Abstract

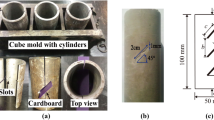

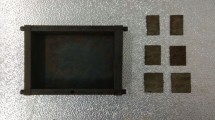

In this study, the influence of fractures on the mechanical properties and cracking behavior of composite rock mass was investigated by preparing rock-like specimens of composite rock mass with different dip angles of fractures using customized molds. The failure process of the sample was recorded using a camera, and the rock failure process analysis technology was used for quantitative investigation of the mechanical mechanism of crack evolution during the loading process of the sample. Based on the experimental results, the crack propagation and coalescence modes of fractured composite rock mass were analyzed, and the distribution laws of contact force chain and maximum principal stress during initial crack initiation were studied from the microscopic perspective. The results show that with the increase in fracture dip angle, when the fracture is located in hard rock, the peak strength of the specimen decreases first, then increases and then decreases. When the fracture is located in both soft rock and hard rock, the peak strength of the specimen is mainly controlled by the fracture in soft rock. The initial crack mainly occurs at the tip of the soft rock fracture, and then converges with the cracks developed at the end of the hard rock fracture through the interface. The crack propagation type and coalescence mode are affected by the joint action of the fracture dip angle and position. In total, eight crack propagation types and six crack coalescence modes were observed during the failure process. The maximum principal stress concentration area is distributed around the fracture and is “butterfly” type. With the increase in fracture dip angle, the maximum principal stress concentration area gets gradually deflected perpendicular to the fracture direction, and does not pass through the interface of soft and hard rocks. The existence of the interface prevents the transmission of stress to a certain extent.

Similar content being viewed by others

References

Cao RH, Cao P, Lin H, Pu CZ, Qu K (2016) Mechanical behavior of brittle rock-like specimens with pre-existing fissures under uniaxial loading: experimental studies and particle mechanics approach. Rock Mech Rock Eng 49(3):763–783. https://doi.org/10.1007/s00603-015-0779-x

Wong RHC, Lin P (2015) Numerical study of stress distribution and crack coalescence mechanisms of a solid containing multiple holes. Int J Rock Mech Min 79:41–54. https://doi.org/10.1016/j.ijrmms.2015.08.003

Zhou XP, Niu Y, Cheng H, Berto F (2021) Cracking behaviors and chaotic characteristics of sandstone with unfilled and filled dentate flaw. Theor Appl Fract Mec 112:102876. https://doi.org/10.1016/j.tafmec.2020.102876

Fan X, Yu H, Deng ZY, He ZM, Zhao YL (2022) Cracking and deformation of cuboidal sandstone with a single nonpenetrating flaw under uniaxial compression. Theor Appl Fract Mec 119:103284. https://doi.org/10.1016/j.tafmec.2022.103284

Wu Q, Kulatilake PHSW (2012) REV and its properties on fracture system and mechanical properties, and an orthotropic constitutive model for a jointed rock mass in a dam site in China. Comput Geotech 43:124–142. https://doi.org/10.1016/j.compgeo.2012.02.010

Chen Y, Zuo JP, Li ZH, Dou R (2020) Experimental investigation on the crack propagation behaviors of sandstone under different loading and unloading conditions. Int J Rock Mech Min 130:104310. https://doi.org/10.1016/j.ijrmms.2020.104310

Zhang K, Jiang Z, Liu XH, Zhang K, Zhu H (2022) Quantitative characterization of the fracture behavior of sandstone with inclusions: experimental and numerical investigation. Theor Appl Fract Mec 121:103429. https://doi.org/10.1016/j.tafmec.2022.103429

Cao RH, Cao P, Fan X, Xiong XG, Lin H (2016) An experimental and numerical study on mechanical behavior of ubiquitous-joint brittle rock-like specimens under uniaxial compression. Rock Mech Rock Eng 49(11):4319–4338. https://doi.org/10.1007/s00603-016-1029-6

Feng F, Chen SJ, Wang YJ, Huang WP, Han ZY (2021) Cracking mechanism and strength criteria evaluation of granite affected by intermediate principal stresses subjected to unloading stress state. Int J Rock Mech Min 143:104783. https://doi.org/10.1016/j.ijrmms.2021.104783

Lee H, Jeon S (2011) An experimental and numerical study of fracture coalescence in pre-cracked specimens under uniaxial compression. Int J Solids Struct 48(6):979–999. https://doi.org/10.1016/j.ijsolstr.2010.12.001

Liu XG, Zhu WC, Zhang PH, Li LK (2021) Failure in rock with intersecting rough joints under uniaxial compression. Int J Rock Mech Min 146:104832. https://doi.org/10.1016/j.ijrmms.2021.104832

Huang D, Gu DM, Yang C, Huang RQ, Fu GY (2016) Investigation on mechanical behaviors of sandstone with two preexisting flaws under triaxial compression. Rock Mech Rock Eng 49:375–399. https://doi.org/10.1007/s00603-015-0757-3

Huang YH, Yang SQ, Ranjith PG, Zhao J (2017) Strength failure behavior and crack evolution mechanism of granite containing pre-existing non-coplanar holes: experimental study and particle flow modeling. Comput Geotech 88:182–198. https://doi.org/10.1016/j.compgeo.2017.03.015

Sivakumar G, Maji VB (2021) Crack growth in rocks with preexisting narrow flaws under uniaxial compression. Int J Geomech 21(4):04021032. https://doi.org/10.1061/(ASCE)GM.1943-5622.0001960

He C, Mishra B, Shi QW, Zhao Y, Lin DJ, Wang X (2023) Correlations between mineral composition and mechanical properties of granite using digital image processing and discrete element method. Int J Min Sci Techno 33(8):949–962. https://doi.org/10.1016/j.ijmst.2023.06.003

Wang X, Li JC, Zhao XB, Liang Y (2022) Propagation characteristics and prediction of blast-induced vibration on closely spaced rock tunnel. Tunn Undergr Sp Tech 123:104416. https://doi.org/10.1016/j.tust.2022.104416

Cao RH, Cao P, Lin H, Ma GW, Chen Y (2018) Failure characteristics of intermittent fissures under a compressive-shear test: experimental and numerical analyses. Theor Appl Fract Mec 96:740–757. https://doi.org/10.1016/j.tafmec.2017.11.002

Zhang XP, Liu QS, Wu SC, Tang XH (2015) Crack coalescence between two non-parallel flaws in rock-like material under uniaxial compression. Eng Geol 199:74–90. https://doi.org/10.1016/j.enggeo.2015.10.007

Liu Y, Dai F, Feng P, Xu NW (2018) Mechanical behavior of intermittent jointed rocks under random cyclic compression with different loading parameters. Soil Dyn Earthq Eng 113:12–24. https://doi.org/10.1016/j.soildyn.2018.05.030

Zhang XP, Wong LNY (2013) Crack initiation, propagation and coalescence in rock-like material containing two flaws: a numerical study based on bonded-particle model approach. Rock Mech Rock Eng 46(5):1001–1021. https://doi.org/10.1007/s00603-012-0323-1

Liu S, Liu HD, Liu HN, Xia ZG, Zhao YW, Zhai JY (2022) Numerical simulation of mesomechanical properties of limestone containing dissolved hole and persistent joint. Theor Appl Fract Mec 122:103572. https://doi.org/10.1016/j.tafmec.2022.103572

Huang CC, Yang WD, Duan K, Fang LD, Wang L, Bo CJ (2019) Mechanical behaviors of the brittle rock-like specimens with multi-non-persistent joints under uniaxial compression. Constr Build Mater 220:426–443. https://doi.org/10.1016/j.conbuildmat.2019.05.159

Li HQ, Wong LNY (2014) Numerical study on coalescence of pre-existing flaw pairs in rock-like material. Rock Mech Rock Eng 47(6):2087–2105. https://doi.org/10.1007/s00603-013-0504-6

Zhou XP, Bi J, Qian QH (2015) Numerical simulation of crack growth and coalescence in rock-like materials containing multiple pre-existing flaws. Rock Mech Roc Eng 48(3):1097–1114. https://doi.org/10.1007/s00603-014-0627-4

Cao P, Liu TY, Pu CZ, Lin H (2015) Crack propagation and coalescence of brittle rock-like specimens with pre-existing cracks in compression. Eng Geol 187:113–121. https://doi.org/10.1016/j.enggeo.2014.12.010

Yang XW, Zhang XP, Zhang Q, Li CD, Wang DJ (2021) Study on the mechanisms of crack turning in bedded rock. Eng Fract Mech 247:107630. https://doi.org/10.1016/j.engfracmech.2021.107630

Ju MH, Li JC, Li J, Zhao J (2020) Loading rate effects on anisotropy and crack propagation of weak bedding plane-rich rocks. Eng Fract Mech 230:106983. https://doi.org/10.1016/j.engfracmech.2020.106983

Ma Q, Liu XL, Tan YL, Elsworth D, Shang JL, Song DJ, Liu XS, Yan FY (2023) Numerical study of mechanical properties and microcrack evolution of double-layer composite rock specimens with fissures under uniaxial compression. Eng Fract Mech 289:109403. https://doi.org/10.1016/j.engfracmech.2023.109403

Debecker B, Vervoort A (2013) Two-dimensional discrete element simulations of the fracture behaviour of slate. Int J Rock Mech Min 61:161–170. https://doi.org/10.1016/j.ijrmms.2013.02.004

Debecker B, Vervoort A (2009) Experimental observation of fracture patterns in layered slate. Int J Fracture 159:51–62. https://doi.org/10.1007/s10704-009-9382-z

Morgan SP, Einstein HH (2017) Cracking processes affected by bedding planes in Opalinus shale with flaw pairs. Eng Fract Mech 176:213–234. https://doi.org/10.1016/j.engfracmech.2017.03.003

Wu Q, Liu YX, Tang HM, Kang JT, Wang LQ, Li CD, Wang D, Liu ZQ (2023) Experimental study of the influence of wetting and drying cycles on the strength of intact rock samples from a red stratum in the three gorges reservoir area. Eng Geol 314:107013. https://doi.org/10.1016/j.enggeo.2023.107013

Lin QB, Cao P, Wen GP, Meng JJ, Cao RH, Zhao ZY (2021) Crack coalescence in rock-like specimens with two dissimilar layers and pre-existing double parallel joints under uniaxial compression. Int J Rock Mech Min 139:104621. https://doi.org/10.1016/j.ijrmms.2021.104621

Alneasan M, Behnia M, Bagherpour R (2019) Analytical investigations of interface crack growth between two dissimilar rock layers under compression and tension. Eng Geol 259:105188. https://doi.org/10.1016/j.enggeo.2019.105188

Yang SQ, Yin PF, Huang YH, Cheng JL (2019) Strength, deformability and X-ray micro-CT observations of transversely isotropic composite rock under different confining pressures. Eng Fract Mech 214:1–20. https://doi.org/10.1016/j.engfracmech.2019.04.030

Liu XS, Tan YL, Ning JG, Lu YW, Gu QH (2018) Mechanical properties and damage constitutive model of coal in coal-rock combined body. Int J Rock Mech Min 110:140–150. https://doi.org/10.1016/j.ijrmms.2018.07.020

Tien MT, Kuo MC, Juang CH (2006) An experimental investigation of the failure mechanism of simulated transversely isotropic rocks. Int J Rock Mech Min 43(8):1163–1181. https://doi.org/10.1016/j.ijrmms.2006.03.011

Wang DJ, Tang HM, Elsworth D, Wang CY (2019) Fracture evolution in artificial bedded rocks containing a structural flaw under uniaxial compression. Eng Geol 250:130–141. https://doi.org/10.1016/j.enggeo.2019.01.011

Zhao ZH, Liu H, Ma Q, Shang JL (2023) Micro-macro damage, deterioration and cracking of heterogeneous composite rock masses with non-penetrating cracks under uniaxial compression. Theor Appl Fract Mec 125:103919. https://doi.org/10.1016/j.tafmec.2023.103919

Cho N, Martin CD, Sego DC (2007) A clumped particle model for rock. Int J Rock Mech Min 44:997–1010. https://doi.org/10.1016/j.ijrmms.2007.02.002

Cundall PA, Strack ODL (1979) A discrete numerical model for granular assemblies. Geotechnique 29(1):47–65. https://doi.org/10.1680/geot.1979.29.1.47

Potyondy DO, Cundall PA (2004) A bonded-particle model for rock. Int J Rock Mech Min 41:1329–1364. https://doi.org/10.1016/j.ijrmms.2004.09.011

Zeng W, Yang SQ, Tian WL (2018) Experimental and numerical investigation of brittle sandstone specimens containing different shapes of holes under uniaxial compression. Eng Fract Mech 200:430–450. https://doi.org/10.1016/j.engfracmech.2018.08.016

Chen SJ, Xia ZG, Feng F, Yin DW (2021) Numerical study on strength and failure characteristics of rock samples with different hole defects. B Eng Geol Environ 80:1523–1540. https://doi.org/10.1007/s10064-020-01964-y

Acknowledgements

The authors greatly acknowledge the financial support from the National Natural Science Foundation of China (Grant No. 52204137), the Natural Science Foundation of Liaoning Province (Grant No. 2022-BS-281), the Education Department Foundation of Liaoning Province (Grant Nos. LJKQZ20222317 and LJKMZ20220661), and the Outstanding Young Scientific and Technological Talents Project of Liaoning University of Science and Technology (Grant No. 2023YQ10).

Funding

The authors greatly acknowledge the financial support from the National Natural Science Foundation of China (Grant No. 52204137), the Natural Science Foundation of Liaoning Province (Grant No. 2022-BS-281), the Education Department Foundation of Liaoning Province (Grant Nos. LJKQZ20222317 and LJKMZ20220661), and the Outstanding Young Scientific and Technological Talents Project of Liaoning University of Science and Technology (Grant No. 2023YQ10).

Author information

Authors and Affiliations

Contributions

ZX and JH performed substantial contributions to the conception and design of the work and revised the manuscript. HW established the numerical simulation models and finished writing the original manuscript. CL, BY and BC processed pictures and data of numerical simulation. LZ completed the laboratory test and data collation. XW designed the discussion and revised the manuscript. All authors reviewed the final manuscript and agreed to submit for publication.

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest. The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this study.

Data availability

Data will be made available on request. The data that underlie the results of this manuscript and conclusions are presented in the figures and tables of this manuscript.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, H., Hu, J., Xia, Z. et al. Mechanical properties and damage evolution characteristics of composite rock mass with prefabricated fractures. Comp. Part. Mech. (2024). https://doi.org/10.1007/s40571-024-00719-w

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40571-024-00719-w