Abstract

The available experimental data for the density, thermal conductivity, and viscosity of liquid titanium, zirconium, hafnium, vanadium, niobium, tantalum, chromium, molybdenum, and tungsten have been critically examined with the intention of establishing reference correlations. All experimental data have been categorized into primary and secondary data according to the quality of measurement, the technique employed, and the presentation of the data, as specified by a series of criteria. In the case of the density, new reference correlations are proposed for liquid titanium, zirconium, hafnium, vanadium, niobium, tantalum, chromium, molybdenum, and tungsten, characterized by an expanded uncertainty (95 %) of 2.0 %, 2.1 %, 1.9 %, 2.2 %, 2.4 %, 2.6 %, 3.2 %, 2.1 %, and 4.1 %, respectively. The thermal conductivity reference correlations for the aforementioned liquid metals, except liquid chromium, are characterized by an expanded uncertainty (95 %) of 14.3 %, 8.4 %, 6.1 %, 11.4 %, 7.6 %, 4.0 %, 4.6 %, and 5.1 %, respectively. Finally, in the case of the viscosity, a review of the available literature shows very large deviations between data from authors for liquid titanium and zirconium, as well as a lack of measurements for the remaining melts. Hence, it is not justified to propose any kind of correlation for those cases.

Similar content being viewed by others

1 Introduction

There is a continual increase in the use of mathematical models to simulate a variety of processes involving liquid metals such as shape-casting, primary and secondary metal production, powder production by spray forming [1], and welding, but also in more specialized uses like self-repair of broken circuits that employ micro-capsules filled with liquid metals [2] and in the generation of extreme-ultraviolet light (EUV) for nanolithography [3, 4]. Depending on which aspect of the process is modeled, there is a need for density, thermal conductivity, and viscosity data for the relevant alloys. Historically, there are wide discrepancies in the thermal conductivity and viscosity data reported for the metallic elements and alloys [5]. For example, we found there is a spread of about 400 % in the reported values of the viscosity for molten aluminum and about 100 % for molten iron [6]. For these reasons, in 2005, a project was initiated by the International Association for Transport Properties, IATP (former Subcommittee on Transport Properties of the International Union of Pure and Applied Chemistry, IUPAC) to critically evaluate the density, the viscosity, and the thermal conductivity of selected liquid metals. Thus

-

In 2006, we proposed reference correlations for the density and the viscosity of liquid aluminum and iron [6], as a result of a project partially financed by IUPAC. Following this, in 2010, we proposed reference correlations for the density and viscosity for liquid copper and tin [7]. The work continued and in 2012 three sets of reference correlations for the density and viscosity were proposed. One set for liquid antimony, bismuth, nickel, lead, and silver was proposed [8], one for liquid cadmium, cobalt, gallium, mercury, indium, silicon, thallium, and zinc [9], and a third set for the liquid eutectic alloys Al + Si, Pb + Bi, and Pb + Sn [10].

-

In 2017, the work was extended to reference correlations for the thermal conductivity of liquid copper, gallium, indium, iron, lead, nickel, and tin [11], and liquid bismuth, cobalt, germanium, and silicon [12].

-

Finally, in 2018, we extended the work to molten salts, and proposed reference correlations for the thermal conductivity of 13 inorganic molten salts [13], and in 2019, for the viscosity of molten LiF-NaF-KF, LiF-BeF2, and Li2CO3-Na2CO3-K2CO3 [14].

The current paper concludes the work on the density, thermal conductivity, and viscosity of pure liquid metals by presenting reference correlations for the liquid density and thermal conductivity of the group IV–VI elements titanium, zirconium, hafnium, vanadium, niobium, tantalum, chromium, molybdenum, and tungsten. In the specific case of the viscosity however, we cannot justify the recommendation of any correlation, due to the present lack of low-uncertainty measurements.

The analysis we use is based on the best available experimental data for the density, thermal conductivity, and viscosity. A prerequisite to the analysis is a critical assessment of the experimental data. Here we define two categories of experimental data: primary data, employed in the development of the correlation, and secondary data, used simply for comparison purposes. According to the recommendation adopted by the Subcommittee on Transport Properties of IUPAC, the primary data are identified by a well-established set of criteria [15]. These criteria have been successfully employed to establish standard reference values for the viscosity and thermal conductivity of fluids over wide ranges of conditions, with uncertainties in the range of 1 %. In the case of liquid metals, it was argued that these criteria needed to be relaxed slightly due to the larger typical uncertainties in the relevant measurement methods. This is primarily due to (i) the difficulties associated with the techniques employed at such high temperatures and (ii) the purity of the liquid metal sample, which can be strongly affected by the surrounding atmosphere and the container used for the melt.

2 Density

2.1 Experimental Techniques

Among the experimental work identified for the density of molten materials, a variety of techniques have been employed to measure this property. Methods reported include electrostatic levitation, resistive wire heating, maximum bubble-pressure, sessile-drop, pendant-drop, and gamma absorption. Most of the methods have been presented in our previous compilation [6] and will only be discussed here very briefly.

A large group of techniques for the measurement of the density of liquid metals at high temperature uses variations of the shadowgraph technique to determine the change of a specimen’s volume. The samples are generally illuminated with a light source, e.g., flash, UV, LED, laser, or X-ray, and the “shadow images” are recorded with the appropriate sensors—now often with fast CCD cameras when light sources are used. Assuming constant mass, measured before or after heating, the temperature-dependent density can easily be calculated. When combined with electromagnetic levitation (EML), a small drop of liquid metal is supported by electromagnetic forces using a high-frequency coil that also doubles as a heater. In the case of combined shadowgraph with electrostatic levitation (ESL), a small sample about 2 mm in diameter is levitated by a Coulomb force, which occurs by the interaction between the surface electronic charge in the sample and the electrical field. In the electrostatic levitation technique, the levitated sample is melted by the lasers (CO2, semiconductors, etc.) under a high vacuum or gas atmosphere. The only chemical interaction of the sample is with the surrounding atmosphere and not having contact with a crucible material is a major advantage of these levitation techniques. Processing the images under the assumption of rotational symmetry or using multiple images from orthogonal directions results in the needed volume change to calculate the temperature-dependent density.

A different approach for heating a sample without crucible contact is realized in the fast resistive pulse heating technique (aka resistive wire heating, wire explosion, µs-pulse heating, isobaric expansion experiment). Here too a background light source illuminates the fast-expanding wire and the change in diameter is detected from the intensity profile. The recorded volume change is related to density in the liquid phase using a known or measured density at room temperature.

The sessile-drop technique evaluates the volume change from the projected image of a liquid drop of known mass resting on a plate or substrate. Provided the shape of the drop is fully symmetrical, the volume of the drop and hence its density, can accurately be calculated.

The maximum-bubble-pressure technique is based on the formation of a hemispherical bubble of an inert gas at the tip of a capillary tube immersed to a certain depth in the melt. The density can be determined by measuring the difference in the overpressure required to form a hemispherical bubble of the inert gas at the tip of the capillary at different depths in the liquid. Alternatively, two identical capillaries at different depth can be used to cancel out depth-independent influencing factors like surface tension on the tip of the capillary.

Finally, the gamma absorption, aka gamma radiation attenuation or gamma densimeter technique is based on the attenuation of a γ-ray beam passing through the liquid metal. The incident beam is attenuated proportional to the mass absorption coefficient, the sample thickness, and the density of the liquid metal sample. Under the assumption that the first two factors stay constant, the change in density of a heated specimen can be determined from the signal change of the gamma radiation detector.

2.2 Data Compilation

We surveyed the published literature, assisted by the NIST Alloy data web application [16], and present in Table 1 the data sets for the density of liquid titanium, zirconium, hafnium, vanadium, niobium, tantalum, chromium, molybdenum, and tungsten. In this table the publication year, the technique employed, the purity of the sample, and the uncertainty quoted by the author are presented. Melting temperatures, Tm (K), are also given [17]. Furthermore, the form in which the data are presented, and the temperature range covered, are noted too. As in our previous publications [6,7,8,9], the minimum temperature considered was the melting temperature. In the last two columns of Table 1, the average absolute percent deviation (AAD) and the bias percent (BIAS) are also given (bold values refer to the whole fit respectively); these will be defined and discussed in detail later. Also note that Table 1 does not include publications [18,19,20,21,22,23,24,25,26,27,28,29,30,31] that were superseded by more recent ones from the same authors, unless the temperature range of measurements was different.

The data sets have been classified into primary and secondary sets according to the criteria referenced earlier. In deriving the correlation, as in our previous publications, the primary data are weighted inversely proportional to their uncertainty squared. Hence investigators that did not quote the uncertainty of the measurements were not included in the primary data set. The only exception to this were the measurements of Tsu et al. [32] which were included in the primary set for chromium, as otherwise, there were only three data sets available. Since these investigators quoted no uncertainty, their measurements were included with an uncertainty of double the highest value in the group. When instead of measurements, an equation was given, the number of calculated values included in the table depended on the temperature range and the uncertainty quoted. We also note that the tungsten measurements of Berthault et al. [33] were not included in the primary dataset as they were consistently lower by about 9 % from all the others, as will be shown later on.

2.3 Density Reference Correlation

The primary density data for liquid metals, shown in Table 1, were employed in a linear regression analysis to represent the density at 0.1 MPa as a function of the temperature. The data were weighted inversely proportional to their uncertainty squared (uncertainties quoted at the 95 % confidence level were reduced by a factor of 2). The following equations were obtained for the density, ρ (kg·m−3), as a function of the absolute temperature, T (K):

and the coefficients c1 (kg·m−3), c2 (kg·m−3·K−1), as well as the melting temperature Tm (K), are shown for each liquid metal, in Table 2. In the same table the expanded uncertainty (95 %), denoted as 2σ (95 %), of each equation is also shown.

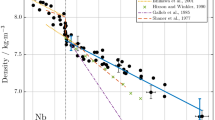

We define the percent deviation as PCTDEV = 100(ρ − ρfit)/ρfit, where ρ is the experimental value of the density and ρfit is the value calculated from Eq. 1—with equivalent relations for the thermal conductivity. The average absolute percent deviation (AAD) is found with the expression AAD = (∑│PCTDEV│)/n, where the summation is over all n points, the bias percent is found with the expression BIAS = (∑PCTDEV)/n. The AAD and BIAS of the data of each investigator are shown in Table 1. The final parameters of the correlation fits, Eq. 1, are presented in Table 2. Figures 1, 2, 3, 4, 5, 6, 7, 8, and 9 show the primary data and the correlation fit from the above equation for each liquid metal, with the vertical line indicating the melting point.

Primary density data and Eq. 1 for liquid titanium as a function of temperature. Reiplinger and Brillo [34] (■), Watanabe et al. [35] (+), Zou et al. [36] (×), Ozawa et al. [37] (○), Rausch [38] (△), Gathers et al. [39] (●), Ivashchenko and Martsenyuk [40] (◆), Saito et al. [41] (▲). Also shown, the melting temperature (--) and values calculated by Eq. 1 ( )

)

Primary density data and Eq. 1 for liquid zirconium as a function of temperature. Nawer and Matson [47]: Ground data (- -) Space data (…), Zhao [48] (△), Yoo et al. [49] ( ), Ishikawa and Paradis [19] (●), Korobenko and Savvatimskii [50] (□), Ivashchenko and Martsenyuk [40] (■). Also shown, the melting temperature (--) and values calculated by Eq. 1 (

), Ishikawa and Paradis [19] (●), Korobenko and Savvatimskii [50] (□), Ivashchenko and Martsenyuk [40] (■). Also shown, the melting temperature (--) and values calculated by Eq. 1 ( )

)

Primary density data and Eq. 1 for liquid hafnium as a function of temperature. Yoo et al. [49] ( +), Cagran et al. [52] (●), Korobenko and Savvatimskii [53] (□), Ishikawa et al. [20] (__), Paradis et al. [54] (○), Arkhipkin et al. [55] (◊), Ivashchenko and Martenyuk [40] (▲). Also shown, the melting temperature (--) and values calculated by Eq. 1 ( )

)

Primary density data and Eq. 1 for liquid vanadium as a function of temperature. Reiplinger and Brillo [34] (□), Paradis et al. [56] (▲), Stankus [57] (◊), Gathers et al. [58] (●), Ivashchenko and Martenyuk [40] (x), Saito et al. [41] (◆). Also shown, the melting temperature (--) and values calculated by Eq. 1 ( )

)

Primary density data and Eq. 1 for liquid niobiuas a function of temperature. Jeon et al. [59] (□), Leitner and Pottlacher [60] (●), Yoo et al. [49] (+), Ishikawa and Paradis [19] (···), Hixson and Winkler [61] (○), Shaner et al. [62] (▲), Ivashchnko and Martenyuk [40] (△). Also shown, the melting temperature (–) and values calculated by Eq. 1 ( )

)

Examining at Figs. 1–9, it can be seen that some correlations, at higher temperatures, are based on measurements of only one investigator. This approach was also adopted in our previous correlations on molten metals and salts [6,7,8,9,10,11,12,13,14,15]. In such cases, the reader is advised to exercise caution. In more detail, looking at Figs. 1–9 together with the uncertainties quoted in Table 1 by the primary investigators, and the AAD of the fit, we note the following:

-

(a) Titanium, zirconium, hafnium, vanadium, niobium, tantalum

There is excellent agreement, i.e., the AAD of the measurements of each investigator in the fit of Eq. 1 for each liquid melt agree very well with the quoted uncertainty.

-

(b) Chromium

In this case, the data of Makeev and Popel [66] were linearly corrected as they employed a value for the melting temperature 90 K lower than the one employed here [17]. Furthermore, as already mentioned, the values of Tsu et al. [32] were included as the fourth set of primary data, with an estimated uncertainty of 4 %, reasonable for the measurement method used, but ultimately still arbitrary, as no uncertainty was specified by the author. Keeping this discussion in mind, in the case of chromium, the AAD of the measurements of each investigator in the fit of Eq. 1 for each liquid melt agree relatively well with the quoted uncertainties.

-

(c) Molybdenum

In the case of molybdenum, we note that the values of Hixson and Winkler [61] are up to 3 % higher than all the others. Nevertheless, the deviations from the straight line are within the mutual uncertainties.

-

(d) Tungsten

Finally, in the case of tungsten, as already mentioned, the 1986 data of Berthault et al. [33] were not considered in the primary data set as they were consistently lower than the other primary sets by about 9 % (see BIAS in Table 1)—although in the case of tantalum they were about 3 % lower.

In conclusion, the reference correlations for the density of the nine liquid metals considered are characterized by an expanded uncertainty (95 %) of less than 3 %, except for chromium (3.2 %) and tungsten (4.1 %), and cover a wide temperature range (except for chromium). As already stated, in the ranges where the correlation is based on the measurements of a single investigator, the reader should be more careful. Finally, values calculated from Eq. 1 with coefficients from Table 2 are presented in Sect. 5.

3 Thermal Conductivity

So far, there have been a few compilations of the thermal conductivity of the Group IV-VI liquid metals. In 1966, Powell et al. [71], and in 1971, Touloukian et al. [72] (also in part published as a journal article by Ho et al. [73]), published such compilations but with very few data in the liquid phase of these metals. Following the publication of more measurements in the literature, in 1996 Mills et al. [74] published a very comprehensive compilation. For the nine liquid metals considered here, Mills et al. [74] proposed a single thermal conductivity value at the melting point (with the exception of Cr). Since then, very few recommendations have been published for individual liquid metals, covering a wide temperature range. In this work, new recommendations for the thermal conductivity of these liquid metals are presented.

3.1 Experimental Techniques

In the case of the thermal conductivity of liquid metals, very few investigators directly measured the thermal conductivity, most measured electrical resistivity, as described later. Direct thermal conductivity measurements include Watanabe et al. [75, 76], who employed the laser modulation calorimetry (ModCal) technique that uses a superconducting magnet to generate a static magnetic field that suppresses surface oscillation, translational motion of the droplet, and convection flow in the droplet. The top of the levitated sample is periodically heated by laser irradiation, and the temperature response at the bottom of the droplet is detected by a pyrometer. The value of the thermal conductivity is obtained by analyzing the temperature variation with the modulation frequency and the phase shift between laser power and temperature response.

In order to measure the thermal diffusivity of liquid metals, Zinovyev and his collaborators [77,78,79,80,81,82,83,84] employed the plane temperature wave (PTW) technique. In this case, a PTW is created by the electronic bombardment of a small area of the sample, resulting in a mean temperature increase at a rate of 500 K·s−1. Oscillations of the surface temperature of the specimen, as well as the values of the phase shift after each modulation period, were registered. To register the point at which the specimen melts, as well as the diffusivity, the signal increase was measured and the melting process was recorded on a magnetic video sound recorder.

However, many investigators go the path of measuring electrical conductivity, or electrical resistivity, instead of thermal conductivity. Heat transport and thus thermal conductivity through a metal needs carriers. One has to distinguish between the component of the thermal conductivity due to electrons and that due to thermal vibration of atoms. Assuming that for liquid metals thermal conductivity, λ, is dominated by the electronic contribution, the electronic component of the thermal conductivity can be calculated by the Wiedemann–Franz law [85], from the following equation

where ρe(T) is the temperature-dependent electrical resistivity and L (= 2.45 × 10−8 W·Ω·Κ−1) is the Loren number [85]. As will be shown in the following section, most of the thermal conductivity values quoted are based on the measurement of electrical conductivity and the use of Eq. 2.

Electrical resistivity for liquid metals is most often obtained by a four-point probe technique in a resistive pulse heating (RPHeat) setup [26, 52, 67, 86,87,88,89,90,91,92]. The technique consists of passing a large current pulse (with the energy being pre-stored in a suitable device like a capacitor) through the material under investigation, shaped as a wire, which is mounted in series of a discharge circuit. Due to its Ohmic resistivity, the sample can be self-heated from room temperature far into the liquid phase within several microseconds. Experiments are typically performed in an inert atmosphere or vacuum. In such experiments, the electrical resistivity, ρe, is usually obtained from the equation [52]

where U(T) is the voltage drop across the sample, I(T) is the current through the setup, l is the active length of the wire, and r is the initial radius of the wire at room temperature. To be absolutely correct, the radius in Eq. 3 should be the expanded-with-temperature radius, and not the initial one. This however can easily be corrected from the volume expansion of the wire, obtained from the change in density with temperature.

In Table 3, measurements of the thermal conductivity are categorized by a superscript as

-

RES: electrical resistivity measurements where the volume expansion is included by the authors.

-

RES, IG: resistivity measurements at initial geometry (based on the initial volume of the wire). These measurements are not adjusted for the volume expansion by the authors. Hence, we have corrected them employing (a) the density equations proposed in this work—extrapolated to higher temperature if necessary, as it is a linear regression, and (b) the density at 298.15 K values of 4506 kg·m−3 (Ti), 8570 kg·m−3 (Nb), 16 400 kg·m−3 (Ta), and 19 300 kg·m−3 (W) [17].

-

TCC: thermal conductivity values directly proposed by the authors, irrespective of the method employed. These values are used unchanged for the correlation.

-

DIF: diffusivity measurements. For the conversion of thermal diffusivity to thermal conductivity, we employed (a) the density equations proposed in this work—extrapolated in temperature, if necessary, as it is a linear regression, and (b) the heat capacity constant values for the liquid melts of 33.51 J·mol−1·K−1 (Ti), and 47.28 J·mol−1·K−1 (V) [5]. We do note that in this case the uncertainty given refers to the diffusivity, hence the actual thermal conductivity uncertainty should be about 2 %–3 % higher.

Table 3 Data sets considered for the thermal conductivity of liquid titanium, zirconium, hafnium, vanadium, niobium, tantalum, chromium, molybdenum, and tungsten

Finally, it should be noted that techniques that measure directly the thermal conductivity or the thermal diffusivity are expected to produce more accurate results than those that calculate the thermal conductivity from the measurement of the electrical conductivity assuming the validity of the Wiedemann–Franz Law in the liquid phase.

3.2 Data Compilation

Table 3 presents the data sets found in the published literature for the thermal conductivity of liquid titanium, zirconium, hafnium, vanadium, niobium, tantalum, chromium, molybdenum, and tungsten. Similar to Table 1, the publication year, the technique employed, the purity of the sample, and the uncertainty quoted by the author are presented. Melting temperatures are also given [17]. Furthermore, the form in which the data are presented, and the temperature range covered, are also noted. As already discussed, the minimum temperature considered was the melting temperature. In the last two columns of Table 3, the average absolute percent deviation (AAD) and the bias percent (BIAS) are also given. We also note that Table 3 does not include publications [28, 69, 93,94,95,96,97,98,99,100,101,102,103] that were superseded by more recent ones from the same authors, unless the range of measurements was different. The data sets have been classified into primary and secondary according to the criteria presented earlier.

3.3 Thermal Conductivity Reference Correlation

The primary thermal data for liquid titanium, zirconium, hafnium, vanadium, niobium, tantalum, chromium, molybdenum, and tungsten, shown in Table 3, were employed in a regression analysis as a function of temperature. The data were weighted inversely proportional to their uncertainty squared (uncertainties quoted at the 95 % confidence level were reduced by a factor of 2). When investigators quoted no uncertainty, their measurements were included with an uncertainty of double the highest value in the group. The following equation was chosen for the thermal conductivity, λ (W·m−1·K−1), as a function of the absolute temperature, T (K):

and the coefficients d0 (W·m−1·K−1), d1 (W·m−1·K−2), and d2 (W·m−1 K−3), as well as the melting temperature Tm (K), are shown for each liquid metal in Table 4. In the same table, the expanded uncertainty (95 %), denoted as 2σ (95 %), of each equation is also shown. The AAD and BIAS (defined in Sect. 2.3) of the data of each investigator from Eq. 4, as well as the whole fit for each liquid metal, are shown in Table 3. Figures 10, 11, 12, 13, 14, 15, 16, and 17 show the primary data for each liquid metal with the melting point indicated by the dashed vertical line.

Primary thermal-conductivity data and Eq. 4 for liquid titanium as a function of temperature. Watanabe et al. [75] (…), Wilthan et al. [90] (▬), Zinovyev et al. [84] (■), Polev [78] (▲), Geld et al. [77] (●), Seydel and Fucke [91] (- ·). Also shown, the melting temperature (--) and values calculated by Eq. 4 ( )

)

Primary thermal-conductivity data and Eq. 4 for liquid zirconium as a function of temperature. Brunner et al. [86] (□), Korobenko and Savvatimsky [50] (○), Zinovyev et al. [81] (△), Gathers [39] (●), Martynyuk et al. [104] (x). Also shown, the melting temperature (--) and values calculated by Eq. 4 ( )

)

Primary thermal-conductivity data and Eq. 4 for liquid vanadium as a function of temperature. Watanabe et al. [76] (○), Pottlacher et al. [89] (◊), Taluts et al. [79] (□), Zinovyev et al. [84] (▲), Seydel and Fucke [91] (●), Gathers et al. [58] (x). Also shown, the melting temperature (--) and values calculated by Eq. 4 ( )

)

Primary thermal-conductivity data and Eq. 4 for liquid niobium as a function of temperature. Wilthan et al. [90] (…), Hixson and Winkler [61] (○), Taluts et al. [79] (□), Cezairliyan and McClure [105] (▲), Zinovyev et al. [82] (△), Gallob et al. [27] (■), Shaner et al. [62] (◊), Martynyuk et al. [104] (x). Also shown, the melting temperature (--) and values calculated by Eq. 4 ( )

)

Primary thermal-conductivity data and Eq. 4 for liquid tantalum as a function of temperature. Jäger et al. [26] (○), Berthault et al. [33] (△), Zinovyev et al. [82] (□), Gathers et al. [65] (●), Shaner et al. [92] (▲), Lebedev et al. [103] ( ). Also shown, the melting temperature (--) and values calculated by Eq. 4 (

). Also shown, the melting temperature (--) and values calculated by Eq. 4 ( )

)

Primary thermal-conductivity data and Eq. 4 for liquid molybdenum as a function of temperature. Cagran et al. [87] (●), Pottlacher [88] (···), Hixson and Winkler [107] (○), Taluts et al. [79] (△), Seydel and Fucke [91] (- ·), Shaner et al. [92] (▲), Martynyuk et al. [104] (x). Also shown, the melting temperature (--) and values calculated by Eq. 4 ( )

)

Primary thermal-conductivity data and Eq. 4 for liquid tungsten as a function of temperature. Wilthan et al. [90] (- ·), Hess et al. [70] (△), Kuskova et al. [109] (○), McClure and Cezairliyan [110] (+), Hixson and Winkler [111] (◆), Taluts et al. [79] (◊), Berthault et al. [33] (□), Zinovyev and Taluts [83] (▲), Seydel and Fucke [91] (●), Shaner et al. [28] ( ), Dikhter and Lebedev [108] (x). Also shown, the melting temperature (--) and values calculated by Eq. 4 (

), Dikhter and Lebedev [108] (x). Also shown, the melting temperature (--) and values calculated by Eq. 4 ( )

)

Examining Figs. 10–17 together with the AAD quoted in Table 3 and the uncertainties shown in Table 4, we note the following:

-

(a)

Titanium, zirconium, hafnium, and vanadium

Looking at Fig. 10, it becomes apparent that the calculated values (Wilthan et al. [90], and Seydel and Fucke [91]) by the Wiedemann–Franz Law are lower than the experimentally measured ones. Watanabe et al. [75] attempted to explain this behavior by suggesting that the contribution of atomic thermal vibration to thermal conductivity cannot be ignored for the titanium melts, and hence questioned the accuracy of the Wiedemann–Franz law. Therefore, the proposed reference correlation up to 2100 K is a weight average of all values, and following this up to 5000 K, the temperature slope is obtained from the measurements of Seydel and Fucke [91]. This way, within its deviation of 12.8% (at the 95 % confidence level), the correlation should be valid.

-

(b)

Niobium, tantalum

A very similar behavior can be observed in zirconium, hafnium, and vanadium. In all these cases, the thermal conductivity values obtained directly by the modulation calorimetry technique or the PTW are higher than those calculated by the Wiedemann–Franz law. Hence, the recommended correlation is obtained in the fashion outlined above. In the case of zirconium, in order to obtain the values of resistivity of Gathers et al. [39] as a function of temperature (they were given as a function of enthalpy), the values of Korobenko and Savvatimsky [50] of enthalpy as a function of temperature were employed.

Furthermore, we note that in the case of vanadium the correlation is restricted to 3900 K as over this temperature, the two sets of measurements (Seydel and Fucke [91] and Gathers et al. [58]) start to diverge with no apparent reason.

In the case of niobium and tantalum, the agreement among the investigators is much better. We note that the correlation for niobium is restricted to 4500 K as after this temperature the data (Gallob et al. [27]) started to curve considerably.

-

(c)

Chromium

In the case of chromium, there is only one set of measurements (Levin et al. [106]), obtained in a 4-point probe method on a liquid sample in a crucible in a furnace heater, with a 7% quoted uncertainty. There are also two sets of measurements (Van Zytveld [112], Baum et al. [113]) near the melting point, but they refer to a much lower melting temperature, and thus they were not included in this analysis. Therefore, no correlation as a function of the temperature can be obtained in this case.

-

(d)

Molybdenum, tungsten

In both these last two melts, the temperature had to be restricted, to 4500 K for molybdenum (measurements of Pottlacher [88], Hixson and Winkler [61], and Seydel and Fucke [91]), and 6000 K for tungsten (Hess et al. [70] and Seydel and Fucke [91]), as above this temperature the measurements started to deviate much more from each other than their mutual uncertainties. It should also be noted that in the case of tungsten, the measurements of Martynyuk et al. [104] were not included in the primary data set, as they were much lower than all the other measurements of the thermal conductivity of tungsten.

In conclusion, it seems that the calculated thermal conductivity values by the Wiedemann–Franz Law are systematically lower than the experimentally measured ones. Therefore, the proposed reference correlations in such cases at low temperature is a weighted average of all values, while the temperature slope is obtained from the measurements calculated by the Wiedemann–Franz Law. The reference correlations for the thermal conductivity of the eight liquid metals (except chromium) considered are characterized by an expanded uncertainty (95 %) of less than 8% (except for titanium and vanadium), and cover a wide range of temperatures. As already stated in the case of the density, in the ranges where the correlation is based on the measurements of a single investigator, the reader should be more careful. Finally, thermal conductivity recommended values calculated from Eq. 4 with coefficients from Table 4 are presented in Sect. 5.

4 Viscosity

4.1 Experimental Techniques

There exist a large number of methods to measure the viscosity of liquids, but those suitable for liquid metals are limited by the low viscosities of metals (of the order of 1–10 mPa·s), their chemical reactivity, and generally high melting points. Proposed methods include: capillary; oscillating cup; rotational bob; oscillating plate; draining vessel; levitated drop, and acoustic methods. These methods have been presented in our previous compilations [6, 7] and will not be discussed here.

Most measurements use some form of oscillating-cup viscometer. A vessel containing the test liquid, normally a cylinder, is suspended by a torsion wire and is set in motion about the vertical axis. The oscillatory motion is damped by viscous friction within the liquid, and consequently the viscosity is determined from the decrement and time period of the motion. The electrostatic levitation technique employed for the measurement of the density of liquid metals is also employed for the measurement of the viscosity. In the electrostatic levitation methods, viscosity was determined by measuring the decay time of the surface oscillation of the levitated sample. When employed properly, it can produce very good results.

In the case of the measurement of the viscosity of liquid metals, the techniques employed are very sensitive to the impurities of the samples, and in particular to surface impurities like sulfur or oxygen.

4.2 Data Compilation

Table 5 presents the data sets found in the published literature that include original experimental measurement results for the viscosity of liquid titanium, zirconium, hafnium, vanadium, niobium, tantalum, chromium, molybdenum, and tungsten. As in Table 1 and 3, the publication year, the technique employed, the purity of the sample, and the uncertainty quoted by the author are presented. Melting temperatures are also given [17]. The form in which the data are presented and the temperature range covered are also noted. The minimum temperature considered was the melting temperature. Note that Table 5 does not include publications [114,115,116,117] that were superseded by more recent ones from the same authors, unless the range of measurements was different. When kinematic viscosity is quoted, the density correlations proposed at Sect. 2 were employed to calculate the dynamic viscosity.

4.3 Viscosity Correlation

Examining Table 5, we note that in the case of titanium and zirconium, there are measurements of various investigators. In the case of hafnium, there are only two sets of measurements, while in the case of vanadium, niobium, tantalum, chromium, and molybdenum there is only one set of measurements for each one. Finally in the case of tungsten only two viscosity values (6111 μPa·s and 7500 μPa·s) at the melting point 3695 K, from the same investigator [68] were found.

Figures 18 and 19 show the primary viscosity data for titanium and zirconium as a function of the temperature. The vertical line shows the melting point for each metal. Although various sets appear in the literature, the deviations between investigators by far exceed the mutual uncertainties—in the case of the viscosity of zirconium for example (see Fig. 19), around 2250 K, viscosity values range between 2500 μPa·s and 8500 μPa·s! Furthermore, the most recent values are the highest values. For the rest of the liquid metals, as it can be seen in Table 5, there are very few measurements in the literature. In conclusion, the very large spread of viscosity measurements for liquid titanium and zirconium, as well as the lack of measurements for the remaining melts, do not justify the proposition of any kind of correlation.

5 Recommended values

Table 6 presents recommended values, calculated from Eqs. 1 and 4, for the density and thermal conductivity of the melts considered.

6 Conclusions

In the case of the density, the proposed reference correlations for the nine liquid metals considered are characterized by an expanded uncertainty (95%) of less than 3% (except for chromium and tungsten) and cover a wide range of temperatures (except for chromium). Furthermore, the reference correlations for the thermal conductivity for the eight liquid metals (except chromium) proposed are characterized by an expanded uncertainty (95%) of less than 8% (except for titanium and vanadium), and also cover a wide range of temperatures. However, the very large spread of viscosity measurements for liquid titanium and zirconium, as well as the lack of measurements for the remaining melts, do not justify the proposition of any kind of correlation.

A further interesting point that ought to be noted is that values of the thermal conductivity calculated by the Wiedemann–Franz Law (a) for titanium, zirconium, and vanadium are lower than the experimental ones, (b) for niobium and molybdenum are higher, while (c) for the remaining metals agree with the experimental values. This observation may need to be further investigated.

Finally, as already stated, in the ranges where the correlations are based on the measurements of a single investigator, the reader should be more careful.

Data Availability

No datasets were generated or analysed during the current study.

References

L. Bing, E.J. Laverna, Compreh. Comput. Mater. 3, 617 (2000). https://doi.org/10.1016/B0-08-042993-9/00023-1

B.J. Blaiszik, S.L.B. Kramer, M.E. Grady, D.A. McIlroy, J.S. Moore, N.R. Sottos, S.R. White, Adv. Mater. 24, 398 (2012). https://doi.org/10.1002/adma.201102888

O.O. Versolato, Plasma Sources Sci. Technol. 28, 083001 (2019). https://doi.org/10.1088/1361-6595/ab3302

E.G. Rasmussen, B. Wilthan, B. Simonds, NIST SP 1500-208, Report from the Extreme Ultraviolet (EUV) Lithography Working Group Meeting: Current State, Needs, and Path Forward, NIST, Boulder, CO (2023) https://doi.org/10.6028/NIST.SP.1500-208

T. Iida, R.I.L. Guthrie, The Thermophysical Properties of Metallic Liquids (Oxford University Press, Oxford, 2015)

M.J. Assael, K.E. Kakosimos, R.M. Banish, J. Brillo, I. Egry, R. Brooks, P.N. Quested, K.C. Mills, A. Nagashima, Y. Sato, W.A. Wakeham, J. Phys. Chem. Ref. Data 35, 285 (2006). https://doi.org/10.1063/1.2149380

M.J. Assael, A.E. Kalyva, K.E. Antoniadis, R.M. Banish, I. Egry, P.N. Quested, J. Wu, E. Kaschnitz, W.A. Wakeham, J. Phys. Chem. Ref. Data 39, 033105 (2010). https://doi.org/10.1063/1.3467496

M.J. Assael, A.E. Kalyva, K.E. Antoniadis, R.M. Banish, I. Egry, J. Wu, E. Kaschnitz, W.A. Wakeham, High Temp. High Press. 41, 161 (2012)

M.J. Assael, I.J. Armyra, J. Brillo, S. Stankus, J. Wu, W.A. Wakeham, J. Phys. Chem. Ref. Data 41, 033101 (2012). https://doi.org/10.1063/1.4729873

M.J. Assael, E.K. Mihailidou, J. Brillo, S. Stankus, J.T. Wu, W.A. Wakeham, J. Phys. Chem. Ref. Data 41, 033103 (2012). https://doi.org/10.1063/1.4750035

M.J. Assael, A. Chatzimichailidis, K.D. Antoniadis, W.A. Wakeham, M.L. Huber, H. Fukuyama, High Temp. High Press. 46, 391 (2017)

M.J. Assael, K.D. Antoniadis, W.A. Wakeham, M.L. Huber, H. Fukuyama, J. Phys. Chem. Ref. Data 46, 033101 (2017). https://doi.org/10.1063/1.4991518

C. Chliatzou, M.J. Assael, K.D. Antoniadis, M.L. Huber, W.A. Wakeham, J. Phys. Chem. Ref. Data 47, 033104 (2018). https://doi.org/10.1063/1.5052343

K.A. Tasidou, J. Magnusson, T. Munro, M.J. Assael, J. Phys. Chem. Ref. Data 48, 043102 (2019). https://doi.org/10.1063/1.5131349

M.J. Assael, A.E. Kalyva, S.A. Monogenidou, M.L. Huber, R.A. Perkins, D.G. Friend, E.F. May, J. Phys. Chem. Ref. Data 47, 021501 (2018). https://doi.org/10.1063/1.5036625

B. Wilthan, V. Diky, A. Kazakov, K. Kroenlein, C. Muzny, D. Riccardi, S. Townsend, NIST Alloy Data. https://doi.org/10.18434/M32153. https://trc.nist.gov/metals_data. Accessed 11 Mar 2023

W.M. Haynes, D.R. Lide, T.J. Bruno, CRC Handbook of Chemistry and Physics, 95th edn (CRC Press, Taylor and Francis Group, Boca Raton, 2014)

T. Ishikawa, C. Koyama, P.F. Paradis, J.T. Okada, Y. Nakata, Y. Watanabe, Int. J. Refract. Met. Hard Mater. 92, 105305 (2020). https://doi.org/10.1016/j.ijrmhm.2020.105305

T. Ishikawa, P.F. Paradis, J. Electron. Mater. 34, 1526 (2005). https://doi.org/10.1007/s11664-005-0160-z

T. Ishikawa, P.F. Paradis, T. Itami, S. Yoda, Meas. Sci. Technol. 16, 443 (2005). https://doi.org/10.1088/0957-0233/16/2/016

P.F. Paradis, T. Ishikawa, R. Fujii, S. Yoda, Appl. Phys. Lett. 86, 041901 (2005). https://doi.org/10.1063/1.1853513

P.F. Paradis, W.K. Rhim, J. Chem. Thermodyn. 32, 123 (2000). https://doi.org/10.1006/jcht.1999.0576

P.F. Paradis, W.K. Rhim, J. Mater. Res. 14, 3713 (1999). https://doi.org/10.1557/JMR.1999.0501

P.F. Paradis, W.K. Rhim, Proc. SPIE, Materials Research in Low Gravity II, vol. 3792, p. 292 (SPIE The International Society for Optical Engineering, 1999). https://doi.org/10.1117/12.351289

J.T. Okada, T. Ishikawa, Y. Watanabe, P.F. Paradis, J. Chem. Thermodyn. 42, 856 (2010). https://doi.org/10.1016/j.jct.2010.02.008

H. Jäger, W. Neff, G. Pottlacher, Int. J. Thermophys. 13, 83 (1992). https://doi.org/10.1007/BF00503358

R. Gallob, H. Jager, G. Pottlacher, High Temp. High Press. 17, 207 (1985)

J.W. Shaner, G.P. Gathers, C. Minichino, High Temp. High Press. 8, 425 (1976)

S. Amore, S. Delsante, H. Kobatake, J. Brillo, J. Chem. Phys. 139, 064504 (2013). https://doi.org/10.1063/1.4817679

J. Brillo, T. Schumacher, K. Kajikawa, Metall. Mater. Trans. A 50, 924 (2018). https://doi.org/10.1007/s11661-018-5047-8

J.J. Wessing, J. Brillo, Metall. Mater. Trans. A 48, 868 (2016). https://doi.org/10.1007/s11661-016-3886-8

Y. Tsu, K. Takano, S. Watanabe, Y. Shiraishi, Tohoku Daigaku Senko Seiren Kenkyusho Iho 34, 131 (1978)

A. Berthault, L. Arles, J. Matricon, Int. J. Thermophys. 7, 167 (1986). https://doi.org/10.1007/bf00503808

B. Reiplinger, J. Brillo, J. Mater. Sci. 57, 7954 (2022). https://doi.org/10.1007/s10853-022-07090-2

M. Watanabe, M. Adachi, H. Fukuyama, J. Mater. Sci. 54, 4306 (2019). https://doi.org/10.1007/s10853-018-3098-2

P.F. Zou, H.P. Wang, S.J. Yang, L. Hu, B. Wei, Metall. Mater. Trans. A 49, 5488 (2018). https://doi.org/10.1007/s11661-018-4877-8

S. Ozawa, Y. Kudo, K. Kuribayashi, Y. Watanabe, T. Ishikawa, Mater. Trans. 58, 1664 (2017). https://doi.org/10.2320/matertrans.L-M2017835

J.P. Rausch, PhD Thesis (Louisiana State University and Agricultural and Mechanical College, 2016)

G.R. Gathers, Int. J. Thermophys. 4, 271 (1983). https://doi.org/10.1007/BF00502358

Y.N.I. Ivashchenko, P.S. Martsenyuk, Zavod. Lab. 39, 42 (1973)

T. Saito, Y. Shiraishi, Y. Sakuma, Trans ISIJ 9, 118 (1969). https://doi.org/10.2355/isijinternational1966.9.118

G.W. Lee, S. Jeon, C. Park, D.-H. Kang, J. Chem. Thermodyn. 63, 1 (2013). https://doi.org/10.1016/j.jct.2013.03.012

U. Seydel, W. Kitzel, J. Phys. F Met. Phys. 9, L153 (1979). https://doi.org/10.1088/0305-4608/9/9/001

V.P. Elyutin, V.I. Kostikov, I.A. Pen’kov, Sov. Powder Metall. Met. Ceram. 9, 736 (1970). https://doi.org/10.1007/BF00836965

M.A. Maurakh, Trans. Indian Inst. Metals 14, 209 (1964)

V.P. Elyutin, M.A. Maurakh, Moskva Izd-vo Akademii nauk SSSR 4, 129 (1956)

J. Nawer, D.M. Matson, High Temp. High Press. 52, 123 (2023). https://doi.org/10.32908/hthp.v52.1315

J. Zhao, PhD thesis (University of Massachusetts, Amherst, 2020)

H. Yoo, C. Park, S. Jeon, S. Lee, G.W. Lee, Metrologia 52, 677 (2015). https://doi.org/10.1088/0026-1394/52/5/677

V.N. Korobenko, A.I. Savvatimskii, Russ. J. Phys. Chem. 77, 1564 (2003)

Y. Ohishi, K. Kurokawa, Y. Sun, H. Muta, J. Nucl. Mater. 528, 151873 (2020). https://doi.org/10.1016/j.jnucmat.2019.151873

C. Cagran, T. Hüpf, B. Wilthan, G. Pottlacher, High Temp. High Press. 37, 205 (2008)

V.N. Korobenko, A.I. Savvatimskii, High Temp. High Press. (Engl. Transl.) 45, 159 (2007). https://doi.org/10.1134/S0018151X07020046

P.F. Paradis, T. Ishikawa, S. Yoda, Int. J. Thermophys. 24, 239 (2003). https://doi.org/10.1023/A:1022326618592

V.I. Arkhipkin, G.A. Grigoriev, V.I. Kostikov, in Physical Chemistry of Boundaries of Melts of Contacting Phases, vol. 74 (Naukova dumka, Kiev, 1976)

P.F. Paradis, T. Ishikawa, T. Aoyama, S. Yoda, J. Chem. Thermodyn. 34, 1929 (2002). https://doi.org/10.1016/S0021-9614(02)00126-X

V. Stankus, High Temp. 31, 684 (1993)

G.R. Gathers, J.W. Shaner, R.S. Hixson, D.A. Young, High Temp. High Press. 11, 653 (1979)

S. Jeon, S. Ganorkar, Y.C. Cho, J. Lee, M. Kim, J. Lee, G.W. Lee, Metrologia 59, 045008 (2022). https://doi.org/10.1088/1681-7575/ac7688

M. Leitner, G. Pottlacher, Metall. Mater. Trans. A 50, 3646 (2019). https://doi.org/10.1007/s11661-019-05262-5

R.S. Hixson, M.A. Winkler, High Press. Res. 4, 555 (1990). https://doi.org/10.1080/08957959008246186

J.W. Shaner, G.R. Gathers, W.M. Hodgson, Proc. 7th Symp. Thermophys. Prop., ed. by A. Cezairliyan, 10–12 May 1977, Gaithersburg, USA, p. 896 (1977)

M. Leitner, W. Schröer, G. Pottlacher, Int. J. Thermophys. 39, 124 (2018). https://doi.org/10.1007/s10765-018-2439-3

M. Dal, F. Coste, M. Schneider, R. Bolis, R. Fabbro, J. Laser Appl. 31, 022604 (2019). https://doi.org/10.2351/1.5096138

G.R. Gathers, Int. J. Thermophys. 4, 149 (1983). https://doi.org/10.1007/bf00500138

V.V. Makeev, P.S. Popel, High Temp. (Engl. Transl.) 28, 525 (1990)

G. Pottlacher, E. Kaschnitz, H. Jäger, J. Phys. Condens. Matter 3, 5783 (1991). https://doi.org/10.1088/0953-8984/3/31/002

P.F. Paradis, T. Ishikawa, R. Fujii, S. Yoda, Heat Transf. Res. 35, 152 (2006). https://doi.org/10.1002/htj.20101

S.V. Koval, N.I. Kuskova, S.I. Tkachenko, High Temp. 35, 863 (1997)

H. Hess, A. Kloss, A. Rakhel, H. Schneidenbach, Int. J. Thermophys. 20, 1279 (1999). https://doi.org/10.1023/A:1022635727340

R.W. Powell, C.Y. Ho, P.E. Liley, Thermal Conductivity of Selected Materials (National Standard Reference Data Series—8 (National Bureau of Standards, 1966). https://doi.org/10.6028/NBS.NSRDS.8

Y.S. Touloukian, R.W. Powell, C.Y. Ho, P.G. Klemens, Thermal Conductivity. Metallic Elements and Alloys (Plenum, New York, 1971)

C.Y. Ho, R.W. Powell, P.E. Liley, J. Phys. Chem. Ref. Data 1, 279 (1972). https://doi.org/10.1063/1.3253100

K.C. Mills, B.J. Monaghan, B.J. Keene, Int. Mater. Rev. 41, 209 (1996). https://doi.org/10.1179/imr.1996.41.6.209

M. Watanabe, M. Adachi, H. Fukuyama, J. Mol. Liq. 324, 115138 (2020). https://doi.org/10.1016/j.molliq.2020.115138

M. Watanabe, M. Adachi, H. Fukuyama, Proc. 22nd Conf. Thermophys. Prop., Venice, Italy, 9–12 September 2023

P.V. Geld, S.A. Ilinykh, S.G. Taluts, V.E. Zinoviev, Dokl. Akad. Nauk SSSR 267, 602 (1982)

V.F. Polev, V.E. Zinoviev, I.G. Korshunov, High Temp. 23, 704 (1985)

S.G. Taluts, V.F. Polev, V.E. Zinovyev, D.M. Tagirova, R.S. Nasyrov, High-Purity Subst. 3, 208 (1988)

S.G. Taluts, V.E. Zinovyev, V.F. Polev, S.A. Ilinykh, Fiz. Met. Metalloved. 58, 617 (1984)

V.E. Zinovyev, V.F. Polev, S.A. Ilinykh, G.P. Zinovyeva, S.G. Taluts, Fiz. Met. Metalloved. 60, 47 (1985)

V.E. Zinovyev, V.F. Polev, S.G. Taluts, P.V. Geld, Fiz. Tverd. Tela 9, 2914 (1986)

V.E. Zinovyev, S.G. Taluts, Fiz. Met. Metalloved. 59, 79 (1985)

V.Y. Zinovyev, V.F. Polev, S.G. Taluts, G.P. Zinovyeva, S.A. Ilinykh, Phys. Met. Metall. 61, 85 (1986)

P. Pichler, G. Pottlacher, Thermal conductivity of liquid metals, in Impact of Thermal Conductivity on Energy Technologies (IntechOpen, London, 2018)

C. Brunner, C. Cagran, A. Seifter, G. Pottlacher, AIP Conf. Proc. 684, 771 (2003). https://doi.org/10.1063/1.1627221

C. Cagran, B. Wilthan, G. Pottlacher, Int. J. Thermophys. 25, 1551 (2004). https://doi.org/10.1007/s10765-004-5758-5

G. Pottlacher, J. Non-Cryst, Solids 250–252, 177 (1999). https://doi.org/10.1016/S0022-3093(99)00116-7

G. Pottlacher, T. Hüpf, B. Wilthan, C. Cagran, Thermochim. Acta 461, 88 (2007). https://doi.org/10.1016/j.tca.2006.12.010

B. Wilthan, C. Cagran, G. Pottlacher, Int. J. Thermophys. 26, 1017 (2005). https://doi.org/10.1007/s10765-005-6682-z

U. Seydel, W. Fucke, J. Phys. F Met. Phys. 10, L203 (1980). https://doi.org/10.1088/0305-4608/10/8/001

J.W. Shaner, G.P. Gathers, C. Minichino, High Temp. High Press. 9, 331 (1977)

A. Cezairliyan, High Temp. High Press. 4, 453 (1972)

E. Kaschnitz, G. Pottlacher, L. Windholz, High Press. Res. 4, 558 (1990). https://doi.org/10.1080/08957959008246187

V.N. Korobenko, A.I. Savvatimskii, Teplofiz. Vys. Temp. 29, 883 (1991)

V.N. Korobenko, A.I. Savvatimskii, High Temp. 39, 525 (2001). https://doi.org/10.1023/A:1017932122529

S.V. Lebedev, J. Exp. Theor. Phys. 5, 243 (1957)

G. Pottlacher, E. Kaschnitz, H. Jäger, J. Non-Cryst. Sol. 156–158, 374 (1993). https://doi.org/10.1016/0022-3093(93)90200-H

U. Seydel, H. Bauhof, W. Fucke, H. Wadle, High Temp. High Press. 11, 35 (1979)

S.G. Taluts, V.F. Polev, V.E. Zinov’ev, D.M. Tagirova, R.S. Nasyrov, Vysok. vesh, Akad. 3, 208 (1988)

K. Boboridis, PhD Thesis (TU-Graz, Austria, 2001)

T. Hüpf, C. Cagran, G. Pottlacher, EPJ Web Conf. 15, 01018 (2011). https://doi.org/10.1051/epjconf/20111501018

S.V. Lebedev, A.I. Savvatimskii, Y.B. Smirnov, High Temp. 9, 578 (1971)

M.M. Martynyuk, I. Karimkhodzhaev, V.I. Tsapkov, Sov. Phys. Tech. Phys. 19, 1458 (1975)

A. Cezairliyan, J.L. McClure, Int. J. Thermophys. 8, 803 (1987). https://doi.org/10.1007/BF00500796

E.S. Levin, P.V. Geld, G.D. Aynshina, Izv. Vyssh. Ucheb. Zaved. Tsvet. Met. 16, 123 (1973)

R.S. Hixson, M.A. Winkler, Int. J. Thermophys. 13, 477 (1992). https://doi.org/10.1007/BF00503884

I.Y. Dikhter, S.V. Lebedev, High Temp. 9, 845 (1971)

N.I. Kuskova, S.I. Tkachenko, S.V. Koval, Int. J. Thermophys. 19, 341 (1998). https://doi.org/10.1023/A:1021427925109

J.L. McClure, A. Cezairliyan, Int. J. Thermophys. 14, 449 (1993). https://doi.org/10.1007/BF00566044

R.S. Hixson, M.A. Winkler, Int. J. Thermophys. 11, 709 (1990). https://doi.org/10.1007/BF01184339

J.B. VanZytveld, J. Non-Cryst. Solids 61 & 62, 1085 (1984). https://doi.org/10.1016/0022-3093(84)90685-9

B.A. Baum, P.V. Geld, S.I. Suchil’nikov, Akad. Nauk SSSR Izv. Metall. Gonoe Dero 2, 149 (1964)

P. Paradis, T. Ishikawa, S. Yoda, Int. J. Thermophys. 23, 825 (2002). https://doi.org/10.1023/A:1015459222027

P.F. Paradis, T. Ishikawa, S. Yoda, J. Appl. Phys. 97, 053506 (2005). https://doi.org/10.1063/1.1854211

P.F. Paradis, T. Ishikawa, N. Koike, Int. J. Refract. Met. Hard Mater. 25, 95 (2007). https://doi.org/10.1016/j.ijrmhm.2006.02.001

W.K. Rhim, K. Ohsaka, P.F. Paradis, R.E. Spjut, Rev. Sci. Instrum. 70, 2796 (1999). https://doi.org/10.1063/1.1149797

T. Ishikawa, P.F. Paradis, J.T. Okada, Y. Watanabe, Meas. Sci. Technol. 23, 025305 (2012). https://doi.org/10.1088/0957-0233/23/2/025305

A.D. Agaev, V.I. Kostikov, V.N. Bobkovskii, Izv. Akad. Nauk. SSSR Met. 3, 43 (1980)

G.A. Grigoriev, V.P. Elyutin, M.A. Maurakh, Izv. Akad. nauk SSSR. Otd. Tekhn. 8, 95 (1957)

S. Xue, W. Dong, D. Chen, Q. Guo, H. He, J. Yu, Rev. Sci. Instrum. 92, 065111 (2021). https://doi.org/10.1063/5.0026974

V.P. Elyutin, M.A. Maurakh, V.D. Turov, Izv. Vyssh. Uchebn. Zaved. Chem. Metall. 8, 110 (1965)

T. Ishikawa, P.F. Paradis, J. Okada, M.V. Kumar, Y. Watanabe, J. Chem. Thermodyn. 65, 1 (2013). https://doi.org/10.1016/j.jct.2013.05.036

B.A. Baum, P.V. Geld, P.V. Kocherov, Russ. Metall. 27, 27 (1967)

Acknowledgements

The authors acknowledge useful discussions with Prof. Gernot Pottlacher, Graz University of Technology, Austria.

Funding

Open access funding provided by HEAL-Link Greece. This study was partially supported by the National Institute of Standards and Technology.

Author information

Authors and Affiliations

Contributions

All authors contributed equally in preparing and reviewing this manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Ntonti, E., Sotiriadou, S., Assael, M.J. et al. Reference Correlations for the Density and Thermal Conductivity, and Review of the Viscosity Measurements, of Liquid Titanium, Zirconium, Hafnium, Vanadium, Niobium, Tantalum, Chromium, Molybdenum, and Tungsten. Int J Thermophys 45, 18 (2024). https://doi.org/10.1007/s10765-023-03305-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10765-023-03305-z

)

)

)

)

). Also shown, the melting temperature (--) and values calculated by Eq.

). Also shown, the melting temperature (--) and values calculated by Eq.  )

)

). Also shown, the melting temperature (--) and values calculated by Eq.

). Also shown, the melting temperature (--) and values calculated by Eq.  )

)

)

)