Abstract

Based on historical developments and the current state of the art in gas-phase transmission electron microscopy (GP-TEM), we provide a perspective covering exciting new technologies and methodologies of relevance for chemical and surface sciences. Considering thermal and photochemical reaction environments, we emphasize the benefit of implementing gas cells, quantitative TEM approaches using sensitive detection for structured electron illumination (in space and time) and data denoising, optical excitation, and data mining using autonomous machine learning techniques. These emerging advances open new ways to accelerate discoveries in chemical and surface sciences.

Graphical abstract

Similar content being viewed by others

Introduction

Properties and functionalities of materials often depend on the conditions to which the materials are exposed during manufacturing, processing, and application, including heat, gases, and light. Responses of materials to these stimuli can be complex, involving geometric, compositional, and electronic changes in the atomic structure. In the current article, we focus on gas-phase transmission electron microscopy (GP-TEM) techniques developed to investigate materials in situ while exposed to gas, heat, and/or light stimuli. The importance of in situ observations has been recognized since the invention of the TEM.1,2 Developments focused on improving microscope performance (imaging resolution and sensitivity) as well as on exposing specimens to relevant gaseous environments without compromising the vacuum conditions required to generate and detect electron beams.3,4

A material’s spatiotemporal response is driven by thermodynamics with kinetics setting the timeline. For example, from thermodynamic considerations, the chemical potential is a function of partial pressures Pi and temperature T of a gas phase i, and the potential can vary by ~0.34 eV per molecule (at room temperature) when changing pressure from 10−10 mbar to 1 bar. Adsorption will consequently affect the surface free energies of many materials sufficiently to drive changes in the type and abundance of exposed surface sites. Also, kinetics exhibit a strong dependence on local surface structure.5 These factors can affect properties and functionalities of nanomaterials and can play an important role in surface reactivity and catalytic functionality. In fact, such insights are desirable to develop a fundamental understanding of the dynamic relationships between surface structures and functions in heterogeneous catalysis. Today, it has become clear that surfaces generally respond dynamically to changes in their surrounding environments because adsorption energies and surface cohesive energies are generally comparable. Hence, enabling in situ studies of nanomaterials under chemically relevant conditions by exposing functional structures to a gaseous environment has been emphasized in the past two decades.5,6

To get an insight into the current and future possibilities for conducting in situ GP-TEM experiments, it is interesting to revisit the “early days” and track progress leading up to “now.” Progress over seven decades of research is illustrated in Figure 1, from the study of conversion of ~150-nm-size colloidal silver particles into silver chloride (Figure 1a)3 to reveal that adsorbed CO molecules cause {100} facets of gold nanoparticles to reconstruct during CO oxidation (Figure 1b).7

Examples of gas-phase transmission electron microscopy (GP-TEM) applications from the pioneering times and up until recently. (a) Conversion of colloidal silver into silver chloride, using the early transmission electron microscope “Übermikroskop.”3 Reprinted with permission from Reference 3. © 1942 Springer Nature. (b) Observation of a single gold nanoparticle during exposure to CO and O2, using an aberration-corrected GP-TEM. For the first time, a molecular species (here: CO) on the catalyst’s active surface has been imaged.7 Reprinted with permission from Reference 7. © 2012 AAAS.

This article serves as a brief review of a number of areas that the authors find important to GP-TEM. We look at the evolution and characteristics of gas cells, in situ and operando experiments, electron-beam effects, light illumination systems, and impact of state-of-the-art data science methods, such as machine learning.

Technologies for gas cells in transmission electron microscopy

The main challenge in introducing gas environments into the electron microscope is the short mean free path of electron beams in gasses. Therefore, confinement of the gas phase close to the specimen is required and mainly two types of technologies have emerged over the years.

The first technology utilizes the concept of differentially pumping individual vacuum stages of the microscope, separated by small apertures, enabling regions of different pressure to be maintained along the column. This allows large pressure differences (~nine orders of magnitude) between the specimen area (up to 20 mbar = 15 Torr) and microscope high-vacuum components (e.g., electron source), with a free “line of sight” for the electrons. Such a microscope, often referred to as “apertured cell,” environmental (cell) TEM, E-TEM, or ETEM, is ideal for lower pressure work of <20 mbar extending over a 5-mm path along the electron-beam trajectory. Earlier approaches have been based on apertured cells8,9,10,11,12,13 with atomic resolution being reported in 1991.14 Apertured cells have continued to evolve and have been incorporated into newer microscope platforms.15,16,17,18,19,20,21 Major improvements in the host electron microscope’s hardware and automation have dramatically improved spatial, energy, and time resolution to ca. 1 Å, 0.1 eV, and 1 ms, respectively. An apertured cell microscope is generally compatible with the use of standard side-entry TEM sample holders, supports various sample geometries, and additional (in situ) functionality, such as heating, cooling, gas sensing, and application of light.

For many applications, heating in gas atmospheres is important. The apertured cell microscope is compatible with furnace heating holders for bulk samples and with miniaturized heating holders, suitable for powders and FIB membrane samples, based on microelectromechanical systems (MEMS) devices.22 For example, MEMS-based holders use orders of magnitude lower powers compared to bulk heating holders, with improved stability for applications requiring rapid heating and cooling rates.23,24,25

The primary limitation of the current generation of apertured cells is that they can only support in situ experiments up to a total pressure of ca. 20 mbar. Such total pressures could equilibrate or kinetically stabilize structures unlike those that may evolve at higher and more technical relevant pressures in the >1 bar regime. Caution is therefore needed in the interpretation of in situ observations using apertured cells because the importance of this pressure gap generally will depend on the reaction under investigation.

The second gas cell technology confines the gas phase to a few micrometers along the beam direction around the TEM sample to allow a corresponding increase in the gas pressure to the range of 1 bar. The confinement is achieved by introducing the gas environment between two electron-transparent membranes (“windows”) that separate the gas phase from the microscope vacuum. Early versions of a windowed cell used, e.g., carbon-based windows and did not report significantly higher pressures than the apertured cell systems,26,27,28 but enabled the first atomic resolution in a TEM gas atmosphere.26 Fortunately, over the past two decades, SiNx-based windowed cells fabricated using MEMS technology25,29 have matured as a robust approach to making high-pressure measurements widely available.

SiNx-based windows are typically 10–50-nm thick. Due to similar ratio of gas path lengths to mean free path, the degree of electron scattering by the gaseous species remains similar to the apertured cell approach, but the thin electron-transparent windows give additional scattering. The windowed cell enables gas pressures up to at least 4 bar,30,31 allowing gas-phase experiments to be conducted under conditions that can be comparable to benchtop catalytic reactors. For thermal catalysis experiments, heating devices can be incorporated by adding a second MEMS-fabricated “window” spaced only a few microns from the heater.

Temperature and pressure can be estimated based on macroscopic stimuli and methods to measure the parameters locally have been explored.32,33 Windowed cells technology places some limitations on the sample preparation relative to a standard apertured cell heating holder geometry. But if appropriate samples deposited on the MEMS heater devices can be achieved, there are remarkable additional benefits.34,35 During operation of a MEMS heater, its resistance is continuously monitored and used to regulate temperature and compensate for any changes in gas pressure and/or gas species.

GP-TEM: From in situ to operando

The commercial availability of apertured and windowed cells has significantly facilitated access to in situ TEM studies of materials exposed to reactive gaseous environments.5,6 Although in situ studies offer unique mechanistic and kinetic insights into gas–surface interactions on heterogeneous materials, the investigations focus primarily on the structural or chemical evolution of the material but consider the reactive environment as static. However, phase transformations associated with anion exchange (e.g., oxidation, carbonization, nitridation, and sulfidation) are correlated with changes in the gas environment. Moreover, in heterogeneous catalysis, the material is deliberately designed to control the conversion of reactant molecules into desired product molecules.

The phrases in situ and operando are often used interchangeably in different fields. Here, we consider an in situ TEM experiment to be one where the structural and chemical changes in the material are characterized in the presence of reactive gases. The term operando was first used in the field of catalysis to correlate surface structure changes from Raman spectroscopy to quantitative measurements of activity and selectivity.36 More generally, an operando experiment is an in situ experiment where a quantitative measurement of a functionality (e.g., catalyst activity/selectivity) is performed simultaneously with the materials characterization. To elucidate the structure–functionality relations from operando measurements, it is usually necessary to perform a series of measurement over a range of different conditions.

For catalytic reactions, the functionality of interest is usually a determination of chemical kinetics associated with converting reactants into product molecules. Kinetic information is in fact readily observable for reactions in which a reactant or product is present in the solid state (e.g., catalytic oxidation of carbonaceous matter or catalyzed growth of carbon nanofibers or sheets).37,38,39,40 However, in the general case where all reactant and product molecular species are gases, gas characterization is needed. Such observations can in principle be obtained directly using mass spectrometry of gas (including water vapor) exiting the environmental cells41,42 indirectly using calorimetry of the reaction power,41 with electron energy-loss spectroscopy (EELS),43,44 or combinations of spectroscopies.45,46

In the case of apertured cells, the volume of the catalyst specimen dispersed on a typical standard grid or MEMS heater device is very small relative to the gas volume. Hence, even for a highly active catalyst, the number of product molecules generated could be below detection limits. This limitation can be addressed by preparing three-dimensional porous pellets of an inert carrier material and impregnating it with a larger amount of catalyst materials.47 Determination of the gas composition in the various cell types has now become somewhat routine making it relatively straightforward to determine reactant conversions (i.e., the fraction of reactants converted into products during an in situ study). This makes it feasible to determine whether catalysis is occurring and how changing reaction conditions could affect the conversion.

Going beyond conversions to a more quantitative measurement of chemical kinetics requires an understanding of the heat and mass transfer characteristics of the reaction cells. An investigation of heat transfer characteristics through the gas phase of apertured cells showed that the conditions were primarily isothermal across the TEM grid placed in a furnace heating holder.48 Moreover, heat and mass transfer were studied in the apertured cell in conjunction with the porous pellet sample under CO oxidation conditions49 and showed the cell has the characteristics approaching a batch reactor as well as a relatively homogeneous gas composition. The gas homogeneity implies that it becomes more straightforward to relate observations of the catalyst structure and functionality anywhere across the TEM grid. With knowledge of the mass of catalyst on the porous pellet, the gas composition along the electron trajectory (from EELS) and modeling, it is possible to estimate the average chemical kinetics during observation in the apertured cell (Figure 2a). With this operando approach, it was shown that thin oxide layers formed on Ru/SiO2 catalyst during CO oxidation were spectator species with no significant catalytic functionality.46

Operando gas-phase transmission electron microscopy (GP-TEM) investigations of nanoparticles catalyzing the CO oxidation reaction. (a) Operando GP-TEM of Ru/SiO2 during steady-state CO oxidation in an apertured gas cell (environmental transmission electron microscopy, ETEM) at ~1 mbar total pressure. (Left) TEM image of Ru/SiO2. (Right) Electron energy-loss spectroscopy (EELS) was employed to detect and quantify catalytic products directly.44 Reprinted with permission from Reference 44. © 2012 American Chemical Society. (b) Operando GP-TEM of Pt nanocrystal during oscillatory CO oxidation in windowed gas cell (nanoreactor) at 1 bar total pressure. The gas entering the reaction zone is 1.0 bar of CO:O2:He at 3%:42%:55% and nanoreactor temperature is 659 K. (Top) Mass spectrometry of the CO, O2, and CO2 pressures, reaction power, and shape factor for the Pt nanoparticle (seen below) as a function of time. Part of the reaction oscillation data is highlighted by the red rectangle. (Bottom) Time-resolved TEM images of a Pt nanoparticle at the gas exit of the reaction zone.41 Reprinted with permission from Reference 41. © 2014 Springer Nature.

The key to understanding structure–reactivity relations is being able to correlate changes in atomic structure with changes in chemical kinetics. The complexity of many catalytic systems makes it difficult to identify an active site with a high degree of confidence because the molecular processes have not yet been visualized in the GP-TEM. However, in favorable cases (such as the Ru system), it could be possible to conclude which surface structures are less active. A similar operando approach has been used to investigate the metal–support interactions during CO oxidation over a Pt/CeO2 catalyst.50 The study shows that the catalytic turnover frequency correlates with fluxional behavior that destabilizes the supported Pt particle, marks an enhanced rate of oxygen vacancy creation and annihilation, and leads to increased strain and reduction in the CeO2 support surface. The advantage of this operando approach is that the catalyst structure and kinetics are determined simultaneously under the same conditions.

The windowed cell can operate at pressures up to and above ambient pressures, as set by the tolerable pressure difference across the electron-transparent windows.25,29 Such pressure levels are attractive as they allow for a more direct comparison to technologically relevant conditions as well as conditions available with complementary photon-based operando techniques. For the windowed cells, the window could impact the sensitivity, especially for detecting lighter elements and modulate atomic-scale image contrast patterns and spectral data.25 The cells can be made of two half chips that are clamped or glued together25,29 or of a monolithic channel.41,51 Whereas the former has advantages in terms of depositing catalyst materials on the electron-transparent windows, the latter is superior with respect to fixing the gas channel height (against bulging) and controlling a unidirectional gas flow, as well as to avoiding gas bypass and leakages that could severely affect the functional interpretation of measurements on the gas phase. Moreover, the gas channel’s height of a few micrometers implies that the reaction zone volume is in the range of hundreds of nanoliters. Hereby, the catalyst-to-gas volume becomes significant for measuring conversion of reactants by catalyst particles dispersed only on the electron-transparent windows in the gas exiting the reaction zones. Under such gas flow conditions, however, gradients in the gas phase along the reaction zone are inherent and could affect the gas-dependent catalyst structure along the gas flow channel. It therefore becomes important to report structural evolution along the gas flow channel and, preferably, relate it to the functional measurements via reactor modeling.41 If desired, EELS can be employed to determine the gas composition along the flow channel. This approach was used to demonstrate that the oscillatory oxidation of carbon monoxide catalyzed by Pt nanoparticles can be mechanistically related to synchronized oscillatory shape changes of the nanoparticles, as rationalized by comparing experimental observations with a time-dependent reactor model that combined a description of mass transport and micro-kinetic model based on density functional theory (DFT) calculations of adsorption and transition state energies (Figure 2b).41

Quantifying and suppressing electron-beam-induced sample alterations

The effect of a gas phase on TEM imaging sensitivity and resolution has been a subject of many studies.52,53,54,55,56 Radiolysis, knock-on damage, charging and free-radical formation with gas molecules have to be considered.57

The differentially pumped apertured cell can accommodate gas environments at pressures of up to 20 mbar and the MEMS-based windowed cell pressures of up to 4 bar,30 corresponding roughly to a diatomic gas path for the electron beam of up to 75 atoms/Å2.54 The gas phase, and in case of the windowed cell, the windows themselves as well, should therefore be considered as an additional random specimen, which can considerably enhance electron scattering, reduce the signal-to-noise ratio (SNR), and modulate the image contrast. It has been shown that the TEM image intensity, and thus its SNR, attenuates with increasing pressure.54,55 The corresponding decay constant reflects that the electron scattering cross sections are large enough to scatter electrons to angles beyond the electron detectors.11,58

The attenuation of the image intensity affects the achievable detection limits because a recognizable image feature requires an image SNR above a threshold value SNRRose59 (see Figure 3). In dynamic experiments, the corresponding electron dose DRose has to be accumulated within a chosen image exposure time t to detect a feature. This exposure time, tcutoff, is determined by (1) the characteristic time scale for the dynamic process under consideration; (2) the drift of the specimen stage; (3) the stability of the electron optics; and (4) the electron dose that can be tolerated without affecting the sample integrity. Therefore, a finite tcutoff translates into a criterion on the corresponding electron dose rate r or, equivalently, the brightness of the microscope’s electron source, which must exceed a critical level.

Schematics of the parameter window (blue) of electron dose, dose rate, and exposure time enabling in situ transmission electron microscopy (TEM) observations under noninvasive illumination. Reprinted with permission from Reference 56. © 2015 Elsevier.

Unexpectedly, the electron dose D and dose rate r affect the combined gas-sample system differently and must be regarded as independent variables. The independent effect of D and r was illustrated by resolution tests of an Au/C sample in N2.54,60 While the host microscope has an inherent resolution limit set by the electron-optical system, the practical image resolution can degrade as gas is admitted to the apertured cell at increasing pressures. For the same dose D delivered at a higher electron dose rate (r = 104 e−/Å2/s), the resolution degrades faster with increasing pressure as compared to using a lower dose rate (r = 102 e−/Å2/s). These findings are surprising because it is commonly expected that only D determines the SNR and therefore practical image resolution. The finding that the image resolution differs markedly even for the same electron dose demonstrates that the gas is not only acting as an intensity (electron dose) attenuator but makes the high spatial TEM resolution dependent on the way the electrons are delivered.54,55,61 The dose-rate-dependent resolution reflects the importance of inelastic scattering events and was speculated to originate from local charge-induced specimen vibrations.54,60

Figure 3 illustrates the relation between D, r, and t. It is important to realize that this two-dimensional parameter space for noninvasive observations depends on the catalyst material and the reaction conditions under investigation. As a complete physical model for beam–gas–sample interaction is lacking, the parameter space is difficult to predict. Therefore, an experimental protocol must be followed to quantify, accommodate, and control the electron illumination to suppress its invasive alterations. Various illustrative examples of such quantitative protocols for enabling chemical meaningful experiments have already been reported over the years.62,63,64,65,66

GP-TEM with optical excitation of the sample

GP-TEM capabilities can be further expanded by optically coupled systems enabling near-atomic-scale imaging of light-induced phenomena. Already in 1984, light was introduced into a TEM to investigate light-induced movement of dislocations in II–VI semiconductors67 and advanced since then such that light can be readily introduced either through modifications to the column or through specialized holders.68,69,70,71,72,73 Apertured cell microscopes can be equipped with both configurations, making it possible to probe materials exposed to gases while under optical illumination/stimulation. Although optically coupled GP-TEM is still a nascent field, the technique facilitates the observation of photocatalytic reactions in situ and on the atomic scale, under various gas and illumination conditions.74

Specifically, inorganic photocatalysts are typically comprised of small metallic and/or semiconducting nanoparticles deposited onto ceramic supports.75 The atomic structure of these nanoparticles and their interfaces significantly influences their optical absorption and chemical reactivity. Structurally similar but not atomically identical structures could give rise to very distinct catalytic activity and selectivity. One of the first in situ photocatalytic experiments was conducted to explore the photoreduction of Cu2O nanoparticles in the presence of water vapor and light.76 Further experiments investigated photocatalytic water-splitting reactions on TiO2 and GaN:ZnO-based photocatalysts.69,73 Excitingly, light-driven surface transformations of anatase TiO2 under exposure to water vapor resulted in surface amorphization that could be explained by the photogeneration of oxygen vacancies and the resulting dissociation of water at particular defect sites.69

Further work focused on photocatalysis involving hydrogen H2 of relevance to, for example, CO2 reduction, acetylene hydrogenation for (poly)ethylene, and ammonia synthesis. Specifically, investigations of photocatalytic transformations of Pd-based nanoparticles under exposure to H2 gas show that excitation of the nanoparticle plasmonic modes affects phase transformations. Optical excitation of plasmons can influence both the speed of the H2-driven transformation as well as the mechanism by which the transformation occurs. In particular, new catalytically active sites were visualized within nanoparticles upon illumination (i.e., plasmons modify certain reaction steps compared to thermally driven reactions). These new “excited-state pathways” enable catalysts that do not face the conventional tradeoff between product yield and product selectivity.77,78

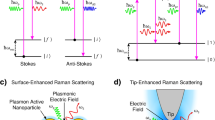

It could be possible to measure adsorbates indirectly through changes in the material morphology or EELS or cathodoluminescence (CL) spectra. An exciting capability for optically coupled GP-TEM is vibrational spectroscopy. Raman and infrared (IR) spectroscopy could locally monitor adsorbates on materials, and also resolve the materials’ local temperature, allowing for quantification of sample heating due to illumination.71,79,80 Historically, the Raman/IR signal is generated through fiber inputs and outputs to the sample in the TEM and therefore limited in resolution to the laser spot size (generally 2–15 µm). Higher resolution has recently been proposed via electron- and light-induced stimulated Raman (ELISR) for nanoscale chemical mapping.81 Unlike typical stimulated Raman spectroscopy, which utilizes two lasers as the pump and Stokes beams, here a laser is used for the Stokes excitation while the electron beam is used as a nanoscale pump. The electron beam excites CL from plasmonic nanoparticles, enhancing the Raman exclusively from the particle that has been excited by the electron beam. This approach could enable nanoscale Raman mapping, paving the way for localized imaging of molecular adsorbates.

Machine learning-enabled data denoising and data analyses: Toward statistical and novel insights

Recently, machine learning (ML)-based TEM data analytics has experienced a significant surge in popularity, as evidenced by numerous reviews focusing on specific TEM techniques, including electron diffraction,82,83 TEM and STEM imaging84,85,86,87,88,89, spectroscopy,90 ptychography,91 in situ mechanical testing TEM,92 and in situ liquid-phase TEM.93,94 Also, ML has been recognized as a major contributing factor in various materials research fields (e.g., energy materials,95 battery materials,96 and nanomaterials97).

GP-TEM enables the investigation of catalysts and other functional materials; however, we believe there is still a vast amount of information embedded in the data that is still unexplored. ML algorithms are trained on prior data, allowing processing of new TEM data based on learned patterns. This enables automating identification of fundamental features and extracting static and dynamic information from in situ (multiframe) data sets of nanoscale and atomic structures (see workflow in Figure 4a).

(a) Potential machine learning (ML)-enhanced gas-phase transmission electron microscopy (GP-TEM) workflows in data denoising and analysis, for example: (b) To retrieve structural changes in irregularly shaped Pt nanoparticles under CO atmosphere at room temperature with dose rate r of 1500 e/Å2/s with unsupervised deep video denoiser denoising. Reprinted with permission from Reference 98. © 2023 Oxford University Press. (c) To identify the surface dynamics of gold atoms on gold nanoparticles, influenced by the gas atmosphere. Reprinted with permission from Reference 99. © 2018 Wiley.

As discussed in the “Quantifying and suppressing the electron-beam-induced sample alterations” section, electron-beam effects on materials should be minimized, so low electron dose and dose rate experimental conditions are often chosen resulting in data sets that exhibit low SNR (i.e., data are very noisy). In order to “regain” a sufficiently high SNR59 and therefore an improved spatial and temporal precision, ML-based denoising techniques have been developed to directly denoise images and spectra.87,98,100,101,102,103 Earlier work used widely varying sources of data (high resolution, diffraction contrast) to train a denoiser.87 Later efforts focused on in situ high-resolution images of nanoparticles98,101,102,103 and performed well after suitable training.

Generating training data sets can be tedious, and there is always a risk that unanticipated structures/images are not included in training resulting in the neural network inferring incorrect images during the up-sampling stage. An unsupervised deep video denoiser (UDVD) seems well suited for denoising in situ movies when a sufficient number of frames have been recorded.104,105 No training data sets are required because the network trains directly on the raw data and the only assumption required is that the noise is uncorrelated. Figure 4b shows a sample “denoised” frame showing a Pt particle aggregate undergoing complex dynamics involving varying size, shape, and orientation.98 Atomic columns are not present in many of the frames and the dynamic complexity would make it challenging to simulate suitable models to train a supervised network. The UDVD flexibility seems to make it applicable not only to in situ image data but also diffraction and spectroscopic data.105

ML-based data analysis can also be employed for detecting, semantic segmenting, and even tracking constituent building blocks, such as nanoparticles, atoms/atomic columns, and defects (see schematic in Figure 4a). Often, a crucial first step in image analysis is to retrieve positions (and sizes) of nanoparticles or positions of atoms (column). Although conventional atom finding methods rely on template or local intensity peak and could work well in specific cases,106,107,108 they can be somewhat tedious to apply, especially on locating atoms on the surface or in and near defects where periodicity is disrupted. For example, a convolutional neural network (CNN) trained solely on simulated HRTEM images was used to identify surface and corner atoms of Au/CeO2 nanocatalyst support in experimental GP-TEM multiframe data sets (movie), as shown in Figure 4c. Subsequently, temporal behavior descriptors such as occurrences and events were quantified at the level of single atomic columns, revealing oxygen-enhanced surface diffusion.99 A CNN model trained on experimental HRTEM images revealed the atomic structure of metal nanoparticles, even detecting the weight of atomic columns (i.e., revealing the 3D shape).109 Also in case of (time dependent, but not yet in gases) STEM experiments, ML-based analytics supports detection and classification of atoms and atomic defects.110,111,112,113

Moreover, ML-based methods can be employed in catalyst research specifically to automate tracking and quantification of nanoparticle sizes, defects, aspect ratios, positions, densities, enabling quantitative assessments of local and collective evolution and related dynamic properties with better statistical rigor. High-throughput analyses, with simultaneous correlation with reaction conditions, provide valuable statistical insights into formation, activation, function, and deactivation of catalysts. ML-assisted GP-TEM was already used in studies of the aging process of bimetallic Pt/Pd/Al2O3 catalysts,114 of the sublimation of an Au-supported model catalyst,115,116 as well as of assessing Ostwald ripening and particle agglomeration of individual PdO/Al2O3 nanocatalysts during in situ calcination.117 In a study of Fe-catalyzed carbon nanotube (CNT) growth, the ML-enabled analysis showed that an H2 atmosphere plays a crucial role in producing high-density CNTs.118

Furthermore, ML-based methods are advantageous to capture the collective behaviors of many nanoparticles during dynamic processes, such as nucleation/growth, coarsening, and sublimation. Recently, point process theory was employed to investigate the formation of Fe nanocatalysts during in situ dewetting.119 It reveals an inverse relationship of the spatial-dependent particle size and the areal density map, suggesting that larger nanoparticles reduce the likelihood of nearby nanoparticle formation by consuming more of the metal film.119 This statistical testing method enables a quantitative comparison of the collective spatial nanoparticle distribution. It can also be used to rationally control experimental conditions.

ML-based methods seem extremely effective in facilitating the exploration of new spatial and temporal information in dynamic GP-TEM experiments. Still, it is important to keep in mind possible biases, artifacts, and other well-known systematic challenges in the ML model outputs. Nonetheless, the prospect of combining ML techniques with analytical models both during experiments and for image interpretation after the experiment is promising for future efforts.

Conclusion

Gas-phase transmission electron microscopy (GP-TEM) has shown importance for revealing atomic-scale processes in materials, chemistry, and surface science. Exciting new technologies and methods show promising aspects in enabling further investigations of nanomaterials under relevant thermal and photochemical reaction environments. New approaches to understand and minimize the still limiting electron-beam effects using more sensitive detectors as well as data denoising and ML-based approaches for autonomous experiments and data mining open possibilities for studying highly sensitive, for example, organic and monolayer material. We believe these new advances offer opportunities to accelerate scientific discoveries with GP-TEM.

Data availability

Not applicable.

References

M. Knoll, E. Ruska, Ann. Phys. 404(5), 607 (1932)

M. Knoll, E. Ruska, Z. Phys. 78, 318 (1932)

V.E. Ruska, Kolloid-Zeitschrift 100(2), 212 (1942)

M. von Ardenne, Z. Phys. Chem. Abteilung B 52, 61 (1942)

F. Tao, P.A. Crozier, Chem. Rev. 116(6), 3487 (2016)

S. Helveg, J. Catal. 328, 102 (2015)

H. Yoshida, Y. Kuwauchi, J.R. Jinschek, K. Sun, S. Tanaka, M. Kohyama, S. Shimada, M. Haruta, S. Takeda, Science 335(6066), 317 (2012)

T. Ito, K. Hiziya, J. Electron Microsc. 6(1), 4 (1958)

H. Hashimoto, T. Naiki, T. Eto, K. Fujiwara, Jpn. J. Appl. Phys. 7(8), 946 (1968)

R. Baker, P. Harris, J. Phys. E 5(8), 793 (1972)

P. Swann, “High Voltage Microscopy Studies of Environmental Reactions,” in Electron Microscopy and Structure of Materials, ed. by G. Thomas (University of California Press, San Francisco, 1972), pp. 878–904

D.L. Allinson, “Environmental Devices in Electron Microscopy,” in Principles and Techniques in Electron Microscopy: Biological Applications, vol. 5, ed. by M.A. Hayat (Van Nostrand Reinhold, New York, 1975), p. 62

P. Butler, K. Hale, “Dynamic Experiments in the Electron Microscope,” in Practical Methods in Electron Microscopy (North Holland, 1981), p. 239

R.C. Doole, G.M. Parkinson, J.M. Stead, Inst. Phys. Conf. Ser. 119, 157 (1991)

E.D. Boyes, P.L. Gai, Ultramicroscopy 67, 219 (1997)

R. Sharma, K. Weiss, Microsc. Res. Tech. 42(4), 270 (1998)

P.L. Hansen, J.B. Wagner, S. Helveg, J.R. Rostrup-Nielsen, B.S. Clausen, H. Topsøe Science 295(5562), 2053 (2002)

T.W. Hansen, J.B. Wagner, R.E. Dunin-Borkowski, Mater. Sci. Technol. 26(11), 1338 (2010)

S. Takeda, H. Yoshida, Microscopy 62(1), 193 (2013)

J.R. Jinschek, Chem. Commun. 50(21), 2696 (2014)

P.L. Gai, E.D. Boyes, “Environmental High Resolution Electron Microscopy (EHREM) in Materials Science,” in In Situ Microscopy in Materials Research, ed. by P.L. Gai (Kluwer Academic Publishers, Dordrecht, 1997), chap. 6, p. 123

M. Zhang, E.A. Olson, R.D. Twesten, J.G. Wen, L.H. Allen, I.M. Robertson, I. Petrov, J. Mater. Res. 20(7), 1802 (2005)

L.F. Allard, W.C. Bigelow, M.J. Yacaman, D.P. Nackashi, Microsc. Res. Tech. 72(3), 208 (2009)

L. Mele, S. Konings, P. Dona, F. Evertz, C. Mitterbauer, P. Faber, R. Schampers, J.R. Jinschek, Microsc. Res. Tech. 79(4), 239 (2016)

J.F. Creemer, S. Helveg, G.H. Hoveling, S. Ullmann, A.M. Molenbroek, P.M. Sarro, H.W. Zandbergen, Ultramicroscopy 108, 993 (2008)

G.M. Parkinson, Catal. Lett. 2(5), 303 (1989)

S. Giorgio, S. Sao Joao, S. Nitsche, D. Chaudanson, G. Sitja, C.R. Henry, Ultramicroscopy 106(6), 503 (2006)

S. Giorgio, M. Cabie, C.R. Henry, Gold Bull. 41(2), 167 (2008)

L.F. Allard, S.H. Overbury, W.C. Bigelow, M.B. Katz, D.P. Nackashi, J. Damiano, Microsc. Microanal. 18(4), 656 (2012)

T. Alan, T. Yokosawa, J. Gaspar, G. Pandraud, O. Paul, F. Creemer, P.M. Sarro, H.W. Zandbergen, Appl. Phys. Lett. 100(8), 081903 (2012)

T. Yokosawa, T. Alan, G. Pandraud, B. Dam, H. Zandbergen, Ultramicroscopy 112(1), 47 (2012)

R. Colby, B. Kabius, D. Alsem, Microsc. Microanal. 19(S2), 474 (2013)

S.B. Vendelbo, P.J. Kooyman, J.F. Creemer, B. Morana, L. Mele, P. Dona, B.J. Nelissen, S. Helveg, Ultramicroscopy 133, 72 (2013)

S. Vijayan, J.R. Jinschek, S. Kujawa, J. Greiser, M. Aindow, Microsc. Microanal. 23(4), 708 (2017)

M. Duchamp, Q. Xu, R.E. Dunin-Borkowski, Microsc. Microanal. 20(6), 1638 (2014)

M.A. Bañares, I.E. Wachs, J. Raman Spectrosc. 33, 359 (2002)

R.T.K. Baker, M.A. Barber, P.S. Harris, F.S. Feates, R.J. Waite, J. Catal. 26(1), 51 (1972)

R.T.K. Baker, J.A. France, L. Rouse, R.J. Waite, J. Catal. 41(1), 22 (1976)

S. Helveg, C. López-Cartes, J. Sehested, P.L. Hansen, B.S. Clausen, J.R. Rostrup-Nielsen, F. Abild-Pedersen, J.K. Nørskov, Nature 427(6973), 426 (2004)

S.B. Simonsen, S. Dahl, E. Johnson, S. Helveg, J. Catal. 255(1), 1 (2008)

S.B. Vendelbo, C.F. Elkjaer, H. Falsig, I. Puspitasari, P. Dona, L. Mele, B. Morana, B.J. Nelissen, R. van Rijn, J.F. Creemer, P.J. Kooyman, S. Helveg, Nat. Mater. 13(9), 884 (2014)

K.A. Unocic, F.S. Walden, N.L. Marthe, A.K. Datye, W.C. Bigelow, L.F. Allard, Microsc. Microanal. 26(2), 229 (2020)

P.A. Crozier, S. Chenna, Ultramicroscopy 111(3), 177 (2011)

S. Chenna, P.A. Crozier, ACS Catal. 2, 2395 (2012)

B.K. Miller, P.A. Crozier, Microsc. Microanal. 20(3), 815 (2014)

B.K. Miller, P.A. Crozier, ACS Catal. 11, 1456 (2021)

B.K. Miller, T. Barker, P.A. Crozier, Ultramicroscopy 156, 18 (2015)

P.M. Mortensen, T.W. Hansen, J.B. Wagner, A.D. Jensen, Ultramicroscopy 152, 1 (2015)

J.L. Vincent, J.W. Vance, J.T. Langdon, B.K. Miller, P.A. Crozier, Ultramicroscopy 218, 113080 (2020)

J.L. Vincent, P.A. Crozier, Nat. Commun.12(1), 1 (2021)

J.F. Creemer, F. Santagata, B. Morana, L. Mele, T. Alan, E. Iervolino, G. Pandraud, P.M. Sarro, “An All-in-One Nanoreactor for High-Resolution Microscopy on Nanomaterials at High Pressures,” 2011 IEEE 24th International Conference on Micro Electro Mechanical Systems (IEEE, Cancun, January 23–27, 2011), pp. 1103–1106

E. Butler, M. Goringe, Krist. Tech. 14(10), 1213 (1979)

H. Yoshida, S. Takeda, Phys. Rev. B 72(19), 195428 (2005)

J.R. Jinschek, S. Helveg, Micron 43(11), 1156 (2012)

M. Ek, S.P.F. Jespersen, C.D. Damsgaard, S. Helveg, Adv. Struct. Chem. Imaging 2(1), 4 (2016)

S. Helveg, C.F. Kisielowski, J.R. Jinschek, P. Specht, G. Yuan, H. Frei, Micron 68, 176 (2015)

R.F. Egerton, P. Li, M. Malac, Micron 35(6), 399 (2004)

M. Suzuki, T. Yaguchi, X.F. Zhang, Microscopy 62(4), 437 (2013)

A. Rose, “Television Pickup Tubes and the Problem of Vision,” in Advances in Electronics and Electron Physics, vol. 1, ed. by L. Marton (Elsevier, 1948), pp. 131–166

C. Kisielowski, P. Specht, S.J. Rozeveld, J. Kang, A.J. Fielitz, D. Barton, A.C. Salazar, O.D. Dubon, D. Van Dyck, D.F. Yancey, Microsc. Microanal. 27(6), 1420 (2021)

C. Kisielowski, J. Mater. Sci. 51, 635 (2016)

C.-H. Li, J. Wu, J.R. Jinschek, Microsc. Microanal. 28(S1), 2544 (2022)

J. Wu, S. Helveg, S. Ullmann, Z. Peng, A.T. Bell, J. Catal. 338, 295 (2016)

S.B. Simonsen, I. Chorkendorff, S. Dahl, M. Skoglundh, J. Sehested, S. Helveg, J. Am. Chem. Soc. 132(23), 7968 (2010)

Y. Kuwauchi, H. Yoshida, T. Akita, M. Haruta, S. Takeda, Angew. Chem. Int. Ed. 51(31), 7729 (2012)

M. Ek, Q.M. Ramasse, L. Amarson, P.G. Moses, S. Helveg, Nat. Commun. 8(1), 305 (2017)

K. Suzuki, M. Ichihara, S. Takeuchi, K. Nakagawa, K. Maeda, H. Iwanaga, Philos. Mag. A 49(3), 451 (1984)

F. Cavalca, A.B. Laursen, B.E. Kardynal, R.E. Dunin-Borkowski, S. Dahl, J.B. Wagner, T.W. Hansen, Nanotechnology 23(7), 075705 (2012)

L.X. Zhang, B.K. Miller, P.A. Crozier, Nano Lett. 13(2), 679 (2013)

B.K. Miller, P.A. Crozier, Microsc. Microanal. 19(2), 461 (2013)

M. Picher, S. Mazzucco, S. Blankenship, R. Sharma, Ultramicroscopy 150, 10 (2015)

A.M. Zak, Nano Lett. 22(23), 9219 (2022)

S. Kadkhodazadeh, F.C. Cavalca, B.J. Miller, L. Zhang, J.B. Wagner, P.A. Crozier, T.W. Hansen, Top. Curr. Chem. 380(6), 52 (2022)

K. Yoshida, J. Yamasaki, N. Tanaka, Appl. Phys. Lett. 84(14), 2542 (2004)

M. Cargnello, Chem. Mater. 31(3), 576 (2019)

J.B. Wagner, F. Cavalca, C.D. Damsgaard, L.D.L. Duchstein, T.W. Hansen, P.A. Crozier, R. Sharma, Micron 43(11), 1169 (2012)

M. Vadai, D.K. Angell, F. Hayee, K. Sytwu, J.A. Dionne, Nat. Commun. 9(1), 4658 (2018)

K. Sytwu, M. Vadai, F. Hayee, D.K. Angell, A. Dai, J. Dixon, J.A. Dionne, Science 371(6526), 280 (2021)

Y. Ohno, Appl. Phys. Express 5(12), 125204 (2012)

F.I Allen, E. Kim, N.C. Andresen, C.P. Grigoropoulos, A.M. Minor, Ultramicroscopy 178, 33 (2017)

A.A. Saleh, D.K. Angell, J.A. Dionne, Phys. Rev. B 102(8), 085406 (2020)

J.-M. Zuo, R. Yuan, Y.-T. Shao, H.-W. Hsiao, S. Pidaparthy, Y. Hu, Q. Yang, J. Zhang, Microscopy 71(Suppl. 1), i116 (2022)

M. Ge, X. Liu, Z. Zhao, F. Su, L. Gu, D. Su, Adv. Theory Simul. 5(4), 2100337 (2022)

L. Zhang, S. Shao, J. Appl. Phys. 132(10), 100701 (2022)

S.V. Kalinin, C. Ophus, P.M. Voyles, R. Erni, D. Kepaptsoglou, V. Grillo, A.R. Lupini, M.P. Oxley, E. Schwenker, M.K.Y. Chan, J. Etheridge, X. Li, G.G.D. Han, M. Ziatdinov, N. Shibata, S.J. Pennycook, Nat. Rev. Methods Primers 2(1), 11 (2022)

M. Ge, F. Su, Z. Zhao, D. Su, Mater. Today Nano 11, 100087 (2020)

J.M. Ede, R. Beanland, Ultramicroscopy 202, 18 (2019)

J. Dan, X. Zhao, S.J. Pennycook, InfoMat 1(3), 359 (2019)

M. Botifoll, I. Pinto-Huguet, J. Arbiol, Nanoscale Horiz. 7, 1427 (2022)

S. Muto, M. Shiga, Microscopy 69(2), 110 (2020)

S. Jesse, M. Chi. A. Belianinov, C. Beekman, S.V. Kalinin, A.Y. Borisevich, A.R. Lupini, Sci. Rep. 6(1), 26348 (2016)

S. Li, C.A. Powell, S. Mathaudhu, B. Gwalani, A. Devaraj, C. Wang, J. Mater. Sci. 57(26), 12177 (2022)

L. Yao, Z. Ou, B. Luo, C. Xu, Q. Chen, ACS Cent. Sci. 6(8), 1421 (2020)

J. Sung, Y. Bae, H. Park, S. Kang, B.K. Choi, J. Kim, J. Park, Annu. Rev. Chem. Biomol. Eng. 13, 167 (2022)

H. Zheng, X. Lu, K. He, J. Energy Chem. 68, 454 (2022)

M.G. Boebinger, J.A. Lewis, S.E. Sandoval, M.T. McDowell, ACS Energy Lett. 5, 335 (2020)

J.J. Scott-Fordsmand, M.J. Amorim, Sci. Total Environ. 859, 160303 (2023)

P.A. Crozier, A.M. Morales, M. Leibovich, S. Mohan, P. Haluai, M. Tan, J. Vincent, A. Gilankar, Y. Wang, C. Fernandez-Granda, Microsc. Microanal. 29, 1595 (2023)

J. Madsen, P. Liu, J. Kling, J.B. Wagner, T.W. Hansen, O. Winther, J. Schiøtz, Adv. Theory Simul. 1(8), 1800037 (2018)

C.M. Pate, J.L. Hart, M.L. Taheri, Sci. Rep. 11(1), 19515 (2021)

S. Mohan, J.L. Vincent, R. Manzorro, P. Crozier, C. Fernandez-Granda, E. Simoncelli, “Adaptive Denoising via GainTuning,” in Advances in Neural Information Processing Systems, vol. 34, ed. by M. Ranzato, A. Beygelzimer, Y. Dauphin, P.S. Liang, J.W. Vaughan (Curran Associates, La Jolla, 2021), p. 23727

J.L. Vincent, R. Manzorro, S. Mohan, B. Tang, D.Y. Sheth, E.P. Simoncelli, D.S. Matteson, C. Fernandez-Granda, P.A. Crozier, Microsc. Microanal. 27(6), 1431 (2021)

S. Mohan, R. Manzorro, J.L. Vincent, B. Tang, D.Y. Sheth, E.P. Simoncelli, D.S. Matteson, P.A. Crozier, C. Fernandez-Granda, IEEE Trans. Comput. Imaging 8, 585 (2022)

D.Y. Sheth, S. Mohan, J.L. Vincent, R. Manzorro, P.A. Crozier, M.M. Khapra, E.P. Simoncelli, C. Fernandez-Granda, “Unsupervised Deep Video Denoising,” in Proceedings of the IEEE/CVF International Conference on Computer Vision (ICCV) (2021), pp. 1759–1768

A. Marcos-Morales, M. Leibovich, S. Mohan, J.L. Vincent, P. Haluai, M. Tan, P. Crozier, D. Fernandez-Granda, Evaluating unsupervised denoising requires unsupervised metrics (2022), Preprint, https://arxiv.org/abs/2210.05553

B.D.A. Levin, E.L. Lawrence, P.A. Crozier, Ultramicroscopy 213, 112978 (2020)

R. Manzorro, Y. Xu, J.L. Vincent, R. Rivera, D.S. Matteson, P.A. Crozier, Microsc. Microanal. 28(6), 1917 (2022)

M. Nord, P.E. Vullum, I. MacLaren, T. Tybell, R. Holmestad, Adv. Struct. Chem. Imag. 3(1), 9 (2017)

M. Ragone, V. Yurkiv, B. Song, A. Ramsubramanian, R. Shahbazian-Yassar, F. Mashayek, Comput. Mater. Sci. 180, 109722 (2020)

M. Ziatdinov, O. Dyck, A. Maksov, X. Li, X. Sang, K. Xiao, R.R. Unocic, R. Vasudevan, S. Jesse, S.V. Kalinin, ACS Nano 11(12), 12742 (2017)

M. Ziatdinov, A. Maksov, S.V. Kalinin, NPJ Comput. Mater. 3(1), 31 (2017)

M. Ziatdinov, O. Dyck, X. Li, B.G. Sumpter, S. Jesse, R.K. Vasudevan, S.V. Kalinin, Sci. Adv. 5(9), eaaw8989 (2019)

S.V. Kalinin, O. Dyck, S. Jesse, M. Ziatdinov, Sci. Adv. 7(17), eabd5084 (2021)

A.C. Meng, K.-B. Low, A.C. Foucher, Y. Li, I. Petrovic, E.A. Stach, Nanoscale 13(26), 11427 (2021)

J.P. Horwath, P.W. Voorhees, E.A. Stach, Nano Lett. 21(12), 5324 (2021)

J.P. Horwath, C. Lehman-Chong, A. Vojvodic, E.A. Stach, ACS Nano 17(9), 8098 (2023)

K. Faraz, T. Grenier, C. Ducottet, T. Epicier, Sci. Rep. 12(1), 2484 (2022)

N.T. Dee, M. Schneider, D.N. Zakharov, P.R. Kidambi, A.J. Hart, Carbon 192, 249 (2022)

A. Aziz Ezzat, M. Bedewy, J. Phys. Chem. C 124(50), 27479 (2020)

Acknowledgments

J.R.J. acknowledges support from DTU Nanolab (starting grant) and from the Novo Nordisk Foundation (Grant No. 110114). S.H. acknowledges support from the Danish National Research Foundation (Grant No. DNRF146). L.F.A. acknowledges support by the US Department of Energy, Office of Energy Efficiency and Renewable Energy, Vehicle Technologies Office, Propulsion Materials Program. J.A.D. acknowledges support from the DOE Office of Science (Grant No. DE-SC0021984). Y.Z. acknowledges support from US NSF Grant No. CBET 2238213. P.A.C. acknowledges support from US NSF Grant Nos. OAC 1940263, 2104105, CBET 1604971, and DMR 184084.

Funding

The authors have not disclosed any funding.

Author information

Authors and Affiliations

Contributions

Not applicable.

Corresponding authors

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding authors state that there is no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Jinschek, J.R., Helveg, S., Allard, L.F. et al. Quantitative gas-phase transmission electron microscopy: Where are we now and what comes next?. MRS Bulletin 49, 174–183 (2024). https://doi.org/10.1557/s43577-023-00648-8

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/s43577-023-00648-8