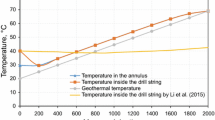

Aiming at the hazards caused by drilling into fractured formations during oil drilling, linear prediction of physical properties of CO2/H2S under different well depths are carried out, based on Fluent to simulate gas-liquid placement in near-critical, critical and supercritical states of gas. The results show that when the well depth is small, the CO2/H2S near-critical state and the initial bottom hole pressure of the critical state invading the annulus are lower than the formation pressure, and the gas invading the annulus is suspended in the annulus until the hydrostatic pressure of the missing drilling fluid is supplemented for about 1s and 1.2 s respectively, the formation pressure can be balanced before the upward return can be continued; the bottom hole pressure of the supercritical state invades the annulus rapidly drops within 2 s; the gas-liquid replacement rate in the supercritical state is slower than that in the non-supercritical state, with a difference of 60-80 s. During the drilling process, it can be judged according to the bottom hole pressure change whether it has encountered a fractured formation and the state of the gas contained, and well control measures should be taken in time.

Similar content being viewed by others

References

Li Jun, Liu Gonghui, Zhou Liujie, et al. Gas-liquid gravity displacement experiment in carbonate fractured formations. Acta Petrolei Sinica, 2018, 39(10): 1187-1192.

Jia Lichun, Chen Mian, Hou Bing, et al. Drilling fluid leakage model and leakage law in fractured formations. Petroleum Exploration and Development, 2014, 41(1): 95-101.

Li Daqi, Kang Yili, Liu Xiushan, et al. Research progress on dynamic model of drilling fluid loss in fractured formations. Petroleum Drilling Technology, 2013, 41(4): 43-47.

Sun T., Zhang H., Gao D., et al. Calculation of the Open-Hole Extended-Reach Limit for an Extended-Reach Well[J]. Chemistry and Technology of Fuels and Oils, 2016, 52(2): 211-217.

Kong X, Sun T., et al. An Empirical Model for Gas-Liquid Bi-Phase Pressure Wave Dispersion Considering Virtual Mass Forces Along Wellbore [J]. Chinese Quarterly of Mechanics, 2023, 44(3): 37-45.

Kong X., Sun T., et al. Gas Overflow Model and Analysis in a Fractured Formation. Chemistry and Technology of Fuels and Oils, 2021, 57(5) : 865-869.

Zhang H., Sun T., Gao D., et al. Modeling Deep-Water Well Killing[J]. Chemistry and Technology of Fuels and Oils, 2014, 50(1): 71-77.

Zhang Zhi, Shi Taihe, Wu You, et al. Study on drilling and production accidents induced by the phase change of supercritical carbon dioxide and hydrogen sulfide in highly acidic gas wells. Drilling and Production Technology, 2007, 30(1): 94-95, 104.

Song P. Y., Zhang S., Xu H. J., et al. Analysis of performance of spiral groove dry gas seal considered effects of both real gas and slip flow[J]. CIESC Journal, 2016, 67(4): 1405-1415.

Xu H. J., Song P. Y., Mao W. Y., et al. Analysis on inertia effect of carbon dioxide dry gas seal at high speed and pressure under laminar condition[J]. CIESC Journal, 2018, 69(10): 4311-4323.

Lv Jiaxing, Hou Lei, Wu Shouzhi, et al. Research on the characteristics of supercritical CO2 pipeline transportation with gas impurities. Natural Gas Chemical Industry, 2020, 45(5): 77-82.

Dousti S., Allaire P. A compressible hydrodynamic of journal bearings lubricated with supercritical carbon dioxide [C]//The 5th International Symposium - Supercritical CO2 Power Cycles. San Antonio, Texas, 2016.

Wen Jianquan. Theoretical study on characteristics of compliant foil bearings lubricated with supercritical carbon dioxide[D]. Harbin: Harbin Institute of Technology, 2017.

Zakariya M. F., Jahn I. H. J. Performance of supercritical CO2 dry gas seals near the critical point[C]//ASME Turbo Expo 2016: Turbomachinery Technical Conference and Exposition. American Society of Mechanical Engineers, 2016: V009T36A007-V009T36A007.

Fairuz Z. M., Jahn I. The influence of real gas effects on the performance of supercritical CO2 dry gas seals[J]. Tribology International, 2016, 102: 333-347.

Gao Teng, Zhao Lingling, Li Siyu. Molecular simulation of supercritical CO2 flow in rock pores. Chinese Journal of Atomic and Molecular Physics. 2019, 36(6): 983-987.

Shen Zhonghou, Wang Haizhu, Li Gensheng. Numerical simulation of rock carrying capacity of supercritical CO2 drilling horizontal well sections. Petroleum Exploration and Development. 2011, 38(2): 233-236.

Song Weiqiang, Wang Ruihe, Ni Hongjian, et al. Numerical simulation of supercritical CO2 carrying rock in horizontal well section. Journal of China University of Petroleum (Edition of Natural Science). 2015, 39(2): 64-68.

Jiang Shuisheng, Zhao Wandong, Zhang Ying, et al. Numerical simulation of supercritical CO2 flooding two-phase flow at pore scale. Progress in Chemical Industry. 2017, 36(11): 3955-3962.

Fang Junwei, Zhu Lixin, Luo Faqiang, et al. Simulation study on the effect of drilling fluid on gas invasion in fractured formations. Drilling Fluid and Completion Fluid, 2019, 36(3): 288-292.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Khimiya i Tekhnologiya Topliv i Masel, No. 6, pp. 127–131, November – December, 2023.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Jing, Z., Yuanhua, L., Dong, Z. et al. Simulation of the Influence of Fracture Gas State on Gas-Liquid Replacement Based on Fluent Two-Phase Flow. Chem Technol Fuels Oils 59, 1257–1263 (2024). https://doi.org/10.1007/s10553-024-01642-9

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10553-024-01642-9