Abstract

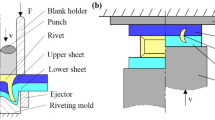

Self-piercing riveting (SPR) is one of the advanced mechanical joining techniques, and it has been widely used in automobile industry. In this paper, the effect of die misalignment on the cross-section parameters and mechanical properties of SPR joints were respectively studied through numerical simulation and experiment, and the mechanical properties degradation mechanism of the misaligned riveted joint were analyzed. A three-dimensional explicit finite element model (FEM) of SPR joint was developed by ABAQUS, and the section observation was performed to evaluate the accuracy of FEM. The riveting process and the strain of SPR joints with different misalignment distance was analyzed, and the quasi-static shear test was carried out. The results revealed that the rivet leg near the die edge was thickened due to limitations in deformation space, and a cavity was formed at the outer edge of the rivet leg near the die center, during the riveting process. It resulted in different cross-section parameters and mechanical properties of SPR joints. Specifically, the interlock distance decreased as the misalignment distance increased. The bottom thickness of the side near the die edge increased with increasing misalignment distance, while that near the die center decreased slightly as the misalignment distance increased. In addition, the maximum shear load decreased nonlinearly with increasing misalignment distance, and the movement of die along the loading end had a significantly greater impact on the maximum shear load than the movement along the fixed end. This was mainly because the interlock distance of SPR joints was asymmetrically and nonlinearly reduced due to the die misalignment.

Similar content being viewed by others

Data availability

The raw/processed data required to reproduce these findings cannot be shared at this time due to technical or time limitations.

References

Busse S, Merklein M, Roll K et al (2010) Development of a mechanical joining process for automotive body-in-white production. Int J Mater Form 3:1059–1062. https://doi.org/10.1007/s12289-010-0953-3

Liao Y, Sun H, Wu G et al (2023) Effect of rivet arrangement on fatigue performance of electromagnetic riveted joint with Φ10 mm diameter rivet. Int J Fatigue 107892. https://doi.org/10.1016/j.ijfatigue.2023.107892

Di Franco G, Fratini L, Pasta A, Ruisi VF (2013) On the self-piercing riveting of aluminium blanks and carbon fibre composite panels. Int J Mater Form 6:137–144. https://doi.org/10.1007/s12289-011-1067

Rusia A, Weihe S (2020) Development of an end-to-end simulation process chain for prediction of self-piercing riveting joint geometry and strength. J Manuf Process 57:519–532. https://doi.org/10.1016/j.jmapro.2020.07.004

Jiang H, Liao Y, Gao S et al (2021) Comparative study on joining quality of electromagnetic driven self-piecing riveting, adhesive and hybrid joints for Al/steel structure. Thin-Walled Struct 164:107903. https://doi.org/10.1016/j.tws.2021.107903

Han L, Thornton M, Shergold M (2010) A comparison of the mechanical behaviour of self-piercing riveted and resistance spot welded aluminium sheets for the automotive industry. Mater Design 31:1457–1467. https://doi.org/10.1016/j.matdes.2009.08.031

Asati B, Shajan N, Akhil Kishore VT et al (2022) A comparative investigation on self-piercing riveting and resistance spot welding of automotive grade dissimilar galvanized steel sheets. Int J Adv Manuf Technol 123:1079–1097. https://doi.org/10.1007/s00170-022-10226-y

Deng J-H, Lyu F, Chen R-M, Fan Z-S (2019) Influence of die geometry on self-piercing riveting of aluminum alloy AA6061-T6 to mild steel SPFC340 sheets. Adv Manuf 7:209–220. https://doi.org/10.1007/s40436-019-00250-9

Karathanasopoulos N, Pandya KS, Mohr D (2021) An experimental and numerical investigation of the role of rivet and die design on the self-piercing riveting joint characteristics of aluminum and steel sheets. J Manuf Process 69:290–302. https://doi.org/10.1016/j.jmapro.2021.07.049

Jiang H, Gao S, Li G, Cui J (2019) Structural design of half hollow rivet for electromagnetic self-piercing riveting process of dissimilar materials. Mater Design 183:108141. https://doi.org/10.1016/j.matdes.2019.108141

Karim MA, Jeong T-E, Noh W et al (2020) Joint quality of self-piercing riveting (SPR) and mechanical behavior under the frictional effect of various rivet coatings. J Manuf Process 58:466–477. https://doi.org/10.1016/j.jmapro.2020.08.038

Duan J, Chen C (2023) Effect of edge riveting on the failure mechanism and mechanical properties of self-piercing riveted aluminium joints. Eng Fail Anal 150:107305. https://doi.org/10.1016/j.engfailanal.2023.107305

Chen G, Zeng K, Xing B, He X (2022) Multiple nonlinear regression prediction model for process parameters of Al alloy self-piercing riveting. J Mater Res Technol 19:1934–1943. https://doi.org/10.1016/j.jmrt.2022.05.118

Pan M, Tang W, Xing Y, Ni J (2018) Numerical simulation analysis for deformation deviation and experimental verification for an antenna thin-wall parts considering riveting assembly with finite element method. J Cent South Univ 25:60–77. https://doi.org/10.1007/s11771-018-3717-8

Du Z, Duan L, Jing L et al (2021) Numerical simulation and parametric study on self-piercing riveting process of aluminium–steel hybrid sheets. Thin-Walled Struct 164:107872. https://doi.org/10.1016/j.tws.2021.107872

Zhao H, Han L, Liu Y, Liu X (2022) Analysis of joint formation mechanisms for self-piercing riveting (SPR) process with varying joining parameters. J Manuf Process 73:668–685. https://doi.org/10.1016/j.jmapro.2021.11.038

Lin J, Qi C, Wan H et al (2021) Prediction of cross-tension strength of self-piercing riveted joints using finite element Simulation and XGBoost Algorithm. Chin J Mech Eng 34:36. https://doi.org/10.1186/s10033-021-00551-w

Ang HQ (2021) An overview of self-piercing riveting process with focus on joint failures, corrosion issues and optimisation techniques. Chin J Mech Eng 34:2. https://doi.org/10.1186/s10033-020-00526-3

Chung C-S, Kim H-K (2016) Fatigue strength of self-piercing riveted joints in lap-shear specimens of aluminium and steel sheets: fatigue. Fatigue Fract Engng Mater Struct 39:1105–1114. https://doi.org/10.1111/ffe.12419

Afonso RM, Alves LM (2023) Double-sided self-pierce riveting: rivet geometry optimization. Int J Mater Form 16:34. https://doi.org/10.1007/s12289-023-01760-5

Haque R (2018) Quality of self-piercing riveting (SPR) joints from cross-sectional perspective: a review. Arch Civ Mech Eng 18:83–93. https://doi.org/10.1016/j.acme.2017.06.003

Asati B, Shajan N, Singh Arora K (2022) Effect of process parameters on joint performance in self-piercing riveted dissimilar automotive steel joints. Mater Today: Proc 62:721–726. https://doi.org/10.1016/j.matpr.2022.03.658

Jessadatavornwong P, Huff G, Freis A et al (2023) Characterization of self-piercing rivet joints using X-ray computed tomography. Tomography Mater Struct 100010. https://doi.org/10.1016/j.tmater.2023.100010

Liao Y, Zhong J, Li G et al (2022) Influence of adhesive on dynamic performance of steel/Al electromagnetic clinched joints. Archiv Civ Mech Eng 22:177. https://doi.org/10.1007/s43452-022-00504-7

Paik JK, Kim KJ, Lee JH et al (2017) Test database of the mechanical properties of mild, high-tensile and stainless steel and aluminium alloy associated with cold temperatures and strain rates. Ships Offshore Struct 12:S230–S256. https://doi.org/10.1080/17445302.2016.1262729

Xu H, Zhang Y, Peng R et al (2021) Simulation and experimental study on the strength of Al7075-T6 clinched joint. Eng Fail Anal 129:105735. https://doi.org/10.1016/j.engfailanal.2021.105735

Fang Y, Huang L, Zhan Z, Huang S, Liu X, Chen Q, Zhao H, Han W (2022) A framework for calibration of self-piercing riveting process simulation model. J Manuf Process 76:223–235. https://doi.org/10.1016/j.jmapro.2022.01.015

Wang J, Zhang G, Zheng X et al (2021) A self-piercing riveting method for joining of continuous carbon fiber reinforced composite and aluminum alloy sheets. Compos Struct 259:113219. https://doi.org/10.1016/j.compstruct.2020.113219

Karim MA, Murugan SP, Bae K et al (2022) Effect of top sheet materials on joint performance of self-piercing riveting. J Weld Join 40:512–524. https://doi.org/10.5781/JWJ.2022.40.6.7

Jiang H, Liao Y, Jing L et al (2021) Mechanical properties and corrosion behavior of galvanized steel/Al dissimilar joints. Archiv Civ Mech Eng 21:168. https://doi.org/10.1007/s43452-021-00320-5

Acknowledgements

This project was supported by the National Natural Science Foundation of China (Nos. 52005173 and 52375331), and the Shenzhen Science and Technology Program (KQTD20200820113110016).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

None.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Liao, Y., Zhang, J., Wu, G. et al. Effect of die misalignment on the joining quality of Al/steel self-piercing riveting structure. Int J Mater Form 17, 14 (2024). https://doi.org/10.1007/s12289-023-01809-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12289-023-01809-5