Abstract

Atmospheric-pressure plasma processing (APPP) is an important method for the fabrication of high-precision optics because it involves highly efficient and nondamaging material removal based on its pure chemical etching mechanism. However, owing to the heat accumulation phenomenon caused by the jet heat flux, the nonlinearity of the material removal rate in APPP is inevitable, making it difficult to achieve deterministic optical surfacing. To bridge this gap, this study focused on analyzing the nonlinear relationship between the material removal rate and heat accumulation. The simulation results indicated that when the sliding distance increased from 10 to 50 mm, the surface temperature of the workpiece increased from 387.3 to 419.5 K, an increase of more than 8%. When the dwell time increased from 0.33 to 2 s, the surface temperature of the workpiece increased from 348.1 to 419.5 K (including the effect of sliding distance), an increase of more than 21%. A novel algorithm that simultaneously considers dwell time and sliding distance was proposed based on the results. A threshold parameter tq was introduced to determine whether to correct the deviation caused by the sliding distance. With the proposed algorithm, the matching residual surface root-mean-square (RMS) error decreased from 97.5 to 39.6 nm. The RMS deviation error of the matching residual surface error converged from 11.6 to 4.7% after surface-figuring experiments. The proposed algorithm is expected to provide a promising solution for future deterministic optical surfacing.

Similar content being viewed by others

References

Moody JD, Pollock BB, Sio H, Strozzi DJ, Ho DD, Walsh C, Kemp GE, Kucheyev SO, Kozioziemski B, Carroll EG, Kroll J, Yanagisawa DK, Angus J, Bhandarkar SD, Bude JD, Divol L, Ferguson B, Fry J, Hagler L, Hartouni E, Herrmann MC, Hsing W, Holunga DM, Javedani J, Johnson A, Kalantar D, Kohut T, Logan BG, Masters N, Nikroo A, Orsi N, Piston K, Provencher C, Rowe A, Sater J, Skulina K, Stygar WA, Tang V, Winters SE, Chittenden JP, Appelbe B, Boxall A, Crilly A, O’Neill S, Davies J, Peebles J, Fujioka S (2022) The magnetized indirect drive project on the national ignition facility. J Fusion Energy 41:1–13. https://doi.org/10.1007/s10894-022-00319-7

Scott F, Kevin C, Stephen D, Andreas D, Philippe G, Anthony JG et al (2023) Control systems and data management for high-power laser facilities. High Power Laser Sci Eng 5:1–25. https://doi.org/10.1017/hpl.2023.49

Zhao Z, Chen H, Zhang Z, Li J, Zhu F, Wan W, He F, Wei H, Chen K, Yan P (2022) High peak power femtosecond cylindrical vector beams generation in a chirped-pulse amplification laser system. Chin Opt Lett 20:031405. https://doi.org/10.3788/COL202220.031405

Zhang X, Hu H, Wang X, Luo X, Zhang G, Zhao W, Wang X, Liu Z, Xiong L, Qi E, Cui C, Wang Y, Li Y, Wang X, Li L, Bai Y, Cheng Q, Zhang Z, Li R, Tang W, Zeng X, Deng W, Zhang F (2022) Challenges and strategies in high-accuracy manufacturing of the world’s largest SiC aspheric mirror. Light Sci Appl 1:1–13. https://doi.org/10.1038/s41377-022-00994-3

Meng J, Li C, Cong ZH, Zhao Z, Wang S, Liu G, Liu Z (2023) Beam quality improvement of the high-energy KTA-OPO based on a confocal unstable cavity with Gaussian reflectivity mirror. Chin Opt Lett 5:051401-1–51405. https://doi.org/10.3788/COL202321.051401

Keidar M, Weltmann KD, Macheret S (2021) Fundamentals and applications of atmospheric pressure plasmas. J Appl Phys 130:080401. https://doi.org/10.1063/5.0065750

Sun R, Nozoe A, Nagahashi J (2021) Novel highly-efficient and dress-free polishing technique with plasma-assisted surface modification and dressing. Precis Eng 71:224–236. https://doi.org/10.1016/j.precisioneng.2021.05.003

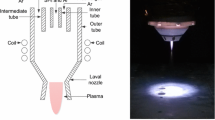

Xin Q, Su X, Alavi S, Wang B, Mostaghimi J (2018) Effects of conical nozzle and its geometry on properties of an inductively coupled plasma jet used for optical fabrication. Appl Therm Eng 128:785–794. https://doi.org/10.1016/j.applthermaleng.2017.07.131

Ji P, Jin H, Li D, Su X, Wang B (2019) Thermal analysis of inductively coupled atmospheric pressure plasma jet and its effect for optical processing. Optik 185:381–389. https://doi.org/10.1016/j.ijleo.2019.03.098

Ji P, Li D, Su X, Jin Y, Qiao Z, Wang B, Ding F (2020) Optimization strategy for the velocity distribution based on tool influence function non-linearity in atmospheric pressure plasma processing. Precis Eng 65:269–278. https://doi.org/10.1016/j.precisioneng.2020.05.015

Ji P, Li D, Su X, Jin Y, Qiao Z, Wang B, Ding F (2021) Investigation of the tool influence function neighborhood effect in atmospheric pressure plasma processing based on an innovative reverse analysis method. Opt Exp 29:31376. https://doi.org/10.1364/OE.439280

Meister J, Böhm G, Eichentopf IM, Arnold T (2009) Simulation of the substrate temperature field for plasma assisted chemical etching. Plasma Process Polym 6(S1):S209–S213. https://doi.org/10.1002/ppap.200930509

Castelli M, Jourdain R, Morantz P, Shore P (2012) Rapid optical surface figuring using reactive atom plasma. Precis Eng 36:467–476. https://doi.org/10.1016/j.precisioneng.2012.02.005

Dai Z, Xie X, Chen H, Zhou L (2018) Non-linear compensated dwell time for efficient fused silica surface figuring using inductively coupled plasma. Plasma Chem Plasma Process 38:443–459. https://doi.org/10.1007/s11090-018-9873-7

Su X, Zhang P, Liu K, Xia L, Li P, Zhao R, Wang B (2019) Fabrication of continuous phase plate using atmospheric pressure plasma processing. Int J Adv Manuf Technol 105:4559–4570. https://doi.org/10.1007/s00170-019-03406-w

Su X, Ji P, Jin Y, Li D, Qiao Z, Ding F, Yue X, Wang B (2021) Freeform surface generation by atmospheric pressure plasma processing using a time-variant influence function. Opt Express 29:11479–11493. https://doi.org/10.1364/OE.421688

Su X, Yue X (2022) Nonlinear dwell-time algorithm for freeform surface generation by atmospheric-pressure plasma processing. Opt Express 30:18348–18363. https://doi.org/10.1364/OE.459248

Peng B, Dun A, Wu L, Wang Z, Xu X (2021) Variable removal function in atmospheric pressure plasma polishing. Chin J Lasers 48:2403002. https://doi.org/10.3788/CJL202148.2403002

Meister J, Arnold T (2011) New process simulation procedure for high-rate plasma jet machining. Plasma Chem Plasma Process 31:91–107. https://doi.org/10.1007/s11090-010-9267-y

Xiang Y, Yu D, Liu F (2018) Determining the heat flux distribution of laminar plasma jet impinging upon a flat surface: An indirect method using surface transformation hardening. Int J Heat Mass Transf 118:879–889. https://doi.org/10.1016/j.ijheatmasstransfer.2017.11.050

Forslund R, Snis A, Larsson S (2019) Analytical solution for heat conduction due to a moving Gaussian heat flux with piecewise constant parameters. Appl Math Model 66:227–240. https://doi.org/10.1016/j.apm.2018.09.018

Liu S, Wang H, Hou J (2022) Morphology characterization of polishing spot and process parameters optimization in magnetorheological finishing. J Manuf Syst 80:259–272. https://doi.org/10.1016/j.jmapro.2022.06.008f

Tang W, Deng W, Yin X (2019) Ion beam figuring high gradient optical aspherical surface. SPIE. https://doi.org/10.1117/122504901

Chen J, Peng B, Wu L, Hu C, Wei C, Shao J (2022) Variable removal function in atmospheric pressure plasma processing for fabrication of continuous phase plate with small spatial period. SPIE. https://doi.org/10.1117/122638397

Funding

This work was supported by the National key research and development program (Grant No. [2022YFB3403403]).

Author information

Authors and Affiliations

Contributions

Conceptualization and methodology, JC and LW; software, JC; validation, CH; formal analysis, JC and LW; writing—original draft preparation, JC; writing—review and editing, LW; supervision, CW and JS; All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflicts of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Chen, J., Wu, L., Wang, L. et al. Research on a Compensation Correction Algorithm for the Removal Function of Atmospheric-Pressure Plasma Processing. Plasma Chem Plasma Process 44, 927–943 (2024). https://doi.org/10.1007/s11090-024-10456-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11090-024-10456-w