Abstract

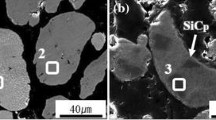

In recent years, the addition of Ni has been widely acknowledged to be capable of enhancing the mechanical properties of Al-Si alloys. However, the effect of Ni on the wear behaviors of Al-Si alloys and Al matrix composites, particularly at elevated temperatures, remains an understudied area. In this study, Al-Si-Cu-Mg-Ni/20wt% SiC particles (SiCp) composites with varying Ni contents were prepared by using a semisolid stir casting method. The effect of Ni content on the dry sliding wear behavior of the prepared composites was investigated through sliding tests at 25 and 350°C. Results indicated that the θ-Al2Cu phase gradually diminished and eventually disappeared as the Ni content increased from 0wt% to 3wt%. This change was accompanied by the formation and increase in δ-Al3CuNi and ε-Al3Ni phases in microstructures. The hardness and ultimate tensile strength of the as-cast composites improved, and the wear rates of the composites decreased from 5.29 × 10−4 to 1.94 × 10−4 mm3/(N·m) at 25°C and from 20.2 × 10−4 to 7 × 10−4 mm3/(N·m) at 350°C with the increase in Ni content from 0wt% to 2wt%. The enhancement in performance was due to the presence of strengthening network structures and additional Ni-containing phases in the composites. However, the wear rate of the 3Ni composite was approximately two times higher than that of the 2Ni composite due to the fracture and debonding of the ε-Al3Ni phase. Abrasive wear, delamination wear, and oxidation wear were the predominant wear mechanisms of the investigated composites at 25°C, whereas delamination wear and oxidation wear were dominant during sliding at 350°C.

Similar content being viewed by others

References

M.C. Şenel, Y. Kanca, and M. Gürbüz, Reciprocating sliding wear properties of sintered Al-B4C composites, Int. J. Miner. Metall. Mater., 29(2022), No. 6, p. 1261.

C.Y. Huang, S.P. Hu, and K. Chen, Influence of rolling temperature on the interfaces and mechanical performance of graphene-reinforced aluminum-matrix composites, Int. J. Miner. Metall. Mater., 26(2019), No. 6, p. 752.

N.C. Kaushik and R.N. Rao, The effect of wear parameters and heat treatment on two body abrasive wear of Al-SiC-Gr hybrid composites, Tribol. Int., 96(2016), p. 184.

N.C. Kaushik and R.N. Rao, Effect of grit size on two body abrasive wear of Al6082 hybrid composites produced by stir casting method, Tribol. Int., 102(2016), p. 52.

E. Safary, R. Taghiabadi, and M.H. Ghoncheh, Mechanical properties of Al-15Mg2Si composites prepared under different solidification cooling rates, Int. J. Miner. Metall. Mater., 29(2022), No. 6, p. 1249.

H.M. Xia, L. Zhang, Y.C. Zhu, et al., Mechanical properties of graphene nanoplatelets reinforced 7075 aluminum alloy composite fabricated by spark plasma sintering, Int. J. Miner. Metall. Mater., 27(2020), No. 9, p. 1295.

X.Z. Kai, Z.Q. Li, G.L. Fan, et al., Enhanced strength and ductility in particulate-reinforced aluminum matrix composites fabricated by flake powder metallurgy, Mater. Sci. Eng. A, 587(2013), p. 46.

M.Y. Zhou, L.B. Ren, L.L. Fan, et al., Progress in research on hybrid metal matrix composites, J. Alloys Compd., 838(2020), art. No. 155274.

Z.M. Zhang, G.L. Fan, Z.Q. Tan, et al., Towards the strength-ductility synergy of Al2O3/Al composite through the design of roughened interface, Compos. Part B, 224(2021), art. No. 109251.

N.C. Kaushik and R.N. Rao, Influence of applied load on abrasive wear depth of hybrid Gr/SiC/Al-Mg-Si composites in a two-body condition, J. Tribol., 139(2017), No. 6, art. No. 061601.

S. Kumar, R.S. Panwar, and O.P. Pandey, Effect of dual reinforced ceramic particles on high temperature tribological properties of aluminum composites, Ceram. Int., 39(2013), No. 6, p. 6333.

D.X. Mao, X.C. Meng, Y.M. Xie, et al., Strength-ductility balance strategy in SiC reinforced aluminum matrix composites via deformation-driven metallurgy, J. Alloys Compd., 891(2022), art. No. 162078.

W. Zhang and J. Xu, Advanced lightweight materials for Automobiles: A review, Mater. Des., 221(2022), art. No. 110994.

A.M. Hassan, A. Alrashdan, M.T. Hayajneh, and A.T. Mayyas, Wear behavior of Al-Mg-Cu-based composites containing SiC particles, Tribol. Int., 42(2009), No. 8, p. 1230.

F. Lin, J. Wang, H. Wu, et al., Synergistic effects of TiC and graphene on the microstructure and tribological properties of Al2024 matrix composites, Adv. Powder Technol., 32(2021), No. 10, p. 3635.

R.K. Singh, A. Telang, and S. Das, Microstructure, mechanical properties and two-body abrasive wear behaviour of hypereutectic Al-Si-SiC composite, Trans. Nonferrous Met. Soc. China, 30(2020), No. 1, p. 65.

Z.Q. Sun, D. Zhang, and G.B. Li, Evaluation of dry sliding wear behavior of silicon particles reinforced aluminum matrix composites, Mater. Des., 26(2005), No. 5, p. 454.

E.A. Diler and R. Ipek, Main and interaction effects of matrix particle size, reinforcement particle size and volume fraction on wear characteristics of Al-SiCp composites using central composite design, Compos. Part B, 50(2013), p. 371.

H. Ghandvar, M.H. Idris, N. Ahmad, and N. Moslemi, Microstructure development, mechanical and tribological properties of a semisolid A356/xSiCp composite, J. Appl. Res. Technol., 15(2017), No. 6, p. 533.

Y. Yalcin and H. Akbulut, Dry wear properties of A356-SiC particle reinforced MMCs produced by two melting routes, Mater. Des., 27(2006), No. 10, p. 872.

D. Li, K. Liu, J. Rakhmonov, and X.G. Chen, Enhanced thermal stability of precipitates and elevated-temperature properties via microalloying with transition metals (Zr, V and Sc) in Al-Cu 224 cast alloys, Mater. Sci. Eng. A, 827(2021), art. No. 142090.

C. Puncreobutr, P.D. Lee, K.M. Kareh, T. Connolley, J.L. Fife, and A.B. Phillion, Influence of Fe-rich intermetallics on solidification defects in Al-Si-Cu alloys, Acta Mater., 68(2014), p. 42.

J. Rakhmonov, G. Timelli, and F. Bonollo, Characterization of the solidification path and microstructure of secondary Al-7Si-3Cu-0.3Mg alloy with Zr, V and Ni additions, Mater. Charact., 128(2017), p. 100.

H. Tan, S. Wang, Y. Yu, et al., Friction and wear properties of Al-20Si-5Fe-2Ni-graphite solid-lubricating composite at elevated temperatures, Tribol. Int., 122(2018), p. 228.

L.J. Zuo, B. Ye, J. Feng, X.J. Xu, X.Y. Kong, and H.Y. Jiang, Effect of S-Al3CuNi phase and thermal exposure on microstructure and mechanical properties of Al-Si-Cu-Ni alloys, J. Alloys Compd., 791(2019), p. 1015.

J. Rakhmonov, K. Liu, L. Pan, F. Breton, and X.G. Chen, Enhanced mechanical properties of high-temperature-resistant Al-Cu cast alloy by microalloying with Mg, J. Alloys Compd., 827(2020), art. No. 154305.

H.L. Yang, S.X. Ji, and Z.Y. Fan, Effect of heat treatment and Fe content on the microstructure and mechanical properties of die-cast Al-Si-Cu alloys, Mater. Des., 85(2015), p. 823.

L.J. Zuo, B. Ye, J. Feng, X.Y. Kong, H.Y. Jiang, and W.J. Ding, Effect of Q-Al5Cu2Mg8Si6 phase on mechanical properties of Al-Si-Cu-Mg alloy at elevated temperature, Mater. Sci. Eng. A, 693(2017), p. 26.

Q. Liu, M.W. Liu, C. Xu, et al, Effects of Sr, Ce and P on the microstructure and mechanical properties of rapidly solidified Al-7Si alloys, Mater. Charact., 140(2018), p. 290.

C. Xu, W.L. Xiao, R.X. Zheng, S. Hanada, H. Yamagata, and C.L. Ma, The synergic effects of Sc and Zr on the microstructure and mechanical properties of Al-Si-Mg alloy, Mater. Des., 88(2015), p. 485.

G. Timelli, D. Caliari, and J. Rakhmonov, Influence of process parameters and Sr addition on the microstructure and casting defects of LPDC A356 alloy for engine blocks, J. Mater. Sci. Technol., 32(2016), No. 6, p. 515.

S.K. Shaha, F. Czerwinski, W. Kasprzak, and D.L. Chen, Tensile and compressive deformation behavior of the Al-Si-Cu-Mg cast alloy with additions of Zr, V and Ti, Mater. Des., 59(2014), p. 352.

S.K. Shaha, F. Czerwinski, W. Kasprzak, J. Friedman, and D.L. Chen, Thermal stability of (AlSi)x(ZrVTi) intermetallic phases in the Al-Si-Cu-Mg cast alloy with additions of Ti, V, and Zr, Thermochim. Acta, 595(2014), p. 11.

J. Feng, B. Ye, L.J. Zuo, et al., Effects of Ni content on low cycle fatigue and mechanical properties of Al-12Si-0.9Cu-0.8Mg-xNi at 350°C, Mater. Sci. Eng. A, 706(2017), p. 27.

Y.G. Li, Y. Yang, Y.Y. Wu, L.Y. Wang, and X.F. Liu, Quantitative comparison of three Ni-containing phases to the elevated-temperature properties of Al-Si piston alloys, Mater. Sci. Eng. A, 527(2010), No. 26, p. 7132.

Y. Ma, A. Addad, G. Ji, et al., Atomic-scale investigation of the interface precipitation in a TiB2 nanoparticles reinforced Al-Zn-Mg-Cu matrix composite, Acta Mater., 185(2020), p. 287.

Z. Asghar, G. Requena, and E. Boller, Three-dimensional rigid multiphase networks providing high-temperature strength to cast AlSi10Cu5Ni1–2 piston alloys, Acta Mater., 59(2011), No. 16, p. 6420.

Z. Asghar, G. Requena, H.P. Degischer, and P. Cloetens, Three-dimensional study of Ni aluminides in an AlSi12 alloy by means of light optical and synchrotron microtomography, Acta Mater., 57(2009), No. 14, p. 4125.

Y.Y. Liu, L.N. Jia, W.B. Wang, Z.H. Jin, and H. Zhang, Effects of Ni content on microstructure and wear behavior of Al-13Si-3Cu-1Mg-xNi-0.6Fe-0.6Mn alloys, Wrar, 500–501(2022), art. No. 204365.

Z. Shi, S. Ochiai, M. Gu, M. Hojo, and J.C. Lee, The formation and thermostability of MgO and MgAl2O4 nanoparticles in oxidized SiC particle-reinforced Al-Mg composites, Appl. Phys. A, 74(2002), No. 1, p. 97.

A. Ureña, E.E. Martínez, P. Rodrigo, and L. Gil, Oxidation treatments for SiC particles used as reinforcement in aluminium matrix composites, Compos. Sci. Technol., 64(2004), No. 12, p. 1843.

Y. Xing, N.Y. Li, C.J. Li, et al., Effects of size and oxidation treatment for SiC particles on the microstructures and mechanical properties of SiCp/Al composites prepared by powder metallurgy, Mater. Sci. Eng. A, 851(2022), art. No. 143664.

J.F. Archard Contact and rubbing of flat surfaces, J. Appl. Phys., 24(1953), No. 8, p. 981.

M. Moazami-Goudarzi and F. Akhlaghi, Wear behavior of Al5252 alloy reinforced with micrometric and nanometric SiC particles, Tribol. Int., 102(2016), p. 28.

C. Subramanian, Some considerations towards the design of a wear resistant aluminium alloy, Wear, 155(1992), No. 1, p. 193.

L. Wang, B.X. Dong, F. Qiu, et al., Dry sliding friction and wear characterization of in situ TiC/Al-Cu3.7–Mg1.3 nanocomposites with nacre-like structures, J. Mater. Res. Technol., 9(2020), No. 1, p. 641.

Acknowledgement

We are grateful for the financial support from Ningbo In-considerably lower amount of wear debris because it contains more intermetallics than the 0Ni composite. Intermetallics contribute to the improved wear resistance of the 2Ni composite at room and high temperatures. Moreover, the addition of Ni is beneficial for improving the strength of Al alloys and composites, especially at high temperatures. This work elucidates how the high-temperature mechanical properties and wear resistance of Al-Si alloys and their composites can be improved through the addition of Ni.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Rights and permissions

About this article

Cite this article

Liu, Y., Jia, L., Wang, W. et al. Effect of Ni content on the wear behavior of Al-Si-Cu-Mg-Ni/SiC particles composites. Int J Miner Metall Mater 31, 374–383 (2024). https://doi.org/10.1007/s12613-023-2701-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-023-2701-y