Abstract

Globally, millions of cubic meters of dye-contaminated wastewater are generated annually from the textile industry. Discharging the dye-contaminated wastewater into natural water streams is detrimental to the ecosystem and human health. Wastewater bioremediation is considered a practical solution for converting wastewater into value-added water for safe reuse especially in irrigation. The present study investigated the immobilization of highly stable spore laccase enzyme of Bacillus amyloliquefaciens A1 by entrapment and adsorption techniques. Based on the results, agarose gel was the most efficient support with 94% immobilization yield. Optimum temperature of immobilized enzyme was at 60 ℃ with complete thermal stability for 120 min. The maximum activity of immobilized enzyme was at pH 6–7 and retained 91% of its activity after 24 h incubation. It showed 100% storage stability after 8 weeks which was higher than that of un-immobilized enzyme (4 weeks). The enzyme activity was nearly stable after 8 consecutive cycles of reuse. Decolorization of 8 textile dyes was studied using the immobilized enzyme. Crystal violet, direct red 81 and acid black 24 were efficiently decolorized (94.5, 77.4, and 68.8%, respectively) within 24 h in the first cycle. Reusability of immobilized enzyme showed 74.6, 53.5, and 51.8% decolorization of the same dyes in the same order after the second cycle. Immobilized spore laccase-treated dye water was used to irrigate lentil seeds and showed germination index about 73% compared to 10.8% for untreated one indicating very low toxicity of the treated dye water.

Similar content being viewed by others

Introduction

Water pollution produced through the discharge of untreated toxic/recalcitrant textile dyes into water bodies has severe harmful impacts on the continuation of life in the biosphere and severely impairs human public health [18, 28]. Synthetic dyes and their metabolic intermediates are considered toxic, mutagenic, and/or carcinogenic [48]. Wastewater generated from textile industries contains many complex organic compounds that are extremely resistant to degradation. The discharge of colored effluents into water streams and rivers contributes to depletion in the dissolved oxygen, thus causing development of anoxic conditions that are extremely lethal to the aquatic organisms [27]. Consequently, the removal of these dyes from wastewater is crucial. In addition, the reuse of treated wastewater for safe irrigation could participate in mitigating some of the climate changes impacts on water and food sectors. These two vital sectors are at present prone to hard climatic conditions inducing water scarcity and droughts in many countries as well as food shortage all over the world.

Several limitations concerning traditional treatment methods either chemically or physically employed in decolorization of dyes are nowadays escalated. These limitations include; harsh reaction conditions, economic considerations, and environmental safety measures [51]. In comparison, the biological treatment especially by enzymatic decolorization and detoxification of dyes effluent is one of the promising challenges gaining support worldwide [17]. In this context, laccases are regarded as efficient enzymes in green decolorization of dyes.

As commonly known, enzymes are efficient catalysts that have been employed in various vital fields, ranging from biomedical therapy to environmental remediation [11]. Laccases (benzenediol: oxygen oxidoreductases, EC: 1.10.3.2) belong to the family of multi-copper oxidases which can catalyze many organic and inorganic substrates as phenols, polyphenols, nonphenolic dyes, amino phenols, and aromatic diamines [5]. These substrates are oxidized through electron transfer to molecular oxygen. The molecular oxygen is further reduced to H2O molecule, with complete oxidation of the substrate compound [24]. This type of enzymes is one of the oldest types that has been discovered by Yoshida in 1883 and detected in higher plants, insects, fungi, and several bacteria [43].

Majority of the laccases have been detected in fungi, but recently bacterial laccases have gained increasing attention through overcoming the disadvantages of other laccases. They are characterized by being highly active, easily handled, and more stable at high pH and temperature [37]. Laccases have been extensively used in biotechnological applications as xenobiotics bioremediation, biobleaching, biosensors, food industry, decolorization of textile dyes, cosmetic, dermatological preparations as well as degradation of lignin in lignocelluloses to produce biofuels [46, 47]. It was reported that various bacteria produce extracellular laccase. The discovery of spore laccase of Bacillus species 20 years ago attracted attention of scientific and industrial communities. Spore laccase is one coat protein of the spores of some Bacilli which is naturally resistant to alkaline and acidic pH, high temperature, ultraviolet radiation, hydrogen peroxide, organic solvents, and other harsh chemical and physical conditions [16].

While most of the environmental conditions as high salt concentration, intense temperature, high pH and presence of heavy metals can affect enzymes during their applications, immobilization of enzymes on supports seems to provide a solution to this problem [40] with more suited properties for immobilized enzymes [54]. Enzyme immobilization is a technique designed for restricting the freedom of enzyme movement through its fixation on or into a support material [9]. Immobilization is most frequently used for stabilization of the enzyme. In addition, it allows its simple separation, reduces enzyme replacement, increases its reusability, and enables the enzymes to be applied in continuous system with ease of reaction control [33]. Other advantages of immobilization include increase of thermal stability, resistance against denaturalizing agents, more flexibility in bioreactors design, and contamination prohibition caused by proteins in the final product. Immobilized laccases have been used in various applications such as enzyme-based fuel cells [39], treatment of olive oil mill wastewater [4], decolorization of dyes [56], and construction of biosensors [42].

In recent years, the immobilization of laccases has been studied for bioremediation of dyes wastewater. Using immobilized laccase instead of the free enzyme or the living microorganism is practice wise due to the reusability of the immobilized enzyme and meanwhile avoids the formation of sludge or biomass.

In a previous study, we isolated a novel spore laccase enzyme from Bacillus amyloliquefaciens A1 with superior organic solvents, salts and hydrogen peroxide stability [16]. Spore laccase enzyme understudy has good characteristics that make it a promising candidate in the industrial and biotechnological applications. This enzyme will be promising in application for dyes wastewater remediation especially those contain solvents, heavy metals and other organic pollutants. It is known that spore laccase is one of the proteins of spore coat. It naturally immobilized to the spores. However, it is difficult to separate the spores after the reaction to add them to a new reaction. Therefore, the entrapment or adsorption of the spores to supports facilitates simple separation of spore laccase, reusability, increase the enzyme stability and make it more suitable for industrial application.

The present study aims to expand the existing attitude toward the immobilization of spore laccase by two techniques to achieve maximum immobilization yield. The characterization of immobilized spore laccase in comparison to un-immobilized one was investigated. Also, the efficiency of the immobilized enzyme for decolorization of some textile dyes was assessed. Finally, the phytotoxicity of the dye-contaminated water after treatment with immobilized spore laccase was studied.

Materials and methods

Microorganism

Bacillus amyloliquefaciens A1 (GenBank accession number MF765339) was isolated from industrial textile wastewater effluent (Clover Brook Textile Company, Cairo, Egypt) and produced spore laccase with high stability in the presence of salts, organic solvents and hydrogen peroxide [16].

Preparation of spore laccase

Bacillus amyloliquefaciens A1 was cultured in 250-mL Erlenmeyer flask contains 25 mL of modified LB medium (tryptone, 10 g/L; yeast extract, 6 g/L; glucose, 10 g/L; FeCl3 (10–5 M) and MnCl2 (10–6 M)). It was incubated for 7 days at 30 ℃ under shaking condition at 140 rpm. After that, it was centrifuged at 5000 rpm for 30 min. The precipitate fraction was washed by sterile distilled water then resuspended in 5 mL of sterile distilled water and used as the spore laccase enzyme source for immobilization.

Immobilization technique

All immobilization processes were performed under sterile conditions. The immobilization of spore laccase by entrapment in agar, agarose, calcium alginate or polyacrylamide gels was performed according to Trelles and Rivero [50] and immobilization by adsorption was according to Jesionowski et al. [23].

Entrapment into agar and agarose gel

Agar and agarose (2%) in saline solution were autoclaved and cooled at 40–45 ℃. Five mL of agar and agarose solution was added to 5 mL of spore suspension and mixed well then dropped by syringe in chilled sunflower oil in ice bath under mild stirring. The formed beads were cured in sunflower oil for 2 h at 4 ℃. Then the beads were washed three times with hexane and twice with saline solution. Finally, they were stored at 4 ℃. Agar and agarose beads were prepared without spore suspension as controls.

Entrapment into calcium alginate beads

Sodium alginate (2%) in saline solution was autoclaved for 5 min. Five mL of sodium alginate was added to 5 mL of bacterial suspension and mixed well. The suspension was dropped by syringe into a sterile 250-mL Erlenmeyer flask containing 50 mL of cold sterile 2% calcium chloride. The formed beads were cured in calcium chloride for 1 h then washed several times with sterile saline solution and stored at 4 ℃. Calcium alginate beads were prepared without spore suspension as control.

Entrapment in 30% polyacrylamide gel

Acrylamide (30%) was prepared by adding 29.2% of acrylamide to 0.8% bisacrylamide and dissolved in sterile distilled water. Five mL of the spore suspension was added to the acrylamide mixture. Then tetramethylethylenediamine (TEMED) and 10% ammonium persulphate were added and gently stirred. The mixture was poured in sterile Petri dish and kept about 20 min for polymerization then washed by sterile saline solution. The gel was cut into small pieces about (1 × 1 cm2) and stored at 4 ℃. Polyacrylamide gel was prepared without spore suspension as control.

Immobilization of spore laccase by adsorption method

All tested supports including stainless steel fiber, glass wall, glass beads, loofah, synthetic sponge, polyurethane foam were boiled for 10 min and then washed several times by distilled water and dried at 60 ℃ for 3 h. Each support was cut into small pieces. Polyurethane foam pieces were soaked in 5% HCl for 1 h, washed to be neutral then soaked in 5% NaOH for another 1 h and washed by water several times to be neutral and dried. The immobilization test was performed on supports with and without glutaraldehyde treatment. Glutaraldehyde used as a cross-linker of ionically absorbed bio-molecules on solid surfaces as a strategy to covalently immobilize proteins.

The tested supports were treated with glutaraldehyde by adding 1 g of support to 10 mL of 0.1% glutaraldehyde and incubated under shaking conditions (140 rpm) for 16 h then collected by centrifugation at 5000 rpm and washed several times with distilled water to remove the excess of glutaraldehyde.

Two methods for spore laccase immobilization were evaluated on both glutaraldehyde treated and untreated supports. In the first method, two sets of 250-mL Erlenmeyer flasks containing 25 mL of optimized LB medium were prepared. To one set, 1 g of supports was added separately. To the other set, 1 g of glutaraldehyde-treated supports was added then both sets were autoclaved. They were inoculated with 1 mL of overnight grown Bacillus amyloliquefaciens A1 in NB and incubated for 7 days under shaking conditions. In the second method, 25 mL of saline solution was added to 1 g of each carrier either treated or untreated with glutaraldehyde then autoclaved. Five mL of spore suspension was added to the carriers and incubated at 30 ℃ for 24 h under shaking conditions. The solutions were filtered with filter paper and the precipitates were washed three times by sterile distilled water. Immobilized spore laccase was stored at 4 ℃. The activity of spore laccase before and after the immobilization was determined and the immobilization yield was calculated as follows:

Aa is the total activity of spore laccase used before immobilization and Aw is the total activity of spore laccase in wash after immobilization.

Optimization of immobilization conditions

This approach depends on studying a number of different values for one factor while keeping the remaining factors constant. All carried experiments were conducted in 250-mL Erlenmeyer flasks and agitated on a rotary shaker.

The influence of agarose concentration (0.5–8%) on spore laccase entrapment was tested.

Also, agarose solution (0.5%) was tested for immobilization of different quantities of spores (1–20 mL).

Characterization of immobilized enzyme

Optimum temperature and thermal stability

The optimum temperature for maximum activity of immobilized spore laccase was determined by incubation of 50 mg of immobilized enzyme with 2.5 mL of 10 mM guaiacol at different temperatures (20–100 ℃) for 30 min. For thermal stability, the immobilized spores were incubated for 0–120 min in a water bath at different temperatures (50, 60 and 70 ℃), then the spore activity was determined.

Optimum pH and pH stability

For the detection of the optimum pH of the immobilized spore laccase, 50 mg of immobilized spore laccase was mixed with 2.5 mL of 10 mM guaiacol prepared at different pH values using citrate phosphate buffer (pH 3, 4.5, 6 and 7), Tris–HCl buffer (pH 7.5, 8, 8.5 and 9), phosphate buffer (pH 6, 7, 7.5 and 8) and carbonate–bicarbonate buffer (pH 9, 9.5, 10 and 10.5) then incubated at 60 ℃ for 30 min. While, for pH stability, the residual activity of immobilized spore laccase was evaluated after incubation of spores at different pH values (6, 7 and 7.5) for 1 h, 6 h and 24 h.

Storage stability

The free and immobilized spore laccase were stored at 4 ℃ in saline solution for 2 months and the activity was determined every week.

Operational stability

The operational stability of spore laccase was determined by incubation of immobilized enzyme with 10 mM guaiacol at 60 ℃ for 30 min. Then, the immobilized spore laccase was collected by filtration, washed with buffer and resuspended in freshly prepared substrate to start a new run. The enzyme activity of immobilized spore laccase was assayed after each run.

Dye decolorization using immobilized spore laccase

Dye-contaminated water samples were prepared using sterile tap water containing different types of dyes (8 dyes) and were tested for their decolorization ability by the immobilized spores. These dyes were selected based on their structural diversity and their significant contribution to water pollution. The decolorization was carried out for 24 h using: acid red 337, acid blue 335, direct red 81, acid black 24, methylene blue, crystal violet, Congo red and methyl orange. Dyes used and their structure, λmax, molecular formula and weight were summarized in Table 1. Decolorization efficiency was evaluated according to El-Bendary et al. [15]. In order to evaluate the reusability of the immobilized spore laccase beads in the decolorization of the tested dyes, they were filtered after the first decolorization cycle then new preparations of textile dyes were added and the decolorization test was repeated.

Dye decolorization was performed in 250-mL Erlenmeyer flasks containing 25 mL of 100 mg/L of the tested dye. These flasks were treated with 1.5 gm of immobilized spore laccase or 1.5 gm of agarose beads without spore laccase (control) and incubated at 30 ℃ under shaking conditions. Portions of the solutions of test sets and controls were centrifuged at 5000 rpm for 30 min and the supernatants were used for optical density measurements at λmax of each dye. Decolorization percent was calculated using the following equation [22]:

where A: absorbance of control; B: absorbance of treated dye solution.

Spore laccase enzyme activity

Spore laccase activity was determined spectrophotometrically following Sondhi and Saini [46] using guaiacol as a substrate. In brief, 50 mg of immobilized spore laccase was mixed with 2.5 mL of 10 mM guaiacol in phosphate buffer at pH 6. The mixture was incubated for 30 min at 60 ℃ in water bath followed by reaction cessation in an ice bath for 15 min. The absorbance was determined using UV–visible spectrophotometer at 470 nm. The unit of enzyme activity is the amount of enzyme required for the oxidation of one µmole of guaiacol/min. Laccase activity was expressed as U/g and calculated using the following equation:

where EA: enzyme activity (U/g); A: absorbance at 470 nm; V: total volume of reaction mixture (mL); v: enzyme quantity (g); t: incubation time (min); e: extinction coefficient (6740 M−1 cm−1).

Application of treated water for reuse in irrigation (phytotoxicity)

In order to evaluate the validity of treated dye-contaminated water for reuse in irrigation, phytotoxicity test of crystal violet on lentil seeds germination was determined as described by Lade et al. [26]. Four sets of Petri dishes were prepared to host 10 seeds of lentils per each dish. The first set was watered with tap water (control), the second set was watered with 100 mg/L crystal violet dye, the third set was watered with un-immobilized spore laccase-treated dye solution, and the last set was watered with the immobilized spore laccase-treated dye solution. The phytotoxicity was evaluated in terms of calculating the following formulas [19]:

Values of GI < 50% are considered highly toxic to the plant, GI values ranging between 50 and 80% indicate low toxicity, while GI values ˃ 80% are of no phytotoxic effect.

Statistical analysis

All experiments were repeated in triplicates. Data were expressed as mean values ± standard errors using the Statistical Package for the Social Sciences (SPSS) version 18.0; including one-way ANOVA test for the normally distributed data at 0.05 level to determine significance between different means.

Results and discussion

Immobilization of spore laccase

Immobilization of enzyme is the confinement of the enzyme molecules onto or within a support matrix either physically or chemically or both, in a way that retains its activity [20]. Figure 1 shows the immobilization efficiency by entrapment method. The contour lines indicated that the agarose gel was the most efficient carrier for immobilization of spore laccase with 94% immobilization yield followed by calcium alginate then agar with immobilization yield of about 65 and 53%, respectively. Meanwhile, acrylamide gel showed very low immobilization yield (only 15%). On the other hand, it is noticeable from the 100% stacked columns represented in Fig. 2 that among glutaraldehyde untreated supports; glass wall was the most dominant carrier and represented about 28.2% of the total tested supports giving immobilization yield 14%, followed by natural loaf and natural sponge (24.1%) with immobilization yield 12%. Among glutaraldehyde-treated supports, synthetic sponge was the most dominant carrier and represented about 23.8% with immobilization yield 16%. In general, the adsorption method showed inferior immobilization yield (only 0.2–16%) with different tested supports either glutaraldehyde treated or untreated (Table 2) compared to the entrapment method. Accordingly, entrapment method was selected in subsequent tests.

The use of immobilized enzyme has many important advantages over the free enzyme including ease of handling, stability, increased localization, reusability, and a decrease in operation costs [21]. Although, various immobilization techniques as entrapment, crosslinking, and adsorption have been used for enzymes or cells immobilization, the entrapment method was found to be a potential choice for this aim being gentle, simple, and most effective [14, 30]. It involves catching of the enzyme within a polymeric network that allows both substrate and product to pass through, meanwhile retains the enzyme activity. It differs from other coupling methods, in which the enzyme is not bound to the matrix or membrane [1]. Agarose gel is considered one of the most efficient materials used for entrapment. It is non-toxic, biocompatible and capable of preserving the enzyme activity during the immobilization process as reported by Sassolas et al. [44].

Comparing the obtained results in this study to others that available from literature, Lu et al. [31] reported that laccase activity of Bacillus amyloliquefaciens LC02 spores entrapped in calcium alginate beads attained 51% yield. The immobilized enzyme presented absolute activity value lower than that obtained for the free enzyme during the oxidation of guaiacol. This evidence can be explained by the mass transfer limitations of the substrate [45]. On the other hand, Khakshour et al. [25] achieved the optimum entrapment conditions in the presence of sodium alginate 2% for the marine Bacillus sp. KC2 spore laccase.

Optimum conditions for immobilization process

Immobilization process needs to be optimized to minimize the loss of enzyme activity and achieve the maximum reusability and stability.

Effect of agarose concentration

Agarose concentration is the most influential factor on immobilization yield of the enzyme. As shown in Fig. 3a, the immobilization rate gradually increases with increasing agarose concentration from 0.5 to 1% then progressively decreased with increasing the agarose concentration to 4%. This might be attributed to the leakage of the enzyme that occurred due to the loose structure of agarose beads prepared at 0.5%. On the other hand, an increase in agarose concentration would lead to the formation of beads with a more compact gel network, making it difficult for the enzyme to leak out from the beads [55]. At higher concentrations of agarose, the compact structure of the beads might decrease the flexibility of the enzyme as well as limit the diffusion of the substrate, leading to a low activity of the immobilized enzyme [30].

Effect of spore laccase concentration

As given in Fig. 3b, the activity of immobilized spore laccase was increased by about eightfold with increasing the concentration of spore laccase from 1 to 10 mL. However, at 20 mL spore concentration, the increase in activity was not much recognizable. In this respect, Zhou et al. [58] mentioned that the relative activity of immobilized Bacillus pumilus W3 spore laccase on DEAE-cellulose was increased rapidly with the increasing the spore amount and reached the maximum activity (100%) at 50 mg/g (wet spores per g dry weight of DEAE-cellulose).

Characterization of immobilized spore laccase

Effect of temperature on activity and stability

Figure 4a shows that the optimum temperature of the immobilized and free spore laccase was at 60 ℃. The activity of immobilized spore laccase decreased about 9% when the reaction was performed at 70 ℃ compared to the free enzyme and it lost the activity at 100 ℃. This is due to the fact that at higher temperatures, the enzyme becomes denatured and loses the three-dimensional structure, leading the enzyme activity to be declined or completely disappeared [49]. In accordance with these data, the optimum temperature of immobilized spore laccase of Bacillus licheniforms LS04 was found to be similar to the free enzyme as reported by Lu et al. [32].

Table 3 shows the thermal stability of immobilized spore laccase at 50–80 ℃ for 120 min. The immobilized spore laccase was stable at 50 and 60 ℃ for 120 min. At 70 ℃ it was completely stable for 60 min then the activity decreased about 29 and 34% after incubation for 90 and 120 min, respectively. While, at 80 ℃, it retained about 100% of its activity after incubation for 40 min, then further incubation times (60, 90 and 120 min) showed reduction in the activity (14, 39 and 58%, respectively). Similarly, the free spore laccase was also stable at 50 and 60 ℃ for 120 min of incubation, while at 70 ℃ about 32 and 38% of its activity were lost after 90 and 120 min of incubation, respectively. At 80 ℃, it retained full activity after incubation for 40 min however; it showed more reduction in the enzyme activity (16, 41 and 62%) after incubation for 60, 90 and 120 min, respectively. It is clear that the thermal stability of immobilized spore laccase slightly increased more than un-immobilized spore laccase. Thermal stability of the immobilized enzyme is one of the most important criteria with respect to the industrial applications. Notably, laccase immobilization led to a significant stabilizing effect towards heat denaturation and the increased resistance to thermal denaturation offers a potential advantage in wastewater treatment applications as mentioned by Lu et al. [30].

It is worth mentioning that, the immobilization can enhance the stability of enzyme by steadiness of its three-dimensional structure, which results in a higher resistance to conformational changes induced by heat, pH and organic solvents [21]. Also, it was mentioned that the enhanced stability and resistance to denaturation is an important property of immobilized enzymes as observed in several previous studies [6, 38].

Effect of pH on activity and stability

As given from Fig. 4b, the maximum activity of immobilized spore laccase was at pH 6–7 using citrate–phosphate buffer or sodium phosphate buffer. It was the same profile of un-immobilized enzyme as tested in a previously published work [16]. Regarding the pH stability of immobilized spore laccase, it showed high stability at pH 6–7.5 with 91% of its activity retained after 24 h incubation (Fig. 4c). It is worth noting that immobilized spore laccase was more pH stable than un-immobilized one which showed a reduction in activity after incubation for 24 h at pH 6–7.5 about 15.5–33.4%.

In accordance with these results, Zhou, et al. [58] reported that the activity of immobilized spore laccase was increased with increasing pH and reached the maximum activity at pH 10 using Bacillus pumilus W3. However, the residual activity of immobilized spore laccase retained 52% and 46% of its initial activity, respectively, at pH 7 and 9 after 10 days of incubation. The pH stability of immobilized spore laccase from Bacillus vallismortis fmb-103 is similar to that of Bacillus pumilus W3 spore laccase [57]. It was evident that immobilization significantly improved the stability of laccase and increased its resistance to inactivation with pH changes.

Storage stability

One of the main goals of any immobilization process is to extend the storage time of the enzymes. Accordingly, storage stability of the immobilized system is very inevitable for successful bio-treatment practices. As shown in Fig. 4d, the immobilized spore laccase enzyme was quite stable when stored at 4 ℃ for 8 weeks. Meanwhile, the un-immobilized enzyme activity was stable for only 4 weeks, after which the activity decreased about 24–39% when storage extended for 5–8 weeks. This enhanced stability of immobilized enzyme is probably a result of autolysis prevention by immobilization.

Laccases in their free forms are not stable under normal storage conditions, as room temperature or under refrigeration where, they loose activity gradually over time as mentioned by Majeau et al. [34]. This is may be due to the denaturation of proteins over time and this problem can be resolved by immobilization. Also, the improved stability of immobilized laccase may be due to the improvement in its active conformation [29].

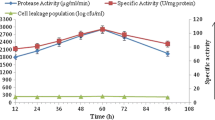

Operation stability

Operation stability refers to the potential of the immobilized enzyme for reusability. The obtained results represented in Fig. 4e illustrate the durability of immobilized spore laccase in repeated use for 8 consecutive cycles with retained activity up to 86%. The high operational stability of laccase immobilized using various supports have been stated in earlier report [31]. Reusability of the entrapped laccase was also studied by Mogharabi et al. [35] who reported that 85% of the immobilized enzyme activity was retained after five successive cycles. In another investigation, Crestini et al. [10] found that the extracellular laccase enzyme immobilized by micro-encapsulation retained 68% of its activity, while the retained activity of laccase enzymes immobilized on alumina pellets was 84% after 10 cycles. It was suggested that the reusability of the immobilized laccase was dependent upon the type of the used substrate, and that the decrease in activity during recycling could be due to the adsorption of the end product on the carrier, thereby limiting the substrate/product diffusion [8].

Dye decolorization by immobilized spore laccase and proposed mechanism

Table 4 shows the efficiency of decolorization for different textile dyes by Bacillus amyloliquefaciens A1 immobilized spore laccase as observed in this study. High decolorization percentages (94.5, 77.4, and 68.8%) were obtained for crystal violet, direct red 81, and acid black 24, respectively, within 24 h of incubation after the first run cycle, while the minimum decolorization effect was observed for Congo red (26.4%). It was evident from the results that, there are variations in the capability of free and immobilized spore laccase to decolorize the tested dyes. This may be attributed to the ability of immobilization process to modify the activity, selectivity, and equipped permanence of the used enzyme [3].

Comparing the present results to those published in a previous work using un-immobilized spore laccase [16], the efficiency of crystal violet decolorization by immobilized enzyme was increased by about 1.6-fold. Generally, dye decolorization by immobilized enzyme is a responsive result to both enzymatic catalysis and adsorption to the support. Many reports about dye decolorization with immobilized laccase confirmed the significant role of support adsorption in contribution to color removal [30].

On the other hand, the reusability of immobilized spore laccase constitutes an important aspect in industrial applications and also in decreasing the process expenditures [12]. As presented in Table 4, the immobilized spore laccase could retain about 79, 69 and 68% of its initial activity in the 2nd cycle of decolorization for crystal violet, direct red 81 and acid black 24, respectively. As recognized from the given results, the advantage of using immobilized spore laccase for dye removal is not only increasing the enzyme stability, but also in its reusability [13].

Lu et al. [31] reported that the spore laccase of Bacillus amyloliquefaciens LC02 entrapped in calcium alginate beads showed 99% decolorization of indigo carmine after fifteen cycles of repeated use in the presence of acytosyringone as mediator. They reported also that high decolorization was achieved for reactive black 5 and crystal violet.

In another study, spore laccase of Bacillus pumilus W3 was efficiently immobilized on amino-functionalized celite and used for dye decolorization. It showed 84 and 70% decolorization for methyl green and acid red 1 after 98 h of treatment, respectively at 37 ℃. Also, it retained 51%, 63% and 74% of its initial decolorization activity for decolorization of methyl green, methyl red and acid red 1 after 7 cycles of reuse [58]. It was concluded that the immobilized spore was active in the second cycle, but the decolorization value was decreased and this may be related to enzyme inactivation, blocking of pores or leakage of enzyme from beads at the end of the first cycle. These restrictions may decrease activity of immobilized enzyme.

Information about laccase-catalyzed decolorization and biodegradation of dyes as well as the exact oxidized products has been reported in literature [7, 36, 41]. A simple proposed mechanism involves oxidation of the substrate (dye) by only oxygen in the presence of a catalyst (immobilized laccase) as shown in Fig. 5. Up on oxidation, the dye loses an electron that moves from one Cu2+ atom to another in the site of catalysis of the enzyme, until finally oxygen is reduced releasing water. As known, laccases typically contain four copper (Cu) atoms per molecule which are categorized into three types; T1 (one copper atom), T2 (one copper atom), and T3 (two copper atoms). The copper atoms are responsible for laccase catalytic activity and mediate the oxidation–reduction process. At stationary phase, all of the copper ions are at 2 + oxidation state. In catalytic phase, the substrate (dye) is oxidized by the mononuclear copper (T1), which behaves as an electron acceptor and changes the oxidation state of Cu2+ into Cu+. After removing an electron from the dye, a cationic radical (unstable) is formed which can be readily oxidized in a second enzymatic reaction. The electron removed from the dye at T1 location is moved to the T2/T3 centers at which reduction of O2 to H2O takes place. In order to completely reduce the molecular oxygen to water, four molecules of the dye (RH-reducing substrate) are needed according to the following stoichiometric enzymatic reaction:

Application of treated water for reuse in irrigation (phytotoxicity)

Increasing the pressure on conventional water resources is expected to expose approximately 60% of the world’s population to serious water scarcity by the year 2025 [53]. Wastewater treatment and reuse seems to be an attractive and practical option among other non-conventional water resources [52]. Crystal violet is a cationic dye belonging to the class triphenyl methyl dyes, with molecular formula C25H30N3Cl and molecular weight 407.98 g/mol. It is used in several manufacturing applications, including textile and leather industry, paper dyeing, printing inks, as well as a principal ingredient in Gram’s stain. Discharging wastewater containing this dye is considered potential biohazard since it is classified as a carcinogenic agent causing several health drawbacks ranging from skin, eyes, and digestive tract irritations to permanent blindness and respiratory system and kidney failure [2].

From this stand point, it is important to evaluate the phytotoxicity of treated dye-contaminated water before reuse in irrigation. In the present study, lentil seeds were selected for this assay. As given in Table 5, seeds irrigated with water (control) showed 90.0% germination with mean shoot and root lengths, respectively, 7.8 and 2.3 cm. On the other hand, lentil seeds irrigated with contaminated water containing 100 mg/L crystal violet dye showed recognizable reduction percentages in germination, shoot, and root lengths reaching about 66.7%, 57%, and 67.4%, respectively. Unlikely, reduction percentages for the seeds watered with dye solution decolorized by immobilized spore laccase did not exceed 11.1%, 21.8%, and 17.4% for the same factors in the same order. Compared to dye solution decolorized by un-immobilized spore laccase, certainly immobilization could achieve better germination results as given from obtained data in this study. The germination index (GI = 73.3%) revealed the lowest toxicity effect of degradation products on lentil seeds irrigated with treated water by immobilized spore laccase as compared to free spore laccase treated (GI = 57.4%) and untreated water (GI = 10.8%).

Conclusions

This study presented the potential of spore laccase enzyme of Bacillus amyloliquefaciens strain A1 immobilized on agarose gel for textile dye decolorization in dye-contaminated water. The immobilization efficiency of tested spore laccase was optimized. The immobilized spore laccase was thermally active at 60 ℃ and thermally stable at 50–80 ℃ for 120 min. Moreover, it retained its complete activity after 2 months of storage at 4 ℃. The immobilized spore laccase could maintain up to 86% of its activity after 8 consecutive cycles of durability (reuse). Out of eight tested dyes, the immobilized enzyme showed recognizable efficiency in decolorization of crystal violet, direct red 81, and acid black 24 dyes. Water contaminated with 100 mg/L crystal violet was successfully converted into value-added treated water and reused for irrigation of lentil seeds. Future plans will be devoted to mediate the process through a bioreactor in order to optimize large-scale production of immobilized spore laccase and reduce the cost for feasible implementation in wastewater treatment plants/and or textile industrial facilities. Subsequent reuse of the treated water in irrigation purposes will be applied. The protocol of treatment system we present is expected to offer a facile and cost-effective management for water contaminated with textile dyes in accordance to the aims of reusability and sustainability.

Availability of data and materials

The datasets generated and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

AL-Saady AJR, Al-Bahrani MHA, Aziz GM (2018) Characterization and immobilization of peroxidase extracted from horse radish and decolorization of some dyes. Int J Curr Microbiol Appl Sci 7:328–339

Arora C, Sahu D, Bharti D, Tamrakar V, Soni S, Sharma S (2019) Adsorption of hazardous dye crystal violet from industrial waste using low-cost adsorbent Chenopodium album. Desalination Water Treat 167:324–332

Asgher M, Iqbal HM, Asad MJ (2012) Kinetic characterization of purified laccase produced from Trametes versicolor IBL-04 in solid state bio processing of corncobs. Bioresource 7:1171–1188

Berrio J, Plou FJ, Ballesteros A, Martinez AT, Martinez MJ (2007) Immobilization of Pycnoporus coccineus laccase on Eupergit C: stabilization and treatment of olive oil mill waste waters. Biocatal Biotransform 25:130–134

Bhattacharyya A, Ahmed M, Wadhwa R, Aggarwal S, Mustafz M, Rajagopalan G (2022) High production of Trametes cinnabarina Laccase (lac1) by suspended and immobilized cells of recombinant Pichia pastoris from crude glycerol. Waste Biomass Valoriz 13:2149–2168

Brena B, Gonzalez-Pombo P, Batista-Viera F (2013) Immobilization of enzymes: a literature survey. Methods Mol Biol 1051:15–31

Brugnari T, Braga DM, dos Santos CSA, Torres BHC, Modkovski TA, Haminiuk CWI, Maciel GM (2021) Laccases as green and versatile biocatalysts: from lab to enzyme market—an overview. Bioresour Bioprocess 8:131

Bryjak J, Kruczkiewicz P, Rekuc A, Peczynska-Czoch W (2007) Laccase immobilization on copolymer of butyl acrylate and ethylene glycol dimethacrylate. Biochem Eng J 35:325–332

Cao L (2006) Adsorption-based Immobilization. In: Coa L, Schmid RD (eds) Carrier-bound Immobilized Enzymes: principles, application and design. Wiley-VCH, Weinheim, pp 169–189

Crestini C, Perazzini F, Saladino R (2010) Oxidative functionalization of lignin by layer-by-layer immobilised laccases and laccase microcapsules. Appl Catal A Gener 372(2):115–123

Datta S, Veena R, Samuel MS, Selvarajan E (2021) Immobilization of laccases and applications for the detection and remediation of pollutants: a review. Environ Chem Lett 19:521–538

Dhokane JP, Bholay AD, Nalawade PM (2017) Bacterial alkaline laccase and its environmental applications. IOSR J Pharm Biol Sci (IOSR-JPBS) 12:1–09

Dodor DE, Hwang HM, Ekunwe SIN (2004) Oxidation of anthracene and benzo[a]pyrene by immobilized laccase from Trametes versicolor. Enzyme Microb Technol 35(2):210–217

Duran N, Rosa MA, D’Annibale A, Gianfreda L (2002) Applications of laccase and tyrosinases (phenol oxidases) immobilized on different supports: a review. Enzyme Microb Technol 31:907–931

El-Bendary MA, Ewais EA, Ezzat SM, Al-Zalama MA (2019) Process optimization of the bio-decolorization of textile dyes by spore-bound laccase of Bacillus amyloliquefaciens. Curr Trend Microbiol 13:23–33

El-Bendary MA, Ezzat SM, Ewais EA, Al-Zalama MA (2021) Optimization of spore laccase production by Bacillus amyloliquefaciens isolated from wastewater and its potential in green biodecolorization of synthetic textile dyes. Prep Biochem Biotechnol 51(1):16–27

El-Sharkawy RM, El-Shora HM (2020) Improvement of synthetic dyes decolorization by immobilized laccase from Penicillium sp. MN749552.1. Res J Pharm Biol Chem Sci (RJPBCS) 11(1):151–162

El-Shora HM, Khateb AM, Darwish DB, El-Sharkawy RM (2022) Thiolation of Myco-Synthesized Fe3O4-NPs: A Novel Promising Tool for Penicillium expansium laccase immobilization to decolorize textile dyes and as an application for anticancer agent. J Fungi 8:71

Gomare SS, Parshetti GK, Govindwar SP (2009) Biodegradation of malachite green by Brevibacillus laterosporus MTCC 2298. Water Environ Res 81:2329–2336

Guisan JM (2013) Immobilization of enzymes and cells. In: Guisan JM (ed) Third edition, Methods in molecular biology, vol 1051. Springer Scientist Business Media New york, Dordrecht

Guzik U, Hupert-Kocurek K, Wojcieszyńska D (2014) Immobilization as a strategy for improving enzyme properties-application to oxidoreductases. Molecules 19(7):8995–9018

Hossen MdZ, Hussain MdE, Hakim Al, Islam K, Uddin MdN, Azad AK (2019) Biodegradation of reactive textile dye Novacron Super Black G by free cells of newly isolated Alcaligenes faecalis AZ26 and Bacillus spp. obtained from textile effluents. Heliyon 5:e02068

Jesionowski T, Zdarta J, Krajewska B (2014) Enzyme immobilization by adsorption: a review. Adsorption 20:801–821. https://doi.org/10.1007/s10450-014-9623-y

Kadam AA, Saratale GD, Ghodake GS, Saratale RG, Shahzad A, Magotra VK, Kumar M, Palem RR, Sung JS (2022) Recent advances in the development of laccase-based biosensors via nano-immobilization techniques. Chemosensors 10:58

Khakshour M, Makhdoumi A, Asoodeh A, Hosseindokht MR (2021) Co-immobilized spore laccase/TiO2 nanoparticles in the alginate beads enhance dye removal by two-step decolorization. Environ Sci Pollut Res. https://doi.org/10.1007/s11356-020-10901-1

Lade HS, Waghmode TR, Kadam AA, Govindwar SP (2012) Enhanced biodegradation and detoxification of disperse azo dye rubine GFL and textile industry effluent by defined fungal–bacterial consortium. Inter Biodet Biodeg 72:94–107

Ledakowicz S, Pa´zdzior K (2021) Recent achievements in dyes removal focused on advanced oxidation processes integrated with biological methods. Molecules 26:870

Liu Y-Q, Maulidiany N, Zeng P, Heo S (2021) Decolourization of azo, anthraquinone and triphenylmethane dyes using aerobic granules: acclimatization and long-term stability. Chemosphere 263:128312

Lonappan L, Liua Y, Rouissia T, Pourcela F, Brara SK, Vermaa M, Surampalli RY (2018) Covalent immobilization of laccase on citric acid functionalized microbiochars derived from different feedstock and removal of diclofenac. Chem Eng J 351:985–994

Lu L, Zhao M, Wang Y (2007) Immobilization of laccase by alginate–chitosan microcapsules and its use in dye decolorization. World J Microbiol Biotechnol 23:159–166

Lu L, Zhao M, Li GF, Li J, Wang TV, Li DB, Xu TF (2012) Decolorization of synthetic dyes by immobilized spore from Bacillus amyloliquefaciens. Catal Commun 26:58–62

Lu L, Zhao M, Wang TN, Zhao LY, Du MH, Li TL, Li DB (2012) Characterization and dye decolorization ability of an alkaline resistant and organic solvents tolerant laccase from Bacillus licheniformis LS04. Bioresource Technol 115:35–40

Maghraby YR, El-Shabasy RM, Ibrahim AH, Azzazy HME (2023) Enzyme immobilization technologies and industrial applications. ACS Omega 31:5184–5196. https://doi.org/10.1021/acsomega.2c07560

Majeau JA, Brar SK, Tyagi RD (2010) Laccases for removal of recalcitrant and emerging pollutants. Bioresource Technol 101:2331–2350

Mogharabi M, Nassiri-Koopaei N, Bozorgi-Koushalshahi M, Nafissi-Varcheh N, Bagherzadeh Gh, Faramarzi MA (2012) Immobilization of laccase in alginate-gelatin mixed gel and decolorization of synthetic dyes. Bioinorg Chem Appl 8:823830

Morsy SAGZ, Tajudin AA, Ali MSM, Shariff FM (2020) Current development in decolorization of synthetic dyes by immobilized laccases. Front Microbiol 11:572309

Narayanan MP, Murugan S (2014) Production, purification and application of bacterial laccase: a review. Biotechnol 13(5):196–205

Nguyen LN, Hai FI, Dosseto A, Richardson C, Price WE, Nghiem LD (2016) Continuous adsorption and biotransformation of micro-pollutants by granular activated carbon-bound laccase in a packed-bed enzyme reactor. Bioresource Technol 210:108–116

Nogala W, Rozniecka E, Zawisza I, Rogalski J, Opallo M (2006) Immobilization of ABTS-laccase system in silicated based electrode for bioelectrocatalytic reduction of dioxygen. Electrochem Commun 8:1850–1854

Patila M, Athanasiou PE, Kortessis L, Potsi G, Kouloumpis A, Gournis D, Stamatis H (2022) Immobilization of laccase on hybrid super-structured nanomaterials for the decolorization of phenolic dyes. Processes 10:233

Pavlović J, Farkas Z, Kraková L, Pangallo D (2022) Color stains on paper: fungal pigments, synthetic dyes and their hypothetical removal by enzymatic approaches. Appl Sci 12:9991

Rodríguez-Delgado G, Alemán-Nava GS, Rodríguez-Delgado JM, Dieck-Assad G, Martínez-Chapa SO, Barceló D, Parra R (2015) Laccase-based biosensors for detection of phenolic compounds. Trends Analy Chem 74:21–45

Rostami A, Abdelrasoul A, Shokri Z, Shirvandi Z (2022) Applications and mechanisms of free and immobilized laccase in detoxification of phenolic compounds—A review. Korean J Chem Eng 39(4):821–832

Sassolas A, Blum LJ, Leca-Bouvier BD (2012) Immobilization strategies to develop enzymatic biosensors. Biotechnol Adv 30:489–511

Silva C, Silva CJ, Zille A, Guebitz GM, Cavaco-Paulo A (2007) Laccase immobilization on enzymatically functionalized polyamide 6,6 fibres. Enzyme Microb Technol 41:867–875

Sondhi S, Saini K (2019) Response surface based optimization of laccase production from Bacillus sp. MSK-01 using fruit juice waste as an effective substrate. Heliyon 5:e01718

Sondhi S, Kaur R, Kaur S, Kaur PS (2018) Immobilization of laccase-ABTS system for the development of a continuous flow packed bed bioreactor for decolorization of textile effluent. Int J Biol Macromol 117:1093–1100

Tomar T, Kahandawala N, Kaur J, Thounaojam L, Choudhary I, Bera S (2023) Bioremediation of synthetic dyes from wastewater by using microbial nanocomposites: an emerging field for water pollution management. Biocatal Agric Biotechnol 51:102767. https://doi.org/10.1016/j.bcab.2023.102767

Tortora GJ, Funke BR, Case CL (2004) Microbiology, 8th edn. Pearson Education Inc, San Francisco

Trelles JA, Rivero CW (2013) Whole cell entrapment techniques. Immob Enzymes Cells Methods Mol Biol Methods Protoc 1051:365–374. https://doi.org/10.1007/978-1-62703-550-7_24

Tripathi M, Singh S, Pathak S, Kasaudhan J, Mishra A, Bala S, Garg D, Singh R, Singh P, Singh PK, Shukla AK, Pathak N (2023) Recent strategies for the remediation of textile dyes from wastewater: a systematic review. Toxics 11:940. https://doi.org/10.3390/toxics11110940

Tzanakakis VA, Paranychianakis NV, Angelakis AN (2020) Water supply and water scarcity. Water 12(9):2347

Ungureanu N, Vlăduț V, Voicu G (2020) Water scarcity and wastewater reuse in crop irrigation. Sustainability 12:9055. https://doi.org/10.3390/su12219055

Unuofin JO, Moubasher HA, Okoh AI, Nwodo UU (2019) Production of polyextremotolerant laccase by Achromobacter xylosoxidans HWN16 and Citrobacter freundii LLJ16. Biotechnol Reports 24:e00337

Won K, Kim S, Kim KJ, Park HW, Moon SJ (2005) Optimization of lipase entrapment in Ca–alginate gel beads. Process Biochem 40:2149–2154

Yamak O, Kalkan NA, Aksoy S, Altinok H, Hasirci N (2009) Semi-interpenetrating polymer networks (semi-IPNs) for entrapment of laccase and their use in Acid Orange 52 decolorization. Proc Biochem 44(4):440–445

Zhang C, Zhang S, Diao HW, Zhao HZ, Zhu XY, Lu FX, Lu ZX (2013) Purification and characterization of a temperature- and pH-stable laccase from the spores of Bacillus vallismortis fmb-103 and its application in the degradation of malachite green. J Agric Food Chem 61:5468–5473

Zhou W, Guan ZB, Cai YJ, Chen Y, Zhang N, Liao XR (2017) Preparation and characterization of immobilized spores with laccase activity from Bacillus pumilus W3 on DEAE-Cellulose and their applications in dye decolorization. Braz J Chem Eng 34(1):41–52

Acknowledgements

The authors thank and appreciate National Water Research Center, National Research Centre and Faculty of Science, Al-Azhar University of Egypt for their technical and moral support.

Funding

Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB). Not applicable.

Author information

Authors and Affiliations

Contributions

MAE-B: conceptualization, methodology, formal analysis, investigation, writing original draft, review and editing the final manuscript. SME: conceptualization, methodology, formal analysis, investigation, writing original draft, review and editing the final manuscript. EAE: writing original draft, review and editing and approve the final manuscript. MAA-Z: investigation, writing original draft, review and editing the final manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

All authors have approved to participate and publish this scientific work.

Consent for publication

Not applicable.

Competing interests

The authors declare that they have no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

El-Bendary, M.A., Ezzat, S.M., Ewais, E.A. et al. Efficient immobilization of highly stable Bacillus amyloliquefaciens spore laccase for biodecolorization of textile dyes in water. Environ Sci Eur 36, 36 (2024). https://doi.org/10.1186/s12302-024-00865-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s12302-024-00865-1