Abstract

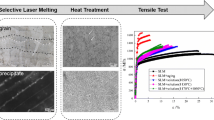

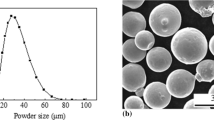

GH 5188 is a solution strengthening cobalt-based superalloy, which is widely used for manufacturing hot components with service temperatures of 1000 ~ 1100 °C. GH 5188 superalloy was fabricated by laser melting deposition (LMD) followed by solution treatment. The effect of heat treatment temperature ranging from 1140 to 1260 ℃ on microstructure and tensile properties of as-LMD specimens was investigated. Optical microscope (OM) and scanning electron microscope (SEM) were used for microstructural observation, and transmission electron microscope (TEM) was employed for phase determination. The results showed that heat treatment did not affect phases within the as-LMD GH 5188 specimens, which were composed of γ, M23C6, M6C, and La2O2C2, whereas heat treatment temperature had an evident effect on the size and content of carbides. In general, heat treatment improved both the ultimate tensile strength (UTS) and the elongation (EL) of as-LMD specimens. With the increase of heat treatment temperature varying from 1140 to 1260 ℃, the UTS enhanced firstly to 1051.9 MPa and then decreased to 934.8 MPa. As the reason, Carbide dispersion distribution contributed to the increase of UTS below the heat treatment at 1180 ℃, and the decrease of volume fraction and size for carbide led to the decrease of UTS above the heat treatment at 1180 ℃. The EL increased slightly at first and then rose rapidly. On the contrary, YS monotonously decreased from 587.1 to 503.6 MPa. The dimples became deeper as the heat treatment temperature increased, indicating better toughness.

Similar content being viewed by others

Data availability

No data was used for the research described in the article.

References

Qu C, Zhou H, Zou X (2018) Experimental study on random vibration fatigue S-N curve of GH 188 alloy under high temperature environment. Adv Eng Res https://doi.org/10.2991/mecae-18.2018.42

Chen LJ, Liaw PK, He YH, Benson ML, Blust JW, Browning PF, Seeley RR, Klarstrom DL (2001) Tensile hold low-cycle fatigue behavior of cobalt-based Haynes ® 188 superalloy. Scr Mater 44:859–865. https://doi.org/10.1016/S1359-6462(00)00702-8

Rao K, Castelli MG, Ellis JR (1995) On the low cycle fatigue deformation of haynes 188 superalloy in the dynamic strain aging regime. Scr Metall Mater 33:1005–1012. https://doi.org/10.1016/0956-716X(95)00320-U

E.C.o.C.A.M. Handbook, China aeronautical materials handbook, Beijing: Standards Press of China, (2002),

Wang YQ, Suneson M (2013) Oxidation behavior of Hf-modified aluminide coatings on Haynes 188 at 1050 ° C. Surf Coat Technol 215:7–15. https://doi.org/10.1016/j.surfcoat.2012.07.091

Lee WS, Kao HC (2014) High temperature deformation behaviour of Haynes 188 alloy subjected to high strain rate loading. Mater Sci Eng A 594:292–301. https://doi.org/10.1016/j.msea.2013.11.076

Dong YP, Wang CY, Song XJ, Chen YH, Zhang MC, Wang SY (2013) Study on plastic deformation behavior of GH 5188 superalloy. Forg Stamping Technol 38:116–121. https://doi.org/10.3969/j.issn.1000-3940.2013.06.025

Liu DH, Chen JD, Chai HR, Jiang YH, Li Z, Qiu WQ, Guo ZH (2021) Study of meta-dynamic recrystallization behavior of GH 5188 superalloy. J Mater Res Technol 15:1179–1189. https://doi.org/10.1016/j.jmrt.2021.08.134

Bonacuse PJ, Kalluri S (1995) Elevated temperature axial and torsional fatigue behavior of Haynes 188. J Eng Mater Technol 117:191–199. https://doi.org/10.1115/1.2804529

Liu W, Xiong HP, Li N, Guo SQ, Qin RY (2018) Microstructure characteristics and mechanical properties of Nb-17Si-23Ti ternary alloys fabricated by in situ reaction laser melting deposition. Acta Metall Sin (Engl Lett) 31:28–36. https://doi.org/10.1007/s40195-017-0619-y

Zhang GD, Xiong HP, Yu H, Qin RY, Liu W, Yuan H (2020) Microstructure evolution and mechanical properties of wire-feed electron beam additive manufactured Ti-5Al-2Sn-2Zr-4Mo-4Cr alloy with different subtransus heat treatments. Mater Des 195:109063. https://doi.org/10.1016/j.matdes.-2020.109063

Zhang GD, Li N, Gao JS, Xiong HP, Yu H, Yuan H (2022) Wire-fed electron beam directed energy deposition of Ti–6Al–2Zr–1Mo–1V alloy and the effect of annealing on the microstructure, texture, and anisotropy of tensile properties. Addit Manuf 49:102511. https://doi.org/10.1016/j.addma.2021.102511

Yang T, Tomus D, Rometsch P, Wu X (2017) Influences of processing parameters on surface roughness of Hastelloy X produced by selective laser melting. Addit Manuf 13:103–112. https://doi.org/10.1016/j.addma.2016.10.010

Liu W, Ren XY, Li N, Gao C, Xiong HP (2021) Rapid directionally solidified microstructure characteristic and fracture behaviour of laser melting deposited Nb–Si–Ti alloy. Prog Nat Sci Mater Int 31:113–120. https://doi.org/10.1016/-j.pnsc.2020.12.003

Miyake M, Matsuda T, Sano T, Hirose A, Shiomi Y, Sasaki M (2020) Microstructure and mechanical properties of additively manufactured CoCrW alloy using laser metal deposition. Weld World 64:1397–1407. https://doi.org/10.1007/s40194-020-00926-y

Li N, Liu W, Wang Y, Zhao ZJ, Yan TQ, Zhang GH, Xiong HP (2021) Laser additive manufacturing on metal matrix composites: a review. Chin J Mech Eng 34:1–16. https://doi.org/10.1186/s10033-021-00554-7

Li N, Huang S, Zhang GD, Qin RY, Liu W, Xiong HP, Shi GQ, Blackburn J (2019) Progress in additive manufacturing on new materials: a review. J Mater Sci Technol 35:242–269. https://doi.org/10.1016/j.jmst.2018.09.002

Wang XY, Liu ZD, Li JY, Chen L, Li BK (2022) Effect of heat treatment on microstructure, corrosion resistance, and interfacial characteristics of Inconel 625 laser cladding layer. Optik 270:169930. https://doi.org/10.1016/j.ijleo.2022.169930

Guevenoux C, Hallais S, Charles A, Charkaluk E, Constantinescu A (2020) Influence of interlayer dwell time on the microstructure of Inconel 718 laser cladded components. Opt Laser Technol 128:106218. https://doi.org/10.1016/j.optlastec.2020.106218

Jinoop AN, Paul CP, Bindra KS (2019) Laser assisted direct energy deposition of Hastelloy-X. Opt Laser Technol 109:14–19. https://doi.org/10.1016/j.optlastec.2018.07.037

Bi G, Sun CN, Chen HC, Ng FL, Ma CK (2014) Microstructure and tensile properties of superalloy IN 100 fabricated by micro-laser aided additive manufacturing. Mater Des 60:401–408. https://doi.org/10.1016/j.matdes.2014.04.020

Zhang XQ, Chai Z, Chen HB, Xu JJ, Xu LM, Lu H, Chen XQ (2021) A novel method to prevent cracking in directed energy deposition of Inconel 738 by in-situ doping Inconel 718. Mater Des 197:109214. https://doi.org/10.1016/j.matdes.2020.109214

Gong XY, You W, Li X, Wang L (2020) Modeling the influence of injection parameters on powder efficiency in laser cladding. Weld World 64:1437–1448. https://doi.org/10.1007/s40194-020-00955-7

Joseph C, Persson C, Colliander MH (2017) Influence of heat treatment on the microstructure and tensile properties of Ni-base superalloy Haynes 282. Mater Sci Eng A 679:520–530. https://doi.org/10.1016/j.msea.2016.10.048

Wang Y, Li N, Jia CL, Liu W, Wu Y, Gao C, Xiong HP (2022) Effects of solution treatment on the microstructural evolution and tensile properties of GH 3230 superalloy manufactured by laser melting deposition. Mater Charact 194:112339. https://doi.org/10.1016/j.matchar.2022.112339

Qiao G, Zhang B, Bai Q, Dilnoza Y (2021) Effect of heat treatment on microstructure and residual stress of GH 3536 superalloy fabricated by selective laser melting. J Mater Eng Perform 30:8892–8900. https://doi.org/10.1007/s11665-021-06094-4

Yin YY, Zhang JH, Huo JX, Zhao K, Zhu XM, Meng XY, Han QQ, Ma YC, Fu ZS, Yin JC (2020) Effect of microstructure on the passive behavior of selective laser melting fabricated Hastelloy X in NaNO3 solution. Mater Charact 165:110370. https://doi.org/10.1016/j.matchar.2020.110370

Liu W, Huang S, Ye C, Jia L, Kang Y, Sha J, Chen B, Wu Y, Xiong H (2023) Progress in Nb-Si ultra-high temperature structural materials: a review. J Mater Sci Technol. https://doi.org/10.1016/j.jmst.2022.11.022

Wei W, Xiao JC, Wang CF, Cheng Q, Guo FJ, He Q, Wang MS, Jiang SZ, Huang CX (2022) Hierarchical microstructure and enhanced mechanical properties of SLM-fabricated GH 5188 Co-superalloy. Mater Sci Eng A 831:142276. https://doi.org/10.1016/j.msea.2021.142276

Zheng XH, Chen X, Zhai Y, Cheng Q, Guo FJ, He Q, Su WL, Zhang C, Ran H (2022) The anisotropy of mechanical properties response on crystallographic features of GH 5188 superalloy fabricated by laser powder bed fusion. Soc Sci Electron Pub. https://doi.org/10.2139/ssrn.4035130.

Xu L, Chu J, Wang J, Zhou Y, Wang D (2022) Effects of process parameters on density of GH 5188 high-temperature alloy after selective laser melting. J Phys: Conf Ser. 012077, https://doi.org/10.1088/1742-6596/2355/1/012077.

Liu C, Guo KK, Zhang YL, Shang S, Liu CS (2021) Influence of energy density on the microstructure and mechanical properties of GH 5188 superalloy formed by laser melting deposition. Fourth International Symposium on High Power Laser Science and En (HPLSE 2021), 262–268, https://doi.org/10.1117/12.2599108.

Yan ZW, Trofimov V, Song CH, Han CJ, Yang YQ, Yang C, Xiao Y, Deng ZT, Chen J (2023) Microstructure and mechanical properties of GH 5188 superalloy additively manufactured via ultrasonic-assisted laser powder bed fusion. J Alloys Compd 939:168771. https://doi.org/10.1016/j.jallcom.2023.168771

Eissel A, Engelking L, Treutler K, Schroepfer D, Wesling V, Kannengiesser T (2023) Investigations on influencing the microstructure of additively manufactured Co-Cr alloys to improve subsequent machining conditions. Weld World 67:1081–1089. https://doi.org/10.1007/s40194-022-01397-z

Parimi LL, Ravi GA, Clark D, Attallah MM (2014) Microstructural and texture development in direct laser fabricated IN718. Mater Charact 89:102–111. https://doi.org/10.1016/j.matchar.2013.12.012

Zhao C, Wang Z, Li DX, Kollo L, Luo ZQ, Zhang WW, Prashanth KG (2020) Cu-Ni-Sn alloy fabricated by melt spinning and selective laser melting: a comparative study on the microstructure and formation kinetics. J Mater Res Technol 9:13097–13105. https://doi.org/10.1016/j.jmrt.2020.09.047

Zeng BS, Wu SQ, Zhang SL (1986) Role and distribution of La in Co-base superalloy GH 188. J Chin Rare Earth Soc 04:48–55

Zeng BS, Wu SQ, Zhang SL (1986) Effect of C and La content on the structures and properties of cobalt-base superalloy GH 188. J Iron Steel Res 02:30–36

Butherus AD, Eick HA (1973) Preparation, characterization, and some thermodynamic properties of lanthanum oxide carbide, La2O2C2. J Inorg Nucl Chem 35:1925–1930. https://doi.org/10.1016/0022-1902(73)80128-9

Seiver RL, Eick HA (1976) The crystal structure of dilanthanum dioxidedicarbide, La2O2C2. J Less-Common Met 44:1–9. https://doi.org/10.1016/0022-5088(76)90113-2

Tucho WM, Cuvillier P, Sjolyst-Kverneland A, Hansen V (2017) Microstructure and hardness studies of Inconel 718 manufactured by selective laser melting before and after solution heat treatment. Mater Sci Eng A 689:220–232. https://doi.org/10.1016/j.msea.2017.02.062

Tomus D, Tian Y, Rometsch PA, Heilmaier M, Wu XH (2016) Influence of post heat treatments on anisotropy of mechanical behaviour and microstructure of Hastelloy-X parts produced by selective laser melting. Mater Sci Eng A 667:42–53

Sukumaran A, Gupta RK, Kumar VA (2017) Effect of heat treatment parameters on the microstructure and properties of Inconel 625 superalloy. J Mater Eng Perform 26:3048–3057. https://doi.org/10.1007/s11665-017-2774-8

Zhou L, Mehta A, McWilliams B, Cho K, Sohn Y (2019) Microstructure, precipitates and mechanical properties of powder bed fused inconel 718 before and after heat treatment. J Mater Sci Technol 35:1153–1164. https://doi.org/10.1016/j.jmst.2018.12.006

Funding

This work was supported by the Beijing Nova Program (Grant No. Z201100006820094) from the Beijing Municipal Science & Technology Commission and the National Natural Science Foundation of China (Grants No. 5177552, 52175369, and U2141205).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights.

(1) GH5188 samples were fabricated by LMD, and effects of heat treatment on microstructure and properties were studied.

(2) Heat treatment had an evident effect on the size and content of carbides but nearly no effect on the phase of the as-LMD samples.

(3) HT improved both strength and elongation of specimens, and all HT samples exhibited a ductile fracture feature.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, Y., Liu, W., Huang, S. et al. Effect of solution heat treatment on the microstructure and mechanical properties of laser melting deposited GH 5188 superalloy. Weld World 68, 939–951 (2024). https://doi.org/10.1007/s40194-024-01695-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-024-01695-8