Abstract

We report on superconducting properties of a novel material: rhenium-lutetium films. Different compositions of RexLu binary are explored from x ≈ 3.8 to close to pure Re stoichiometry. The highest critical temperature, up to  7 K, is obtained for x ≈ 10.5 in accordance with electron dispersive spectroscopy results. Depending on the deposition conditions, polycrystalline or amorphous films are obtainable, both of which are interesting for practical use. Crystalline structure of polycrystalline phase is identified as a non-centrosymmetric superconductor using grazing incidence x-ray diffractometry. Superconducting properties were characterized both resistively and magnetically. Magnetoresistivity and AC/DC susceptibility measurements allowed us to determine

7 K, is obtained for x ≈ 10.5 in accordance with electron dispersive spectroscopy results. Depending on the deposition conditions, polycrystalline or amorphous films are obtainable, both of which are interesting for practical use. Crystalline structure of polycrystalline phase is identified as a non-centrosymmetric superconductor using grazing incidence x-ray diffractometry. Superconducting properties were characterized both resistively and magnetically. Magnetoresistivity and AC/DC susceptibility measurements allowed us to determine  and

and  of these films, as well as estimate coherence length

of these films, as well as estimate coherence length  and magnetic penetration depth

and magnetic penetration depth  . We also provide information on surface morphology of these films. Demonstration of superconductivity in this material justifies the point of view that Lu plays a role of group 3 transition metal in period 6 of the Periodic table of elements. Then, in analogy with Re–Nb, Re–Ti, Re–Hf and Re–Zr, one can expect that crystalline Re–Lu also breaks time-reversal symmetry. If that is proven by future experiments, in combination with noncentrosymmetric feature, these films could be used for forming nonreciprocal current devices, such as superconducting diodes, without involvement of external magnetic fields.

. We also provide information on surface morphology of these films. Demonstration of superconductivity in this material justifies the point of view that Lu plays a role of group 3 transition metal in period 6 of the Periodic table of elements. Then, in analogy with Re–Nb, Re–Ti, Re–Hf and Re–Zr, one can expect that crystalline Re–Lu also breaks time-reversal symmetry. If that is proven by future experiments, in combination with noncentrosymmetric feature, these films could be used for forming nonreciprocal current devices, such as superconducting diodes, without involvement of external magnetic fields.

Export citation and abstract BibTeX RIS

Original content from this work may be used under the terms of the Creative Commons Attribution 4.0 license. Any further distribution of this work must maintain attribution to the author(s) and the title of the work, journal citation and DOI.

1. Introduction

Non-centrosymmetric superconductors (NCS) with broken time-reversal symmetry (TRS) are related to 'hot topics' in contemporary research of quantum materials. Theory predicts that a nonreciprocal response (such as directional transport and propagation of electrons, photons, phonons, magnons) in quantum materials with broken inversion symmetry can occur ubiquitously when the TRS is further broken [1]. Breaking the TRS is possible in presence of magnetic field. This field may be of intrinsic nature, for example, because of magnetochiral effect or spin-orbital interaction [2, 3], or be applied externally. The inversion symmetry is broken in NCS; in case of ordinary superconductors, the methods of nanopatterning can be used. This suggestion was experimentally verified; as a result, many experimental designs have been reported with nonreciprocal current control, such as diodes, transistors, quadristors, etc, see articles [4–12] to name a few. However, in all of these works, the TRS was broken by a magnetic field of external origin. One recent report [13] avoids magnetic field and achieved superconducting diode effect (SDE) via chiral eutectic superconductor Sr2RuO4 in Nb/Ru/Sr2RuO4 topological Josephson junction. Application of these type of materials inherently breaking TRS is a promising way to abandon the necessity of external magnetic fields in designing SDE-based devices. To succeed with this line of development, it is attractive to employ materials with possibly higher critical temperature and available easily in a thin film form. From that point of view, it is reasonable to explore Re-based compounds, such as Re–Nb [14], Re–Ti [15, 16], Re–Hf [17] and Re–Zr [18]. Pure rhenium is centrosymmetric. However, the compounds named belong to NCS. Moreover, muon spectroscopy revealed broken time-reversal symmetry [14–18], complementing their NCS origin. Thin-film superconductors of these materials can be easily deposited, and they are resistant to oxidation, have low resistivity, and/or are compatible with high magnetic fields [19, 20]. As such, SDE and other similar effects in these liquid-helium temperature superconductors look promising in quantum computation technologies [21–23].

Rhenium itself belongs to transition metals, and in bulk form at ambient conditions, it superconducts below  K [24–26]. In a thin film form Tc

is higher [24, 27–30] and can reach values up to 6 K. Compounds of Re with other transition metals allowed material scientists to achieve not only higher values of Tc

, but also, as was mentioned above, to demonstrate broken TRS in addition to NCS. The physical mechanisms yielding broken TRS in these materials are not yet clear. As shown in 1985 by Volovik and Gor'kov, magnetic superconductors may exist in non-trivial superconducting classes both with singlet and triplet pairing [31]. From this point of view it is interesting to explore the occurrence of superconductivity in Re–Lu compositions, since there is an arguable opinion that the lanthanide Lu is closer to transition metals than La itself [32]. In particular, the Periodic table group IIIB representatives Sc and Y are non-superconductive at ambient conditions, and so is Lu, while La has

K [24–26]. In a thin film form Tc

is higher [24, 27–30] and can reach values up to 6 K. Compounds of Re with other transition metals allowed material scientists to achieve not only higher values of Tc

, but also, as was mentioned above, to demonstrate broken TRS in addition to NCS. The physical mechanisms yielding broken TRS in these materials are not yet clear. As shown in 1985 by Volovik and Gor'kov, magnetic superconductors may exist in non-trivial superconducting classes both with singlet and triplet pairing [31]. From this point of view it is interesting to explore the occurrence of superconductivity in Re–Lu compositions, since there is an arguable opinion that the lanthanide Lu is closer to transition metals than La itself [32]. In particular, the Periodic table group IIIB representatives Sc and Y are non-superconductive at ambient conditions, and so is Lu, while La has  K. Low-lying nonhydrogenic f-orbitals are absent in Y, Sc and Lu but present in La. Structure of metals, their oxides and chlorides are similar for Y, Sc and Lu, but different for La. More details on these and other features and relevant references can be found in reference [33]. Thus, Lu can be considered as an interesting representative of transition metals' group. However, Re–Lu superconductor has not yet been reported either in bulk or thin film form.

K. Low-lying nonhydrogenic f-orbitals are absent in Y, Sc and Lu but present in La. Structure of metals, their oxides and chlorides are similar for Y, Sc and Lu, but different for La. More details on these and other features and relevant references can be found in reference [33]. Thus, Lu can be considered as an interesting representative of transition metals' group. However, Re–Lu superconductor has not yet been reported either in bulk or thin film form.

To partially close this gap, we report here on superconducting properties of amorphous and polycrystalline Re–Lu films with critical temperature of complete transition up to about 7 K 1 . We studied morphology of the films, magnetotransport and magnetic susceptibility which allowed us to estimate basic features of superconducting state, such as the critical fields, coherence length, and London penetration depth.

2. Experimental details

The Re–Lu films were prepared via magnetron sputtering in our ATC series UHV Hybrid deposition system (AJA International, Inc.) with a base pressure of  Torr. The Re target (ACI Alloys, Inc. 99.99% purity) was accommodated inside of a 1.5" DC gun. The Lu target (Heeger Materials, Inc. purity Lu/TREM 99.99%) was placed inside of a 2" DC gun. The sapphire substrate (AdValue Technology, thickness 650 µm, C-cut) was cleaned thoroughly with isopropyl alcohol before it was mounted on the holder. In our chamber's configuration, the substrate holder is at the center of the chamber facing upwards, while the (five) sputtering guns are located at the top. The substrate is rotated in plane throughout the whole deposition process to ensure a homogeneous deposition layer over the whole surface. Our predeposition in-situ cleaning of the substrate typically involves heating it up to 900 °C for 10 min followed by a gentle bombardment of Ar+ at 600 °C for 5–10 min using a Kaufman ion source at 45° to the substrate surface. Then the temperature was raised back to 900 °C and kept at that value for 30 min. Afterwards, the temperature was reduced to 600 °C and simultaneous deposition took place for 10 min, at pressure 3–4 mTorr (the increase to 4 mTorr was sometimes required for plasma stability; such action did not change the stoichiometry and just non-essentially reduced the deposition speed), with gun power 250–260 W and anode voltage 460-605 V for Re, and with gun power 45-90 W and anode voltage correspondingly 275-325 V for Lu. Keeping the Re gun power constant, and varying the sputtering power of Lu from case to case allowed us to vary the values of x in composition Rex

Lu (see table 1). After the deposition, the temperature was again raised to 900 °C for in-situ annealing for 30 min and then cooled down to ambient temperature. All the heating/cooling protocols consistently used a 30 °C min−1 ramp rate.

Torr. The Re target (ACI Alloys, Inc. 99.99% purity) was accommodated inside of a 1.5" DC gun. The Lu target (Heeger Materials, Inc. purity Lu/TREM 99.99%) was placed inside of a 2" DC gun. The sapphire substrate (AdValue Technology, thickness 650 µm, C-cut) was cleaned thoroughly with isopropyl alcohol before it was mounted on the holder. In our chamber's configuration, the substrate holder is at the center of the chamber facing upwards, while the (five) sputtering guns are located at the top. The substrate is rotated in plane throughout the whole deposition process to ensure a homogeneous deposition layer over the whole surface. Our predeposition in-situ cleaning of the substrate typically involves heating it up to 900 °C for 10 min followed by a gentle bombardment of Ar+ at 600 °C for 5–10 min using a Kaufman ion source at 45° to the substrate surface. Then the temperature was raised back to 900 °C and kept at that value for 30 min. Afterwards, the temperature was reduced to 600 °C and simultaneous deposition took place for 10 min, at pressure 3–4 mTorr (the increase to 4 mTorr was sometimes required for plasma stability; such action did not change the stoichiometry and just non-essentially reduced the deposition speed), with gun power 250–260 W and anode voltage 460-605 V for Re, and with gun power 45-90 W and anode voltage correspondingly 275-325 V for Lu. Keeping the Re gun power constant, and varying the sputtering power of Lu from case to case allowed us to vary the values of x in composition Rex

Lu (see table 1). After the deposition, the temperature was again raised to 900 °C for in-situ annealing for 30 min and then cooled down to ambient temperature. All the heating/cooling protocols consistently used a 30 °C min−1 ramp rate.

Table 1. Re/Lu stoichiometry ratios from EDS, with Tc and deposition parameters.

| Re/Lu | PLu, W | Tsubstr, °C | Pressure, mTorr | Tc , K | Crystallinity |

|---|---|---|---|---|---|

| 3.8 | 90 | 600 | 3 | 5.25 | Amorphous |

| 7.4 | 55 | 30 | 4 | 6.1 | Amorphous |

| 7.5 | 70 | 600 | 3 | 5.8 | Amorphous |

| 10.5 | 55 | 600 | 3 | 6.95 | Polycrystalline |

| 11.5 | 55 | 600 | 3 | 6.75 | Polycrystalline |

99 99 | 45 | 600 | 4 | 6.3 | Polycrystalline |

The deposition rate at these regimes was about 10 nm min−1 which was obtained ex-situ using x-ray reflectivity method (via Rigaku SmartLab diffractometer). These measurements can also be used to characterize the quality of the films which turned out to be rather high (see appendix

Grazing incidence diffraction (GID) data were taken using Rigaku SmartLab x-ray diffractometer to determine whether the films are amorphous or polycrystalline. Details of the analysis of our GID data, including the evidence of small inclusions of pure Re existent in the material are presented in Results. For these reasons, the compositional characterization of films by the value of x should be understood throughout the whole article as an approximate value introduced for the convenience of description. It corresponds to the EDS outcome at a given energy (20 keV) and characterizes the film's material as a whole, but not the precise formula of the Re–Lu superconducting phase.

3. Results

Our initial choice of x for examining Rex

Lu composition was  , in rough analogy with the well-known NCS superconductor Re0.82Nb0.18, known for its breaking of TRS. The composition with

, in rough analogy with the well-known NCS superconductor Re0.82Nb0.18, known for its breaking of TRS. The composition with  indeed turned out to be an amorphous superconductor with

indeed turned out to be an amorphous superconductor with  5.3 K, see figure 1(a). Figure 1(b) demonstrates that for

5.3 K, see figure 1(a). Figure 1(b) demonstrates that for  , both field cooled (FC) and zero field cooled (ZFC) curves of magnetic moment measurement show magnetic flux expulsion consistent with the behavior of type-II superconductors. We will discuss this in greater detail below.

, both field cooled (FC) and zero field cooled (ZFC) curves of magnetic moment measurement show magnetic flux expulsion consistent with the behavior of type-II superconductors. We will discuss this in greater detail below.

Figure 1. (a) Resistive superconducting transition in amorphous (at x = 3.8) and polycrystalline (at x = 10.5) Rex Lu films; (b) Magnetic flux expulsion below Tc by polycrystalline Re10.5Lu film. The FC curve shows weaker diamagnetic response indicating the presence of trapped fluxes, consistent with type-II superconductor behavior.

Download figure:

Standard image High-resolution imageLowering the relative concentration of the co-deposited Lu first increased and then decreased the Tc

, with the optimum  K corresponding to

K corresponding to  (shown also in figure 1). Though the normal state resistivities of these two compositions are not much different, they have very different surface morphologies, figure 2.

(shown also in figure 1). Though the normal state resistivities of these two compositions are not much different, they have very different surface morphologies, figure 2.

Figure 2. Surface morphology of Rex Lu films obtained by scanning electron microscope (in these SEM images, the intergraticule distance is 0.5 µm) in case of amorphous (panel (a), x = 3.8) and crystalline (panel (b), x = 10.5) films. Insets show 3D image of corresponding film's surface obtained via atomic force microscope (NT-MDT NTEGRA).

Download figure:

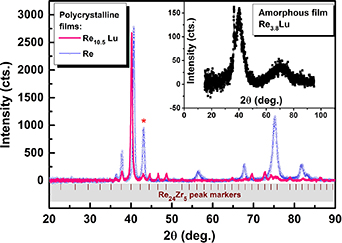

Standard image High-resolution imageComparative characteristics of our films with various values of x are shown in table 1. To characterize the crystalline structure of our films we used grazing incidence x-ray diffractometry which minimizes the reflections of the substrate, figure 3. In this way it was recognized that the films with  are amorphous, and those with

are amorphous, and those with  are polycrystalline. While GID is distinct from the powder diffraction method, it is still meaningful to compare our polycrystalline spectrum with the powder diffraction database. Using the online Crystallography Open Database, we matched our spectrum with the powder data of Re24Zr5 (figure 3), which allowed us to draw qualitative justification that the films belong to the

are polycrystalline. While GID is distinct from the powder diffraction method, it is still meaningful to compare our polycrystalline spectrum with the powder diffraction database. Using the online Crystallography Open Database, we matched our spectrum with the powder data of Re24Zr5 (figure 3), which allowed us to draw qualitative justification that the films belong to the  space group within the 217 cubic crystal symmetry. However, the observed peak at 43° suggests that the film also contains pure Re phase. Hence, taking both the GID and EDS results into account, the superconducting phase of the film is likely to have stoichiometry

space group within the 217 cubic crystal symmetry. However, the observed peak at 43° suggests that the film also contains pure Re phase. Hence, taking both the GID and EDS results into account, the superconducting phase of the film is likely to have stoichiometry  . A proper phase identification to find the precise atomic percentage of compositional elements requires a powder x-ray diffraction performed on an actual powder specimen, which will be left for future studies. Table 2 shows the crystal structure parameters of Re and Re10.5Lu/Re24Zr5.

. A proper phase identification to find the precise atomic percentage of compositional elements requires a powder x-ray diffraction performed on an actual powder specimen, which will be left for future studies. Table 2 shows the crystal structure parameters of Re and Re10.5Lu/Re24Zr5.

Figure 3. Grazing incidence x-ray diffraction pattern of polycrystalline Re10.5Lu film compared to that of pure Re film [30]. Inset corresponds to amorphous film Re3.8Lu. Asterisk indicates a peak which does not belong to the Re24Zr5 dataset (the latter is shown in the shaded grey zone). It coincides with pure Re peak.

Download figure:

Standard image High-resolution imageTable 2. Crystal lattice parameters comparison.

| a, Å | b, Å | c, Å | volume, Å3 | space group | |

|---|---|---|---|---|---|

| Re, bulk [24–26] | 2.761 | 2.761 | 4.458 | 29.430 |

|

| Re, film [30] | 2.782 | 2.782 | 4.484 | 30.053 |

|

| Re10.5Lu/Re24Zr5 | 9.5743(5) | 9.5743(5) | 9.5743(5) | 877.636 |

|

The results of magnetic and magnetotransport characterization of these films are shown in figures 4 and 5. Magnetic measurements of thin film properties are complicated by the presence of the substrate which is much more massive than the film itself. In our case, another complication is related with the smallness of  which constitutes units of Oe. To address this complication, we applied demagnetization procedures before the measurements since the superconducting magnets of PPMS may have residual field of tens of Oe. In addition, the residual field shift after such procedures was determined for correcting the magnetic field values to actual zero, for example, by measuring the properties of calibration samples. As a result, the diamagnetic curve in figure 4, inset (a) has the required property

which constitutes units of Oe. To address this complication, we applied demagnetization procedures before the measurements since the superconducting magnets of PPMS may have residual field of tens of Oe. In addition, the residual field shift after such procedures was determined for correcting the magnetic field values to actual zero, for example, by measuring the properties of calibration samples. As a result, the diamagnetic curve in figure 4, inset (a) has the required property  . Moreover, the characteristic 'butterfly' patterns of polycrystalline film Re10.5Lu in figure 4, as well as for the amorphous film (inset (b) in figure 4) have the same required feature. Also, they both have a noticeable clockwise tilt caused by the substrate diamagnetism. Inset (b) demonstrates the 'butterfly' of Re3.8Lu amorphous film. Its zoomed-in virgin curve (inset (c)), in addition to demonstrating the Meissner effect, confirms the required accuracy in our magnetic measurements. As follows from this figure 4(c) and the calculations of Ginzburg–Landau parameter κ below, one should expect trapped flux in the measurement results presented in figure 1(b).

. Moreover, the characteristic 'butterfly' patterns of polycrystalline film Re10.5Lu in figure 4, as well as for the amorphous film (inset (b) in figure 4) have the same required feature. Also, they both have a noticeable clockwise tilt caused by the substrate diamagnetism. Inset (b) demonstrates the 'butterfly' of Re3.8Lu amorphous film. Its zoomed-in virgin curve (inset (c)), in addition to demonstrating the Meissner effect, confirms the required accuracy in our magnetic measurements. As follows from this figure 4(c) and the calculations of Ginzburg–Landau parameter κ below, one should expect trapped flux in the measurement results presented in figure 1(b).

Figure 4. Magnetic moment vs. magnetic field of polycrystalline film Re10.5Lu (main curve); of sapphire substrate (inset (a)); of amorphous film Re3.8Lu (inset (b)) with its virgin curve detailed in inset (c).

Download figure:

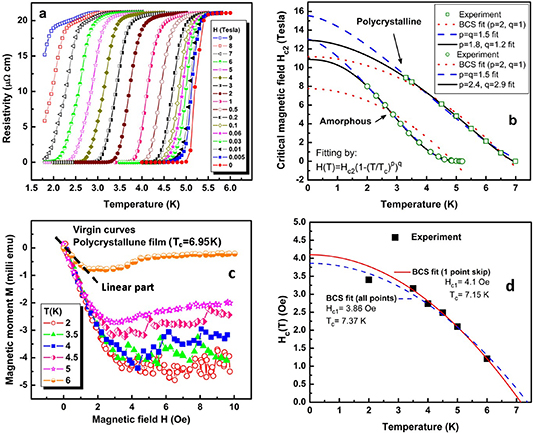

Standard image High-resolution imageFigure 5. (a) Magnetotransport measurements for determining critical field  vs. temperature in case of x = 3.8 (amorphous) film. Similar measurements were performed in case of x = 10.5 (polycrystalline) film. (b) Determining

vs. temperature in case of x = 3.8 (amorphous) film. Similar measurements were performed in case of x = 10.5 (polycrystalline) film. (b) Determining  for polycrystalline and amorphous films. The Tc

value for each in-field measurement was chosen using the 50% criterion of the transition height of the resistivity curves. (c) Virgin curves of polycrystalline film at various temperatures for determining the value of

for polycrystalline and amorphous films. The Tc

value for each in-field measurement was chosen using the 50% criterion of the transition height of the resistivity curves. (c) Virgin curves of polycrystalline film at various temperatures for determining the value of  (panel d). This value of

(panel d). This value of  is constructed in (d) using the linear part of experimental data (one such line is shown in panel c—dashed line for T = 6 K data) via modeling in accordance with the relation

is constructed in (d) using the linear part of experimental data (one such line is shown in panel c—dashed line for T = 6 K data) via modeling in accordance with the relation ![$H_{c1}(T) = H_{c1}(0)[1-(T/T_{c})^{2}]$](https://content.cld.iop.org/journals/0953-2048/37/3/035005/revision2/sustad1f7eieqn27.gif) .

.

Download figure:

Standard image High-resolution image4. Discussion

As follows from table 1, both stoichiometric ratio and substrate's temperature affect the crystalline properties of this material. Moreover, the stoichiometric ratio itself depends on the substrate temperature at deposition. The last entry in table 1 corresponds to less than 1%(at.) of Lu in the composition—we reached here the resolution limit of our EDS. Meanwhile, as follows from [30], pure Re films grown in similar conditions (600 °C) are amorphous and do not superconduct down to 1.8 K, and when grown at 30 °C they superconduct at 3.6 K. The role of the substrate-film interplay is also important; for example, bulk Re does not superconduct above 1.8 K [24].

Our samples'  (T) curves show different behavior compared to the conventional BCS dependence

(T) curves show different behavior compared to the conventional BCS dependence ![$H_{c2} (T) = H_{c2}(0)[1 - (T/T_{c} )^{2}]$](https://content.cld.iop.org/journals/0953-2048/37/3/035005/revision2/sustad1f7eieqn35.gif) . Therefore, following [34, 35] the curves can instead be fitted using the expression

. Therefore, following [34, 35] the curves can instead be fitted using the expression ![$H_{c2} (T ) = H_{c2}(0)[1 - (T/T_{c} )^{p}]^{q}$](https://content.cld.iop.org/journals/0953-2048/37/3/035005/revision2/sustad1f7eieqn36.gif) where the exponents p = q were chosen to be 3/2. A slightly better fit to the data can be obtained when the constraints on p and q are removed by choosing p = 1.8, q = 1.2. This fit is shown in figure 5(b) which yields

where the exponents p = q were chosen to be 3/2. A slightly better fit to the data can be obtained when the constraints on p and q are removed by choosing p = 1.8, q = 1.2. This fit is shown in figure 5(b) which yields  T. Using the Ginzburg–Landau relation

T. Using the Ginzburg–Landau relation  , where

, where  Wb is the flux quantum [36], the estimated coherence length of our film with

Wb is the flux quantum [36], the estimated coherence length of our film with  K is

K is  nm.

nm.

Combining  and the estimate for

and the estimate for  from panel (d) in figure 5 (

from panel (d) in figure 5 ( Oe)

2

into the standard expression

Oe)

2

into the standard expression ![$H_{c1} = [\phi _{0}/(4\pi \lambda _{L}^{2})] [ln(\lambda _{L}/\xi ) + 0.12]$](https://content.cld.iop.org/journals/0953-2048/37/3/035005/revision2/sustad1f7eieqn46.gif) [37], the estimate for our film's magnetic penetration depth is

[37], the estimate for our film's magnetic penetration depth is  nm. Finally, the Ginzburg–Landau parameter can also be calculated,

nm. Finally, the Ginzburg–Landau parameter can also be calculated,  , which shows that our film, being of type-II, is rather close to the theoretical boundary separating type-I and type-II superconductors of

, which shows that our film, being of type-II, is rather close to the theoretical boundary separating type-I and type-II superconductors of  . This value of κ for polycrystalline Re10.5Lu matches with the reported values for pure Re films [30], though the individual values of λL

and ξ are different.

. This value of κ for polycrystalline Re10.5Lu matches with the reported values for pure Re films [30], though the individual values of λL

and ξ are different.

For the amorphous Re3.8Lu with  K, the value of

K, the value of  is a bit smaller:

is a bit smaller:  T (second curve in figure 5(b), obtained with the fitting parameters p = 2.4 and q = 2.9) yielding an estimate: ξ = 5.5 nm. From figure 4(c),

T (second curve in figure 5(b), obtained with the fitting parameters p = 2.4 and q = 2.9) yielding an estimate: ξ = 5.5 nm. From figure 4(c),  K) ≈ 3 Oe. Taking into account that

K) ≈ 3 Oe. Taking into account that  K) = 0, one can use parabolic approximation as above and obtain an estimate

K) = 0, one can use parabolic approximation as above and obtain an estimate  Oe

3

. This yields

Oe

3

. This yields  nm and κ = 0.89, as in the case of polycrystalline films. Table 3 contains extracted values of these data.

nm and κ = 0.89, as in the case of polycrystalline films. Table 3 contains extracted values of these data.

Table 3. Summary of parameters of the representative superconductors.

, Oe , Oe |

, T , T |

, nm , nm |

, nm , nm | κ | |

|---|---|---|---|---|---|

| Amorphous (x ≈ 3.8) | 3.88 | 11 | 5.5 | 4.87 | 0.89 |

| Polycrystalline (x ≈ 10.5) | 4 | 13 | 5.05 | 4.48 | 0.89 |

5. Summary

We introduced a new material, Rex

Lu ( ). In particular, Re10.5Lu exceeds the critical temperature of known Re6Hf, Re6Zr and Re6 Ti. While these predecessors have never been reported having

). In particular, Re10.5Lu exceeds the critical temperature of known Re6Hf, Re6Zr and Re6 Ti. While these predecessors have never been reported having  6 K, either in bulk or thin film form, Re10.5Lu demonstrated

6 K, either in bulk or thin film form, Re10.5Lu demonstrated  K. Thus, the idea that Lu can successfully play the role of a transition element in Re–Lu compound is confirmed by this research. By analogy, one can expect that this NCS material will also break TRS. It will be very interesting to explore that property, though that goal is beyond this paper. The indirect proof of broken TRS may be obtained by effects related to nonreciprocal current control devices made of this material: demonstration of nonreciprocity in absence of applied magnetic field may serve as such a proof.

K. Thus, the idea that Lu can successfully play the role of a transition element in Re–Lu compound is confirmed by this research. By analogy, one can expect that this NCS material will also break TRS. It will be very interesting to explore that property, though that goal is beyond this paper. The indirect proof of broken TRS may be obtained by effects related to nonreciprocal current control devices made of this material: demonstration of nonreciprocity in absence of applied magnetic field may serve as such a proof.

The simplicity of the described deposition method may facilitate the application of this material for the range of devices mentioned in Introduction. Also, the information obtained by our research may provide grounds for further fundamental studies based on band-structure computations of superconducting state in Re–Lu materials to quantitatively explain the discovered features including fitting parameters p and q for  curves. Finally, the parameters λL

and ξ estimated above may be used for modeling of phenomena in Re–Lu-based superconducting devices.

curves. Finally, the parameters λL

and ξ estimated above may be used for modeling of phenomena in Re–Lu-based superconducting devices.

Acknowledgments

This research was supported by the ONR Grant Nos. N00014-21-1-2879, N00014-20-1-2442 and N00014-23-1-2866. We are grateful to Physics Art Frontiers for technical assistance.

Data availability statement

All data that support the findings of this study are included within the article (and any supplementary files).

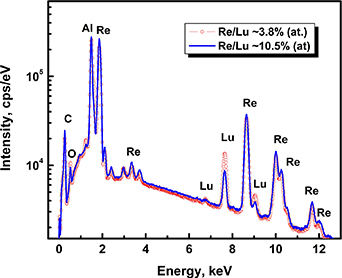

Appendix A: Compositional analysis

Compositional analysis was performed using standard energy-dispersive x-ray spectroscopy in scanning electron microscope, as was mentioned in the main text. The results were accumulated and averaged from many points. They were also acquired via mapping. These two methods revealed consistently similar values, which yield a Re to Lu ratio of about 10.5, as indicated in figure A1.

Figure A1. EDS data from polycrystalline and amorphous samples.

Download figure:

Standard image High-resolution imageSimilar analysis was performed for the amorphous film which revealed the ratio  . The plotted EDS spectrum contains the peaks of the film as well as those belonging to the sapphire (Al2O3) substrates (carbon is always present during EDS analysis). To minimize the substrate interference, we performed measurements below maximum energy (= 30 keV). At 20 keV the spread of compositional data between the measured points becomes acceptably small.

. The plotted EDS spectrum contains the peaks of the film as well as those belonging to the sapphire (Al2O3) substrates (carbon is always present during EDS analysis). To minimize the substrate interference, we performed measurements below maximum energy (= 30 keV). At 20 keV the spread of compositional data between the measured points becomes acceptably small.

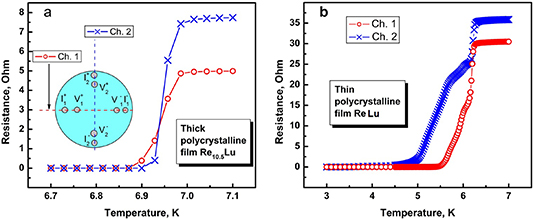

Appendix B: Multichannel resistivity measurements

To characterize the phase homogeneity of deposited films we used resistivity measurements described in figure B1. In this figure, the large circle indicates thin film (8 mm in diameter) with 2 sets of 4-probe contacts (schematically notated as  and

and  ) placed in mutually orthogonal directions for channels 1 and 2. At each temperature step, PPMS consecutively performed measurements for these channels. The plotted data are indicative of very good compositional homogeneity in relatively thick films (thickness

) placed in mutually orthogonal directions for channels 1 and 2. At each temperature step, PPMS consecutively performed measurements for these channels. The plotted data are indicative of very good compositional homogeneity in relatively thick films (thickness  nm). Thinner films (

nm). Thinner films ( nm) are less perfect though still can be utilized in devices biased at helium temperatures.

nm) are less perfect though still can be utilized in devices biased at helium temperatures.

Figure B1. Testing lateral homogeneity of (a) thick and (b) thin polycrystalline films.

Download figure:

Standard image High-resolution imageAppendix C: X-ray reflectivity measurements

X-ray reflectivity (XRR), as was first noticed by Kiessig in 1931 [38] (more recent references and the detailed description of this method can be found in [39]) can be used for characterization of thin film quality, as explained in figure C1.

Figure C1. XRR curves for Re–Lu and Re–Nb films. The modeled curve for ReLu film which yields the parameters mentioned in the text is also shown.

Download figure:

Standard image High-resolution imageIn particular, it allows us to model the density, thickness, and roughness of the deposited film and its surface layer. We used the Simple Reflectivity Model of free software GenX [40] for processing our Rigaku SmartLab data, figure C1. It yields the parameters: film thickness = 311 Å, density = 17.5 g cm−3, roughness = 3 Å; top surface layer thickness = 10 Å, density = 16.1 g cm−3; and substrate roughness 4 Å. For comparison, we presented in figure C1 also a similar curve obtained for Re–Nb film, which was recently used for achieving high-quality Dayem bridges [41]. The comparison demonstrates obvious superiority of Re–Lu film in surface and possibly interface roughness which is important for nanoscale devices.

Footnotes

- 1

This value is higher than that of other Re-based compounds except ReNb.

- 2

In this fitting procedure, the value of Tc is a free parameter. As follows from figure 5(d), its value is close to the experimental

K.

K. - 3

In this fitting procedure, the experimental value of Tc is used, and the parabola is enforced to go through 2 points:

and

and  (2.5 K) ≈ 3 Oe. This method is less accurate, however, it is satisfactory for estimates.

(2.5 K) ≈ 3 Oe. This method is less accurate, however, it is satisfactory for estimates.