Abstract

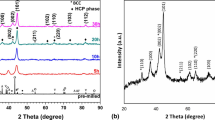

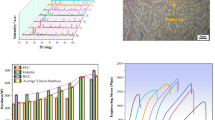

In the AlxCoCrFeNi high entropy alloys (HEAs), adding Al promotes a microstructure shift from fcc to bcc or their mixtures, which increases the overall strength of the alloys. To understand the strengthening mechanism, it is crucial to study the microstructure and mechanical properties of each constitution phase with varying compositions in addition to the amounts of strengthening phases. However, systematic research on the strengthening effect of Al content in individual fcc and bcc phases is lacking. In the present work, seven AlxCoCrFeNi HEAs with different Al contents were prepared by arc melting. According to XRD, SEM and TEM observations and thermodynamic calculations, the phase constitutions of the alloys change in a sequence of fcc → fcc + A2 (disordered bcc) + B2 (ordered bcc) → A2 + B2 as the Al content increases. The addition of Al to the fcc phase generates substantial lattice distortion, but the nanoindentation hardness of the fcc phase is stabilized at about 3.6 GPa, meaning no solid solution hardening effect present in the fcc phase. However, with increasing Al content, the hardness of the bcc-based alloys increases, which is mostly attributable to the increasing amount of the B2 phase.

Graphical Abstract

Similar content being viewed by others

References

J.W. Yeh, S.K. Chen, S.J. Lin, J.Y. Gan, T.S. Chin, T.T. Shun, C.H. Tsau, S.Y. Chang, Adv. Eng. Mater. 6, 299 (2004). https://doi.org/10.1002/adem.200300567

B. Cantor, I.T.H. Chang, P. Knight, A.J.B. Vincent, Mater. Sci. Eng. A 375–377, 213 (2004). https://doi.org/10.1016/j.msea.2003.10.257

J.W. Yeh, S.K. Chen, Y.L. Chen, Frontiers in the Design of Materials, ed. by B. Raj, S. Ranganathan, S.L. Mannan, K. Bhanu Sankara Rao, M.D. Matthew, P. Shankar (CRC Press, Boca Raton, 2007), pp.31–47

D.B. Miracle, O.N. Senkov, Acta Mater. 122, 448 (2017). https://doi.org/10.1016/j.actamat.2016.08.081

Z. Liu, Z.P. Xiong, K.X. Chen, X.W. Cheng, Mater. Lett. 315, 131933 (2022). https://doi.org/10.1016/j.matlet.2022.131933

N. Kumar, M. Fusco, M. Komarasamy, R.S. Mishra, M. Bourham, K.L. Murty, Nucl. Mater. 495, 154 (2017). https://doi.org/10.1016/j.jnucmat.2017.08.015

Suprianto, C.L. Chen, Met. Mater. Int. 29, 420 (2023). https://doi.org/10.1007/s12540-022-01258-w

G. Qin, R. Chen, H. Zheng, H. Fang, L. Wang, Y. Su, J. Guo, H. Fu, Mater. Sci. Technol. 35, 578 (2019). https://doi.org/10.1016/j.jmst.2018.10.009

L.W. Lan, X.J. Wang, R.P. Guo, H.J. Yang, J.W. Qiao, Mater. Sci. Technol. 42, 85 (2020). https://doi.org/10.1016/j.jmst.2019.08.051

S.K. Varma, F. Sanchez, S. Moncayo, C.V. Ramana, Mater. Sci. Technol. 38, 189 (2020). https://doi.org/10.1016/j.jmst.2019.09.005

B. Gwalani, S. Gorsse, D. Choudhuri, Y.F. Zheng, R.S. Mishra, R. Banerjee, Scr. Mater. 162, 18 (2019). https://doi.org/10.1016/j.scriptamat.2018.10.023

Y.L. Zhao, T. Yang, Y.R. Li, L. Fan, B. Han, Z.B. Jiao, D. Chen, C.T. Liu, J.J. Kai, Acta Mater. 188, 517 (2020). https://doi.org/10.1016/j.actamat.2020.02.028

B. Gwalani, S. Gorsse, D. Choudhuri, M. Styles, Y.F. Zheng, R.S. Mishra, R. Banerjee, Acta Mater. 153, 169 (2018). https://doi.org/10.1016/j.actamat.2018.05.009

J.Y. He, H. Wang, H.L. Huang, X.D. Xu, M.W. Chen, Y. Wu, X.J. Liu, T.G. Nieh, K. An, Z.P. Lu, Acta Mater. 102, 187 (2016). https://doi.org/10.1016/j.actamat.2015.08.076

B. Gwalani, V. Soni, M. Lee, S.A. Mantri, Y. Ren, R. Banerjee, Mater. Design 121, 254 (2017). https://doi.org/10.1016/j.matdes.2017.02.072

S.G. Ma, Y. Zhang, Mater. Sci. Eng. A 532, 480 (2012). https://doi.org/10.1016/j.msea.2011.10.110

G. Qin, W.T. Xue, C.L. Fan, R.R. Chen, L. Wang, Y.Q. Su, H.S. Ding, J.J. Guo, Mater. Sci. Eng. A 710, 200 (2018). https://doi.org/10.1016/j.msea.2017.10.088

Y.D. Wu, Y.H. Cai, X.H. Chen, T. Wang, J.J. Si, L. Wang, Y.D. Wang, X.D. Hui, Mater. Design 83, 651 (2015). https://doi.org/10.1016/j.matdes.2015.06.072

C.L. Wang, C.J. Liang, M.J. Yang, C. Huang, Z.F. Yao, B. Qiu, K.X. Zhang, Y.G. Xie, M.L. Liang, W.J. Liu, J.J. Yang, S.F. Zhou, Mater. Design 221, 110940 (2022). https://doi.org/10.1016/j.matdes.2022.110940

Y.J. Zhou, Y. Zhang, Y.L. Wang, G.L. Chen, Appl. Phys. Lett. 90, 181904 (2007). https://doi.org/10.1063/1.2734517

W.R. Wang, W.L. Wang, S.C. Wang, Y.C. Tsai, C.H. Lai, J.W. Yeh, Intermetallics 26, 44 (2012). https://doi.org/10.1016/j.intermet.2012.03.005

Y.-F. Kao, T.-J. Chen, S.-K. Chen, J.-W. Yeh, J. Alloys Compd. 488, 57 (2009). https://doi.org/10.1016/j.jallcom.2009.08.090

K.B. Zhang, Z.Y. Fu, Intermetallics 22, 24 (2012). https://doi.org/10.1016/j.intermet.2011.10.010

M. Zhang, L.J. Yao, M. Zhu, Y.Q. Liu, Z.Y. Jian, J. Mater. Eng. Perform. 30, 1472 (2021). https://doi.org/10.1007/s11665-020-05411-7

J.Y. He, W.H. Liu, H. Wang, Y. Wu, X.J. Liu, T.G. Nieh, Z.P. Lu, Acta Mater. 62, 105 (2014). https://doi.org/10.1016/j.actamat.2013.09.037

I. Basu, V. Ocelík, J.T. De Hosson, Acta Mater. 157, 83 (2018). https://doi.org/10.1016/j.actamat.2018.07.031

G.F. Shang, W.S. Zheng, J.J. Wang, X.-G. Lu, Mater. Sci. Eng. A 846, 143294 (2022). https://doi.org/10.1016/j.msea.2022.143294

A. Takeuchi, A. Inoue, Mater. Trans. JIM 41, 1372 (2000). https://doi.org/10.2320/matertrans1989.41.1372

S. Guo, C. Ng, J. Lu, C.T. Liu, J. Appl. Phys. 109, 103505 (2011). https://doi.org/10.1063/1.3587228

Y. Zhang, Y.J. Zhou, J.P. Lin, G.L. Chen, P.K. Liaw, Adv. Eng. Mater. 10, 534 (2008). https://doi.org/10.1002/adem.200700240

T. Egami, Y. Waseda, J. Non-Cryst. Solids 64, 113 (1984). https://doi.org/10.1016/0022-3093(84)90210-2

X. Yang, Y. Zhang, Mater. Chem. Phys. 132, 233 (2012). https://doi.org/10.1016/j.matchemphys.2011.11.021

J.O. Andersson, T. Helander, L.H. Hoglund, P.F. Shi, B. Sundman, Calphad 26, 273 (2002). https://doi.org/10.1016/S0364-5916(02)00037-8

Thermo-Calc Software (2020). TCHEA4. Available online at: https://www.thermocalc.com/products-services/databases/thermodynamic/ (accessed May 20, 2020)

Z.J. Sun, X.P. Tan, C.C. Wang, M. Descoins, D. Mangelinck, S.B. Tor, E.A. Jägle, S. Zaefferer, D. Raabe, Acta Mater. 204, 116505 (2021). https://doi.org/10.1016/j.actamat.2020.116505

J. Charkhchian, A. Zarei-Hanzaki, A. Moshiri, H.R. Abedi, T.M. Schwarz, R. Lawitzki, G. Schmitz, K. Chadha, C. Aranas Jr., J. Shen, J.P. Oliveira, Adv. Eng. Mater. 25, 2300164 (2023). https://doi.org/10.1002/adem.202300164

W.C. Oliver, G.M. Pharr, J. Mater. Res. 7, 1564 (1992). https://doi.org/10.1557/JMR.1992.1564

J.E. Zorzi, C.A. Perottoni, Mater. Sci. Eng. A 574, 25 (2013). https://doi.org/10.1016/j.msea.2013.03.008

A.C. Fischer-Cripps, Introduction to Contact Mechanics (Springer, New York, 2000)

R.L. Fleischer, Acta Metall. 11, 203 (1963). https://doi.org/10.1016/0001-6160(63)90213-X

T.H. Courtney, Mechanical Behaviour of Materials (McGraw-Hill, New York, 1990)

S. Qiu, X.C. Zhang, J. Zhou, S. Cao, H. Yu, Q.M. Hu, Z.M. Sun, J. Alloys Compd. 846, 156321 (2020). https://doi.org/10.1016/j.jallcom.2020.156321

G.F. Shang, L. Jiang, Z.-Z. Liu, X.-G. Lu, J. Alloys Compd. 917, 165513 (2022). https://doi.org/10.1016/j.jallcom.2022.165513

G.J. Diao, M.Y. Wu, A.Q. He, Z. Xu, S.E. Mousavi, D.Y. Li, Lubricants 11, 392 (2023). https://doi.org/10.3390/lubricants11090392

Acknowledgements

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Shang, G., Wang, J., Liu, ZZ. et al. Effect of Al Content on Microstructure and Mechanical Properties of the fcc and bcc Phases of AlxCoCrFeNi High Entropy Alloys. Met. Mater. Int. (2024). https://doi.org/10.1007/s12540-024-01635-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12540-024-01635-7