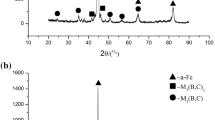

During the tunneling process of high-abrasion stratum with strong impact by tunnel boring machines (TBM), disc cutter rings made of H13 and DC53 steels are prone to failures like wear and chipping. To improve the service life of the cutter ring, a new kind of Cr-Mo-W-V medium carbon alloy cutter ring steel (DQ1) with better hardness and toughness was developed. The effects of the heat treatment process on the microscopic structure and mechanical properties of DQ1 steel were studied by the spectrometer, optical microscope, Rockwell hardness tester, and impact tester. The wear resistance of DQ1, H13, and DC53 steel was compared and analyzed through the abrasive wear test and rock breaking test. The results indicate that outstanding mechanical properties and wear resistance of DQ1 steel were obtained after quenching at 1040°C and tempering at 540°C, the hardness was 4.4 HRC higher than that of H13 steel, and the impact absorption energy was 85.7% higher than that of DC53 steel. In excavating strong impact and high abrasion formations, the average service life of the DQ1 steel cutter ring was increased by 24.6% compared with the H13 steel cutter ring, and the brittle fracture problem common in the DC53 cutter ring did not appear. The research achievements can facilitate to improve the excavation efficiency and reduce the cost of TBM in high strength and high erosion strata.

Similar content being viewed by others

References

N. Afrasiabi, R. Rafiee, and M. Noroozi, “Investigating the effect of discontinuity geometrical parameters on the TBM performance in hard rock,” Tunn Undergr Sp Tech, 84, 326–333 (2019).

S. M. Pourhashemi, K. Ahangari, J. Hassanpour, et al., “Evaluating the influence of engineering geological parameters on TBM performance during grinding process in limestone strata,” Bull Eng Geol Environ, 80, 3023–3040 (2021).

J. Hassanpour, J. Rostami, J. Zhao, et al., “TBM performance and disc cutter wear prediction based on ten years experience of TBM tunnelling in Iran,” Geomech Tunnelling, 8, No. 3, 239–247 (2015).

A. K. Agrawal, S. Chattopadhyaya, and V. M. S. R. Murthy, “Delineation of cutter force and cutter wear in different edge configurations of disc cutters – an analysis using discrete element method,” Eng Fail Anal, 129, 105727–105740 (2021).

M. Petrica, E. Badisch, and T. Peinsitt, “Abrasive wear mechanisms and their relation to rock properties,” Wear, 308, Nos. 1–2, 86–94 (2013).

Z. Z. Zhang, “Study on the abrasion of disc cutters on full face rock tunnel boring machine,” Mod Tunnelling Technol, 44, 32–36 (2007).

X. H. Zhang, L. K. Lin, Y. M. Xia, et al., “Experimental study on wear of TBM disc cutter rings with different kinds of hardness,” Tunn Undergr Sp Tech, 82, 346–357 (2018).

G. Barzegari, A. Uromeihy, and J. Zhao, “Parametric study of soil abrasivity for predicting wear issue in TBM tunneling projects,” Tunn Undergr Sp Tech, 48, 43–57 (2015).

Y. H. Ge, Y. B. Liu, P. Lin, et al., “Effects of rock properties on the wear of TBM disc cutter: a case study of the Yellow river diversion project, China,” Int J Geomech, 22, No. 4, 4022011.1–4022011.10 (2022).

N. Espallargas, P. D. Jakobsen, L. Langmaack, et al., “Influence of corrosion on the abrasion of cutter steels used in TBM tunnelling,” Rock Mech Rock Eng, 48, No. 1, 261–275 (2015).

J. Fu, Y. M. Xia, Z. Zhang, et al., “Failure analysis on the fracture of disc cutter in EPB shield machine,” Eng Fail Anal, 108, No. 4, 104341 (2020).

D. J. Ren, J. S. Shen, J. Chai, et al., “Analysis of disc cutter failure in shield tunnelling using 3D circular cutting theory,” Eng Fail Anal, 90, 23–35 (2018).

L. H. Jia, Y. Shang, W. M. Long, et al., “Effect of alloy composition of materials for TBM cutter rings on microstructure and wear resistance,” J Cent South Univ, 51, No. 10, 2730–2738 (2020).

J. Z. Jiang, K. Wang, H. Guo, et al., “Microstructure and wear resistance of novel TBM cutter ring steel,” Tribology, 41, No. 1, 17–26 (2021).

J. Li, Y. Gong, S. P. Zhao, et al., “Material and processing optimization on disc cutter of tunnel boring machine for failure prevention,” Eng Fail Anal, 138, 106363–106372 (2022).

Y. Hu, J. Tian, M. Xu, et al., “The preparation of H13 steel for TBM cutter and the performance test close to working condition,” Appl Sci, 8, No. 10, 1877 (2018).

A. Umantsev and G. B. Olson, “Ostwald ripening in multicomponent alloys,” Scr Metall Mater, 29, No. 8, 1135–1140 (1993).

J. Z. Jiang, Y. Liu, and C. M. Liu, “Effect of tempering temperature on the microstructure, mechanical properties and abrasive wear behavior of a new C–Cr–Mo–V alloy steel used in TBM cutter ring,” J Mater Res Technol, 20, 195–209 (2022).

H. H. Chen, J. D. Xing, and W. Li, Wear Resistant Material Application Manual [in Chinese], Machinery Industry Press, Beijing (2012).

Acknowledgments

This research was funded in part by the National Key Research and Development Program (Grant No. 2020YFB1709504).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Problemy Mitsnosti, No. 6, p. 128, November – December, 2023.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Han, M.Z., Guo, J.B., Li, J. et al. Process Optimization and Performance of New TBM Disc Cutter Ring Steel. Strength Mater (2024). https://doi.org/10.1007/s11223-024-00617-9

Received:

Published:

DOI: https://doi.org/10.1007/s11223-024-00617-9