Abstract

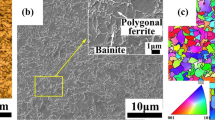

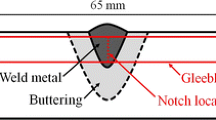

A study was made to understand the possible effect of the Al/O ratio on the Charpy V-notch impact properties of submerged arc weld metals within the optimum range of Al/O ratio previously reported to be 0.45–0.75. To vary the Al/O ratio of weld metals in such a narrow range, two base plates different in aluminum content were selected, and a bead-in-groove weld was made on each plate using the same welding condition. From the chemical compositions obtained, the Al/O ratio of each plate was determined to be 0.47 and 0.75. Charpy impact tests showed that the ductile–brittle transition temperature (DBTT) of a low Al/O ratio was about 25 °C lower than that of a high Al/O ratio. The improvement in toughness is concluded to be attributable to the microstructural refinement that can be quantified by two different parameters: AF content increased from 70 to 79% and grain size decreased from 8 to 6 μm. These results also indicated that even a slight variation in aluminum content of base plates could cause a marked variation in weld microstructure and toughness. In addition, the inclusions in the weld of low Al/O ratio were confirmed to be covered by the TiO layer, but no manganese-depleted zone (MDZ) was observed.

Similar content being viewed by others

References

Abson DJ, Pargeter RJ (1986) Factors influencing as-deposited strength, microstructure, and toughness of manual metal arc welds suitable for C-Mn steel fabrication. Int Met Review 31(4):141–194

Sarma DS, Karasev AV, Jönsson PG (2009) On the role of non-metallic inclusions in the nucleation of acicular ferrite in steels. ISIJ Int 49(7):1063–1074. https://doi.org/10.2355/isijinternational.49.1063

Loder D, Michelic SK, Bernhard C (2017) Acicular ferrite formation and its influencing factors—a review. J Mater Sci Res 6(1):24–43. https://doi.org/10.5539/jmsr.v6n1p24

Xuan C, Mu W (2022) New insights of heterogeneous nucleation and anisotropic growth of acicular ferrite on non-metallic inclusion. Mater Des 221(9):110892. https://doi.org/10.1016/j.matdes.2022.110892

Yamada T, Terasaki H, Komizo Y (2009) Relation between inclusion surface and acicular ferrite in low carbon low alloy steel weld. ISIJ Int 49(7):1059–1062. https://doi.org/10.2355/isijinternational.49.1059

Seo JS, Lee C, Kin HJ (2013) Influence of oxygen content on microstructure and inclusion characteristics of bainitic weld metals. ISIJ Int 53(2):279–285. https://doi.org/10.2355/isijinternational.53.279

Horii Y, Ichikawa K, Ohkita S, Ohkita S, Funaki S, Yurioka N (1995) Chemical composition and crystal structure of oxide inclusions promoting acicular ferrite transformation in low alloy submerged arc weld metal. Quarterly J Jap Weld Soc 13(4):500–507. https://doi.org/10.2207/qjjws.13.500

Homma R, Shinohara Y, Kadoi K, Inoue H (2021) Effect of S and Si on the formation of intragranular ferrite and inclusions in ultra-low oxygen weld metal of low carbon steel. ISIJ Int 61(1):309–316. https://doi.org/10.2355/isijinternational.ISIJINT-2020-112

Mills AR, Thewlis G, Whiteman JA (1987) Nature of inclusions in steel weld metals and their influence on formation of acicular ferrite. Mater Sci Tech 3(12):1051–1061

Koseki T, Ohkita S, Yurioka N (1997) Thermodynamic study of inclusion formation in low alloy steel weld metals. Sci Tech Weld Join 2(2):65–69. https://doi.org/10.1179/stw.1997.2.2.65

Ito Y, Nakanishi M (1976) Study on Charpy impact properties of weld metal with submerged arc welding. Sumitomo Search 15:42–61

Evan GM (1992) The effect of titanium in SMA C-Mn steel multipass deposits. Weld J 71(12):447s–454s

Evan GM (1993) Effect of titanium in manganese-containing SMA weld deposit. Weld J 72(3):123s–133s

Evan GM (1995) Microstructure and properties of ferritic steel welds containing Al ad Ti. Weld J 74(8):249s–261s

Evan GM (1996) Microstructure and properties of ferritic steel welds containing Ti ad B. Weld J 75(8):251s–260s

Johnson MQ, Evan GM, Edwards GR (1995) The influence of titanium additions and interpass temperature on the microstructures and mechanical properties of high strength SMA weld metals. ISIJ Int 35(10):1222–1231. https://doi.org/10.2355/isijinternational.35.1222

Seo K, Kim K-h, Kim HJ, Ryoo H, Evans GM, Lee C (2020) Microstructural and inclusion characteristics of C-Mn steel welds at a minimal level of titanium. Met Mater Int 26(8):1226–1234. https://doi.org/10.1007/s12540-019-00390-4

Horii Y (1995) Effect of chemical composition on strength and toughness of welds made by large heat input submerged arc welding, Doctoral thesis, Osaka University, Osaka, Japan. http://hdl.handle.net/11094/39436. Accessed 03-03-2024

Yamada T, Terasaki H, Komizo Y (2007) Microstructural evolution in low carbon steel Ti-B weld metals with several Al levels quarterly. J Jap Weld Soc 25(4):514–518. https://doi.org/10.2207/qjjws.25.514

Terashima H, Hart PHM (1983) Proc. Int Conf on ‘Effect of residual impurity and micro-alloying elements on weldability and weld properties’, TWI, London, Paper 27

Yamada T, Terasaki H, Komizo Y (2008) Microscopic observation of inclusions contributing to formation of acicular ferrite in steel weld metal. Sci Tech Weld Join 13(2):118–125. https://doi.org/10.1179/174329308X271797

Takada A, Terasaki H, Komizo Y (2013) Effect of aluminum content on acicular ferrite formation in low carbon steel weld metals. Sci Tech Weld Join 18(2):91–97. https://doi.org/10.1179/1362171812Y.0000000086

Fujiyama N, Shigesato G (2021) Effect of Mn and Al on acicular ferrite formation in SAW weld metal. ISIJ Int 61(5):1614–1622. https://doi.org/10.2355/isijinternational.ISIJINT-2020-407

Milani JM, Saeid T (2020) Acicular ferrite nucleation and growth in API5L-X65 steel submerged arc welded joints. Mat Sci Tech 36(13):1398–1406. https://doi.org/10.1080/02670836.2020.1783774

Seo K, Ryoo H, Kim HJ, Yoon JG, Lee C (2022) Nature of nonmetallic inclusions in electrogas weld metal. Weld World 66:379–390

Takada A, Terasaki H, Komizo Y (2014) Role of inclusions for formation of acicular ferrite in low carbon steel weld deposits. IIW Doc II-1886–14, IIW, Italy

Byun J-S, Cho YW, Chung SH, Shim J-H, Lee DN (1999) Nucleation of intragranular ferrite at Ti2O3 particle in low carbon steel. Acta Meter 47(9):1751–1760

Byun J-S, Shim J-H, Cho YW, Lee DN (2003) Non-metallic inclusion and intragranular nucleation of ferrite in Ti-killed steel. Acta Meter 51:1593–1606

Li Y, Wan XL, Cheng L, Wu KM (2016) Effect of oxides on nucleation of ferrite: first principle modelling and experimental approach. Mat Sci Tech 32(1):88–93. https://doi.org/10.1179/1743284715Y.0000000102

Seo K, Kim Y-M, Kim HJ, Lee C (2015) Characterization of inclusions formed in Ti-containing steel weld metals. ISIJ Int 55(8):1730–1738. https://doi.org/10.2355/isijinternational.ISIJINT-2014-800

Seo K, Kim Y-M, Evans GM (2015) Formation of Mn-depleted zone in Ti-containing weld metals. Weld World 59(3):373–380. https://doi.org/10.1007/s40194-014-0207-y

Kang Y, Han K, Park JH, Lee C (2015) Variation in the chemical driving force for intergranular nucleation in the multi-pass weld metal of Ti-containing high-strength low-alloy steel. Met Mater Trans A 46A(8):2015–3581

Homma R, Shigesato G, Fujioka M, Kadoi K, Inoue H (2022) Mn depletion behavior at oxide/matrix interface in low oxygen weld metal of low carbon steel. Tetsu-to-Hagane 108(3):211–223. https://doi.org/10.2355/tetsutohagane.TETSU-2021-087

Wang B, Liu X, WANG G, (2018) Inclusion characteristics and acicular ferrite nucleation in Ti-containing weld metals of X80 pipeline steel. Met Mater Trans A 49A(6):2124–2138. https://doi.org/10.1007/s11661-018-4570-y

Homma R, Kadoi K, Inoue H (2021) Effects of Ti and Al on the formation of intragranular ferrites in the ultra-low-oxygen Si-Mn weld metals of low-carbon steel. Mater Today Commun 29:102963. https://doi.org/10.1016/j.mtcomm.2021.102963

Nakayama K, Kisaya Y, Kimura F, Terasaki H (2020) A study on mechanism of acicular ferrite formation in GMA weld metals. Quarterly J Jap Weld Soc 38(4):229–233. https://doi.org/10.2207/qjjws.38.229

Rule Requirements for Materials and Welding_Part 2 (2019), American Bureau Shipping, USA

ASTM E23–23a, Standard test methods for notched bar impact testing of metallic materials, ASTM Int, PA, USA, https://doi.org/10.1520/E0023-23A

Hunt AC, Kluken AO, Edward GR (1994) Heat input and dilution effects in micro-alloyed steel weld metal. Weld J 73(1):9s–15s

Hidaka T, Suenaga K, Okazaki Y, Ishida H (2009) Influence of oxides on microstructure and notch toughness of weld metal with flux-cored wires for high strength steel quarterly. J Jap Weld Soc 27(2):154s–157s. https://doi.org/10.2207/qjjws.27.154s

Jia X, Li H, Yang Y, Hao Y, Wang B, Wang B (2024) Evolution of complex oxide inclusions during the smelting process of oxide metallurgical steel and their effect on acicular ferrite nucleation. Met Mater Trans A 55A(3):724–753. https://doi.org/10.1007/s11661-023-0726608

Yamamoto K, Hasegawa T, Katamura J (1996) Effect of boron on intra-granular ferrite formation in Ti-oxide bearing steels. ISIJ Int 36(1):80–86. https://doi.org/10.2355/isijinternational.36.80

Seo JS, Seo K, Kim HJ, Lee C (2014) Effect of titanium content on weld microstructure and mechanical properties of bainitic GMA welds. Weld World 58:893–901

Pargeter RJ, Dolby RE (1980) A scheme for the quantitative description of ferritic weld microstructures, IIW Doc. IXJ-29–80, IIW, Italy

Davey TG, Widgery DJ (1976) A technique for the characterization of weld metal microstructure, IIW Doc. II-389–76, IIW, Italy

Farrar RA, Zhang Z (1995) Aspect ratios and morphology of acicular ferrite in C-Mn-Ni weld metals. Mater Sci Tech 11(8):759–764

Funding

This work was supported by the Korea Institute of Energy Technology Evaluation and Planning(KETEP) grant funded by the Korea government (MOTIE) (20206510100030, Development of Repair Technology for Class 2, 3 Large Bore Piping in Operating Nuclear Power Plant).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Recommended for publication by Commission IX - Behaviour of Metals Subjected to Welding

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Seo, K., Kang, Y., Kim, H.J. et al. Evaluation of microstructure and toughness of SAW steel weld metals with optimum Al/O ratio. Weld World (2024). https://doi.org/10.1007/s40194-024-01749-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40194-024-01749-x