Abstract

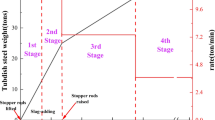

A rotating stopper-rod technique was proposed to suppress the formation of free-surface vortex in the tundish. The large eddy simulation model coupled with volume of fluid model was developed to study the steel–slag–gas three-phase flow behavior. The critical slag entrapment height of the free-surface vortex and mass of residual steel were predicted at different rotating speeds (30, 60, 90 and 120 r/min) of the rotating stopper-rod. The numerical model was verified by water model experiment. The results showed that by rotating the stopper-rod in the opposite direction of the vortex above the submerged entry nozzle, the formation of vortex can be effectively disturbed and the critical height of the free-surface vortex can be reduced. Particularly for the 2nd strand, when the rotating speeds are 30, 60, 90 and 120 r/min, the critical height of the free-surface vortex above the 2nd strand is 7.3, 4.7, 6.3 and 7.4 cm, respectively. A reasonable rotating speed should be 60 r/min, which can reduce about 2 tons of residual steel. Other rotating speeds just can reduce about 1.6 tons of residual steel.

Similar content being viewed by others

References

Y. Yin, J. Yang, J. Zhang, L. Tang, J. Mater. Res. Technol. 23 (2023) 1781–1791.

C. Huang, Y. Sun, W. Liu, J. Li, S. Yang, J. Dong, Materials 16 (2023) 3209.

A. Gupta, R. Kumar, R.K. Singh, Met. Mater. Int. 28 (2022) 1246–1256.

G. Solorio-Diaz, A. Ramos-Banderas, J. de J. Barreto, R.D. Morales, Steel Res. Int. 78 (2007) 248–253.

Z. Li, M. Zhang, F. Zhou, Y. Lu, X. Zhang, H. Gu, Ironmak. Steelmak. 49 (2022) 1039–1047.

H.X. Li, Q. Wang, H. Lei, J.W. Jiang, Z.C. Guo, J.C. He, ISIJ Int. 54 (2014) 1592–1600.

H. Tang, Y. Liang, Acta Metall. Sin. 52 (2016) 519–528.

Y. Ruan, Y. Yao, S. Shen, B. Wang, J. Zhang, J. Huang, Steel Res. Int. 91 (2020) 1900616.

M. Xuan, M. Chen, K. Zhang, X. Hua, The Minerals, Met. Mater. Ser. Springer, Cham, Germany, 2021.

Q. Wang, L. Wang, H. Li, J. Jiang, X. Zhu, Z. Guo, J. He, Acta Metall. Sin. 54 (2017) 959–968.

B. Khadem Rabe, S.H. Ghoreishi Najafabadi, H. Sarkardeh, Proc. Inst. Civ. Eng. Water Manag. 171 (2018) 18–29.

X. Gao, H. Zhang, J. Liu, B. Sun, Y. Tian, Eng. Appl. Comput. Fluid Mech. 12 (2018) 182–194.

D.Y. Sheng, Z. Zou, Metals 11 (2021) 208.

K. Takahashi, M. Ando, T. Ishii, ISIJ Int. 54 (2014) 304–310.

X. Li, B. Li, Z. Liu, D. Wang, T. Qu, S. Hu, C. Wang, R. Gao, Metall. Mater. Trans. B 52 (2021) 3246–3264.

X. Li, B. Li, Z. Liu, R. Niu, Y. Liu, C. Zhao, C. Huang, H. Qiao, T. Yuan, Metals 9 (2018) 7.

X. Zhao, X. Li, J. Zhang, Metals 11 (2021) 374.

Q. Zhou, T. Zhu, L. Zhang, W. Chen, T. Yuan, Z. Liu, Iron and Steel 57 (2022) No. 7, 68–78.

W. Chen, L. Zhang, Metall. Mater. Trans. B 52 (2021) 528–547.

Q. Li, L. Zhang, W. Chen, Y. Wang, Z. Zhao, J. Zhang, Chinese Journal of Engineering 44 (2022) 690–702.

W. Chen, L. Zhang, Q. Ren, Y. Ren, W. Yang, Metall. Mater. Trans. B 53 (2022) 1446–1461.

J. Zhang, S. Yang, J. Li, W. Yang, Y. Wang, X. Guo, ISIJ Int. 55 (2015) 1684–1692.

N. Alkishriwi, M. Meinke, W. Schröder, A. Braun, H. Pfeifer, Steel Res. Int. 77 (2006) 565–575.

A. Leonard, Advances in Geophysics 18 (1975) 237–248.

Ansys Inc. Fluent, Ansys. 19.0 User’s Guide, 2019.

J. Zhang, Q. Liu, Z. Xin, B. Lu, J. Zhang, J. Li, IOP Conf. Ser.: Mater. Sci. Eng. 668 (2019) 012007.

F. Nicoud, F. Ducros, Flow Turbul. Combust. 62 (1999) 183–200.

H. Zhang, J. Wang, Q. Fang, G. Wu, P. Zhao, H. Ni, Steel Res. Int. 93 (2022) 2100536.

Acknowledgements

The authors would like to express their gratitude for the financial support provided by the National Natural Science Foundation of China (52004191), the China Postdoctoral Science Foundation (2022M711120) and the Science and Technology Research Project of Education Department of Hubei Province (B2022020). Besides, the numerical calculation is supported by High-Performance Computing Center of Wuhan University of Science and Technology.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Fang, Q., Zhao, P., Zhang, H. et al. Formation of free-surface vortex and vortex suppression by rotating stopper-rod at end of tundish casting. J. Iron Steel Res. Int. 31, 1104–1116 (2024). https://doi.org/10.1007/s42243-023-01150-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42243-023-01150-w