Abstract

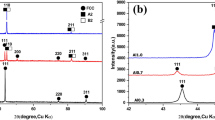

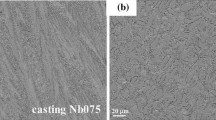

AlCoCrFeNi2.1 eutectic high-entropy alloys (HEAs) are a new kind of alloy with high entropy and eutectic properties. Their advantages in terms of strength and shape matching can be fully exploited using extreme high-speed laser cladding (EHLA). In this paper, AlCoCrFeNi2.1 eutectic HEA coatings were prepared by conventional laser cladding (CLA) and EHLA. The microstructures and phase compositions of the two coatings were analyzed by scanning electron microscopy, x-ray diffraction, and electron backscatter diffraction. The microhardness and wear resistance values of the coatings were tested using a microhardness tester and a friction and wear tester, respectively. The results showed that the surface qualities of both the CLA and EHLA coatings were good and had no cracks or defects. Compared with those of the CLA coating, the EHLA coating had finer grains and a more uniform distribution. Both coatings contained face-centered cubic (FCC) and body-centered cubic (BCC) phases, but the BCC phase of the EHLA coating was less precipitated than the CLA coating. The higher microhardness and better wear resistance of the EHLA coatings occurred in the presence of Hall–Petch strengthening.

Graphical Abstract

Similar content being viewed by others

References

E.P. George, D. Raabe and R.O. Ritchie, High-Entropy Alloys, Nat. Rev. Mater., 2019, 4(8), p 515-534. https://doi.org/10.1038/s41578-019-0121-4

Y. Fu, J. Li, H. Luo et al., Recent Advances on Environmental Corrosion Behavior and Mechanism of High-Entropy Alloys, J. Mater. Sci. Technol., 2021, 80, p 217-233. https://doi.org/10.1016/j.jmst.2020.11.044

P. Sathiyamoorthi and H.S. Kim, High-Entropy Alloys with Heterogeneous Microstructure: Processing and Mechanical Properties, Prog. Mater. Sci., 2022, 123, 100709. https://doi.org/10.1016/j.pmatsci.2020.100709

X. Wang, W. Guo and Y. Fu, High-Entropy Alloys: Emerging Materials for Advanced Functional Applications, J. Mater. Chem., 2021, 9(2), p 663-701. https://doi.org/10.1039/d0ta09601f

J. Luo, W. Sun, R. Duan et al., Laser Surface Treatment-Introduced Gradient Nanostructured TiZrHfTaNb Refractory High-Entropy Alloy with Significantly Enhanced Wear Resistance, J. Mater. Sci. Technol., 2022, 110, p 43-56. https://doi.org/10.1016/j.jmst.2021.09.029

Y. Zhang, T.T. Zuo, Z. Tang et al., Microstructures and Properties of High-Entropy Alloys, Prog. Mater. Sci., 2014, 61, p 1-93. https://doi.org/10.1016/j.pmatsci.2013.10.001

Z. Lei, X. Liu, Y. Wu et al., Enhanced Strength and Ductility in a High-Entropy Alloy via Ordered Oxygen Complexes, Nature, 2018, 563(7732), p 546-550. https://doi.org/10.1038/s41586-018-0685-y

S. Shajahan, A. Kumar, M. Chopkar et al., Oxidation Study of CoCrCuFeNiSix High Entropy Alloys, Mater. Res. Express., 2020, 7(1), 016532. https://doi.org/10.1088/2053-1591/ab640a

X.L. Shang, Z.J. Wang, F. He et al., The Intrinsic Mechanism of Corrosion Resistance for FCC High Entropy Alloys, Sci. China. Technol. Sc., 2018, 61, p 189-196. https://doi.org/10.1007/s11431-017-9114-1

R.O. Ritchie et al., A Fracture-Resistant High-Entropy Alloy for Cryogenic Applications, Science, 2014, 345(6201), p 1153-1158. https://doi.org/10.1126/science.1254581

J.Y. He, W.H. Liu, H. Wang et al., Effects of Al Addition on Structural Evolution and Tensile Properties of the FeCoNiCrMn High-Entropy Alloy System, Acta Mater., 2014, 62(1), p 105-113. https://doi.org/10.1016/j.actamat.2013.09.037

O.N. Senkov, G.B. Wilks, J.M. Scott et al., Mechanical Properties of Nb25Mo25Ta25W25 and V20Nb20Mo20Ta20W20 Refractory High Entropy Alloys, Intermetallics, 2011, 19, p 698-706. https://doi.org/10.1016/j.intermet.2011.01.004

Y. Lu, Y. Dong, S. Guo et al., A Promising New Class of High-Temperature Alloys: Eutectic High-Entropy Alloys, Sci. Rep., 2014, 4(1), p 6200. https://doi.org/10.1038/srep06200

I.S. Wani, T. Bhattacharjee, S. Sheikh et al., Ultrafine-Grained AlCoCrFeNi2.1 Eutectic High-Entropy Alloy, Mater. Res. Lett., 2016, 4(3), p 174-179. https://doi.org/10.1080/21663831.2016.1160451

Y. Lu, Y. Dong, H. Jiang et al., Promising Properties and Future Trend of Eutectic High Entropy Alloys, Scripta Mater., 2020, 187, p 202-209. https://doi.org/10.1016/j.scriptamat.2020.06.022

X. Gao, Y. Lu, B. Zhang et al., Microstructural Origins of High Strength and High Ductility in an AlCoCrFeNi2.1 Eutectic High-Entropy Alloy, Acta Mater., 2017, 141, p 59-66. https://doi.org/10.1016/j.actamat.2017.07.041

P. Shi, R. Li, Y. Li et al., Hierarchical Crack Buffering Triples Ductil-ity in Eutectic Herringbone High-Entropy Alloys, Science, 2021, 373(6557), p 912-918. https://doi.org/10.1126/science.abf6986

Y. Lu, X. Wu, Z. Fu et al., Ductile and Ultrahigh-Strength Eutectic High-Entropy Alloys by Large-Volume 3D Printing, J. Mater. Sci. Technol., 2022, 126, p 15-21. https://doi.org/10.1016/j.jmst.2022.04.004

Y. Zhang, J. Li, X. Wang et al., The Interaction and Migration of Deformation Twin in an Eutectic High-Entropy Alloy AlCoCrFeNi2.1, J. Mater. Sci. Technol., 2019, 35(5), p 902-906. https://doi.org/10.1016/j.jmst.2018.09.067

W. Pan, P. Fu, Z. Li et al., Microstructure and Mechanical Properties of AlCoCrFeNi2.1 Eutectic High-Entropy Alloy Synthesized by Spark Plasma Sintering of Gas-Atomized Powder, Intermetallics, 2022, 144, p 107523. https://doi.org/10.1016/j.intermet.2022.107523

L. Zhu, P. Xue, Q. Lan et al., Recent Research and Development Status of Laser Cladding: A Review, Opt. Laser Technol., 2021, 138, 106915. https://doi.org/10.1016/j.optlastec.2021.106915

Y. Liu, Y. Ding, L. Yang et al., Research and Progress of Laser Cladding on Engineering Alloys: A Review, J. Manuf. Process., 2021, 66, p 341-363. https://doi.org/10.1016/j.jmapro.2021.03.061

Y. Guan, X. Cui, D. Chen et al., Realizing High Strength and Toughness of Gradient High-Entropy Alloy Coating by In-Situ Interface Reaction of FeCoCrNi/FeCoCrAl, Surf. Coat. Technol., 2023, 464, 129569. https://doi.org/10.1016/j.surfcoat.2023.129569

A.A. Siddiqui and A.K. Dubey, Recent Trends in Laser Cladding and Surface Alloying, Opt. Laser Technol., 2021, 134, 106619. https://doi.org/10.1016/j.optlastec.2020.106619

X. Wen, X. Cui, G. Jin et al., Corrosion and Tribo-Corrosion Behaviors of Nano-lamellar Ni1.5CrCoFe0.5Mo0.1Nbx Eutectic High-Entropy Alloy Coatings: The Role of Dual-Phase Microstructure, Corros. Sci., 2022, 201, p 110305. https://doi.org/10.1016/j.corsci.2022.110305

X.L. Yan, S.Y. Dong, B.S. Xu et al., Progress and Challenges of Ultrasonic Testing for Stress in Remanufacturing Laser Cladding Coating, Materials, 2018, 11(2), p 293. https://doi.org/10.3390/ma11020293

O. Raykis, Alternative with a Future: High-Speed Laser Metal Deposition Replaces Hard Chrome Plating, Laser Tech. J., 2017, 14, p 28-30. https://doi.org/10.1002/latj.201700006

T. Schopphoven, A. Gasser and G. Backes, EHLA: Extreme High-Speed Laser Material Deposition: Economical and Effective Protection Against Corrosion and Wear, Laser Tech. J., 2017, 14, p 26-29. https://doi.org/10.1002/latj.201700020

Y. Liang, Z.Y. Liao, L.L. Zhang et al., A Review on Coatings Deposited by Extreme High-Speed Laser Cladding: Processes, Materials, and Properties, Opt. Laser Technol., 2023, 164, 109472. https://doi.org/10.1016/j.optlastec.2023.109472

J. Zhou, Y. Cheng, Y. Wan et al., Solidification Characteristics and Microstructure of TaNbZrTi Refractory High Entropy Coating by Extreme High-Speed Laser Cladding, Int. J. Refract. Met. H., 2023, 115, 106257. https://doi.org/10.1016/j.ijrmhm.2023.106257

Q. Yan, K. Yang, Z.D. Wang et al., Surface Roughness Optimization and High-Temperature Wear Performance of H13 Coating Fabricated by Extreme High-Speed Laser Cladding, Opt. Laser Technol., 2022, 149, 107823. https://doi.org/10.1016/j.optlastec.2021.107823

Q. Zhang, Q. Wang, B. Han et al., Comparative Studies on Microstructure and Properties of CoCrFeMnNi High Entropy Alloy Coatings Fabricated by High-Speed Laser Cladding and Normal Laser Cladding, J. Alloy. Compd., 2023, 947, 169517. https://doi.org/10.1016/j.jallcom.2023.169517

W. Yuan, R. Li, Z. Chen et al., A Comparative Study on Microstructure and Properties of Traditional Laser Cladding and High-Speed Laser Cladding of Ni45 Alloy Coatings, Surf. Coat. Technol., 2021, 405, 126582. https://doi.org/10.1016/j.surfcoat.2020.126582

Y. Ding, W. Bi, C. Zhong et al., A Comparative Study on Microstructure and Properties of Ultra-High-Speed Laser Cladding and Traditional Laser Cladding of Inconel625 Coatings, Materials, 2022, 15(18), p 6400. https://doi.org/10.3390/ma15186400

A. Meghwal, S. Pinches, A. Anupam et al., Structure-Property Correlation of a CoCrFeNi Medium-Entropy Alloy Manufactured Using Extreme High-Speed Laser Material Deposition (EHLA), Intermetallics, 2023, 152, 107769. https://doi.org/10.1016/j.intermet.2022.107769

C. Du, L. Hu, X. Ren et al., Cracking Mechanism of Brittle FeCoNiCrAl HEA Coating Using Extreme High-Speed Laser Cladding, Surf. Coat. Technol., 2021, 424, 127617. https://doi.org/10.1016/j.surfcoat.2021.127617

M. Liu, H. Jiang, G. Chang et al., Effect of Laser Remelting on Corrosion and Wear Resistance of Fe82Cr16SiB Alloy Coatings Fabricated by Extreme High-Speed Laser Cladding, Mater. Lett., 2022, 325, 132823. https://doi.org/10.1016/j.matlet.2022.132823

B. Shen, B. Du, M. Wang et al., Comparison on Microstructure and Properties of Stainless Steel Layer Formed by Extreme High-Speed and Conventional Laser Melting Deposition, Front. Mater., 2019, 6, p 248. https://doi.org/10.3389/fmats.2019.00248

G. Ma, B. Xu, H. Wang, X. Wang, G. Li and S. Zhang, Research on the Microstructure and Space Tribology Properties of Electric-Brush Plated Ni/MoS2-C Composite Coating, Surf. Coat. Tech., 2013, 221, p 142-149. https://doi.org/10.1016/j.surfcoat.2013.01.039

L. Zhang, Y. Ji, Q. Ye et al., An AlCoCrFeNi2.1 High-Entropy Alloy Coating with Uniform Microstructure and High Hardness, Mater. Lett., 2023. https://doi.org/10.1016/j.matlet.2023.134636

Acknowledgments

This research was financially supported by National Natural Science Foundation of China (Nos. 52005113, 52275366, 52203378), Tianjin Science and Technology Plan Project (22JCYBJC01590), and Young Talent Support Project of Guangzhou Association for Science and Technology (QT-2023-038).

Author information

Authors and Affiliations

Contributions

JW contributed to investigation and writing-original draft. YL contributed to methodology and review & editing. BL and YC helped in investigation and data curation. JL and NT contributed to conceptualization, review & editing. YZ and ZL helped in investigation.

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, J., Li, Y., Lu, B. et al. Microstructure and Properties of AlCoCrFeNi2.1 Eutectic High-Entropy Alloy Coatings Fabricated by Extreme High-Speed and Conventional Laser Cladding. J Therm Spray Tech 33, 992–1005 (2024). https://doi.org/10.1007/s11666-024-01734-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-024-01734-2