Abstract

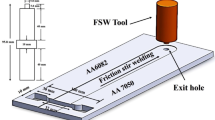

This work deals with the regression models and multi-objective optimization method of the ultimate tensile strength, percentage of elongation, and average arithmetic surface roughness of butt friction stir welded AA2024-T3 aluminum alloy. Machining experiments were carried out according to the face centered central composite design of the response surface methodology. The effect of friction stir welding process parameters such as rotation speed, welding speed, and tool shoulder diameter on responses was investigated. Adequacies of the models are checked by the analysis of variance. The optimization of multiple responses was performed using the desirability analysis to achieve the higher ultimate tensile strength, maximum percentage of elongation, and minimum arithmetic surface roughness. From this investigation, it is found that the joints fabricated with the tool rotational speed of 752 rpm, welding speed of 100 mm/min, and tool shoulder diameter of 12.5 mm yield the maximum ultimate tensile strength and percentage of elongation, and minimum arithmetic surface roughness of 379.69 MPa, 10.22% MPa, and 6.66 HV, respectively. The effects of process parameters on the microhardness of welded zone were studied. The macrostructure, microstructure, and residual stress characterization of joints are examined.

Similar content being viewed by others

Data Availability

All data generated or analyzed during this study are included in this manuscript.

Code Availability

Not applicable for that section.

References

Boulahem K, Ben Salem S, Bessrour J (2018) Prediction model of ultimate tensile strength and investigation on microstructural characterization of friction stir welded AA2024-T3. Int J Adv Manuf Technol 95:1473–1486. https://doi.org/10.1007/s00170-017-1215-z

Boukraa M, Chekifi T, Lebaal N (2022) Friction stir welding of aluminum using a multi-objective optimization approach based on both Taguchi method and grey relational analysis. Exp Tech. https://doi.org/10.1007/s40799-022-00573-6

Boukraa M, Chekifi T, Lebaal N, Aissani M (2022) Robust optimization of both dissolution time and heat affected zone over the friction stir welding process using SQP technique. Exp Tech 46:677–689. https://doi.org/10.1007/s40799-021-00515-8

Nagarajan BM, Manoharan M (2022) Influence of cooling conditions on tensile lap shear strength and microstructure of friction stir welded aluminum alloy 5052–H32 and polycarbonate light weight hybrid joint. J Manuf Process 82:390–402. https://doi.org/10.1016/j.jmapro.2022.08.008

Dinesh Kumar R, IlharUl Hassan MS, Muthukumaran S, Venkateswaran T, Sivakumar D (2019) Single and multi-response optimization and validation of mechanical properties in dissimilar friction stir welded AA2219-T87 and AA7075-T73 alloys using T-GRA. Exp Tech 43:245–259. https://doi.org/10.1007/s40799-019-00305-3

Safeen W, Hussain S, Wasim A, Jahanzaib M, Aziz H, Abdalla H (2016) Predicting the tensile strength, impact toughness, and hardness of friction stir-welded AA6061-T6 using response surface methodology. Int J Adv Manuf Technol 87:1765–1781. https://doi.org/10.1007/s00170-016-8565-9

Deepandurai K, Parameshwaran R (2016) Multiresponse optimization of FSW parameters for Cast AA7075/SiCp composite. Mater Manuf Process 31:1333–1341. https://doi.org/10.1080/10426914.2015.1117628

Babu N, Karunakaran N, Balasubramanian V (2015) A study to estimate the tensile strength of friction stir welded AA 5059 aluminium alloy joints. Int J Adv Manuf Technol: 1333–1341. https://doi.org/10.1007/s00170-015-7391-9

Heidarzadeh A (2019) Tensile behavior, microstructure, and substructure of the friction stir welded 70/30 brass joints: RSM, EBSD, and TEM study. Arch Civ Mech Eng 19:137–146. https://doi.org/10.1016/j.acme.2018.09.009

Sachinkumar CD, Narendranath S (2021) Analysis of the effect of friction stir welding parameters on characteristics of AA6061 composites using response surface methodology. Trans Indian Inst Met 74:1303–1319. https://doi.org/10.1007/s12666-021-02214-9

Zhao S, Bi Q, Wang Y, Shi J (2017) Empirical modeling for the effects of welding factors on tensile properties of bobbin tool friction stir-welded 2219–T87 aluminum alloy. Int J Adv Manuf Technol 90:1105–1118. https://doi.org/10.1007/s00170-016-9450-2

Ahmadnia M, Shahraki S, Kamarposhti MA (2016) Experimental studies on optimized mechanical properties while dissimilar joining AA6061 and AA5010 in a friction stir welding process. Int J Adv Manuf Technol 87:2337–2352. https://doi.org/10.1007/s00170-016-8636-y

Periyasamy P, Mohan B, Balasubramanian V, Rajakumar S, Venugopal S (2013) Multi-objective optimization of friction stir welding parameters using desirability approach to join Al/SiCp metal matrix composites. Tran Nonferr Metal Soc China 23:942–955. https://doi.org/10.1016/S1003-6326(13)62551-0

Vahdati M, Moradi M, Shamsborhan M (2020) Modeling and optimization of the yield strength and tensile strength of Al7075 butt joint produced by FSW and SFSW using RSM and desirability function method. Trans Indian Inst Met 73:2587–2600. https://doi.org/10.1007/s12666-020-02075-8

Senthil SM, Parameshwaran R, Ragu Nathan S, Bhuvanesh Kumar M, Deepandurai K (2020) A multi-objective optimization of the friction stir welding process using RSM-based-desirability function approach for joining aluminum alloy 6063–T6 pipes. Struct Multidisc Optim 62:1117–1133. https://doi.org/10.1007/s00158-020-02542-2

Zuo L, Zuo D, Zhu Y, Wang H (2018) Effect of process parameters on surface topography of friction stir welding. Int J Adv Manuf Technol 98:1807–1816. https://doi.org/10.1007/s00170-018-2326-x

Shigematsu I, Kwon Y-J, Saito N (2009) Dissimilar friction stir welding for tailor-welded blanks of aluminum and magnesium alloys. Mater Trans 50:197–203. https://doi.org/10.2320/matertrans.MER2008326

Moshwan R, Yusof F, Hassan MA, Rahmat SM (2015) Effect of tool rotational speed on force generation, microstructure and mechanical properties of friction stir welded Al–Mg–Cr–Mn (AA 5052 O) alloy. Mater Des 66:118–128. https://doi.org/10.1016/j.matdes.2014.10.043

Derazkola HA, Aval HJ, Elyasi M (2015) Analysis of process parameters effects on dissimilar friction stir welding of AA1100 and A441 AISI steel. Sci Technol Weld Join 20:553–562. https://doi.org/10.1179/1362171815Y.0000000038

Zhou Z, Yue Y, Ji S, Li Z, Zhang L (2017) Effect of rotating speed on joint morphology and lap shear properties of stationary shoulder friction stir lap welded 6061–T6 aluminum alloy. Int J Adv Manuf Technol 88:2135–2141. https://doi.org/10.1007/s00170-016-8924-6

Li JQ, Liu HJ (2013) Effects of tool rotation speed on microstructures and mechanical properties of AA2219- T6 welded by the external non-rotational shoulder assisted friction stir welding. Mater Des 43:299–306. https://doi.org/10.1016/j.matdes.2012.07.011

Ilangovan M, Boopathy SR, Balasubramanian V (2015) Microstructure and tensile properties of friction stir welded dissimilar AA6061–AA5086 aluminium alloy joints. Tran Nonferr Metal Soc China 25:1080–1090. https://doi.org/10.1016/S1003-6326(15)63701-3

Malarvizhi S, Balasubramanian V (2012) Influences of tool shoulder diameter to plate thickness ratio (D/T) on stir zone formation and tensile properties of friction stir welded dissimilar joints of AA6061 aluminum AZ31B magnesium alloys. Mater & De 40:453–460. https://doi.org/10.1016/j.matdes.2012.04.008

Padmanaban G, Balasubramanian V (2009) Selection of FSW tool pin profile, shoulder diameter and material for joining AZ31B magnesium alloy – An experimental approach. Mater Des 30:2647–2656. https://doi.org/10.1016/j.matdes.2008.10.021

Dialami N, Cervera M, Chiumenti M (2020) Defect formation and material flow in friction stir welding. Eur J Mech A/Solids 80:103912. https://doi.org/10.1016/j.euromechsol.2019.103912

Kah P, Rajan R, Martikainen J, Suoranta R (2015) Investigation of weld defects in friction-stir welding and usion welding of aluminium alloys. Int J Mech Mater Eng 10(1):26. https://doi.org/10.1186/s40712-015-0053-8

Mishra D, Shree S, Gupta A, Priyadarshi A, Das SM, Pal SK, Chakravarty D, Pal S, Chattopadhyay T, Pal A (2021) Weld defect localization in friction stir welding process. Weld World 65(3):451–461. https://doi.org/10.1007/s40194-020-01028-5

Ranjan R, Khan AR, Parikh C, Jain R, Mahto RP, Pal S, Pal SK, Chakravarty D (2016) Classification and identification of surface defects in friction stir welding an image processing approach. J Manuf Process 22:237–253. https://doi.org/10.1016/j.jmapro.2016.03.009

Lakshminarayanan AK, Balasubramanian V (2013) Process parameters optimisation for friction stir welding of AISI 409M grade ferritic stainless steel. Exp Tech 37:59–73. https://doi.org/10.1111/j.1747-1567.2011.00802.x93

AbdElnabi MM, El Mokadem A, Osman T (2022) Optimization of process parameters for friction stir welding of dissimilar aluminum alloys using different Taguchi arrays. Int J Adv Manuf Technol 121:3935–3964. https://doi.org/10.1007/s00170-022-09531-3

Wahid MA, Siddiquee AN, Khan ZA, Majeed T, Sharma N (2019) Friction stir welding of AA-5754 in water and air: a comparative study. Mater Res Express 6:016545. https://doi.org/10.1088/2053-1591/aae6fd

Franchim AS, Fernandez FF, Travessa DN (2011) Microstructural aspects and mechanical properties of friction stir welded AA2024-T3 aluminium alloy sheet. Mater Des 32:4684–4688. https://doi.org/10.1016/j.matdes.2011.06.055

Rajakumar S, Muralidharan C, Balasubramanian V (2012) Developing empirical relationships to predict grain size and hardness of the weld nugget of friction stir welded AA7075-T6 aluminium alloy joints. Exp Tech 36:6–17. https://doi.org/10.1111/j.1747-1567.2010.00677.x

Moghadam DG, Farhangdoost K, Nejad RM (2016) Microstructure and residual stress distributions under the influence of welding speed in friction stir welded 2024 aluminum alloy. Metall Mater Trans B 47:2048–2062. https://doi.org/10.1007/s11663-016-0611-3

Zhu R, Gong W-b, Cui H (2020) Temperature evolution, microstructure, and properties of friction stir welded ultra-thick 6082 aluminum alloy joints. Int J Adv Manuf Technol 108(1):331–343. https://doi.org/10.1007/s00170-020-05422-7

Carlone P, Palazzo GS (2013) Influence of process parameters on microstructure and mechanical properties in AA2024-T3 friction stir welding. Metallogr Microstruct Anal 2:213–222. https://doi.org/10.1007/s13632-013-0078-4

Genevois C, Deschamps A, Denquin A, Doisneau-cottignies B (2005) Quantitative investigation of precipitation and mechanical behaviour for AA2024 friction stir welds. Acta Mater 53:2447–2458. https://doi.org/10.1016/j.actamat.2005.02.007

Morozova I, Królicka A, Obrosov A, Yang Y, Doynov N, Weiß S, Michailov V (2022) Precipitation phenomena in impulse friction stir welded 2024 aluminium alloy. Mater Sci Eng A 852:143617. https://doi.org/10.1016/j.msea.2022.143617

Zhang Z, Xiao BL, Ma ZY (2014) Hardness recovery mechanism in the heat-affected zone during long-term natural aging and its influence on the mechanical properties and fracture behavior of friction stir welded 2024Al– T351 joints. Acta Mater 73:227–239. https://doi.org/10.1016/j.actamat.2014.04.021

Zhang ZH, Li WY, Li JL, Chao YJ (2014) Effective predictions of ultimate tensile strength, peak temperature and grain size of friction stir welded AA2024 alloy joints. Int J Adv Manuf Technol 73:1213–1218. https://doi.org/10.1007/s00170-014-5926-0

Genevois C, Fabrègue D, Deschamps A, Poole WJ (2006) On the coupling between precipitation and plastic deformation in relation with friction stir welding of AA2024 T3 aluminium alloy. Mater Sci Eng A 441:39–48. https://doi.org/10.1016/j.msea.2006.07.151

He J, Ling Z, Li H (2016) Effect of tool rotational speed on residual stress, microstructure, and tensile properties of friction stir welded 6061–T6 aluminum alloy thick plate. Int J Adv Manuf Technol 84:1953–1961. https://doi.org/10.1007/s00170-015-7859-7

Jamshidi AH (2015) Microstructure and residual stress distributions in friction stir welding of dissimilar aluminium alloys. Mater Des 87:405–413. https://doi.org/10.1016/j.matdes.2015.08.050

Nie L, Wu YX, Gong H (2020) Prediction of temperature and residual stress distributions in friction stir welding of aluminum alloy. Int J Adv Manuf Technol 106:3301–3310. https://doi.org/10.1007/s00170-019-04826-4

Jafari H, Mansouri H, Honarpisheh M (2019) Investigation of residual stress distribution of dissimilar Al-7075-T6 and Al-6061-T6 in the friction stir welding process strengthened with SiO2 nanoparticles. J Manuf Process 43:145–153. https://doi.org/10.1016/j.jmapro.2019.05.023

Lemmen HJK, Alderliesten RC, Pieters RRGM, Benedictus R, Pineault JA (2010) Yield strength and residual stress measurements on friction-stir-welded aluminum alloys. J Aircr 47:1570–1583. https://doi.org/10.2514/1.C000212

Acknowledgements

We would like to thank Dr. Anis Hor of the department of mechanics, structures and materials (DMSM) of the High Institute of Aeronautics and Space (Toulouse), France, for all their cooperation and contribution to research work. My sincerest thanks are also extended to the technicians of this department for their help in doing the residual stresses measurement.

Funding

The authors did not receive support from any organization for the submitted work.

Author information

Authors and Affiliations

Contributions

Khaled Boulahem: Conceptualization, Supervision, Methodology, Funding acquisition,

Writing- original draft preparation.

Sahbi Ben Salem: Conceptualization, Methodology, Validation.

Seddik Shiri: Investigation, Formal analysis.

Jamel Bessrour: Review & Editing.

All the authors read and approved the manuscript.

Corresponding author

Ethics declarations

Ethics Approval

Not applicable for that section.

Consent to Participate

Not applicable for that section.

Consent for Publication

The authors consent that the work entitled as “Experimental modeling and multi-response optimization in friction stir welding process parameters of AA2024-T3 using response surface methodology and desirability approach” for possible publication in Experimental Techniques.

Informed Consent

- The authors introduced in the manuscript have read and approved the manuscript, and given approval for submission and successive publication of the manuscript.

- The authors listed in the manuscript have accepted authorship and actively participated to complete this manuscript.

Financial Interests

The authors declare they have no financial interests.

Disclosure of Potential Conflicts of Interest

- We know of no conflicts of interest or personal relationships that could have appeared to influence the work reported in this paper.

Competing Interests

Not applicable. The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Boulahem, K., Salem, S.B., Shiri, S. et al. Experimental Modeling and Multi-Response Optimization in Friction Stir Welding Process Parameters of AA2024-T3 Using Response Surface Methodology and Desirability Approach. Exp Tech (2024). https://doi.org/10.1007/s40799-023-00691-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40799-023-00691-9