity in the hood duct, before fire, was close to 0.5 m/s.

References

Aprin L, Ferry L, Heymes F, Sonnier R, Zavaleta P (2022) Chapter 9—Correlation between laboratory- and real-scale fire analyses. Analysis of flame retardancy in polymer science. Elsevier, pp 333–379

Organisation for Economic Co-operation and Development (OECD) Nuclear Energy Agency (NEA), Committee on the Safety of Nuclear Installations (CSNI) (2021) OECD/NEA FIRE Database Version 2019:01, Paris, France (limited to FIRE Database Project member countries only)

Keski-Rahkonen O, Mangs J (2002) Electrical ignition sources in nuclear power plants: statistical, modelling and experimental studies. Nucl Eng Des 213:209–221

McGrattan K, Lock A, Marsh N, Nyden M, Bareham S, Price M, Morgan AB, Galaska M, Schenck K, Stroup D (2012) Cable heat release, ignition, and spread in tray installations during fire (CHRISTIFIRE), vol 1: Horizontal trays, NUREG/CR-7010, U.S.NRC

Zavaleta P, Hanouzet R, Beji T (2019) Improved assessment of fire spread over horizontal cable trays supported by video fire analysis. Fire Technol 55:233–255. https://doi.org/10.1007/s10694-018-0788-x

Zavaleta P, Suard S, Audouin L (2019) Cable tray fire tests with halogenated electric cables in a confined and mechanically ventilated facility. Fire Mater 43:543–560. https://doi.org/10.1002/fam.2717

Fernandez-Pello AC, Hirano T (1983) Controlling mechanisms of flame spread. Combust Sci Technol 32(1–4):1–31. https://doi.org/10.1080/00102208308923650

Quintiere J (2002) Surface flame spread. In: Chapter 12—SFPE handbook of fire protection engineering, Sect. 2, 3rd edn., pp. 246–257

Gollner MJ, Miller CH, Tang W, Singh AV (2017) The effect of flow and geometry on concurrent flame spread. Fire Saf J 91:68–78. https://doi.org/10.1016/j.firesaf.2017.05.007

deRis JN (1969) Twelfth international symposium on combustion. The Combustion Institute, Pittsburgh, p 241

Kobayashi Y, Konno Y, Huang X, Nakaya S, Tsue M, Hashimoto N, Fujita O, Fernandez-Pello C (2018) Effect of insulation melting and dripping on opposed flame spread over laboratory simulated electrical wires. Fire Saf J 95:1–10. https://doi.org/10.1016/j.firesaf.2017.10.006

Hu L, Zhang Y, Yoshioka K, Izumo H, Fujita O (2015) Flame spread over electric wire with high thermal conductivity metal core at different inclinations. Proc Combust Inst 35:2607–2614. https://doi.org/10.1016/j.proci.2014.05.059

Wang Z, Wang J (2020) A comprehensive study on the flame propagation of the horizontal laboratory wires and flame-retardant cables at different thermal circumstances. Process Saf Environ Prot 139:325–333. https://doi.org/10.1016/j.psep.2020.04.030

Mangs J, Hostikka S (2013) Vertical flame spread on charring materials at different ambient temperatures. Fire Mater 37:230–245. https://doi.org/10.1002/fam.2127

Atreya A, Carpenter C, Harkleroad M (1985) Effect of sample orientation on piloted ignition and flame spread, fire safety science. In: Grant CE, Pagni PJ (eds) Proceedings of the first international symposium, international association for fire safety science. Hemisphere Publishing Corp, NY, p 97

Meinier R (2021) Étude expérimentale et analytique de l’inflammation et de la propagation du feu sur un chemin de câbles électriques. IMT Mines Alès

Vincent C, Corn S, Longuet C, Aprin L, Rambaud G, Ferry L (2019) Experimental and numerical thermo-mechanical analysis of the influence of thermoplastic slabs installation on the assessment of their fire hazard. Fire Saf J 108:102850. https://doi.org/10.1016/j.firesaf.2019.102850

Meinier R, Sonnier R, Zavaleta P, Suard S, Ferry L (2018) Fire behavior of halogen-free flame retardant electrical cables with the cone calorimeter. J Hazard Mater 342:306–316. https://doi.org/10.1016/j.jhazmat.2017.08.027

Meinier R, Fellah M, Sonnier R, Zavaleta P, Suard S, Ferry L (2022) Ignition and charring of PVC-based electric cables. Fire Technol 58:689–707. https://doi.org/10.1007/s10694-021-01168-0

IEC 60332-1-2. Tests on electric and optical fibre cables under fire conditions—Part 1–2: test for vertical flame propagation for a single insulated wire or cable—procedure for 1 kW pre-mixed flame. International Electrotechnical Commission (IEC)

BS EN 50575:2014+A1:2016. Power, control and communication cables: cables for general applications in construction works subject to reaction to fire requirements

IEC 60332-3-23. Tests on electric cables under fire conditions—Part 3–23: test for vertical flame spread of vertically-mounted bunched wires or cables—Category B. International Electrotechnical Commission (IEC)

NF C32-070, Janvier 2001, Conducteurs et câbles isolés pour installations, Essais de classification des conducteurs et câbles du point de vue de leur comportement au feu, AFNOR

IEC/EN 61034-2. Measurement of smoke density of cables burning under defined conditions—Part 2: test procedure and requirements. International Electrotechnical Commission (IEC)

IEC/EN 60754-2. Test on gases evolved during combustion of materials from cables—Part 2: determination of acidity (by pH measurement) and conductivity. International Electrotechnical Commission (IEC)

Zavaleta P, Audouin L (2018) Cable tray fire tests in a confined and mechanically ventilated facility. Fire Mater 42:28–43. https://doi.org/10.1002/fam.2454

Boulet P, Parent G, Acem Z, Collin A, Försth M, Bal N, Rein G, Torero J (2014) Radiation emission from a heating coil or a halogen lamp on a semitransparent sample. Int J Therm Sci 77:223–232. https://doi.org/10.1016/j.ijthermalsci.2013.11.006

Pretrel H, Zavaleta P, Suard S (2022) Experimental investigation of the effects of a sidewall and cable arrangement on a horizontal cable tray fire in an open atmosphere. Fire Mater. https://doi.org/10.1002/fam.3114

Zavaleta P, Bascou S, Suard S (2017) Effects of cable tray configuration on fire spread. In: Proceeding of the fifteenth international fire and materials conference. San Francisco, pp. 17–30

Quintiere JG (1993) A simulation model for fire growth on materials subject to a room-corner test. Fire Saf J 20:313–339. https://doi.org/10.1016/0379-7112(93)90053-S

Girardin B, Fontaine G, Duquesne S, Forsth M, Bourbigot S (2015) Characterization of thermo-physical properties of eva/ath: application to gasification experiments and pyrolysis modeling. Materials 161:7837–7863

Shi J, Boyer G, Mourzenko V, Thovert JF (2020) Evolutive models for the geometry and heat conductivity of an intumescent eva-ath composite during its thermal degradation. Materials 13:5258

Shi J, Boyer G, Mourzenko V, Thovert JF (2023) A comprehensive numerical model for the pyrolysis of intumescent polymers: application to EVA-ATH compounds. Chem Eng Sci 268:118385

Acknowledgements

The authors thank V. Lemaux and F. Vigroux for the preparation and performance of the tests. The authors are also grateful to Electricité de France (EdF) that sponsored this work through a bilateral partnership with IRSN.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Supplementary file1 (MP4 34627 kb)

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zavaleta, P., Meinier, R., Suard, S. et al. Flame Spread Experiments on a Horizontal Preheated Cable Layer. Fire Technol 60, 641–667 (2024). https://doi.org/10.1007/s10694-023-01521-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10694-023-01521-5