Abstract

The review, titled “A Review on Recent Developments in Ultrasonic Welding of Polymers and Polymeric Composites,” comprehensively examines advancements in ultrasonic welding within the last decade. Employing a meticulous material-by-material approach, the study delves into the evolution of ultrasonic welding techniques, focusing on diverse advanced materials. Notably, the review encompasses significant developments in ultrasonic welding applied to carbon fiber–reinforced polymers such as PEEK, PA, PPS, and PEI, as well as glass fiber–reinforced polymers (GFRP). Additionally, the review extends its purview to various thermoplastics, including ABS, PP, and PE. The review synthesizes a nuanced understanding of the challenges and innovations associated with ultrasonic welding in diverse polymer and composite contexts by systematically analyzing each material category. This inclusive examination facilitates a holistic comprehension of the advancements made in ultrasonic welding technology, offering valuable insights for researchers, practitioners, and industry professionals. The review is a timely and comprehensive resource for those seeking to stay abreast of the latest developments in ultrasonic welding, fostering continued progress and innovation in polymer and polymeric composite joining methodologies.

Similar content being viewed by others

Abbreviations

- USW:

-

Ultrasonic welding

- PEEK:

-

Poly-ether-ether-ketone

- PA:

-

Polyamide

- PPS:

-

Poly-phenyl sulfide

- PEI:

-

Poly-ether imide

- FRTP:

-

Fiber-reinforced thermoplastic polymer

- CFRP:

-

Carbon fiber–reinforced polymer

- GFRP:

-

Glass fiber–reinforced polymer

- ABS:

-

Acrylonitrile butadiene styrene

- PP:

-

Polypropylene

- PE:

-

Polyethylene

- FFF:

-

Fused filament fabrication

- LSS:

-

Lap shear stress

- ED:

-

Energy director

- HAZ:

-

Heat-affected zone

- SSUW:

-

Single-sided ultrasonic welding

- DoS:

-

Degree of crystallinity

- ESW:

-

Energy controlled sequential ultrasonic welding

- DSW:

-

Displacement-controlled sequential ultrasonic welding

- MSW:

-

Multiple equispaced ultrasonic welding

- MMF:

-

Multiple equispaced mechanical fastening

- DP :

-

Detachment pressure

- MWCNT:

-

Multi-walled carbon nanotubes

- Recommended for publication by Commission XVI:

-

Polymer Joining and Adhesive Technology

References

Levy A, Le Corre S, Poitou A (2014) Ultrasonic welding of thermoplastic composites: a numerical analysis at the mesoscopic scale relating processing parameters, flow of polymer and quality of adhesion. Int J Mater Form 7(1):39–51

Hufenbach W, Modler N, Winkler A (2013) Sensitivity analysis for the manufacturing of thermoplastic e-preforms for active textile reinforced thermoplastic composites. Procedia Mater Sci 2:1–9

Selvaraju S, Ilaiyavel S. Applications of composites in marine industry. J Eng … [Internet]. 2011;II(II):89–91. Available from: http://www.technicaljournalsonline.com/jers/VOL II/JERS VOL II ISSUE II APRIL JUNE 2011/ARTICLE 19 JERS VOL II ISSUE II APRIL- JUNE 2011.pdf

Bhudolia SK, Gohel G, Leong KF, Islam A. 2020 Advances in ultrasonic welding of thermoplastic composites: a review. Materials (Basel) 13(6).

Liu Z, Li Y, Liu Z, Yang Y, Li Y, Luo Z (December 2022) 2023 Ultrasonic welding of metal to fiber-reinforced thermoplastic composites: a review. J Manuf Process [Internet] 85:702–12. https://doi.org/10.1016/j.jmapro.2022.12.001

H Li, C Chen, R Yi, Y Li, J Wu 2022 Ultrasonic welding of fiber-reinforced thermoplastic composites : a review. Int J Adv Manuf Technol [Internet] (0123456789). https://doi.org/10.1007/s00170-022-08753-9

Vinson JR (1989) Adhesive bonding of polymer composites. Polym Eng Sci 29(19):1325–1331

Thoppul SD, Finegan J, Gibson RF (2009) Mechanics of mechanically fastened joints in polymer-matrix composite structures - a review. Compos Sci Technol [Internet] 69(3–4):301–29. https://doi.org/10.1016/j.compscitech.2008.09.037

Camanho PP, Matthews FL (1997) Stress analysis and strength prediction of mechanically fastened joints in FRP: a review. Composites Part A: Applied Science and Manufacturing 28(6):529–547. https://doi.org/10.1016/S1359-835X(97)00004-3

Pavkovic K, Cizmar D, Stepinac M, Pospiš N. 2023 Embedment strength and stiffness for large diameter mechanical fastener 13th World Conf Timber Eng WCTE 2023 5:2834–40.

I Sioutis, K Tserpes 2023 A literature review on crack arrest features for composite materials and composite joints with a focus on aerospace applications. Aerospace 10(2).

Xu W, Zhang B, Addison O, Wang X, Hou B, Yu F (2023) Mechanically-assisted crevice corrosion and its effect on materials degradation. Corros Commun [Internet] 11:23–32. https://doi.org/10.1016/j.corcom.2023.01.002

Ekladious A, Wang J, Baker A, Chowdhury N, Chang P, Chiu WK (2023) Numerical and experimental studies on the joint performance of fastened, bonded, and hybrid thin metal joints used in aircraft structures. Mater Res Proc 27:340–349

Gupta S, Pal S, Ray BC (2023) An overview of mechanical properties and failure mechanism of FRP laminates with hole/cutout. J Appl Polym Sci 140(20):1–20

Palanivel R (2023) A contemporary review of the advancements in joining technologies for battery applications. Mater Tehnol 57(3):275–281

Cheng S, Chen D, Shi Y (1991) Analysis of adhesive-bonded joints with nonidentical adherends. J Eng Mech 117(3):605–623

Pethrick RA (2015) Design and ageing of adhesives for structural adhesive bonding-a review. Proc Inst Mech Eng Part L J Mater Des Appl 229(5):349–379

Davies P, Sohier L, Cognard JY, Bourmaud A, Choqueuse D, Rinnert E et al (2009) Influence of adhesive bond line thickness on joint strength. Int J Adhes Adhes 29(7):724–736

Molitor P, Barron V, Young T (2001) Surface treatment of titanium for adhesive bonding to polymer composites: a review. Int J Adhes Adhes 21(2):129–136

W Brockmann, PL Geiß, J Klingen, B Schröder. 2009 Adhesive bonding: materials, applications and technology. Adhes Bond Mater Appl Technol 1–414.

Barnes TA, Pashby IR (2000) Joining techniques for aluminum spaceframes used in automobiles Part II - adhesive bonding and mechanical fasteners. J Mater Process Technol 99(1):72–9

Higgins A (2000) Adhesive bonding of aircraft structures. Int J Adhes Adhes 20(5):367–376

Yacobi BG, Martin S, Davis K, Hudson A, Hubert M (2002) Adhesive bonding in microelectronics and photonics. J Appl Phys 91(10 I):6227–62

Bowen RL (1965) Adhesive bonding of various materials to hard tooth tissues II Bonding to Dentin Promoted by a Surface-active Comonomer. J Dent Res 44(5):895–902

Hargou K, Pingkarawat K, Mouritz AP, Wang CH (2013) Ultrasonic activation of mendable polymer for self-healing carbon-epoxy laminates. Compos Part B Eng 45(1):1031–1039

B Ehrhart, B Valeske, C Bockenheimer. 2013 Non-destructive evaluation (NDE) of aerospace composites: methods for testing adhesively bonded composites. Non-Destructive Eval Polym Matrix Compos Tech Appl 220–37

Jia Z, Bhatia A, Aronson RM, Bourne D, Mason MT (2019) A survey of automated threaded fastening. IEEE Trans Autom Sci Eng 16(1):298–310

Pethrick RA (2012) Composite to metal bonding in aerospace and other applications [Internet]. Welding and Joining of Aerospace Materials. Woodhead Publishing Limited, pp 28–319. https://doi.org/10.1533/9780857095169.2.288

Eroglu O, Langeheinecke HJ, Enzinger N, Fischer F (2019) Contribution to mechanical fasteners for composite structures - an automated industrial approach. Mater Today Proc 34:326–331

T Nakayama, J Ikai, Y Sugimoto, T Katsuya. Brazing of aluminum and its alloys [Internet]. Vol. 1956, Journal of Japan Institute of Light Metals. Woodhead Publishing Limited; 1956. 80–89 p. Available from: 9780857090256.3.607

Iliev G, Hardan L, Kassis C, Bourgi R, Cuevas-Suárez CE, Lukomska-Szymanska M, et al. Shelf life and storage conditions of universal adhesives: a literature review. Vol. 13, Polymers. MDPI AG; 2021.

Kim W-J, Park Y-J, Lee H-P, Lim S-H, Kim J-I (2013) A study on the toxicity analysis of combustion gases of architectural surface materials and architectural adhesives. J Korean Soc Saf 28(4):48–52

Kläusler O, Clauß S, Lübke L, Trachsel J, Niemz P (2013) Influence of moisture on stress-strain behavior of adhesives used for structural bonding of wood. Int J Adhes Adhes 44:57–65

Ringhofer A, Grabner M, Silva CV, Branco J (2014) The influence of moisture content variation on the withdrawal capacity of self-tapping screws. Holztechnologie 55(3):33–40

Baldan A (2004) Adhesively-bonded joints and repairs in metallic alloys, polymers, and composite materials: adhesives, adhesion theories, and surface pretreatment. J Mater Sci 39(1):1–49

Moraes SLD, Pellizzer EP, Verri FR, Santiago JF, Silva JVL (2015) Three-dimensional finite element analysis of stress distribution in retention screws of different crown–implant ratios. Comput Methods Biomech Biomed Engin 18(7):689–696

Xin Z, Ma Y, Chen Y, Wang B, Xiao H, Duan Y (2023) Fusion-bonding performance of short and continuous carbon fiber synergistic reinforced composites using fused filament fabrication. Compos Part B 248(2021):110370. https://doi.org/10.1016/j.compositesb.2022.110370

Jang YY, Ha JC, Lee D, Lee Y, Nam SY, Yang SB et al (2023) Dissimilar material bonding technology for lightweight future mobility: a review. Polym Test [Internet] 129(August):108281. https://doi.org/10.1016/j.polymertesting.2023.108281

Weidmann F, Ziegmann G, Wieser J (2023) A review of mode I dominant interfacial fracture toughness test methods of skin-core bonding for thermoplastic composite sandwich structures. J Thermoplast Compos Mater 36(6):2643–2673

Panda S, Nayak N, Mishra A (2017) Engineering polymers in automobile seat belt lock applications: its development, investigation, and performance analysis. J Prod Eng 20(1):63–68

Shi H, Wang JP, Zhang LX, Luo SH (2015) Investigating the application of ultrasonic welding technology in waterproof composites. Adv Mater Res 1095:762–765

Yeh HJ (2013) Ultrasonic welding of medical plastics. Joining and assembly of medical materials and devices. Elsevier Ltd, pp 296–322

Novosibirskiĭ gosudarstvennyĭ tekhnicheskiĭ universitet, Institute of Electrical and Electronics Engineers. Russia Siberia Section, Institute of Electrical and Electronics Engineers., Novosibirskii gosudarstvennyi tekhnicheskii universitet. 2015 16th International Conference of Young Specialists on Micro/Nanotechnologies and Electron Devices : proceedings : Erlagol, Altai, 29 June - 3 July 2015. 597 p.

Kistrup K, Poulsen CE, Hansen MF, Wolff A (2015) Ultrasonic welding for fast bonding of self-aligned structures in lab-on-a-chip systems. Lab Chip 15(9):1998–2001

Chen Y, Ye L, Kinloch AJ, Zhang YX (2022) 3D printed carbon-fiber reinforced composite lattice structures with good thermal-dimensional stability. Compos Sci Technol 227:109599. https://doi.org/10.1016/j.compscitech.2022.109599

Li G, Zhao J, Jiang J, Jiang H, Wu W, Tang M (2018) Ultrasonic strengthening improves the tensile mechanical performance of fused deposition modeling 3D printing. Int J Adv Manuf Technol 96(5–8):2747–2755

Bose S, Chelladurai HM, Ponappa K (2023) Submerged ultrasonic welding of fused filament fabricated short carbon-fibre-reinforced polyamide plates with energy directors. In: Proceedings of the Institution of Mechanical Engineers, Part L: Journal of Materials: Design and Applications

Boyard N. Heat transfer in polymer composite materials: forming processes. 2016.

Villegas IF (2019) Ultrasonic welding of thermoplastic composites. Front Mater 6:291

Jones I (2013) Ultrasonic and dielectric welding of textiles. Joining textiles: principles and applications. Elsevier Ltd, pp 374–97

Şahin ÖS, Koellhoffer S, Gillespie J, Advani S, Bogetti T (2014) Thermal modeling during continuous ultrasonic welding. Turkish J Eng Environ Sci 38(1):79–96

Gohel G, Bhudolia SK, Kantipudi J, Leong KF, Barsotti RJ (2020) Ultrasonic welding of novel Carbon/Elium® with carbon/epoxy composites. Compos Commun 1:22

Bhudolia SK, Gohel G, Kah Fai L, Barsotti RJ (2020) Fatigue response of ultrasonically welded carbon/Elium® thermoplastic composites. Mater Lett 1:264

Vendan SA, Natesh M, Garg A, Gao L (2019) Ultrasonic welding of polymers. confluence of multidisciplinary sciences for polymer joining. Springer, Singapore, pp 73–101

Thang NV, Lenfeld P (2018) The effect of different heights and angles of energy director on interface temperature for ultrasonic welding of thermoplastics. In: IOP Conference Series: Materials Science and Engineering (vol 371, no 1). IOP Publishing, p 012053

Fernandez I, Stavrov D, Bersee HEN (2009) Ultrasonic welding of advanced thermoplastic composites: an investigation on energy directing surfaces. ICCM Int Conf Compos Mater

Hopmann C, van Aaken A (2014) Ultrasonic welding of polyamide—influence of moisture on the process relevant material properties. Weld World 58(6):787–793

Benatar A (2015) Ultrasonic welding of plastics and polymeric composites. Power ultrasonics: applications of high-intensity ultrasound. Elsevier Inc, pp 295–312

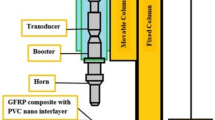

Lionetto F, Dell’Anna R, Montagna F, Maffezzoli A (2015) Ultrasonic assisted consolidation of commingled thermoplastic/glass fiber rovings. Front Mater 21:2

Krabbe S, Achatz DE, Nieradzik T, Gerhardy C, Schomburg WK (2015) Ultrasonic welding of chemical optical sensors supporting O2, pH, and CO2 imaging in microfluidic systems. Procedia Eng 120:598–601

Bhudolia SK, Gohel G, Fai LK, Barsotti RJ (2020) Investigation on ultrasonic welding attributes of novel carbon/Elium® composites. Materials (Basel) 13(5):1117

Tsiangou E, de Freitas ST, Benedictus R, Villegas IF (2021) On the sensitivity of the ultrasonic welding process of epoxy- to polyetheretherketone (PEEK)-based composites to the welding force and amplitude of vibrations. Compos Part C Open Access 5:100141

Yan M, Tian X, Peng G, Li D, Zhang X (2018) High-temperature rheological behavior and sintering kinetics of CF/PEEK composites during selective laser sintering. Compos Sci Technol 165:140–147. https://doi.org/10.1016/j.compscitech.2018.06.023

Tsiangou E, Kupski J, Teixeira de Freitas S, Benedictus R, Villegas IF (2021) On the sensitivity of ultrasonic welding of epoxy- to polyetheretherketone (PEEK)-based composites to the heating time during welding. Compos Part A Appl Sci Manuf 144

Tsiangou E, Teixeira de Freitas S, Villegas IF, Benedictus R (2020) Ultrasonic welding of epoxy- to polyetheretherketone- based composites: investigation on the material of the energy director and the thickness of the coupling layer. J Compos Mater 54(22):3081–3098

Brito CBG, Teuwen J, Dransfeld C, Fernandez Villegas I (2020) Influence of the angle between adherends on ultrasonic welding of thermoplastic composites. EMUS 2020. https://doi.org/10.23967/emus.2020.006

Tao W, Su X, Wang H, Zhang Z, Li H, Chen J (2019) Influence mechanism of welding time and energy director to the thermoplastic composite joints by ultrasonic welding. J Manuf Process 1(37):196–202

Villegas IF, van Moorleghem R (2018) Ultrasonic welding of carbon/epoxy and carbon/PEEK composites through a PEI thermoplastic coupling layer. Compos Part A Appl Sci Manuf 109:75–83

Zhi Q, Ma JM, Tan XR, Liu ZX, Tian ZG, Wang PC (2021) Single-sided ultrasonic welding of carbon fiber/Nylon 66 composite. Weld World 65:2047–2058

Zhang GP, Li JC, Liu ZX, Wang PC (2020) Application of ultrasonic welding to repair adhesively bonded short carbon fiber reinforced Nylon 6 composites. Int J Adhes Adhes 100:102603

Tutunjian S, Dannemann M, Modler N, Kucher M, Fellermayer A (2020) A numerical analysis of the temporal and spatial temperature development during the ultrasonic spot welding of fiber-reinforced thermoplastics. J Manuf Mater Process 4(2):30

Lee TH, Fan HT, Li Y, Shriver D, Arinez J, Xiao G, et al. 2020 Enhanced performance of ultrasonic welding of short carbon fiber polymer composites through control of morphological parameters. J Manuf Sci Eng Trans ASME 142(1).

Goto K, Imai K, Arai M, Ishikawa T (2019) Shear and tensile joint strengths of carbon fiber-reinforced thermoplastics using ultrasonic welding. Compos Part A Appl Sci Manuf 116:126–137

Li Y, Arinez J, Liu Z, Hwa Lee T, Fan HT, Xiao G et al (2018) Ultrasonic welding of carbon fiber reinforced composite with variable blank holding force. J Manuf Sci Eng 140(9):091011

Gao YH, Zhi Q, Lu L, Liu ZX, Wang PC (2018) Ultrasonic welding of carbon fiber reinforced nylon 66 composite without energy director. J Manuf Sci Eng Trans ASME 140(5)

Chen LY, Zhi Q, Li JC, Liu ZX, Wang PC (2018) Single-sided ultrasonic welding of CF/nylon 6 composite without energy directors. Weld J 97(1):17s–25s

Wang K, Shriver D, Li Y, Banu M, Hu SJ, Xiao G et al (2017) Characterization of weld attributes in ultrasonic welding of short carbon fiber reinforced thermoplastic composites. J Manuf Process 1(29):124–132

Wang K, Li Y, Banu M, Li J, Guo W, Khan H (2017) Effect of interfacial preheating on welded joints during ultrasonic composite welding. J Mater Process Technol 1(246):116–122

Wang K, Shriver D, Banu M, Jack Hu S, Xiao G, Arinez J et al (2017) Performance prediction for ultrasonic spot welds of short carbon fiber-reinforced composites under shear loading. J Manuf Sci Eng Trans ASME 139(11). https://doi.org/10.1115/1.4037320

Zhi Q, Tan XR, Liu ZX (2017) Effect of moisture on the ultrasonic welding of carbon-fiber-reinforced polyamide 66 composites. Weld J 96(6):185s–192s

Kirby M, Naderi A, Palardy G. 2022 Predictive thermal modeling and characterization of ultrasonic consolidation process for woven thermoplastic composites. SSRN Electron J 1–41.

Takeda SI, Tanks JD, Sugimoto S, Iwahori Y (2021) Application of sheet-like energy directors to ultrasonic welding of carbon fiber-reinforced thermoplastics. Adv Compos Mater 30(2):192–204

Zhao A, Tsakoniatis T, Rans I, Villegas CF, Benedictus IF. Multi-spot ultrasonic welding of thermoplastic composite single-lap joints: effect of spot spacing and number of spots on weld strength [Internet]. 2020. Available from: http://staff.tudelft.nl/en/R.Benedictus/

Jongbloed B, Teuwen J, Benedictus R, Villegas IF (2020) On differences and similarities between static and continuous ultrasonic welding of thermoplastic composites. Compos Part B Eng 15:203

Jongbloed B, Teuwen J, Palardy G, Fernandez Villegas I, Benedictus R (2020) Continuous ultrasonic welding of thermoplastic composites: enhancing the weld uniformity by changing the energy director. J Compos Mater 54(15):2023–2035

Jongbloed B, Teuwen J, Palardy G, Villegas I (2018) Improving weld uniformity in continuous ultrasonic welding of thermoplastic composites. In: Proceedings of the 18th European Conference on Composite Materials: 24-28th June 2018, Athens

Zhao T, Broek C, Palardy G, Villegas IF, Benedictus R (2018) Towards robust sequential ultrasonic spot welding of thermoplastic composites: welding process control strategy for consistent weld quality. Compos Part A Appl Sci Manuf 1(109):355–367

Senders F, van Beurden M, Palardy G, Villegas IF (2016) Zero-flow: a novel approach to continuous ultrasonic welding of CF/PPS thermoplastic composite plates. Adv Manuf Polym Compos Sci 2(3–4):83–92

Villegas IF, Palardy G (2017) Ultrasonic welding of CF/PPS composites with integrated triangular energy directors: melting, flow, and weld strength development. Compos Interfaces 24(5):515–528

Koutras N, Amirdine J, Boyard N, Fernandez Villegas I, Benedictus R (2019) Characterisation of crystallinity at the interface of ultrasonically welded carbon fiber PPS joints. Compos Part A Appl Sci Manuf 125:105574

Tsiangou E, Teixeira de Freitas S, Fernandez Villegas I, Benedictus R (2019) Investigation on energy director-less ultrasonic welding of polyetherimide (PEI)- to epoxy-based composites. Compos Part B Eng 173:105574

Palardy G, Villegas IF (2017) On the effect of flat energy directors thickness on heat generation during ultrasonic welding of thermoplastic composites. Compos Interfaces 24(2):203–214

Palardy G, Fernandez Villegas I (2015) Ultrasonic welding of thermoplastic composites with flat energy directors: influence of the thickness of the energy director on the welding process.

Villegas IF, Palardy G (2016) Ultrasonic welding of thermoplastic composite coupons for mechanical characterization of welded joints through single lap shear testing. J Vis Exp (108). https://doi.org/10.3791/53592

Villegas IF (2015) In situ monitoring of ultrasonic welding of thermoplastic composites through power and displacement data. J Thermoplast Compos Mater 28(1):66–85

Dobrotă D, Lazăr SV (2021) Ultrasonic welding of pbt-gf30 (70% polybutylene terephthalate + 30% fiberglass) and expanded polytetrafluoroethylene (e-ptfe). Polymers (Basel) 13(2):1–19

Kalyan Kumar R, Omkumar M (2020) sonic welding of GF/PA6T composites: experimental investigation and process optimization. Materials Today: Proceedings. Elsevier Ltd, pp 1180–6

Li W, Frederick H, Palardy G (2021) Multifunctional films for thermoplastic composite joints: ultrasonic welding and damage detection under tension loading. Compos Part A Appl Sci Manuf 1:141

Alrubaie MAA (2020) Ultrasonic welding of glass fiber reinforced pp thermoplastic composites: an investigation of the outer layer orientation and the fiber volume fraction. Key Engineering Materials. Trans Tech Publications Ltd, pp 3–13

Nikoi R, Sheikhi MM, Arab NBM (2015) Experimental analysis of effects of ultrasonic welding on weld strength of polypropylene composite samples. Int J Eng Trans A Basics 28(3):447–453

Gutnik VG, Gorbach NV, Dashkov AV (2002) Some characteristics of ultrasonic welding of polymers. Fibre Chem 34(6):426–432

Rajput C, Kumari S, Prajapati V, Dinbandhu, Abhishek K (2019) Experimental investigation on peel strength during ultrasonic welding of polypropylene H110MA. Materials today: proceedings. Elsevier Ltd, pp 1302–5

Raza SF, Khan SA, Mughal MP (2019) Optimizing the weld factors affecting ultrasonic welding of thermoplastics. Int J Adv Manuf Technol 103(5–8):2053–2067

Kuratani F, Miyano S, Washio S (2019) Effect of contact area with a fixture on the dynamic behavior of joint interface in ultrasonic welding of thermoplastics. Journal of Physics: Conference Series. Institute of Physics Publishing

Natesh M, Yun L, ArungalaiVendan S, Ramesh Kumar KA, Gao L, Niu X et al (2019) Experimental and numerical procedure for studying strength and heat generation responses of ultrasonic welding of polymer blends. Meas J Int Meas Confed 1(132):1–10

Chinnadurai T, ArungalaiVendan S, Rusu CC, Scutelnicu E (2018) Experimental investigations on the polypropylene behavior during ultrasonic welding. Mater Manuf Process 33(7):718–726

Parmar U, Pandya DH (2016) Experimental investigation of ultrasonic welding on non-metallic material. Procedia Technol 23:551–557

Tang SH, Cheng CW, Yeh RY, Hsu RQ (2018) Direct joining of 3D-printed thermoplastic parts to SLM-fabricated metal cellular structures by ultrasonic welding. Int J Adv Manuf Technol 99(1–4):729–736

Tofangchi A, Han P, Izquierdo J, Iyengar A, Hsu K (2019) Effect of ultrasonic vibration on interlayer adhesion in fused filament fabrication 3D printed ABS. Polymers 11(2):315

Masuzawa N, Hori K, Ide M (1998) Ultrasonic welding of plastic pipes using torsional vibration. Japanese J Appl Physics, Part 1 Regul Pap Short Notes Rev Pap 37(5 SUPPL B):3007–8

Flanagan M, Grogan DM, Goggins J, Appel S, Doyle K, Leen SB et al (2017) Permeability of carbon fiber PEEK composites for cryogenic storage tanks of future space launchers. Compos Part A Appl Sci Manuf 101:173–184. https://doi.org/10.1016/j.compositesa.2017.06.013

Poodts E, Minak G, Zucchelli A (2013) Impact of sea-water on the quasi-static and fatigue flexural properties of GFRP. Compos Struct [Internet] 97:222–30. https://doi.org/10.1016/j.compstruct.2012.10.021

Montagna LS, Kondo MY, Callisaya ES, Mello C, de Souza BR, Lemes AP, et al. 2022 A review on research, application, processing, and recycling of PPS-based materials. Polimeros 32(1). https://doi.org/10.1590/0104-1428.20210108

Author information

Authors and Affiliations

Contributions

In the collaborative effort of this work, H. Chelladurai and K. Ponappa played critical roles in conceiving ideas and refining the manuscript’s format. Meanwhile, Sandeep Bose took charge of sourcing information and composing the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Bose, S., Chelladurai, H. & Ponappa, K. A review on recent developments in ultrasonic welding of polymers and polymeric composites. Weld World (2024). https://doi.org/10.1007/s40194-024-01693-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40194-024-01693-w