Abstract

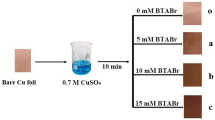

A novel finding that the electrochemical performance of the commercial lithium titanate (Li4Ti5O12, LTO) can be significantly improved by using a novel current collector of CuI particles modified copper foil is reported for the first time in this work. Firstly, a large number of particles with well-defined shapes were prepared on the commercial copper foil surface via a very simple soaking process, in which the soaking solution contained only CuSO4, H2SO4 and [Bmim]I. As indicated by the XRD and XPS measurements, the particles observed on the surface of the copper foil were identified as CuI particles. That is, CuI particles modified copper foils (denoted as CuI/Cu) were successfully prepared at room temperature. CuI/Cu prepared in the presence of 0.4, 0.6 and 0.8 g of [Bmim]I were nominated as CF (copper foil) a, b and c, respectively. Inconceivably, as compared to the conventional LTO electrode, the LTO electrodes assembled using the newly prepared CFs exhibited a significantly improved electrochemical performance, i.e., all as-prepared CFs showed an evident promoting effect on the electrochemical performance of the traditional LTO electrodes. For instance, the initial discharge capacity (DC) of the LTO electrode assembled using CF b (called electrode b) at 0.2 C was 307 mAh g−1, which was about 1.86 times higher than that of the LTO electrode prepared using the conventional copper foil current collector (165 mAh g−1). Particularly, as the applied current rate was as high as 10 C, the DC value of electrode b (117 mAh g−1), even after 100 cycles, was still about 2.54 times that of the traditional LTO electrode (46 mAh g−1). In this preliminary work, a new method for preparing CuI particles was developed, along with a novel approach to significantly improve the electrochemical properties of the commercial LTO electrode. The method did not require any strong oxidants or reducing agents, nor did it demand any additional energy expenditure during the preparation of CuI particles. Moreover, the approach did not require any changes in the assembly procedure for the LTO electrodes being studied. This work was very meaningful for the development of the CuI-related research field as well as for the electrochemical performance improvement of LTO-based lithium-ion batteries (LIBs).

Similar content being viewed by others

References

Sun C, Wang Y-J, Gu H, Fan H, Yang G, Ignaszak A et al 2020 Nano Energy 77 105092

Liang J, Zhou Z, Zhang Q, Hu X, Peng W, Li Y et al 2021 J. Power Sources 495 229758

Gao C, Jiang Z, Wang P, Jensen L R, Zhang Y and Yue Y 2020 Nano Energy 74 104868

Yokokura T J, Qi Z, Wang H, Manikandan P, Pol V G and Rodriguez J R 2022 Carbon Trends 8 100178

Meng C, Yuan M, Cao B, Lin X, Zhang J, Li A et al 2022 Carbon 192 347

Jin X, Han Y, Zhang Z, Chen Y, Li J, Yang T et al 2022 Adv. Mater. 34 2109356

Le S H, Huang C and Grant P S 2019 Nano Energy 61 96

Jin Y, Yu H, Gao Y, He X, White T A and Liang X 2019 J. Power Sources 436 226859

Tian K, Hui X, Wang H, Zhang Z, Zhang L, Wang C et al 2022 Electrochim. Acta 415 140242

Hernández-Carrillo R A, Ramos-Sánchez G, Guzmán-González G, García-Gomez N A, González I and Sanchez-Cervantes E M 2018 J. Alloys Compd. 735 1871

Wang H, Wang L, Lin J, Yang J, Wu F, Li L et al 2021 Electrochim. Acta 368 137470

Temeche E, Buch E, Zhang X, Brandt T, Hintennach A and Laine R M 2021 ACS Appl. Energy Mater. 4 1894

Hong H-J, Lee S-Y, Kwon S, Kim B-S, Yoon S and Park I-S 2021 J. Alloys Compd. 886 161296

Lv S-X, Chen Q-L, Song F-X and Li Y-N 2021 Appl. Surf. Sci. 555 149637

Li X, Huang X, Chen Y, Mei J, Xu W, Wang L et al 2021 Electrochim. Acta 390 138874

Gong S H, Lee J H, Chun D W, Bae J-H, Kim S-C, Yu S et al 2021 J. Energy Chem. 59 465

Xiao X, Liu L, Zhang L, Wang Q, Yan H, Zhao B et al 2022 J. Alloys Compd. 897 162744

Ding K, Gu H, Zheng C, Liu L, Liu L, Yan X et al 2014 Electrochim. Acta 146 585

Wang C, Wang X, Lin C and Zhao X S 2019 Small 15 1902183

Feng Y, Liu H, Zhao X and Dong W 2020 J. Phys. Chem. Solids 146 109569

Peng J, Chen B, Wang Z, Guo J, Wu B, Hao S et al 2020 Nature 586 390

Wen S, Li Z, Zou C, Zhong W, Wang C, Chen J et al 2021 New J. Chem. 45 10541

Zhou S, Liu G, Ding N, Shang L, Dang R and Zhang J 2020 Surf. Coat. Technol. 399 126150

Lee S H, Johnston C and Grant P S 2020 Energy Technol. 8 2000253

Qin W, Liu H, An J and Wen X 2020 J. Power Sources 479 229090

Zhu X, Jiang X, Yao X, Leng Y, Wang L and Xue Q 2019 ACS Appl. Mater. Interfaces 11 26880

Zhang Y, Xiao R, Liao X, Ma Z, Huang Y and Li Q 2020 ChemElectroChem 7 2896

Toigo C, Frankenberger M, Billot N, Pscherer C, Stumper B, Distelrath F et al 2021 Electrochim. Acta 392 138978

Chen C-H, Chiu J-M, Shown I and Wang C-H 2022 ACS Omega 7 10205

Ding K, Zhao J, Sun Y, Chen Y, Wei B, Zhang Y et al 2016 Ceram. Int. 42 19187

Geng F, Yang L, Dai B, Guo S, Gao G, Xu L et al 2019 Surf. Coat. Technol. 360 269

Singh N and Taunk M 2020 ChemistrySelect 5 12236

Li S, Zhang Y, Yang W and Fang X 2019 Adv. Mater. Interfaces 6 1900669

Fang L, Dong S, Shi L and Sun Q 2019 New J. Chem. 43 12744

Liu P and Hensen E J M 2013 J. Am. Chem. Soc. 135 14032

Salaha N, Abusorrahb A M, Salahc Y N, Almasoudid M, Baghdadia N, Alshahria A et al 2020 Ceram. Int. 46 27244

Ding K, Okajima T and Ohsaka T 2007 Electrochemistry 75 35

Ding K, Jia Z, Wang Q, He X, Na T, Tong R et al 2001 J. Electroanal. Chem. 513 67

Ding K, Han J, Gao X, Zhou L and Qu R 2019 Mater. Chem. Phys. 232 354

Zhang G Q, Li W, Yang H, Wang Y, Rapole S B, Cao Y et al 2013 J. New Mater. Electrochem. Syst. 16 025

Fu Z, Chen L, Wan L, Wang F, Du J, Yang X et al 2018 Ionics 24 1579

Ding K, Zhao J, Zhou J, Zhao Y, Chen Y, Liu L et al 2016 Mater. Chem. Phys. 177 31

Deng Z, Xu Z, Deng W and Wang X 2022 J. Power Sources 521 230970

Yi T-F, Liu H, Zhu Y-R, Jiang L-J, Xie Y and Zhu R-S 2012 J. Power Sources 215 258

Peta K, Bartkowiak T, Galek P and Mendak M 2021 Tribol. Int. 163 107139

Acknowledgements

This work was supported by the National Natural Science Foundation of China (No. 21706004), the National Key Research and Development Project (No. 2019YFC1908303), the Innovation Ability Improvement Project of Hebei Province (225A4402D) and the Graduate Student Innovation Ability Training Program of Hebei Normal University (CXZZSS2022060).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ding, K., Di, M., Shi, F. et al. Significantly improved electrochemical performance of the commercial lithium titanate (Li4Ti5O12) achieved by using a novel current collector of cuprous iodide-modified copper foil. Bull Mater Sci 47, 18 (2024). https://doi.org/10.1007/s12034-023-03097-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12034-023-03097-w