Abstract

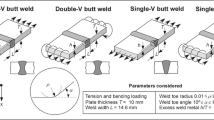

The structural hot-spot stress approach is an effective method for assessing welding details when nominal stress is hard to determine due to geometric or loading complexities. Hot spots can be classified into two types: type “a,” which refers to a weld toe located on a plate surface, and type “b,” denoting one located on a plate edge. Previous studies on type “b” hot spots have mainly focused on in-plane gusset welded joints, and the applicability of type “b” hot-spot S-N curves proposed for in-plane gusset joints in IIW to the other details is not well understood. In this study, fatigue tests were conducted with a load-carrying attachment welded on a plate surface, where a crack occurred from a weld toe on the plate edge. The tests were also numerically simulated using finite element analysis. Upon evaluating the test results through the nominal stress, structural hot-spot stress (4, 8, and 12 mm method), and notch stress approaches, it was found that all the data lie above FAT71 for nominal stress, FAT100 for hot-spot stress, and FAT225 for effective notch stress.

Similar content being viewed by others

References

Fisher JW, Kulak GL, Smith IFC (1998) A fatigue primer for structural engineers. National Steel Bridge Alliance

Hobbacher AF (2016) Recommendations for fatigue design of welded joints and components, 2nd edn. Springer, Cham

Niemi E, Fricke W, Maddox SJ (2018) Structural hot-spot stress approach to fatigue analysis of welded components, designer’s guide, 2nd ed. Springer Singapore

Marshall PW, Wardenier J (2005) Tubular versus non-tubular hot spot stress methods, Proceedings of the fifteenth international offshore and polar engineering conference, 254-263

Niemi E (1995) Stress determination for fatigue analysis of welded components. Woodhead Publishing

Dong P (2001) A structural stress definition and numerical implementation for fatigue analysis of welded joints. Int J Fatigue 23(10):865–876

Xiao ZG, Yamada K (2004) A method of determining geometric stress for fatigue strength evaluation of steel welded joints. Int J Fatigue 26(12):1277–1293

Niemi E (1994) On the determination of hot spot stresses in the vicinity of edge gussets, IIW documentation, XIII-1555-94

Saito F, Anami K, Ikehara I, Shibuya A, Ono S (2017) Fatigue strength improvement at attachement side boxer weld by low temperature transformation welding material. J Struct Eng 63A:681–689 (in Japanese)

Fricke W, Gao L, Paetzold H (2017) Fatigue assessment of local stresses at fillet welds around plate corners. Int J Fatigue 101(2):169–176

Nussbaumer A, Borges L, Davaine L (2018) Fatigue design of steel and composite structures, 2nd edn: Eurocode 3: Design of steel structures part 1-9 – Fatigue / Eurocode 4: Design of composite steel and concrete structures, ECCS

Fricke W (2012) IIW recommendations for the fatigue assessment of welded structures by notch stress analysis. Woodhead Publishing

Acknowledgements

They would also like to express their sincere gratitude to Mr. Yoshimine at Nippon Sharyo, Ltd. for fabricating the specimens.

Funding

The authors gratefully acknowledge the support provided by the Japan Society for the Promotion of Science (JSPS) KAKENHI (Grant Number 21K04233).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Recommended for publication by Commission XIII - Fatigue of Welded Components and Structures

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Hanji, T., Tateishi, K., Rabsel, N. et al. Structural hot-spot stress approach for toe cracking from plate edge of load-carrying welded attachment. Weld World (2024). https://doi.org/10.1007/s40194-024-01724-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40194-024-01724-6