Abstract

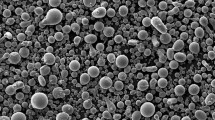

The present study investigated the effect of mechanical milling on Cr3C2-NiCr coatings deposited using the HVOF spraying method. The milling process was carried out using powder with varying characteristics to produce fine-grained and flaky powders. The milled powder coatings exhibited higher density and reduce porosity, leading to improve surface hardness and bond strength. To evaluate the performance of these coatings, hot corrosion and erosion tests were conducted under controlled conditions. The hot corrosion test was performed in a chloride environment using a vapor-condensed salt mixture (45% NaCl + 55% KCl) at 600 °C for 100 hours, while the erosion test was conducted at room temperature with an impact angle of 90°. The results showed that the milled powder coating demonstrated superior resistance to both corrosion and erosion compared to the unmilled powder coating. Specifically, the corrosion mass product and erosion rate of the milled powder coating were 3.40 mg/cm2 and 0.62 mg/g, respectively, while those of the unmilled powder were 10.07 mg/cm2 and 1.84 mg/g, respectively. This study revealed that the microstructure of powder coating has a significant effect on its erosion and hot corrosion performance. Furthermore, the research investigated the mechanisms responsible for these performances and concluded that the coating’s porosity and homogeneous structure can enhance its resistance against both erosion and corrosion.

Similar content being viewed by others

References

K.O. Yoro and M.O. Daramola, CO2 Emission Sources, Greenhouse Gases, and the Global Warming Effect, Advances in Carbon Capture, 2020 https://doi.org/10.1016/b978-0-12-819657-1.00001-3

Y. Xu, K. Yang, J. Zhou and G. Zhao, Coal-Biomass Co-Firing Power Generation Technology: Current Status, Challenges and Policy Implications, Sustain., 2020, 12(9), p 3692. https://doi.org/10.3390/su12093692

Z. Liu, S. Ma, X. Pan and J. Chen, Experimental Study on the Load Response Rate under the Dynamic Combined Combustion of PC Coal and CFB Coal in a CFB Boiler, Fuel, Elsevier, 2018, 2019(236), p 445–451. https://doi.org/10.1016/j.fuel.2018.07.091

J. Eklund, J. Phother, E. Sadeghi, S. Joshi and J. Liske, High - Temperature Corrosion of HVAF - Sprayed Ni - Based Coatings for Boiler Applications, Oxid. Met., 2019, 91(5), p 729–747. https://doi.org/10.1007/s11085-019-09906-0

H. Chi, M.A. Pans, M. Bai, C. Sun, T. Hussain, W. Sun, Y. Yao, J. Lyu and H. Liu, Experimental Investigations on the Chlorine-Induced Corrosion of HVOF Thermal Sprayed Stellite-6 and NiAl Coatings with Fluidised Bed Biomass/Anthracite Combustion Systems, Fuel, 2021, 288(1), p 119607. https://doi.org/10.1016/j.fuel.2020.119607

E. Sadeghi, N. Markocsan and S. Joshi, Advances in Corrosion-Resistant Thermal Spray Coatings for Renewable Energy Power Plants. Part I: Effect of Composition and Microstructure, J. Therm. Spray Technol., 2019, 28(8), p 1749–1788. https://doi.org/10.1007/s11666-019-00938-1

N. Abu-warda, A.J. López, F. Pedraza and M.V. Utrilla, Fireside Corrosion on T24 Steel Pipes and HVOF NiCr Coatings Exposed to Different Salt Mixtures, Corros. Sci., 2020, 173(May), p 108747. https://doi.org/10.1016/j.corsci.2020.108747

L. Ahuja, D. Mudgal, S. Singh and S. Prakash, A Comparative Study to Evaluate the Corrosion Performance of Zr Incorporated Cr3C2-(NiCr) Coating at 900 °C, Ceram. Int., 2018, 44(6), p 6479–6492. https://doi.org/10.1016/j.ceramint.2018.01.047

D. Fantozzi, Chlorine-Induced High Temperature Corrosion of Thermally Sprayed Coatings, 2021.

S. Esmaeil, Ni-Based Coatings for High Temperature Corrosion Protection, 2018, https://www.diva-portal.org/smash/get/diva2:1203387/FULLTEXT02.pdf.

P. Lu, Q. Huang, A.T. Bourtsalas, N.J. Themelis, Y. Chi and J. Yan, Review on Fate of Chlorine during Thermal Processing of Solid Wastes, J. Environ. Sci., 2019, 78, p 13–28. https://doi.org/10.1016/j.jes.2018.09.003

S. Karlsson, J. Pettersson and G. Johansson, Alkali Induced High Temperature Corrosion of Stainless Steel: The Influence of NaCl, KCl, Oxid. Met., 2012, 78, p 83–102. https://doi.org/10.1007/s11085-012-9293-7

P. Pelka, Analysis of Role of Erosion Process of Coal Particles in Generation of Loss of Incomplete Combustion in Fluidized Bed Boilers, Web Conf., 2017, 13(04005), p 1–5. https://doi.org/10.1051/e3sconf/20171304005

B.H. Lee, K.M. Kim, Y.H. Bae, H.S. Oh, G.B. Kim, C.H. Jeon and Y.H. Ahn, Effect of Bed Particle Size on the Gas-Particle Hydrodynamics and Wall Erosion Characteristics in a 550 MWe USC CFB Boiler Using CPFD Simulation, Energy, Elsevier Ltd, 2022, 254, 124263. https://doi.org/10.1016/j.energy.2022.124263

M.S. Vinod Kumar, R. Suresh and N. Jegadeeswaran, Study of Solid Particle Erosion Behavior of HVOF Spray Coated Superco-605 Superalloy, Mater. Today Proc., 2020, 45, p 10–14. https://doi.org/10.1016/j.matpr.2020.09.103

H. Lu, Y. Li, F. Li, J. Li, L. Wang, X. Ran, Z. Li and L. Kong, Erosion Wear Behavior of NiCr+Cr3C2–NiCr Coating under Multi-Impact Angle and Novel Coating Structure Design, J. Mater. Res. Technol., 2021, 14, p 3123–3133. https://doi.org/10.1016/j.jmrt.2021.08.136

S. Matthews and B. James, Review of Thermal Spray Coating Applications in the Steel Industry: Part 1 - Hardware in Steel Making to the Continuous Annealing Process, J. Therm. Spray Technol., 2010, 19(6), p 1267–1276. https://doi.org/10.1007/s11666-010-9518-8

X. Zhang, F. Li, Y. Li, Q. Lu, Z. Li, H. Lu, X. Ran and X. Qi, Comparison on Multi-Angle Erosion Behavior and Mechanism of Cr3C2-NiCr Coatings Sprayed by SPS and HVOF, Surf. Coatings Technol., 2020, 403(1), p 126366. https://doi.org/10.1016/j.surfcoat.2020.126366

D. Wu, S. Liu, Z. Yuan, P. Cao, X. Wei and C. Zhang, Effect of Pre-Oxidation on High-Temperature Chlorine-Induced Corrosion Properties of Air Plasma-Sprayed Ni-5 % Al Coatings, J. Therm. Spray Technol., 2021, 30(1), p 1927–1939. https://doi.org/10.1007/s11666-021-01248-1

H. Li, H. Liu, X. Zhang, G. Wang, Q. Zhou, T. Chen and H. Yao, Summary of Improving Erosion and Corrosion Resistance of Heat Exchange Surfaces in Boilers through HVOF Technology, CIESC J., 2021, 72(4), p 1833–1846. https://doi.org/10.11949/0438-1157.20200985

Y. Kawahara, An Overview on Corrosion-Resistant Coating Technologies in Biomass/Waste-to-Energy Plants in Recent Decades, Coatings, 2016, 6(3), p 34. https://doi.org/10.3390/coatings6030034

L. Baiamonte, S. Björklund, A. Mulone, U. Klement and S. Joshi, Carbide-Laden Coatings Deposited Using a Hand-Held High-Velocity Air-Fuel (HVAF) Spray Gun, Surf. Coatings Technol., 2020, 2021(406), 126725. https://doi.org/10.1016/j.surfcoat.2020.126725

W.Y. Zhai, Y.M. Gao, Z.F. Huang and L. He, Cr3C2–20%Ni Cermets Prepared by High Energy Milling and Reactive Sintering, and Their Mechanical Properties, Adv. Appl. Ceram., 2016, 115(6), p 327–332.

S.S. Chatha, H.S. Sidhu and B.S. Sidhu, High Temperature Hot Corrosion Behaviour of NiCr and Cr 3C 2-NiCr Coatings on T91 Boiler Steel in an Aggressive Environment at 750°C, Surf. Coatings Technol., 2012, 206(19–20), p 3839–3850. https://doi.org/10.1016/j.surfcoat.2012.01.060

W. Zhou, K. Zhou, C. Deng, K. Zeng and Y. Li, Hot Corrosion Behaviour of HVOF-Sprayed Cr3C2-NiCrMoNbAl Coating, Surf. Coatings Technol., 2017, 309, p 849–859. https://doi.org/10.1016/j.surfcoat.2016.10.076

T.S. Sidhu, S. Prakash and R.D. Agrawal, Hot Corrosion Studies of HVOF Sprayed Cr3C2-NiCr and Ni-20Cr Coatings on Nickel-Based Superalloy at 900 °C, Surf. Coatings Technol., 2006, 201(3–4), p 792–800. https://doi.org/10.1016/j.surfcoat.2005.12.030

H. Lu, Y. Li, F. Li and J. Li, Erosion Wear Behavior of NiCr þ Cr 3 C 2 e NiCr Coating under Multi e Impact Angle and Novel Coating Structure Design, J. Mater. Res. Technol., 2021, 14, p 3123–3133. https://doi.org/10.1016/j.jmrt.2021.08.136

D. Singh and R. Kumar, Synthesis and Characterization of Nanocrystalline Ni-Cr-Al Alloy Powder, Mater. Today Proc., 2020, 41, p 821–824. https://doi.org/10.1016/j.matpr.2020.09.155

A. Zakeri, F. Ghadami, A. SabourRouhaghdam and B. Saeedi, Study on Production of Modified MCrAlY Powder with Nano Oxide Dispersoids as HVOF Thermal Spray Feedstock Using Mechanical Milling, Mater. Res. Express, 2019, 7(1), p 015030. https://doi.org/10.1088/2053-1591/ab6121

G.C. Ji, C.J. Li, Y.Y. Wang and W.Y. Li, Erosion Performance of HVOF-Sprayed Cr 3C 2-NiCr Coatings, J. Therm. Spray Technol., 2007, 16(4), p 557–565.

A. International, G76, Standard Test Method for Conducting Erosion Tests by Solid Particle Impingement Using Gas Jets, 2013, https://doi.org/10.1520/G0211-14.2.

R. Kumar, R. Kumar and S. Kumar, Erosion Corrosion Study of HVOF Sprayed Thermal Sprayed Coatings on Boiler Tubes: A Review, Int. J. Sci. Manag. Stud., 2018, 01(03), p 1–6. https://doi.org/10.51386/25815946/ijsms-v1i3p101

S. Sivasankaran, K. Sivaprasad, R. Narayanasamy and P.V. Satyanarayana, X-Ray Peak Broadening Analysis of AA 6061100–x-x Wt.% Al 2O3 Nanocomposite Prepared by Mechanical Alloying, Mater. Charact., 2011, 62(7), p 661–672. https://doi.org/10.1016/j.matchar.2011.04.017

G.K. Williamson and W.H. Hall, X-Ray Line Broadening from Filed Aluminium and Wolfram, Acta Metall., 1953, 1(1), p 22–31. https://doi.org/10.1016/0001-6160(53)90006-6

C. Suryanarayana, Mechanical Alloying: A Novel Technique to Synthesize Advanced Materials, Research, 2019, 2019, p 4219812. https://doi.org/10.34133/2019/4219812

C. Yang, Q.Y. Chen, X.B. Bai, Z. Zhu, G.C. Ji, H.T. Wang, H.L. Yao and F. Wang, Influence of Spray Parameters on Particle Deposition Behaviour, Microstructure, Phase Constitutions, and Mechanical Properties of High Velocity Oxy-Fuel Sprayed WC-Cr3C2-Co Coatings, Ceram. Int., 2023, 49(5), p 8463–8477. https://doi.org/10.1016/j.ceramint.2022.11.009

A. Zakeri, P. Tahvili, E. Bahmani, A. Sabour and R. Aghdam, Effect of the Powder Manufacturing Process on Characteristics of Nanostructured MCrAlY Coatings: Dry vs Wet Ball Milling, J. Compos. Compd., 2021, 2(5), p 9–17.

Q. Zhang, C.J. Li, C. Xin, G.J. Yang and S.C. Lui, Study of Oxidation Behavior of Nanostructured NiCrAlY Bond Coatings Deposited by Cold Spraying, Surf. Coat. Technol., 2008, 202, p 3378–338. https://doi.org/10.1016/j.surfcoat.2007.12.028

R. Kumar, J. Joardar, R.K.S. Raman, V.S. Raja, S.V. Joshi and S. Parida, Effect of Chromium and Aluminum Addition on Anisotropic and Microstructural Characteristics of Ball Milled Nanocrystalline Iron, J. Alloys Compd., 2016, 671, p 164–169. https://doi.org/10.1016/j.jallcom.2016.02.096

C.A.D. Cunha, N.B.D. Lima, J.R. Martinelli, A.H.D.A. Bressiani, A.G.F. Padial and L.V. Ramanathan, Microstructure and Mechanical Properties of Thermal Sprayed Nanostructured Cr3C2-Ni20Cr Coatings, Mater. Res., 2008, 11(2), p 137–143. https://doi.org/10.1590/s1516-14392008000200005

A. Zakeri, E. Bahmani and A.S.R. Aghdam, Impact of MCrAlY Feedstock Powder Modification by High-Energy Ball Milling on the Microstructure and High-Temperature Oxidation Performance of HVOF-Sprayed Coatings, Surf. Coatings Technol., 2020, 395(May), p 125935. https://doi.org/10.1016/j.surfcoat.2020.125935

A. Gil, V. Shemet, R. Vassen, M. Subanovic, J. Toscano, D. Naumenko, L. Singheiser and W.J. Quadakkers, Effect of Surface Condition on the Oxidation Behaviour of MCrAlY Coatings, Surf. Coatings Technol., 2006, 201(7), p 3824–3828. https://doi.org/10.1016/j.surfcoat.2006.07.252

T.S. Sidhu, S. Prakash and R.D. Agrawal, Studies on the Properties of High-Velocity Oxy-Fuel Thermal Spray Coatings for Higher Temperature Applications, Mater. Sci., 2005, 41(6), p 805–823. https://doi.org/10.1007/s11003-006-0047-z

G.R. Li, B.W. Lv, G.J. Yang, W.X. Zhang, C.X. Li and C.J. Li, Relationship Between Lamellar Structure and Elastic Modulus of Thermally Sprayed Thermal Barrier Coatings with Intra-Splat Cracks, J. Therm. Spray Technol., 2015, 24(8), p 1355–1367.

E. Sadeghi and S. Joshi, Chlorine-Induced High-Temperature Corrosion and Erosion-Corrosion of HVAF and HVOF-Sprayed Amorphous Fe-Based Coatings, Surf. Coat. Technol., 2019, 371, p 20–35. https://doi.org/10.1016/j.surfcoat.2019.01.080

L. Ahuja, D. Mudgal, S. Singh and S. Prakash, A Comparative Study to Evaluate the Corrosion Performance of Zr Incorporated Cr 3 C 2 - ( NiCr ) Coating at 900 ° C, Ceram. Int., 2018, 44(6), p 6479–6492. https://doi.org/10.1016/j.ceramint.2018.01.047

Y. Ding, Effects of Elevated Temperature Exposure on the Microstructural Evolution of Ni(Cr)-Cr3C2 Coated 304 Stainless Steel, 2009, http://etheses.nottingham.ac.uk/917/.

M. Ksiazek, L. Boron, M. Radecka, M. Richert and A. Tchorz, Mechanical and Tribological Properties of HVOF-Sprayed (Cr3C2-NiCr+Ni) Composite Coating on Ductile Cast Iron, J. Mater. Eng. Perform., 2016, 25(8), p 3185–3193.

M. Daroonparvar, M.U.F. Khan, Y. Saadeh, C.M. Kay, A.K. Kasar, P. Kumar, L. Esteves, M. Misra, P. Menezes, P.R. Kalvala, H.R. Bakhsheshi-Rad and R.K. Gupta, Modification of Surface Hardness, Wear Resistance and Corrosion Resistance of Cold Spray Al Coated AZ31B Mg Alloy Using Cold Spray Double Layered Ta/Ti Coating in 35 wt% NaCl Solution, Corros. Sci., 2020, 176(1), p 109029. https://doi.org/10.1016/j.corsci.2020.109029

M. Waldi, E.A. Basuki and B. Prawara, Quality Characterization of HVOF Thermal Spray Coating with NiCr Matrix Composite for Protection Application of Coal Fired Boiler Tubes, IOP Conf. Ser. Mater. Sci. Eng., 2018 https://doi.org/10.1088/1757-899X/432/1/012011

J. Wang, C. Ai, X. Yun, Z. Chen and B. He, Effects of 3D Roughness Parameters of Sandblasted Surface on Bond Strength of HVOF Sprayed WC-12Co Coatings, Coatings, 2022, 12(10), p 1451.

Y.Y. Wang, C.J. Li and A. Ohmori, Influence of Substrate Roughness on the Bonding Mechanisms of High Velocity Oxy-Fuel Sprayed Coatings, Thin Solid Films, 2005, 485(1–2), p 141–147.

Y.Y. Wang, C.J. Li and A. Ohmori, Examination of Factors Influencing the Bond Strength of High Velocity Oxy-Fuel Sprayed Coatings, Surf. Coatings Technol., 2006, 200(9), p 2923–2928.

R. Kromer, J. Cormier and S. Costil, Role of Powder Granulometry and Substrate Topography in Adhesion Strength of Thermal Spray Coatings, J. Therm. Spray Technol., 2016, 25(5), p 933–945.

K. Wathanyu, K. Tuchinda, S. Daopiset, S. Sirivisoot, J. Kondas and C. Bauer, Study of the Properties of Titanium Porous Coating with Different Porosity Gradients on 316L Stainless Steel by a Cold Spray Process, J. Therm. Spray Technol., 2022, 31(3), p 545–558.

H. Lu, J. Shang, X. Jia, Y. Li, F. Li, J. Li and Y. Nie, Erosion and Corrosion Behavior of Shrouded Plasma Sprayed Cr3C2-NiCr Coating, Surf. Coatings Technol., 2019, 2020(388), p 125534. https://doi.org/10.1016/j.surfcoat.2020.125534

S. Sharma, High Temperature Erosive Wear Study of NiCrFeSiB Flame Sprayed Coatings, J. Inst. Eng. Ser. D, 2012, 93(1), p 7–12. https://doi.org/10.1007/s40033-012-0006-9

H.E. Evans, Oxidation Failure of TBC Systems: An Assessment of Mechanisms, Surf. Coatings Technol., 2011, 206(7), p 1512–1521. https://doi.org/10.1016/j.surfcoat.2011.05.053

K.A. Habib, M.S. Damra, J.J. Carpio, I. Cervera and J.J. Saura, Performance of NiCrAlY Coatings Deposited by Oxyfuel Thermal Spraying in High Temperature Chlorine Environment, J. Mater. Eng. Perform., 2014, 23(10), p 3511–3522. https://doi.org/10.1007/s11665-014-1160-z

H.G. Kim and S.H. Lim, Microstructural Characterization of Oxide Layers Formed on Ni–20Cr–8Al Alloy Foam Using Transmission Electron Microscopy, Surf. Interface Anal., 2017, 49(9), p 880–884.

G.C. Ji, C.J. Li, Y.Y. Wang and W.Y. Li, Microstructural Characterization and Abrasive Wear Performance of HVOF Sprayed Cr3C2-NiCr Coating, Surf. Coatings Technol., 2006, 200(24), p 6749–6757.

Y. Zhang, K. Chong, Q. Liu, Y. Bai, Z. Zhang, D. Wu and Y. Zou, High-Temperature Tribological Behavior of Thermally-Treated Supersonic Plasma Sprayed Cr3C2-NiCr Coatings, Int. J. Refract. Met. Hard Mater., 2020, 2021(95), p 105456. https://doi.org/10.1016/j.ijrmhm.2020.105456

W. Zhou, K. Zhou, Y. Li, C. Deng and K. Zeng, Applied Surface Science High Temperature Wear Performance of HVOF-Sprayed Cr 3 C 2 -WC-NiCoCrMo and Cr 3 C 2 -NiCr Hardmetal Coatings, Appl. Surf. Sci., 2017, 416, p 33–44. https://doi.org/10.1016/j.apsusc.2017.04.132

Acknowledgment

The authors would like to thank to collaborative research project between National Research and Innovation Agency (BRIN) and PT. Pembangkitan Jawa Bali (PJB) with contract No. 409.SPK/061/BMUM/2021 and National Research and Innovation Agency (BRIN) with contract No. 3/III.10/HK/2023 for supporting the present research work.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ramandhany, S., Triyono, D., Sugiarti, E. et al. Effect of Structure Density of Milled Powder on Hot Corrosion and Erosion Resistance of HVOF-Sprayed Cr3C2-NiCr Coating. J Therm Spray Tech 33, 1075–1099 (2024). https://doi.org/10.1007/s11666-024-01720-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-024-01720-8