Abstract

Material flow control (MFC) is a key element of production planning and control. The literature typically categorizes different MFC methods according to how MFC is realized. This distinction overlooks that MFC decisions can be subdivided into three independent tasks that are executed as orders progress through the system: (i) order generation, (ii) order release, and (iii) production authorization. MFC methods are typically designed for only one of these three tasks, which leaves a large part of the order flow uncontrolled. This study therefore not only provides a new categorization of MFC methods, but also argues for the simultaneous application (or the combining) of three different MFC methods for order generation, order release, and production authorization. To support this argument, the performance effects of an integrated MFC approach are evaluated. Findings show that each individual MFC method impacts different performance metrics, which can be explained by the presence of a hierarchy of workloads, where each workload level constrains the succeeding hierarchical level. Each MFC method has a main impact on a different workload. This has important implications for the design of MFC methods and extends recent literature on hierarchical production planning and control systems.

Similar content being viewed by others

1 Introduction

This study proposes a new structure for material flow control (MFC) methods in make-to-stock contexts, where customer orders are fulfilled from a finished goods inventory that is replenished by a capacitated production system. This shop structure is omnipresent in practice and consequently of high industrial relevance. In our study, a production planning and control approach is considered a MFC method if it answers a ‘whether’ question about material flow, e.g. whether or not to release orders. It is the function of the method, and not its characteristics (such as planning or control) or its position in the overall (hierarchical) planning and control system, that determines if it is classified as a MFC method. This allows MFC methods to be distinguished from other approaches that answer a ‘which’ question and fall under the broader topic of scheduling and sequencing. Although this definition is subjective or arbitrary, it provides a clear line that distinguishes between the different production planning and control methods in the literature. Creating this subset is needed to provide the backbone for our study. It extends more classical distinctions and supplements them.

The main categorization of different MFC methods in the literature is in terms of how material flow control is realized, e.g. as a pull system, if a work-in-process (WIP) cap is enforced, or as a push system, if a WIP cap is not enforced (Hopp & Spearman 2004). This overlooks the fact that MFC can be subdivided into three independent tasks as orders flow through the system: (i) the generation of orders; (ii) the release of orders to the shop floor; and (iii) the production authorization of orders on the shop floor. Most importantly, MFC methods are typically designed for only one of these three tasks. Adopting a single MFC method that is only designed for one of these tasks to control the whole production order lifecycle, may leave a significant part of the order flow either uncontrolled or insufficiently supported. We therefore argue that the application of MFC methods should be contingent on the stage of order progress, from order generation through to delivery to the customer, meaning different methods should be used at different stages of an order’s lifecycle or journey through the shop. To prove this conjecture, we assess the combined performance effect of using different MFC methods for order generation, order release, and production authorization via discrete event simulation. This extends prior literature, which has typically assumed that only one system is used for MFC. This literature has introduced and compared many MFC methods and concepts, such as Kanban (e.g. Ohno 1988; Shingo 1989; Lage Junior & Godinho Filho 2010), Material Requirements Planning (MRP; Orlicky 1975; Vollmann et al. 1997), Drum-Buffer-Rope (DBR; e.g. Goldratt & Cox 1984; Watson et al. 2007), Constant Work-in-Process (ConWIP; e.g. Spearman et al. 1990; 2021), Paired-cell Overlapping Loops of Cards with Authorization (POLCA; e.g. Suri 1998; Vandaele et al., 2008; Riezebos 2010), WorkLoad Control (WLC; e.g. Land & Gaalman 1996; Thürer et al. 2012), Control of Balance by Card Based Navigation (COBACABANA; e.g. Land 2009; Thürer et al. 2014a; Braglia et al. 2021), and Demand Driven MRP (DDMRP; Ptak & Smith 2011, 2016; Miclo et al. 2019; Acosta et al. 2020). Most of these methods are widely applied in practice, and every company executes some form of MFC. But, to the best of our knowledge, no prior study has assessed the combined impact of using three different MFC methods—each for a different MFC decision.

Graves et al. (1995) recognized that MFC methods address two important problems: (i) whether an order should be released onto the shop floor; and, (ii) whether a station should be authorized to produce. This subdivision provided a means of categorizing MFC methods, but it also suggested that MFC methods for order release and production authorization can be combined, or a MFC method that focusses on both tasks can be created—a possibility not explored by Graves et al. (1995). Only recently did Thürer et al. (2020) show that MFC methods for order release, such as Workload Control and ConWIP, can and should be combined with MFC methods for production authorization, such as POLCA. But neither Graves et al. (1995) nor Thürer et al. (2020) considered MFC methods for order generation that address the problem of whether an order should be generated in the first place. This distinction, between MFC methods that generate production orders and MFC methods that control the flow of production orders once they have been generated, was recognized by Lödding (2012). The author defined order generation, order release (which can be centralized, decentralized or hybrid), sequencing, and capacity control as key manufacturing control tasks. But, to the best of our knowledge, no study to-date has assessed the combined performance effect of an integrated system that controls the flow of the whole order lifecycle from generation through to completion. While several studies on hybrid systems exist, these studies typically focus on one MFC task or a subset. For example, the literature on Base-stock Kanban/ConWIP systems (Bagni et al. 2021), which focusses on order release or combinations of order release with production authorization (e.g. Bonvik et al. 1997; Dallery & Liberopoulos 2000; Baynat et al. 2002; Geraghty & Heavy 2004; Olaitan & Geraghty. 2013; Onyeocha et al. 2015). Meanwhile, a good summary and an evaluation of different customized token-based production control systems was provided by González-R and Framinan (2009). Further, a general token-based control system for order release and production authorization was introduced by González-R and Framinan (2009) and González‐R et al. (2012). Note that focusing on a subset of MFC tasks assumes other tasks are realized by immediate generation, immediate release, and/or immediate production authorization. If an order is not generated, then it cannot be released, and if it is not released, then it cannot be produced, and if it is not produced, then it will not be completed. All managers need to execute all three tasks but only a subset is typically taken consciously.

In response to the above, this study contributes to the literature in two keyways:

-

It provides a simple, logical and coherent means of classifying MFC methods that extends classical push/pull (e.g. Hopp & Spearman 2004), make-to-stock/make-to-order (e.g. Stevenson et al. 2005) or planning versus control categorizations; and,

-

It uses discrete event simulation to evaluate for the first time the performance effects of an integrated system that simultaneously uses three different MFC methods for order generation, order release, and production authorization, which provides guidance to managers and fellow researchers on which combination of MFC methods to use in their shop, or which tasks to include in the design of a single MFC method.

The remainder of this paper is structured as follows. Section 2 introduces MFC methods and categorizes them according to their focus on order generation, order release, and production authorization. Section 3 then outlines the integrated system of MFC methods that is considered in this study, before the simulation model used to assess the performance of this system is detailed in Sect. 4. The results are then presented in Sect. 5 and discussed in Sect. 6. Finally, Sect. 7 provides conclusions, managerial implications, and future research directions.

2 Background

The order lifecycle of interest to MFC decision-making can be subdivided into three stages: order generation, order release, and production authorization. This is illustrated in Fig. 1. We argue that the MFC methods introduced in the literature can be categorized according to their suitability for each stage of an order’s progress through the shop and the associated control task. The most important MFC methods are categorized and briefly introduced in Sects. 2.1, 2.2, 2.3, respectively. A discussion of the literature is then presented in Sect. 2.4. Note that MFC methods are essentially blocking systems. There exists consequently a strong link between our study and the literature on blocking mechanisms and production systems with intermediate finite buffers (e.g. Dallery & Gershwin 1992; Weiss et al. 2019). In this study we focus only on planning and control systems specifically designed to induce a certain kind of blocking to improve performance. The blocking is a managerial decision rather than a physical constraint.

2.1 MFC methods for order generation

The MFC methods summarized in this section determine whether production orders should be generated. MRP is arguably the most prominent plan-based method for generating orders. Originally developed for complex products and assembly contexts, it derives the orders based on planning using the bill of materials, inventory levels, and a so-called lead time offset to backward schedule (or ‘explode’) the production requirements for each component (Orlicky 1975; Vollmann et al. 1997). MRP is a classic push method that generates orders from a plan, which may lead to excessive WIP levels if actual production progress falls short of planned progress.

The re-order point method and the Kanban method (Ohno 1988; Shingo 1989; Lage Junior & Godinho Filho 2010) are arguably the most prominent MFC methods for order generation that are not based on a production plan. The re-order point method was used even before MRP and the advent of computers in industry. It is a continuous review system that generates orders of fixed (or variable) quantities (the re-order quantity) when the re-order point is reached. A figure illustrating the calculations underlying a re-order point system is provided in an appendix (see Fig. 5). A critical issue is the determination of the safety inventory Imin, for which different approaches have been presented in the literature (see, e.g. Schmidt et al. 2012 for a review). Kanban became famous as a result of the success of the Toyota Production System for creating a so-called pull system, in which actual demand generates orders. The Kanban method is inherently linked to the re-order point method (Shingo 1989), with the Kanban cards representing the maximum inventory in the system.

Alternative order generation methods include Synchro MRP, which uses a Kanban system and a daily production plan generated by a higher-level production planning and control system, and Demand-Driven MRP (DDMRP). For Synchro MRP, an order can only be generated by the Kanban method if a planned output level has not yet been reached (Hall 1986; Lödding 2012; Bertolini et al. 2013). Meanwhile, DDMRP combines the re-order point method and MRP (Ptak & Smith 2011, 2016; Miclo et al. 2019; Acosta et al. 2020). It decouples subsets of dependent parts (so called “pathways”) in the product structure by keeping critical parts in inventory. The inventory buffers of critical parts are controlled by re-order points, which are calculated based on a so-called “net flow equation”. If the net flow position falls to a pre-determined re-order point level, a production order for the replenishment of critical parts is generated. The generation of non-critical parts (until the next decoupling point of critical parts) is based on MRP logic, which is referred to as a “decoupled explosion”.

2.2 MFC methods for order release

The MFC methods summarized in this section determine whether production orders should be released to the shop floor. If orders are released onto the shop floor directly after order generation, then an immediate release (IMR) approach has been effectively realized. The obvious drawback of IMR is its inability to hold back orders before the planned release date, which would enable production orders to be coordinated, WIP levels in production to be regulated, and/or loads to be balanced across resources on the shop floor. For most order release methods, orders do therefore not flow directly onto the shop floor, but rather they are withheld in a so-called backlog or pre-shop pool from where they are released to meet certain performance targets.

Methods that focus on coordination typically realize release based on an order’s due date, i.e. orders are released once their planned release date has been reached to realize the production plan. Order release according to the due date is the classical order release method used in MRP (Thürer et al. 2022). This supports the coordination of different orders for assembly. In a context without assembly, this is typically referred to as Backward Infinite Loading (BIL, e.g. Ragatz & Mabert 1988). But order release based on the order due date is unable to regulate WIP levels or to balance the loads of workstations, and it does not realize input–output control (e.g. Wight 1970).

ConWIP is arguably the best-known order release method that regulates WIP by aligning the input and output of work (Spearman et al. 1990; 2021; Framinan et al. 2003; Jaegler et al. 2018), limiting the number of orders or jobs released to the shop floor. An important benefit of ConWIP is that it can effectively avoid excess WIP levels in production. In contrast to release by order due date, orders may be released to the shop floor earlier or later than planned with ConWIP. The sequence in which orders are considered for release is determined by a so-called backlog sequencing decision, which is typically urgency based. Meanwhile, DBR uses a so-called rope to align the input of work with the output rate of the bottleneck. In the original DBR approach, this rope was a lead time offset based on the expected time for a given job to reach the bottleneck (see e.g. Simons and Simpson 1997). Later, the rope was interpreted as the number of jobs released to the bottleneck but not yet completed, with a job released whenever this number fell below a limit (e.g. Chakravorty & Atwater, 1996; Watson & Patti 2008). In general, we can always express inventory and time buffers as either inventories or flow times (Land et al. 2021). A drum schedule is used to determine the sequence in which orders are considered for release. A similar method, that controls the aggregate of the processing times instead of the number of jobs, is the Starvation Avoidance (SA) trigger presented in Glassey & Resende (1988).

Arguably the best-known methods that focus on balancing the workload across stations are Workload Control and Load-Oriented Order Release (LOOR; e.g. Bechte, 1988; Wiendahl et al. 1992; Breithaupt et al. 2002). The sequence in which orders are considered for release is determined by a pool sequencing rule. There are also Workload Control methods that control the bottleneck load (e.g. Enns & Prongue Costa 2002; Neuner & Haeussler, 2021) and that control the load of the whole system (the so-called extended aggregate load method in Land & Gaalman 1996). But the distinguishing characteristic of Workload Control order release methods is that the load is controlled at each station (e.g. Bechte, 1988; Cigolini, & Portioli-Staudacher 2002; Land 2006). In other words, an order is only released if its workload, together with the workload of the jobs already released to a station and not yet completed, fits within a workload norm at all stations in its routing. COBACABANA represents a card-based version of the Workload Control order release method (Land 2009). One drawback of these MFC methods is that deviations between planned and actual sequencing might be introduced at order release since orders need to fit within the workload limits, and this may increase the variance of lateness.

Finally, in addition to the above rule-based release methods, there are also release methods that use optimization (Irastorza & Deane 1974, Haeussler & Netzer, 2020; Haeussler et al., 2020) or machine learning (Schneckenreither et al., 2021). These methods may focus on the calculation of planned release dates for order release based on due dates, or on optimizing the set of jobs for release in order to realize a balanced workload (Fernandes et al. 2020a).

2.3 MFC methods for production authorization

The MFC methods summarized under production authorization provide the go-ahead for a specific operation of an order to be undertaken on the shop floor. If all orders released to the shop floor can be processed at the corresponding stations, then immediate authorization is realized. Alternatively, a time-based production authorization procedure, which is similar to order release by planned release date, may be followed. As such, orders are only authorized to be produced if an operation-specific authorization date has been reached. While this type of production authorization is an integral part of POLCA, avoiding the early completion of orders, it is often neglected both in simulation studies and, to the best of our knowledge, in practical applications because of its direct detrimental impact on tardiness performance (Thürer et al. 2019).

The load regulating element of POLCA uses card-loops between pairs of stations, e.g. between stations 1 and 2, to signal whether there is capacity at the next downstream station in the routing of an order. Only if a POLCA card from the next station in the routing of an order is available can an order start to be processed at a station. A similar method, referred to as decentralized work-in-process (DEWIP), was introduced by Lödding et al. (2003). The difference is that DEWIP uses the WIP at the next station in the routing of an order together with the WIP already processed at any of the preceding stations to decide whether or not an order has authorization to start processing.

Note that, in practice, most companies operate with immediate authorization. However, production authorization can regulate WIP levels using local control loops, which ensures capacity availability at downstream stations and offers the potential to operate stations at defined WIP levels. If companies use IMR, then authorizing the first operation effectively triggers the order to be released from the backlog; hence, production authorization may be used as an order release method. However, in the following we are interested in the combination of dedicated order release methods and production authorization.

2.4 Discussion of the literature

Sections 2.1, 2.2, 2.3 above outlined MFC methods that are specifically suited to order generation, order release, and production authorization, respectively. These methods are summarized in Table 1. From the table we can observe that there are both push and pull methods (according to, e.g. Hopp & Spearman 2004), methods that are deemed suitable either for make-to-stock or make-to-order production environments (according to, e.g. Stevenson et al. 2005), and methods that can be considered planning or control.

We argue that different types of methods can be chosen for different tasks, and that the different methods can be combined into one integrated MFC system. That is, MFC must always comprise all tasks to be effective, because if orders are not generated, released, and authorized, they will not ultimately be produced. Of course, if order release is set to immediate release and production authorization is set to immediate authorization then essentially one system is created by generating orders; but this should be a conscious managerial decision. Similarly, if only order release is applied, order generation should still follow some rational method determined by management. In this study, we are therefore interested in the combined use of MFC methods, which leads to the following research question (RQ): How does the simultaneous use of three different MFC methods—for order generation, order release, and production authorization—affect performance when compared to the use of only one or two MFC methods?

The following section outlines our chosen integrated MFC system before discrete event simulation is used to evaluate the approach and answer the above question. Our study is, to the best of our knowledge, the first to assess the impact of combining three different MFC methods.

3 An integrated MFC system

In this section we propose an integrated MFC system for order generation, release, and authorization. For order generation, we use the re-order point method since it is one of the most applied pull methods for order generation. Since we will not consider an assembly shop the use of MRP is also not justified. MRP creates order due dates to coordinate different material flows. In our modelled scenario, material flows need to be coordinated with capacity, not other material flows. Therefore, we also neglect order release methods that focus on coordination, such as order release according to order due date (which is typically combined with MRP), and instead focus on release methods that coordinate workload and capacity. For load-based release methods, Fredendall et al. (2010) showed that Workload Control has the potential to outperform both ConWIP and DBR in the shop that is used in our study. We consequently use Workload Control for order release. Finally, POLCA is used for production authorization since it is arguably one of the best-known and widely applied methods for this particular task. We recognize that this choice of methods is somewhat arbitrary, but we accept this limitation in order to test our proposition that different methods can and should be combined.

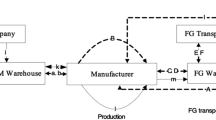

The control structure of the resulting MFC system—that combines re-order point, Workload Control and POLCA—is given in Fig. 2 for a shop producing three products (A, B and C) that move from station 1 to station 2 to station 3. We use this simplified shop structure here to enable a visualization of the system. The figure uses the framework proposed in Liberopoulos & Dallery (2000). It highlights the limited overlap in the control spheres of these three MFC methods.

Since we assume that there is no output queue, there are only four elements. First, the stocks SA, SB and SC contain the finished goods inventory of the three products. Second, queue P0 is the pool of generated production orders that are to enter the shop floor. Queue PAi contains the production orders completed at the preceding station to which a POLCA card from the preceding station is still attached. The POLCA cards are contained in Queue AsPOLCA for station s with s = 1…. n, where n is the number of stations in the system. The three MFC tasks can be summarized as follows:

-

Order generation: The customer consumes products from the stocks SA, SB and SC at a demand rate λCustomer that is independent for each product. If the re-order point for a product is reached, production orders (the re-order quantity) are generated. This creates an arrival rate of production orders λProduction to the pool P0 that is dependent on the demand rate, the availability of products, the re-order point, and the re-order quantity.

-

Order release: All orders are considered for release whenever a new production order enters P0, or an operation is completed at a station on the shop floor. Take Rj to be the ordered set of operations in the routing of order j. An order j is released if its processing time pij at the ith operation in its routing—corrected for station position i—together with the workload \({W}_{s}\) released to station s (corresponding to operation i) and yet to be completed fits within the workload norm \({N}_{s}\) at this station, that is \(\frac{{p}_{ij}}{i}+{W}_{s}\le {N}_{s}\) \(\forall i\in {R}_{j}\). That means it enters PA1 and its load contribution is included, i.e. \({W}_{s}:={W}_{s}+\frac{{p}_{ij}}{i}\) \(\forall i\in {R}_{j}\). Otherwise, the order remains in the pool and its processing time does not contribute to the station load. Since a released job contributes to \({W}_{s}\) until its operation at this station is complete, the load contribution to a station is calculated by dividing the processing time of the operation at a station by the station’s position in a job’s routing (Oosterman et al. 2000).

-

Production authorization: Once released, an order waits in queue PA1 until its production is authorized, i.e. a POLCA 1–2 card is available in queue A1. Once this card is available, the job may be processed. After processing, the job moves to queue PA2 of the next station (with the POLCA 1–2 card still attached). The job waits in queue PA2 until a POLCA 2–3 card is available in queue A2, it has the highest priority, and the station has capacity. After processing, the POLCA 1–2 card is freed and moves back to queue A1 and the job moves to the queue of the next station PA3 with the POLCA 2–3 card attached. Once completed, the order flows into the warehouse or finished goods inventory, which realizes the replenishment rate (λReplenish). POLCA uses starvation avoidance cards, as proposed in Thürer et al. (2017), in a bid to avoid premature station idleness and POLCA-specific blocking (Lödding et al. 2003). Finally, time-based authorization is neglected since it was shown to have a direct negative impact on throughput times and tardiness performance in Thürer et al. (2019).

4 Simulation

This study focuses on a make-to-stock context, where customer orders are fulfilled from a finished goods inventory, which is replenished by a capacitated production system. This is different from studies on advanced demand information, which also assume that customers arrive randomly in time but each customer places an order for a non-fixed number of end items to be delivered at a specific time (e.g., Karaesmen et al. 2002; Liberopoulos & Tsikis 2003; Claudio & Krishnamurthy 2009; Jodlbauer & Dehmer 2020). In our study, demand is directly fulfilled from the finished goods inventory, and the main decision is when to trigger replenishment orders. The simulation model of the capacitated production system largely follows the model of a semi-conductor plant used in Fredendall et al. (2010). Using this model, which is based on an observed industrial example, allows for a comparison to be made with previous literature whilst also ensuring a close link is maintained with practice. The main difference compared to the model used in Fredendall et al. (2010) is the introduction of a warehouse with a finished goods inventory from which demand is fulfilled, thereby transforming the model from a make-to-order to a make-to-stock system.

Our simulation model is implemented using ARENA simulation software. The simulated shop produces 10 different products using 13 stations, where each station is a single constant capacity resource. Finished products are stored in a warehouse, with demand satisfied from this finished goods inventory. Table 2 provides the inter-arrival times of demand for each product type together with the job characteristics, while Table 3 details the processing time distributions used for each station together with the average utilization rate. All distributions are taken from Fredendall et al. (2010) and consequently based on an observed industrial example. The same holds for the equal mean inter-arrival times, which are introduced to control this environmental parameter. Set-up times are considered sequence independent and part of the processing time to keep our study focused. Once a production order is generated, it enters the pre-shop pool and waits to be released onto the shop floor. Once an order is completed on the shop floor, it enters the warehouse directly. This means that the time implications of transporting products are omitted in order to keep our study focused on the three core elements of MFC.

4.1 Parametrization of material flow control

As in previous simulation studies on order generation, release control and production authorization (e.g. Land & Gaalman 1998; Cigolini, & Portioli-Staudacher 2002; Fernandes & Carmo-Silva 2006; Germs & Riezebos 2010; Thürer et al. 2012; Harrod & Kanet 2013; Braglia et al. 2014; Fernandes et al. 2021), it is assumed that all orders are accepted, materials are available, and all necessary information regarding shop floor routings, processing times, etc. is known once an order is generated. The parameterization of the different MFC methods is as follows.

4.1.1 Order generation

The safety stock levels (SSLs) in the re-order point calculations are determined using Eq. (1). This approach was chosen since it provides the best trade-off in terms of simplicity and performance according to the results in Schmidt et al. (2012).

Two levels of the safety factor SF are considered: 0 and 1. A SF of 0 means that there is no safety stock, and that the ROP is equal to the demand during the replenishment time (TRP). The SF of 1 was set arbitrarily to realize a fill rate that can be considered good while still maintaining performance differences. The mean demand per period (D) is equal for all products and can be obtained from Table 2. The standard deviation of demand per period \({\sigma }_{D}\) was approximated by a Monte Carlo simulation for each product type. The replenishment time TRP and the standard deviation of the replenishment time \({\sigma }_{TRP}\), were obtained via preliminary simulation experiments. Values are based on the scenario where all orders are released and authorized immediately for all scenarios. The re-order point calculation is summarized in the Appendix Table 9. The inventory position is given by the finished goods inventory (on hand) plus replenishment orders on their way (open orders) minus any open demand. It is compared with the final (rounded) re-order point for each product type, and when the inventory position is equal or smaller than the re-order point a production order is generated.

We also consider two levels of re-order quantities: 1 and 5. In this study, the re-order quantity is not expressed in terms of the lot size, but rather in terms of the number of production orders generated. Since we do not consider sequence dependent set-up times and we neglect other lot sizing effects to keep our study focused, a re-order quantity of 5 does not appear meaningful. We do however include it as an experimental variable since it reduces the level of control exercised by the re-order point method. The production orders that are generated progress independently, following the findings in Fernandes et al. (2020b). The main effect of a higher order quantity is consequently that production orders are generated with a higher variance (i.e. less frequently).

4.1.2 Order release

Five workload norms are considered for Workload Control order release. The tightest level is set to 3.5 time units, and the level is increased stepwise by multiplying the preceding level by 1.15 (and rounded). This results in norms of 3.5, 4, 4.6, 5.3 and 6.1 time units. As a baseline measure, experiments without controlled order release have also been executed, i.e. where jobs are released onto the shop floor immediately after being generated (IMR).

4.1.3 Production authorization

POLCA loops are created to reflect every possible routing step of orders. Four levels for the number of cards per loop are considered: 4, 6, 8, and 10 cards per loop. These parameters were set based on preliminary simulation experiments. The same number of cards is used within each loop in a given experiment to keep the experimental setting reasonable. As a baseline measure, experiments without production authorization have also been executed, i.e. where all jobs are immediately authorized (IMA).

4.2 Scheduling and sequencing

An order is scheduled as soon as it is generated. Complexities such as creating production orders by combining or dividing customer orders are deliberately neglected in our study to keep it focused. The main scheduling task is the determination of operation due dates. In this study we will use simple forward scheduling. This means an allowance for the operation throughput time is added to the due date of the preceding operation, beginning from the planned release date. The planned release date is given by adding an allowance for the pool waiting time to the order generation date. Allowances for the station throughput time and the pool waiting time are given by the cumulative moving average, i.e. the average of all throughput and waiting times realized until the current simulation time. In practice, average replenishment lead times can be achieved by providing the required capacity levels. As we refrain from implementing capacity control, average replenishment lead times will vary for each factor level combination. This effect is compensated for by using a cumulative moving average for each scenario.

The planned release date is used to determine the sequence in which orders are considered for release from the pool. Card allocation for production authorization follows operation due dates. Finally, first-come-first-served (FCFS) is used for the dispatching decision, i.e. the decision concerning which authorized order to process next at a given station on the shop floor. FCFS is used as it maintains the card allocation sequence.

4.3 Experimental design and performance measures

Table 4 provides a summary of the MFC system considered. We used a full factorial design for this system, which results in 120 (2 × 2 × 6 × 5) scenarios. Each scenario of the experimental design was replicated 100 times. Results were collected over 13,000 time units following a warm-up period of 3000 time units. These simulation conditions allow us to obtain stable results while keeping the simulation run time to a reasonable level.

Five main performance measures are considered: the fill rate (FR), i.e. the fraction of customer orders that can be fulfilled from stock when the customer order arrives (our service level is 100%, i.e. we assume that there are no lost sales); the customer waiting time (CWait), i.e. the time a customer has to wait when the ordered product is not in stock; the finished goods inventory (FGI), i.e. the average number of products in the warehouse; the total throughput time (TTT), i.e. the mean of the warehouse entry date minus the mean of the pool entry date (which refers to the order generation date) across orders; and, the standard deviation of the total throughput time (SDTTT). In addition, and since we consider order release control, we also measure the mean of the shop floor throughput time (SFTT). While the total throughput time includes the time that an order waits before being released, the shop floor throughput time only measures the time after an order has been released to the shop floor.

5 Results

An ANOVA has been conducted to give a first indication of the relative impact of the four experimental factors, i.e. the safety factor, re-order quantity, Workload Control norm, and the number of POLCA cards. The results are provided in an appendix (see Tables 10, 11, 12, 13, 14, 15). All main effects and most of the two-way interactions were shown to be statistically significant, except for the safety factor. The safety factor has no impact on the shop floor throughput time, the total throughput time or the standard deviation of the total throughput time. There are some significant three-way interactions, but no significant four-way interactions. To further assess this, detailed performance results will be presented next in Sect. 5.1 before a robustness analysis is presented in Sect. 5.2.

5.1 Performance assessment

Simulation results for a safety factor of 1 and 0 are presented in Tables 5 and 6, respectively. By comparing the results in Tables 5 and 6 we can observe that, as expected, there is a strong reduction in the fill rate and finished goods inventory when the safety factor, and thus the reorder point, is reduced. Detailed results also highlight that the safety factor has no effect on throughput time related performance measures, as further confirmed by the ANOVA. Workload Control order release reduces shop floor throughput times and, given its load balancing capability, can also reduce total throughput times, which in turn leads to an increase in the fill rate and finished goods inventory. If workload norms are too tight then the number of sequence deviations increases, as can be seen from the standard deviation of the total throughput time results. This deterioration in timing performance offsets the improvement in load balancing at a certain point and, as a result, the fill rate decreases. Finally, while POLCA has almost no performance effect when the re-order quantity is 1, it allows for a further reduction in throughput times when the re-order quantity is 5. In general, and as expected, increasing the re-order quantity from 1 to 5 increases the levels of work-in-process (and consequently throughput times) and finished goods inventory. This significantly enhances the potential of order release and production authorization to reduce throughput times.

Overall, the following conclusions can be obtained from the results in Tables 5 and 6:

-

Re-order point order generation: The fill rate is largely determined by the re-order points calculated for each product type. Throughput times are largely determined by the re-order quantity. An increase in the re-order quantity increases the number of production orders that are generated simultaneously, which induces peaks in the load and thus in the level of work-in-process.

-

Workload control order release: The shop floor throughput time is largely determined by order release, which can also reduce total throughput times if norms are set appropriately. This reduction in total throughput times has an impact on the replenishment time and thus on both the finished goods inventory and the fill rate. However, this impact is marginal if order generation is effective (i.e. for a re-order quantity of 1).

-

POLCA production authorization: The shop floor throughput times can be further reduced by exercising production authorization if order generation and order release are less effective; but the performance impact is less than that achieved by order release. If order generation is effective, then POLCA has no performance effect, or the effect is even negative.

5.2 Robustness analysis

The above presentation of results neglected differences across products. To understand whether the above results are influenced by the characteristics of specific product types, we also collected the fill rate per product type. The results for a re-order quantity of 5 and a safety factor of 0 are given in Table 7. We focus on these scenarios since this emphasizes the impact of order release and order authorization.

In terms of the direct effect of our three MFC methods, the following can be observed from Table 8:

-

Re-order point order generation is sensitive to variability in the interarrival times, leading the higher inter-arrival time variability for product types 2, 6 and 10 (see Table 2 above) to lower fill rates. This can be observed from the row for IMR and IMA in Table 8. Order generation is also sensitive to the routing length (i.e. the number of stations in the routing of an order) since a longer routing length implies longer replenishment times. But this effect is dependent on the re-order quantity.

-

Workload control order release improves the fill rate for all product types if the workload norm is set appropriately This can be observed from the rows of the table representing different workload norms and IMA.

-

POLCA production authorization is sensitive to the routing sequence. Performance improves for all product types except types 1 and 4. This can be observed by focusing on the rows for IMR and the different levels of POLCA cards in Table 7. For example, for product Type 1, the fill rate is 86.4% for IMA and 78.4% for a card level of 4. If we take a closer look at the routings of the different product types then we can observe that three product types (types 1, 2 and 4) share the same routing step from Station 9 (the station with the highest average utilization) to Station 10. This means that there is high competition for the POLCA 9–10 cards, which at the same time take a significant amount of time to circulate. To prove this conjecture, Table 8 summarizes the time until card allocation and the operation throughput time after card allocation per job type for stations 9 and 10. From the table we can observe that waiting times for cards are substantially longer for jobs that have Station 10 as the next routing step (marked bold). While this increase is offset for product Type 2, for types 1 and 4 it leads to the observed deterioration in the fill rate.

6 Discussion

In general, our results highlight a clear hierarchy of control based on the workload, which is similar to the hierarchy of workloads used within the workload control concept (Kingsman et al. 1989; Kingsman 2000). Workload control’s hierarchy of workloads consists of: (i) the shop floor workload; (ii) the planned workload, which consists of the shop floor workload and orders in the pre-shop pool; and, (iii) the total workload, which consists of the planned workload plus a percentage of customer enquiries based on order winning history, known as the “strike rate” (e.g. Kingsman et al. 1996). This total workload is similar to the master production schedule in the MRP literature, but the MPS is a plan for production per period whereas the total workload is partly a state variable. For our integrated MFC system, order generation controls the transfer of incoming customer orders into production orders, i.e. the planned workload. Order release then controls the transfer of the pool load into the shop floor workload; but it does not have any direct impact on the set of production orders. Finally, production authorization controls the station load, i.e. the transformation of shop floor orders into finished goods; but it has no direct impact on the set of shop floor orders. Consequently, the impact of each control level is limited by the workload it actually controls. This is illustrated in Fig. 3.

Workload Control’s hierarchy of workloads was mainly developed for a make-to-order context where orders may be heavily customized meaning orders are only completed after demand is known (Kingsman et al. 1989). In a make-to-stock context, where demand is typically fulfilled from stocks, an additional important workload emerges—that of the finished goods inventory. Most importantly, it is the finished goods inventory that determines customer satisfaction in terms of the delivery and waiting time, not the throughput times. The finished goods inventory acts as the customer order decoupling or order penetration point (van Donk 2001; Olhager 2003; Calle et al. 2016; Land et al. 2021), separating the customer from the production system. The throughput times that are a result of Workload Control’s hierarchy of workloads only indirectly influence the finished goods inventory and the fill rate since, in a make-to-stock context, throughput times become replenishment times.

The impact of order generation and order release over time is visualized in Fig. 4. The horizontal axis refers to (simulation) time while the vertical axis indicates the cumulative number of orders that are demanded, generated, released, completed, and delivered. Such cumulative representations over time have been used for many decades as they help to explain industrial dynamics (e.g. Forrester 1961; Nyhuis & Wiendahl 2008; Land et al. 2021). The horizontal distance between curves indicates throughput and waiting times while the vertical distance between curves indicates the workload between two decisions at any moment in time. Figure 4 presents an excerpt of a representative simulation run for a safety factor of 1, a re-order quantity of 1, and a workload norm of 4 with immediate authorization.

Figure 4 shows that the sum of the finished goods inventory and planned workload (i.e. the vertical distance between the delivery and entry curves) is not affected by order release. Instead, it is mainly determined by order generation. Order release only affects the timing in terms of when work-in-process becomes finished goods inventory. The hierarchy of workload thus leads to the following hierarchy of control:

Order generation, which controls the finished goods inventory and the planned workload. Order release and production authorization only have an indirect impact through the replenishment times. This means that if the focus is on the finished goods inventory and fill rate, and if an effective order generation method is in place, then the use of order release and production authorization is questionable. This is supported by the results obtained with a re-order quantity of 1 in Tables 5 and 6 and by the ANOVA results for the fill rate and the total throughput time, which reflects the planned workload. Both are given in the Appendix (see Tables 10 and 13, respectively).

Order release, which controls the shop floor workload. This means control is largely focused on the shop floor throughput times. Order release only affects total throughput times through its load balancing capability, but this effect is marginal if order generation already tightly controls the planned workload. This is supported by the ANOVA results for total throughput times and shop floor throughput times. Both are given in the Appendix (see Tables 13 and 15, respectively). Meanwhile, order release delays specific order types if norms are too tight, which explains the strong effect on customer waiting times observed in Tables 5 and 6. This is further supported by the ANOVA results for the customer waiting time given in Appendix Table 11. If order generation is less effective in controlling the planned workload, then order release also has a significant impact on the finished goods inventory and fill rate through its impact on replenishment times. This is supported by the results obtained with a re-order quantity of 5. Similarly, order release becomes more important in contexts where there is no finished goods inventory buffer, such as in make-to-order contexts, which often realize immediate order generation. However, effective customer enquiry management that already creates a balanced workload has a similar impact to effective order generation in make-to-order contexts (Thürer et al. 2014b).

Production authorization, which controls the station loads. This means that control is largely focused on operation throughput times, which creates an impact on shop floor throughput times. Product authorization can act as a substitute of order release control in its absence, being the release controlled by the authorization of the first station in the routing of the job. Yet, its positive performance effects are less, which may result in negative overall performance effects when order generation is effective. If an effective order release method is in place, the main impact of production authorization is on further reducing shop floor throughput times. The limited effect of POLCA is also supported by the ANOVA results presented in the Appendix.

This hierarchy extends the idea of hierarchical production planning and control systems in which higher level decisions that consider longer time frames (and more aggregate information) constrain lower-level decisions that consider shorter time frames (McKay et al. 1995). The fundamental structure of these hierarchical production planning and control systems consists of a planning level, typically used for order generation and coordination, and a scheduling level that authorizes production (Missbauer & Uzsoy 2022). Both are mediated by order release. The hierarchy of workloads presented above extends hierarchical production planning and control systems because: the workload is more closely linked to performance indicators, as it mediates any decision; and, order generation does not necessarily consider longer time frames, e.g. all three MFC methods integrated in our study (re-order point, Workload Control and POLCA) only focused on current information.

Finally, our study also extends research on general MFC systems that are able to mimic other MFC methods, such as Production Authorization Cards (PAC; e.g. Buzacott & Shanthikumar 1992). PAC allows for realizing different MFC methods according to parametrization. It was therefore not categorized in Sect. 2, since its categorization as either order generation, order release or production authorization would change according to the parametrization. But PAC can only mimic one MFC system at a time. It would consequently need to be applied three times along the material flow or product lifecycle to execute all three MFC tasks. Future research is therefore needed to extend PAC and/or customized token-based production control systems (e.g. González-R and Framinan 2009). This would provide greater flexibility to companies and better reflect their idiosyncratic needs that may change over time.

7 Conclusions

Material Flow Control (MFC) is a key part of production planning and control. MFC methods can be categorized according to how material flow control is realized, e.g. as a pull system if a work-in-process cap is enforced, or otherwise as a push system. Similarly, the different methods can be considered more suitable for either make-to-stock or make-to-order production environments. But these distinctions overlook the fact that material flow control decisions can be subdivided into three independent tasks along the flow of an order: whether an order should be generated, whether an order should be released, and whether the production of an order should be authorized. This provides a new categorization of MFC methods that extends existing categorizations. MFC methods are typically designed for one of these three tasks, which means that a significant part of an order’s flow may remain insufficiently controlled or uncontrolled if only one method is applied. In answer to our research question—How does the simultaneous use of three different MFC methods—for order generation, order release, and production authorization—affect performance when compared to the use of only one or two MFC methods?—we have found that:

-

In principle, MFC methods for order generation, order release and production authorization can be combined, since each influences a different workload in the hierarchy of workloads, and consequently different performance metrics.

-

Yet, since there is a hierarchy of workloads, where order generation constrains order release and order release constrains production authorization, the benefits of simultaneous applying different MFC methods is limited. For example, if effective order generation is in place, then the usefulness of order release and production authorization can be questioned. Our study is in the context of make-to-stock production; but the same holds for make-to-order contexts if customer enquiry management already creates a balanced workload (as shown in Thürer et al. 2014b).

7.1 Managerial implications

Order release and production authorization only have a marginal impact from a customer perspective if: (i) there is a finished goods inventory that buffers, or decouples, the customer from the shop floor, as is typical in make-to-stock contexts, and (ii) there is an effective order generation method in place to control the finished goods inventory and planned workload. Order release can help to control work-in-process and shop floor throughput times in this context, and to a certain extent production authorization can substitute for order release. The main question is whether the additional investment required to achieve an integrated end-to-end material flow control system is justifiable. In contrast, in make-to-order contexts without a finished goods inventory, the customer directly experiences the total throughput time in the form of a waiting time. In this context, order release has a stronger impact from a customer perspective and is therefore much more justified.

7.2 Limitations and future research

A main limitation of our study is its limited experimental setting. While we chose a widely accepted model of a real-life shop, this shop neglects complexities such as assembly, which would require a different focus to that of our MFC system. In general, different alternative MFC systems exist for each element of MFC (i.e. order generation, order release, and production authorization), where the choice is largely determined by the control focus at each stage, i.e. whether the emphasis is on the workload or on coordination (timing). In this study, we arbitrarily chose a set of methods to test our proposition that three different MFC methods can and should be combined. Future research is needed to generalize and falsify our findings by considering other combinations of methods. Future research could also use customized token-based systems to create a MFC method that allows for more flexible integration of the different MFC tasks. Another main limitation is the neglect of sequencing. While this is justified by our focus on MFC, future research could investigate how different sequencing rules impact the results. This becomes even more important in an assembly context. Finally, future research could also explore the combined effect of MFC, sequencing and capacity adjustments, although the complexity of simultaneously considering all three kinds of decisions is likely to require new solutions, such as in the form of advanced planning and scheduling systems. Our study provides a starting point for informing the structure of such systems.

Data availability

The data that support the findings of this study are available from the corresponding author, [MT], upon reasonable request.

References

Acosta PVA, Mascle C, Baptiste P (2020) Applicability of Demand-Driven MRP in a complex manufacturing environment. Int J Prod Res 58(14):4233–4245

Bagni G, Godinho Filho M, Thürer M, Stevenson M (2021) Systematic review and discussion of production control systems that emerged between 1999 and 2018. Prod Plan Control 32(7):511–525

Baynat B, Buzacott JA, Dallery Y (2002) Multiproduct Kanban-like control systems. Int J Prod Res 40(16):4225–4255

Bechte W (1988) Theory and practise of load-oriented manufacturing control. Int J Prod Res 26(3):375–395

Bertolini M, Braglia M, Romagnoli G, Zammori F (2013) Extending value stream mapping: the synchro-MRP case. Int J Prod Res 51(18):5499–5519

Bonvik AM, Couch CE, Gershwin SB (1997) A comparison of production line control mechanisms. Int J Prod Res 35(3):789–804

Braglia M, Castellano D, Frosolini M (2014) Optimization of POLCA-controlled production systems with a simulation-driven genetic algorithm. Int J Adv Manuf Technol 70:385–395

Braglia M, Marrazzini L, Padellini L (2021) COBACABANA: a real industrial application in a job shop system. Prod Plan Control (in print).

Breithaupt JW, Land M, Nyhuis P (2002) The workload control concept: theory and practical extensions of load oriented order release. Prod Plan Control 13(7):625–638

Buzacott JA, Shanthikumar JG (1992) A general approach for coordinating production in multiple-cell manufacturing systems. Prod Oper Manag 1(1):34–52

Calle M, González-R PL, Leon JM, Pierreval H, Canca D (2016) Integrated management of inventory and production systems based on floating decoupling point and real-time information: a simulation based analysis. Int J Prod Econ 181:48–57

Cigolini R, Portioli-Staudacher A (2002) An experimental investigation on workload limiting methods with ORR policies in a job shop environment. Prod Plan Control 13(7):602–613

Claudio D, Krishnamurthy A (2009) Kanban-based pull systems with advance demand information. Int J Prod Res 47(12):3139–3160

Dallery Y, Gershwin SB (1992) Manufacturing flow line systems: a review of models and analytical results. Queueing Systems 12(1):3–94

Dallery Y, Liberopoulos G (2000) Extended Kanban control system: combining Kanban and base stock. IIE Trans 32(4):369–386

Enns ST, Prongue Costa M (2002) The effectiveness of input control based on aggregate versus bottleneck workloads. Prod Plan Control 13(7):614–624

Fernandes NO, Carmo-Silva S (2006) Generic POLCA—a production and materials flow control mechanism for quick response manufacturing. Int J Prod Econ 104(1):74–84

Fernandes NO, Thürer M, Pinho TM, Torres P, Carmo-Silva S (2020a) Workload control and optimised order release: an assessment by simulation. Int J Prod Res 58(10):3180–3193

Fernandes NO, Thürer M, Stevenson M, Carmo-Silva S (2020b) Lot synchronization in make-to-order shops with order release control: an assessment by simulation. Int J Prod Res 58(21):6724–6738

Fernandes NO, Thürer M, Stevenson M (2021) Direct workload control: simplifying continuous order release. Int J Prod Res (in print)

Forrester JW (1961) Industrial dynamics. MIT Press, Cambridge

Framinan JM, González PL, Ruiz-Usano R (2003) The CONWIP production control system: review and research issues. Prod Plan Control 14(3):255–265

Fredendall LD, Ojha D, Patterson JW (2010) Concerning the theory of workload control. Eur J Oper Res 201(1):99–111

Geraghty J, Heavy C (2004) A comparison of hybrid push/pull and CONWIP/pull production inventory control policies. Int J Prod Econ 91(1):75–90

Germs R, Riezebos J (2010) Workload balancing capability of pull systems in MTO production. Int J Prod Res 48(8):2345–2360

Glassey CR, Resende MG (1988) Closed-loop job release control for VLSI circuit manufacturing. IEEE Trans Semicond Manuf 1:36–46

Goldratt EM, Cox J (1984) The goal: excellence in manufacturing. North River Press, New York

González-R PL, Framinan JM (2009) The pull evolution: from Kanban to customised token-based systems. Prod Plan Control 20(3):276–287

González-R PL, Framinan JM, Pierreval H (2012) Token based pull production control systems: an introductory overview. J Intell Manuf 23(1):5–22

Graves RJ, Konopka JM, Milne RJ (1995) Literature review of material flow control mechanisms. Prod Plan Control 6(5):395–403

Hall RW (1986) Synchro MRP: combining Kanban and MRP. The Yamaha PYMAC system. In: Driving the productivity machine: production planning and control in Japan. APICS, Falls Church, pp 43–56

Harrod S, Kanet JJ (2013) Applying work flow control in make-to-order shops. Int J Prod Econ 143:620–626

Haeussler S, Stampfer C, Missbauer H (2020) Comparison of two optimization based order release models with fixed and variable lead times. Int J Prod Res 227.

Haeussler S, Netzer P (2020) Comparison between rule- and optimization-based workload control concepts: a simulation optimization approach. Int J Prod Res 58(12):3724–3743

Hopp WJ, Spearman ML (2004) To pull or not to pull: what is the question? Manuf Serv Oper Manag 6(2):133–148

Irastorza JC, Deane RH (1974) A loading and balancing methodology for job shop control. AIIE Trans 6(4):302–307

Jaegler Y, Jaegler A, Burlat P, Lamouri S, Trentesaux D (2018) The ConWip production control system: a systematic review and classification. Int J Prod Res 56(17):5736–5757

Jodlbauer H, Dehmer M (2020) An extension of the reorder point method by using advance demand spike information. Comput Oper Res 124:105055

Karaesmen F, Buzacott JA, Dallery Y (2002) Integrating advance order information in make-to- stock production systems. IIE Trans 34(8):649–662

Kingsman BG (2000) Modeling input-output workload control for dynamic capacity planning in production planning systems. Int J Prod Econ 68(1):73–93

Kingsman BG, Tatsiopoulos IP, Hendry LC (1989) A structural methodology for managing manufacturing lead times in make-to-order companies. Eur J Oper Res 40:196–209

Kingsman BG, Hendry LC, Mercer A, De Souza A (1996) Responding to customer enquiries in make-to-order companies: problems and solutions. Int J Prod Econ 46–47:219–231

Lage Junior M, Godinho Filho M (2010) Variations of the Kanban system: literature review and classification. Int J Prod Econ 125:13–21

Land M (2006) Parameters and sensitivity in workload control. Int J Prod Econ 104(2):625–638

Land MJ (2009) Cobacabana (control of balance by card-based navigation): a card-based system for job shop control. Int J Prod Econ 117:97–103

Land MJ, Gaalman GJC (1996) Workload control concepts in job shops: a critical assessment. Int J Prod Econ 46–47:535–538

Land MJ, Gaalman GJC (1998) The performance of workload control concepts in job shops: Improving the release method. Int J Prod Econ 56–57:347–364

Land MJ, Thürer M, Stevenson M, Fredendall LD, Scholten K (2021) Inventory diagnosis for flow improvement—a design science approach. J Oper Manag 67(5):560–587

Liberopoulos G, Tsikis I (2003) Unified modelling framework of multi‐stage production‐inventory control policies with lot sizing and advance demand information. In: Stochastic modeling and optimization of manufacturing systems and supply chains. Springer, New York

Liberopoulos G, Dallery Y (2000) A unified framework for pull control mechanisms in multi-stage manufacturing systems. Ann Oper Res 93(1–4):325–355

Lödding H (2012) Handbook of manufacturing control: fundamentals, description, configuration. Springer Science & Business Media, Heidelberg

Lödding H, Yu K-W, Wiendahl H-P (2003) Decentralized WIP-oriented manufacturing control (DEWIP). Prod Plan Control 14(1):42–54

McKay KN, Safayeni FR, Buzacott JA (1995) A review of hierarchical production planning and its applicability for modern manufacturing. Prod Plan Control 6(5):384–394

Miclo R, Lauras M, Fontanili F, Lamothe J, Melnyk SA (2019) Demand driven MRP: assessment of a new approach to materials management. Int J Prod Res 57(1):166–181

Missbauer H, Uzsoy R (2022) Order release in production planning and control systems: challenges and opportunities. Int J Prod Res (in print)

Neuner P, Haeussler S (2021) Rule based workload control in semiconductor manufacturing revisited. Int J Prod Res 59(19):5972–5991

Nyhuis P, Wiendahl HP (2008) Fundamentals of production logistics: theory, tools and applications. Springer Science & Business Media, Heidelberg

Ohno T (1988) Toyota production system: beyond large-scale production, 1st ed. Productivity Press, New York

Olaitan OA, Geraghty J (2013) Evaluation of production control strategies for negligible-setup, multiproduct, serial lines with consideration for robustness. J Manuf Technol Manag 24(3):331–357

Olhager J (2003) Strategic positioning of the order penetration point. Int J Prod Econ 85(3):319–329

Onyeocha CE, Wang J, Khoury J, Geraghty J (2015) A Comparison of HK-CONWIP and BK-CONWIP control strategies in a multi-product manufacturing system. Oper Res Perspect 2:137–149

Oosterman B, Land MJ, Gaalman G (2000) The influence of shop characteristics on workload control. Int J Prod Econ 68(1):107–119

Orlicky J (1975) Material requirements planning. McGraw-Hill, New York

Ptak C, Smith C (2011) Orlicky’s material requirements planning 3/E. McGraw Hill Professional, New York

Ptak C, Smith C (2016) Demand driven material requirements planning (DDMRP). Industrial Press, Norwalk

Ragatz GL, Mabert VA (1988) An evaluation of order release mechanisms in a job-shop environment. Decis Sci 19(1):167–189

Riezebos J (2010) Design of POLCA material control systems. Int J Prod Res 48(5):1455–1477

Schmidt M, Hartmann W, Nyhuis P (2012) Simulation based comparison of safety-stock calculation methods. CIRP Ann 61(1):403–406

Schneckenreither M, Haeussler S, Gerhold C (2021) Order release planning with predictive lead times: a machine learning approach. Int J Prod Res 59(11):3285–3303

Shingo S (1989) A study of the Toyota production system from an industrial engineering viewpoint. Productivity Press, Cambridge, MA

Simons JV, Simpson WP III (1997) An exposition of multiple constraint scheduling as implemented in the goal system (formerly disaster). Prod Oper Manag 6:3–22

Spearman ML, Woodruff DL, Hopp WJ (1990) CONWIP: a pull alternative to Kanban. Int J Prod Res 28(5):879–894

Spearman ML, Woodruff DL, Hopp WJ (2021) CONWIP Redux: reflections on 30 years of development and implementation. Int J Prod Res (in print)

Stevenson M, Hendry LC, Kingsman BG (2005) A review of production planning and control: the applicability of key concepts to the make-to-order industry. Int J Prod Res 43(5):869–898

Suri R (1998) Quick response manufacturing: a companywide approach to reducing lead times. Productivity Press, Portland

Thürer M, Stevenson M, Silva C, Land MJ, Fredendall LD (2012) Workload control (WLC) and order release: a lean solution for make-to-order companies. Prod Oper Manag 21(5):939–953

Thürer M, Land MJ, Stevenson M (2014a) Card-based workload control for job shops: improving COBACABANA. Int J Prod Econ 147:180–188

Thürer M, Stevenson M, Silva C, Land MJ, Fredendall LD, Melnyk SA (2014b) Lean control for make-to-order companies: integrating customer enquiry management and order release. Prod Oper Manag 23(3):463–476

Thürer M, Fernandes NO, Carmo-Silva S, Stevenson M (2017) Improving performance in POLCA controlled high variety shops: an assessment by simulation. J Manuf Syst 44:143–153

Thürer M, Fernandes NO, Stevenson M, Silva C, Carmo-Silva S (2019) POLC-A: an assessment of POLCA’s authorization element. J Intell Manuf 30(6):2435–2447

Thürer M, Fernandes NO, Stevenson M (2020) Material flow control in high-variety make-to-order shops: combining COBACABANA and POLCA. Prod Oper Manag 29(9):2138–2152

Thürer M, Fernandes NO, Stevenson M (2022) Production planning and control in multi-stage assembly systems: an assessment of Kanban, MRP, OPT (DBR) and DDMRP by simulation. Int J Prod Res 60(3):1036–1050

van Donk DP (2001) Make to stock or make to order: The decoupling point in the food processing industries. Int J Prod Econ 69(3):297–306

Vandaele N, Van Nieuwenhuyse I, Claerhout D, Cremmery R (2008) Load-based POLCA: An integrated material control system for multiproduct, multimachine job shops. Manuf. Serv. Oper. Manag 10(2):181–197

Vollmann TE, Berry WL, Whybark DC (1997) Manufacturing planning and control systems. McGraw-Hill, Irwin

Watson KJ, Patti A (2008) A comparison of JIT and TOC buffering philosophies on system performance with unplanned machine downtime. Int J Prod Res 46(7):1869–1885

Watson KJ, Blackstone JH, Gardiner SC (2007) The evolution of a management philosophy: the theory of constraints. J Oper Manag 25:387–402

Weiss S, Schwarz JA, Stolletz R (2019) The buffer allocation problem in production lines: Formulations, solution methods, and instances. IISE Trans 51(5):456–485

Wiendahl HP, Gläßner J, Petermann D (1992) Application of load-oriented manufacturing control in industry. Prod Plan Control 3(2):118–129

Wight O (1970) Input/output control a real handle on lead time. Prod Invent Manag J 11(3):9–31

Funding

Open Access funding enabled and organized by Projekt DEAL.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

There is no potential conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

See Tables 9, 10, 11, 12, 13, 14, 15 and Fig. 5.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Thürer, M., Fernandes, N.O., Lödding, H. et al. Material flow control in make-to-stock production systems: an assessment of order generation, order release and production authorization by simulation. Flex Serv Manuf J (2024). https://doi.org/10.1007/s10696-024-09532-2

Accepted:

Published:

DOI: https://doi.org/10.1007/s10696-024-09532-2