Abstract

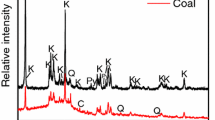

China’s need for energy resources is growing every day. Future energy demands will be partly met by low-temperature pyrolysis of oil-rich coal, which is a form of coal-to-oil technology. Under the existing fully-mechanized coal mining technology, oil-rich coal is mechanically broken into different particle sizes by a shearer and used in different industrial utilization directions. However, due to differences in particle size and material composition, the pyrolysis products of oil-rich coal with different natural particle sizes are different, which affect the pyrolysis efficiency of oil-rich coal with different particle sizes. In order to explore the differences and influencing factors of pyrolysis products of oil-rich coal with different particle sizes, and taking Jurassic oil-rich coal in northern Shaanxi as the research object, the differences and causes of pyrolysis production of oil and gas from nine kinds of oil-rich coal with different natural particle sizes under existing coal mining conditions are discussed according to particle size characteristics, pore structure, heat transfer velocity and molecular structure. The findings demonstrate that the pyrolysis characteristics of coal do not show a single trend with change in particle size. With decrease in particle size, the ash and sulfur contents were relatively high, and the tar yield increased first and then decreased. In contrast, the light fraction decreased overall, and the heavy fraction decreased. The tar yield of 0.125–0.25 mm was the highest, and the tar content was 1.996 g. For the gas components produced by pyrolysis, the contents of CH4, CO and H2 first increased and then decreased with decrease in particle size, while the contents of CO2 and CnHm showed the opposite trend. Larger particles (about 30 mm) affect the escape efficiency of pyrolysis products and the amount of carbon deposition due to the difference in porosity (interparticle resistance) of the inner surface and pyrolysis bed, resulting in secondary reactions of the products escaped from a primary reaction, thus affecting the differences in pyrolysis products. The heat transfer process of coal was affected by particle size, and the thermal conductivity increased gradually with decrease in particle size, which is consistent with the change of tar yield with particle size. The maceral components and molecular structure functional groups in coal with different particle sizes were also different, which resulted in the differences in tar yield. Studies have shown that smaller particle sizes have longer alkyl side chains, and pyrolysis accompanied by rising temperature causes different changes in the aliphatic hydrocarbon content in coal coke after pyrolysis. The aliphatic hydrocarbon content decreased the most when the particle size was 0.125 mm, which is more beneficial to the improvement of tar yield. In addition, vitrinite is a good carrier of tar yield, and the granular coal vitrinite after crushing is enriched to smaller particles.

Source: Zhang et al. (2022)

Similar content being viewed by others

References

Chen, Q. H. (2009). Study on thermophysical properties measurement and temperature field distribution of loose coal bulk [D]. Anhui University of Science and Technology(Chinese).

Chen, X. Y., Zhao, Y., Liu, L., Zhang, L. Y., Zhang, Z., & Qiu, P. H. (2018). Evaluation of chemical structure, pyrolysis reactivity and gaseous products of Shenmu coal of different particle sizes. Journal of Analytical and Applied Pyrolysis, 130, 294–304.

Chen, Y. L., Zhang, S. C., & He, R. (2014). Development of improved lattice fragmentation and diffusion model forcoal pyrlysis, part 2: Effect of intra-porous diffusion on the volatile yields. Combustion Science and Technology, 186(6), 766–784.

Gan, J. Q., Zhou, Z. Y., & Yu, A. B. (2017). Effect of particle shape and size on effective thermal conductivity of packed beds. Powder Technology, 311, 157–166.

Guo, P., Liu, C. Y., Wang, J. Q., Deng, Y., Mao, G. Z., & Wang, W. Q. (2018). Detrital-zircon geochronology of the Jurassic coal-bearing strata in the western Ordos Basin, North China: Evidences for multi-cycle sedimentation. Geoscience Frontiers, 9(6), 1725–1743.

Jia, X., Wang, Q. H., Cen, K. Y., & Cheng, L. M. (2016). Sulfur transformation during the pyrolysis of coal mixed with coal ash in a fixed bed reactor. Fuel, 177, 260–267.

Jiang, H. X., Wang, M. Y., Li, Y., Jin, L. J., & Hu, H. Q. (2020). Integrated coal pyrolysis with steam reforming of propane to improve tar yield. Journal of Analytical and Applied Pyrolysis, 147, 104805.

Ju, Y., Zhu, Y., Zhang, Y. W., Zhou, H. W., Peng, S. P., & Ge, S. R. (2022). Effects of high-power microwave irradiation on tar-rich coal for realizing in situ pyrolysis, fragmentation, and low-carbon utilization of tar-rich coal. International Journal of Rock Mechanics and Mining Sciences, 157, 105165.

Ku, M., Yao, W., Liu, J. X., Zhang, H., Ma, J. F., & Jiang, X. M. (2019). Investigating permeability of coal samples of various porosities under stress conditions. Energies, 12(4), 762.

LeBlanc, J., Quanci, J., & Castaldi, M. J. (2017). Investigating secondary pyrolysis reactions of coal tar via mass spectrometry techniques. Energy & Fuels, 31(2), 1269–1275.

Li, C., Fang, M. X., Xiao, P., Shi, Z. H., Cen, J. M., Yan, Q. K., Wang, Q. H., & Luo, Z. Y. (2016). Investigation of the evolution behavior of light tar during bituminous coal pyrolysis in a fluidized bed reactor. Chemical Research in Chinese Universities, 32(6), 1019–1027.

Li, L. L., Tahmasebi, A., Dou, J. X., Lee, S., Li, L. C., & Yu, J. L. (2020). Influence of functional group structures on combustion behavior of pulverized coal particles. Journal of the Energy Institute, 93(5), 2124–2132.

Liu, P., Zhang, D. X., Wang, L. L., Zhou, Y., Pan, T. Y., & Lu, X. L. (2016). The structure and pyrolysis product distribution of lignite from different sedimentary environment. Applied Energy, 163, 254–262.

Luo, L., Yao, W., Liu, J. X., Zhang, H., Ma, J. F., & Jiang, X. M. (2019). The effect of the grinding process on pore structures, functional groups and release characteristic of flash pyrolysis of superfine pulverized coal. Fuel, 235, 1337–1346.

Meng, D. X., Wang, T., Xu, J. L., & Chen, X. L. (2019). A numerical study on the pyrolysis of large coal particles: Heat transfer and volatile evolution. Fuel, 254, 115668.

Murakami, T. (2021). Effect of tar-adsorbing particles on tar components generated by lignite gasification in a fluidized bed gasifier. Journal of the Japan Petroleum Institute, 64(4), 197–202.

Peng, Y. F., Chen, S. S., Sun, F. J., Hu, Z. F., & Zhou, Y. G. (2021). Investigation on the kinetics of pyrolysis reaction of large coal particles based on TGA. Clean Coal Technology, 27(6), 128–133. (Chinese).

Qi, X. Y., Chen, L. Z., Xin, H. H., Ji, Y. C., Bai, C. W., Song, R. Q., Xue, H. B., & Liu, F. M. (2018). Reaction mechanism and thermodynamic properties of aliphatic hydrocarbon groups during coal self-Heating. Energy & Fuels, 32(10), 10469–10477.

Sahu, A., & Mishra, D. P. (2023). Effects of intrinsic properties, particle size, bulk density, and specific gravity on thermal properties of coal dusts. Environmental Science and Pollution Research, 30(14), 41236–41252.

Sasongko, D., Arifpin, N. Y., Rasrendra, C. B., & Indarto, A. (2016). Numerical simulation of coal pyrolysis with tar and gas products prediction. Asia-Pacific Journal of Chemical Engineering, 11(2), 220–228.

Shen, J., Liu, J. X., Xing, Y. F., Zhang, H., Luo, L., & Jiang, X. M. (2018). Application of TG-FTIR analysis to superfine pulverized coal. Journal of Analytical and Applied Pyrolysis, 133, 154–161.

Shi, Q. M., Li, C. H., Wang, S. M., Ji, R. J., Xue, W. F., Mi, Y. C., Wang, S. Q., & Cai, Y. (2023). Variation of molecular structures affecting tar yield: A comprehensive analysis on coal ranks and depositional environments. Fuel, 335, 127050.

Shi, Q. M., Li, C. H., Wang, S. M., Li, D. L., Wang, S. Q., Du, F. P., Qiao, J. W., & Cheng, Q. (2022). Effect of the depositional environment on the formation of tar-rich coal: A case study in the northeastern Ordos Basin, China. Journal of Petroleum Science and Engineering, 216, 110828.

Shi, Q. M., Qin, Y., & Chen, Y. L. (2020). Relationship between thermal conductivity and chemical structures of chinese coals. ACS Omega, 5(29), 18424–18431.

Sun, N. X. (2016). Research on thermal characteristics and thermodynamic crushing mechanism of low-rank coal [D]. China University of Mining and Technology (Chinese)

Wang, A. M., Huang, J. W., Zhao, M., Liu, Y., Cao, D. Y., Wei, Y. C., & Wei, L. T. (2023). Effects of functional groups in coal with different vitrinite/ inertinite ratios on pyrolysis products. ACS Omega, 8(20), 18202–18211.

Wang, S. M., Sun, Q., Qiao, J. W., & Wang, S. Q. (2020). Geological guarantee of coal green mining. Journal of China Coal Society, 45, 8–15. (Chinese).

Wei, J. T., Guo, Q. H., Ding, L., Gong, Y., Yu, J. Q., & Yu, G. S. (2019). Understanding the effect of different biomass ash additions on pyrolysis product distribution, char physicochemical characteristics, and char gasification reactivity of bituminous coal. Energy & Fuels, 33(4), 3068–3076.

Wen, Y. X., Xu, X., & Xiao, Y. H. (2013). Effects of pyrolysis conditions on the pore structure and reactivity of chars. Proceedings of the CSEE, 33, 63–68. (Chinese).

Wu, L., Guan, Y. N., Li, C. C., Shi, L., Yang, S. S., Rajasekhar, R. B., Ye, G., Zhang, Q. L., Liew, R. K., Zhou, J., Vinu, R., & Lam, S. S. (2023). Free-radical behaviors of co-pyrolysis of low-rank coal and different solid hydrogen-rich donors: A critical review. Chemical Engineering Journal, 474, 145900.

Wu, L., Guan, Y. N., Li, C. C., Zhou, J., Liu, T. T., Ye, G., Zhang, Q. L., Song, Y. H., & Zhu, R. Y. (2023). Insight into product characteristics from microwave co-pyrolysis of low-rank coal and corncob: Unraveling the effects of metal catalysts. Fuel, 342, 127860.

Wu, L., Guan, Y. N., Zhou, J., Jiang, X., Liu, T. T., & Pan, J. (2023). Effects of variable amounts of volatiles in corncob on microwave co-pyrolysis of low-rank coal and corncob. Fuel, 332, 126133.

Xu, Q., Yang, S. Q., Yang, W. M., Tang, Z. Q., Hu, X. C., Song, W. X., & Zhou, B. Z. (2020). Micro-structure of crushed coal with different metamorphic degrees and its low-temperature oxidation. Process Safety and Environmental Protection, 140, 330–338.

Xu, Q., Yang, S. Q., Yang, W. M., Tang, Z. Q., Hu, X. C., Song, W. X., Zhou, B. Z., & Yang, K. (2021a). Secondary oxidation of crushed coal based on free radicals and active groups. Fuel, 290, 120051.

Xu, T., Yang, P. X., Zhang, J., Gao, K., Shang, J. X., Yang, B. L., & Wu, Z. Q. (2021b). Heat effect of oxidation of aliphatic hydrocarbon groups on the piecewise characteristics and spontaneous combustion tendency of coal. Solid Fuel Chemistry, 55(5), 338–347.

Yan, D. W., Gu, M. Y., He, X. H., Wang, J. L., Wang, F. L., & Pan, J. Z. (2021). Structural characterization and NO generation characteristics of coal char under O-2/CO2 atmosphere. Journal of Thermal Science, 30(4), 1237–1250.

Yang, F., Gao, K., Yu, Z. Y., Ma, L., Cao, H. S., Yang, P. X., Guo, W., Zhang, J., Yang, B., & Wu, Z. Q. (2023). Thermodynamic analysis of in situ underground pyrolysis of tar-rich coal: Primary reactions. ACS Omega, 8(21), 18915–18929.

Yang, H., Fletcher, T. H., Li, Y., Jin, L. J., Li, S. F., Shang, Y., & Hu, H. Q. (2020). Modeling the influence of changes in aliphatic structure on char surface area during coal pyrolysis. Aiche Journal, 66(2), e16834.

Yao, Q. X., Ma, M. M., Liu, Y. Q., Ma, D., Chen, H. Y., Hao, Q. Q., Sun, M., & Ma, X. X. (2022). The structural and pyrolysis characteristics of vitrinite and inertinite from Shendong coal and the gasification performance of chars. Journal of Analytical and Applied Pyrolysis, 164, 105519.

Yin, L., Xiao, Y., Li, Q. Y., Tian, Y., & Shu, C. M. (2023). Temperature effect on thermal conductivity of oxidized coal associated with its predictive model during coal pyrolysis. Energy, 274, 127417.

Yu, Z. Y., Guo, W., Yang, P. X., Zhang, J., Gao, K., Shang, J. X., Yang, B. L., & Wu, Z. Q. (2023). In-situ infrared and kinetic characteristics analysis on pyrolysis of tar-rich coal and macerals. Fuel, 348, 128601.

Zhang, D. X., Liu, P., Lu, X. Y., Wang, L. L., & Pan, T. Y. (2016). Upgrading of low rank coal by hydrothermal treatment: Coal tar yield during pyrolysis. Fuel Processing Technology, 141, 117–122.

Zhang, L., Zhikun, H., Hao, S., et al. (2022). Basic characteristics of oil extraction by low temperature pyrolysis of oil-rich coal in northern Shaanxi [J]. Coal Engineering, 54(09):124–128.

Zhang, Y. Q., Pan, D. F., Qu, X., & Liang, P. (2018). Secondary catalytic effect of circulating ash on the primary volatiles from slow and fast pyrolysis of coal. Energy & Fuels, 32(2), 1328–1335.

Acknowledgments

The author would like to thank Shaanxi Coal Caojiatan Mining Company for providing important information and the experimental platform provided by the Shaanxi Provincial Key Laboratory of Coal Green Geology Support. The study was supported by National Natural Science Funds of China (Grant No. 42002194, Grant No. 42330808). Science and Technology Research Program of Shaanxi Coal and Chemical Industry Group Co., Ltd. (No. 2021SMHKJ-A-J-07-02).Natural Science Basic Research Program of Shaanxi (2021JLM-12).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

Author Gang Su and Longxiang Jiao are employed by Shaanxi Shanmei Caojiatan Mining Co., Ltd. Weifeng Xue is employed by Shaanxi Coal Chem Ind Technol Res Inst Co Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Qiao, J., Liang, X., Wang, C. et al. Differences of Pyrolysis Products and Controlling Factors of Oil-Rich Coal with Different Grain Sizes under Fully-Mechanized Mining Conditions. Nat Resour Res 33, 867–886 (2024). https://doi.org/10.1007/s11053-024-10315-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11053-024-10315-7