Abstract

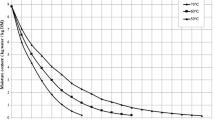

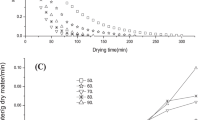

Curcuma longa L. rhizomes (CL) are aromatic spices known for their natural dye properties. These rhizomes contain considerate quantities of nutrients and bioactive compounds. Nevertheless, due to their perishable nature, they necessitate water removal process. This research aims to evaluate the adequacy of the analytical model established by Dincer and Dost in 1995, using experimental data from the Refractive Window (RW) drying method, focusing on solid samples in the flat plate configuration of Curcuma longa L. A comparative analysis will be carried out with the model devised by Crank in 1975, which relies on the traditional solution of Fick's second law. The primary objective is to determine the mass transfer parameters and the thermodynamic characteristics relevant to the drying procedure. The drying process for the samples was observed to be relatively rapid. In their natural state, the samples had a moisture content of 80.71 ± 1.12% (on a dry basis). According to the Dincer and Dost model, the moisture diffusivity ranged from 0.85 × 10–8 m2 s−1 to 2.15 × 10–8 m2 s−1, and the mass transfer coefficient varied from 1.60 × 10–6 to 1.12 × 10–6 m s−1. The entropy value (ΔS) obtained was negative (ΔS < 0). The thermodynamic properties indicated a non-spontaneous process with positive values for enthalpy and Gibbs free energy, along with negative values for entropy.

Similar content being viewed by others

Data availability

Data will be made available on request.

References

Serpa Guerra AM, Gómez Hoyos C, Velásquez-Cock JA, Rojo PG, Eceiza A, Urbina L, Zuluaga R (2021) Cellulose nanofibers from banana rachis added to a Curcuma longa L. rhizome suspension: Color, stability and rheological properties. Food Struct 27:100180. https://doi.org/10.1016/j.foostr.2021.100180

Tamfu AN, Ceylan O, Kucukaydin S, Duru ME (2020) HPLC-DAD phenolic profiles, antibiofilm, anti-quorum sensing and enzyme inhibitory potentials of Camellia sinensis (L.) O. Kuntze and Curcuma longa L. LWT 133:110150. https://doi.org/10.1016/j.lwt.2020.110150

Jyotirmayee B, Mahalik G (2022) A review on selected pharmacological activities of Curcuma longa L. Int J Food Prop 25:1377–1398. https://doi.org/10.1080/10942912.2022.2082464

Ibáñez MD, Blázquez MA (2020) Curcuma longa L. Rhizome essential oil from extraction to its agri-food applications. Rev Plants 10:44. https://doi.org/10.3390/plants10010044

Borges J, Saturnino K, Cruz V, Araújo E (2019) Ação Antioxidante Da Curcumina (Curcuma longa L.) na injúria de isquemia e reperfusão tecidual. Enciclopédia Biosf 16:48–62. https://doi.org/10.18677/EnciBio_2019A4

Mishra R, Gupta AK, Kumar A, Lal LK, Saikia D, Chanotiya CS (2018) Genetic diversity, essential oil composition, and in vitro antioxidant and antimicrobial activity of Curcuma longa L. germplasm collections. J Appl Res Med Aromat Plants 10:75–84. https://doi.org/10.1016/j.jarmap.2018.06.003

Serpa Guerra AM, Gómez Hoyos C, Velásquez-Cock JA, Acosta LV, Rojo PG, Giraldo AMV (2020) The nanotech potential of turmeric (Curcuma longa L.) in food technology: a review. Crit Rev Food Sci Nutr 60:1842–1854. https://doi.org/10.1080/10408398.2019.1604490

Chumroenphat T, Somboonwatthanakul I, Saensouk S, Siriamornpun S (2021) Changes in curcuminoids and chemical components of turmeric (Curcuma longa L.) under freeze-drying and low-temperature drying methods. Food Chem 339:128121. https://doi.org/10.1016/j.foodchem.2020.128121

Sharma S, Dhalsamant K, Tripathy PP, Manepally RK (2021) Quality analysis and drying characteristics of turmeric (Curcuma longa L.) dried by hot air and direct solar dryers. LWT 138:110687. https://doi.org/10.1016/j.lwt.2020.110687

An NN, Lv WQ, Li D, Wang LJ, Wang Y (2023) Effects of hot-air microwave rolling blanching pretreatment on the drying of turmeric (Curcuma longa L.): physiochemical properties and microstructure evaluation. Food Chem 398:133925. https://doi.org/10.1016/j.foodchem.2022.133925

Borah A, Hazarika K, Khayer SM (2015) Drying kinetics of whole and sliced turmeric rhizomes (Curcuma longa L.) in a solar conduction dryer. Inf Process Agric 2:85–92. https://doi.org/10.1016/j.inpa.2015.06.002

Alolga RN, Osae R, Ibrahim TS, Onoja V, Apaliya MT, Kwaw E, Huang F-Q (2022) Distinct metabolomes and quality characteristics of vacuum-assisted osmosonic-pretreated Curcuma longa L. rhizomes subjected to different drying methods. Ind Crops Prod 185:115156. https://doi.org/10.1016/j.indcrop.2022.115156

Moses JA, Norton T, Alagusundaram K, Tiwari BK (2014) Novel drying techniques for the Food Industry. Food Eng Rev 6:43–55. https://doi.org/10.1007/s12393-014-9078-7

Zarein M, Samadi SH, Ghobadian B (2015) Investigation of microwave dryer effect on energy efficiency during drying of apple slices. J Saudi Soc Agric Sci 14:41–47. https://doi.org/10.1016/j.jssas.2013.06.002

Prathapan A, Lukhman M, Arumughan C, Sundaresan A, Raghu KG (2009) Effect of heat treatment on curcuminoid, colour value and total polyphenols of fresh turmeric rhizome. Int J Food Sci Technol 44:1438–1444. https://doi.org/10.1111/j.1365-2621.2009.01976.x

Waghmare R (2021) Refractance window drying: a cohort review on quality characteristics. Trends Food Sci Technol 110:652–662. https://doi.org/10.1016/j.tifs.2021.02.030

de Santos SJL, da Silva LHM, da Rodrigues AMC (2022) Prediction of mass transfer parameters and thermodynamic properties using the refractance WindowTM technique for drying of Yam (Dioscorea Trifida) paste. Food Sci Technol 42:e67021. https://doi.org/10.1590/fst.67021

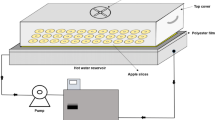

Rajoriya D, Shewale SR, Hebbar HU (2019) Refractance Window Drying of Apple slices: Mass transfer Phenomena and Quality parameters. Food Bioprocess Technol 12:1646–1658. https://doi.org/10.1007/s11947-019-02334-7

Raghavi LM, Moses JA, Anandharamakrishnan C (2018) Refractance window drying of foods: a review. J Food Eng 222:267–275. https://doi.org/10.1016/j.jfoodeng.2017.11.032

Darvishi H, Farhudi Z, Behroozi-Khazaei N (2017) Mass Transfer Parameters and Modeling of Hot Air Drying Kinetics of Dill leaves. Chem Prod Process Model 12:20150079. https://doi.org/10.1515/cppm-2015-0079

Ertekin C, Firat MZ (2017) A comprehensive review of thin-layer drying models used in agricultural products. Crit Rev Food Sci Nutr 57:701–717. https://doi.org/10.1080/10408398.2014.910493

Perussello CA, Mariani VC, Amarante ÁCC (2014) Thermophysical properties of Okara during Drying. Int J Food Prop 17:891–907. https://doi.org/10.1080/10942912.2011.628430

Crank J (1975) The mathematics of diffusion, 2nd edn. Oxford University Press, London, pp 69–88

Ratti C (2001) Hot air and freeze-drying of high-value foods: a review. J Food Eng 49:311–319. https://doi.org/10.1016/S0260-8774(00)00228-4

Dincer I, Dost S (1995) An Analytical Model for Moisture Diffusion in Solid objects during Drying. Dry Technol 13:425–435. https://doi.org/10.1080/07373939508916962

Nadi F, Tzempelikos D (2018) Vacuum drying of apples (cv. Golden Delicious): drying characteristics, thermodynamic properties, and mass transfer parameters. Heat Mass Transf 54:1853–1866. https://doi.org/10.1007/s00231-018-2279-5

Santos NC, Almeida RLJ, da Silva GM, Monteiro SS, André AMMCN (2020) Effect of ultrasound pre-treatment on the kinetics and thermodynamic properties of guava slices drying process. Innov Food Sci Emerg Technol 66:102507. https://doi.org/10.1016/j.ifset.2020.102507

Araujo WD, Goneli ALD, Corrêa PC, Hartmann Filho CP, Martins EAS (2017) Mathematical modelling of thin-layer drying in peanut fruit. Rev Ciência Agronômica 48:448–457. https://doi.org/10.5935/1806-6690.20170052

da Costa RDS, da Cruz Rodrigues AM, Borges Laurindo J, da Silva LHM (2019) Development of dehydrated products from peach palm–tucupi blends with edible film characteristics using refractive window. J Food Sci Technol 56:560–570. https://doi.org/10.1007/s13197-018-3454-x

A.O.A.C. (1990) Official methods of analysis, 15th edn. Association of Official Analytical Chemist, Washington DC

Akpinar EK, Dincer I (2005) Moisture transfer models for slabs drying. Int Commun Heat Mass Transf 32:80–93. https://doi.org/10.1016/j.icheatmasstransfer.2004.04.037

Dincer I, Hussain MM (2002) Development of a new Bi–Di correlation for solids drying. Int J Heat Mass Transf 45:3065–3069. https://doi.org/10.1016/S0017-9310(02)00031-5

Ray A, Mohanty S, Jena S, Sahoo A, Acharya L, Panda PC, Sial P, Duraisamy P, Nayak S (2022) Drying methods affects physicochemical characteristics, essential oil yield and volatile composition of turmeric (Curcuma longa L). J Appl Res Med Aromat Plants 26:100357. https://doi.org/10.1016/j.jarmap.2021.100357

Prasad J, Vijay VK, Tiwari GN, Sorayan VPS (2006) Study on performance evaluation of hybrid drier for turmeric (Curcuma longa L.) drying at village scale. J Food Eng 75:497–502. https://doi.org/10.1016/j.jfoodeng.2005.04.061

Onwude DI, Hashim N, Janius RB, Nawi NM, Abdan K (2016) Modeling the thin-layer drying of fruits and vegetables: A review. Compr Rev Food Sci Food Saf 15:599–618. https://doi.org/10.1111/1541-4337.12196

Aghbashlo M, Kianmehr MH, Khani S, Ghasemi M (2009) Mathematical modelling of thin-layer drying of carrot. Int Agrophysics 23:313–317

Surendhar A, Sivasubramanian V, Vidhyeswari D, Deepanraj B (2019) Energy and exergy analysis, drying kinetics, modeling and quality parameters of microwave-dried turmeric slices. J Therm Anal Calorim 136:185–197. https://doi.org/10.1007/s10973-018-7791-9

Azimi-Nejadian H, Hoseini SS (2019) Study the effect of microwave power and slices thickness on drying characteristics of potato. Heat Mass Transf 55:2921–2930. https://doi.org/10.1007/s00231-019-02633-x

Ju H-Y, Zhang Q, Mujumdar AS, Fang X-M, Xiao H-W, Gao Z-J (2016) Hot-air drying kinetics of Yam Slices under step change in relative humidity. Int J Food Eng 12:783–792. https://doi.org/10.1515/ijfe-2015-0340

Dinrifo RR (2012) Effects of pre-treatments on drying kinetics of sweet potato slices. Agric Eng Int CIGR J 14:136–145

Bezerra CV, Meller da Silva LH, Corrêa DF, Rodrigues AMC (2015) A modeling study for moisture diffusivities and moisture transfer coefficients in drying of passion fruit peel. Int J Heat Mass Transf 85:750–755. https://doi.org/10.1016/j.ijheatmasstransfer.2015.02.027

Beigi M, Torki-Harchegani M, Tohidi M (2017) Experimental and ANN modeling investigations of energy traits for rough rice drying. Energy 141:2196–2205. https://doi.org/10.1016/j.energy.2017.12.004

Onwude DI, Hashim N, Abdan K, Janius R, Chen G, Kumar C (2018) Modelling of coupled heat and mass transfer for combined infrared and hot-air drying of sweet potato. J Food Eng 228:12–24. https://doi.org/10.1016/j.jfoodeng.2018.02.006

Zhang W, Chen C, Pan Z, Zheng Z (2021) Vacuum and Infrared-Assisted Hot Air Impingement Drying for Improving the Processing Performance and quality of Poria cocos (Schw.) Wolf Cubes. Foods 10:992. https://doi.org/10.3390/foods10050992

Guiné RP, Barroca MJ, Silva V (2013) Mass transfer Properties of pears for different drying methods. Int J Food Prop 16:251–262. https://doi.org/10.1080/10942912.2011.551864

Shewale SR, Rajoriya D, Hebbar HU (2019) Low humidity air drying of apple slices: Effect of EMR pretreatment on mass transfer parameters, energy efficiency and quality. Innov Food Sci Emerg Technol 55:1–10. https://doi.org/10.1016/j.ifset.2019.05.006

Kusumaningrum A, Prasetyo DJ, Herawati ERN, Nurhikmat A (2019) Modelling the drying characteristics of the traditional Indonesian crackers kerupuk. Res Agric Eng 65:137–144. https://doi.org/10.17221/27/2019-RAE

Sobowale SS, Agbawodike JI, Kewuyemi YO, Adebo OA (2022) Response surface methodology approach for predicting microwave-convective drying characteristics of sweet potato slices. J Food Process Preserv 46:e16683. https://doi.org/10.1111/jfpp.16683

Almeida RLJ, Santos NC, Padilha CE, Monteiro SS, Santos ES (2021) dos Impact of hydrothermal pretreatments on physicochemical characteristics and drying kinetics of starch from red rice (Oryza sativa L.). J Food Process Preserv 45:e15448. https://doi.org/10.1111/jfpp.15448

Rashid MT, Ma H, Jatoi MA, Safdar B, El-Mesery HS, Sarpong F, Ali Z, Wali A (2019) Multi-frequency ultrasound and sequential infrared drying on drying kinetics, thermodynamic properties, and quality assessment of sweet potatoes. J Food Process Eng 42:e13127. https://doi.org/10.1111/jfpe.13127

Lisboa HM, Araujo H, Paiva G, Oriente S, Pasquali M, Duarte ME, Mata MERMC (2019) Determination of characteristic properties of mulatto beans (Phaseolus vulgaris L.) during convective drying. J Agric Food Res 1:100003. https://doi.org/10.1016/j.jafr.2019.100003

Goneli ALD, Corrêa PC, Oliveira GHH, Botelho FM (2010) Water Desorption and Thermodynamic properties of Okra seeds. Trans ASABE 53:191–197. https://doi.org/10.13031/2013.29486

Almeida RLJ, Santos NC, Padilha CE, Mota MM, de Silva A, de André VM, dos Santos AMMCN (2022) Application of pulsed electric field and drying temperature response on the thermodynamic and thermal properties of red rice starch (Oryza Sativa L). J Food Process Eng 45:e13947. https://doi.org/10.1111/jfpe.13947

Cagnin C, de Lima MS, da Silva RM, Plácido GR, da Silva MAP, de Freitas BSM, de Oliveira DEC (2017) Garlic: kinetic drying and thermodynamic properties. Biosci J 43:905–913

Funding

PROPESP - Office for Research and Graduate Studies at Universidade Federal do Para. CAPES - Coordination for the Improvement of Higher Education Personnel. CNPq - National Research and Development Council, grants 312207/2021-2 and 305150/2022-7.

Author information

Authors and Affiliations

Contributions

N. Cunha: Conceptualization, Methodology, Formal analysis, Investigation, Writing. L. H. Meller. Silva: Investigation, Formal analysis. A. M. C. Rodrigues: Conceptualization, Methodology, Formal analysis, Review & editing.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Cunha, N., da Silva, L.H.M. & da Cruz Rodrigues, A.M. Drying of Curcuma longa L. slices by refractance window: Effect of temperature on thermodynamic properties and mass transfer parameters. Heat Mass Transfer 60, 617–626 (2024). https://doi.org/10.1007/s00231-024-03455-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-024-03455-2