Abstract

Although tungsten inert gas welding is considered one of the cleanest welding techniques, which is virtually “fumeless”, recent studies show, there is a significant amount of nano-sized particles generated during the process. To protect the welding personnel from possible harmful effects of inhalation of fume particles, fume extractor torches are developed. One such welding fume extractor torch was tested and compared to a conventional one during manual welding of unalloyed structural steel. Using the fume extractor torch, a significantly lower amount of nano-particles was measured in the welder’s personal breathing zone effectively decreasing the exposure to possible harmful effects of those nano-sized particles.

Similar content being viewed by others

1 Introduction

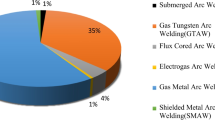

Welding is a crucial process across various industries, involving about 11 million professional welders globally and many more occasional welding equipment users [1, 2]. Most fusion welding techniques expose workers to hazardous substances like manganese, hexavalent chromium, nickel oxide, and iron particles in form of welding fumes [3,4,5,6].

Metal active/inert gas (MAG/MIG) welding is among the most commonly used methods in steel construction and is particularly emissive due to high deposition rates and to the applied high current. It releases particles and gases that contain various metals and metal oxides, leading to a risk of respiratory diseases and neurological disorders [7,8,9]. Tungsten inert gas (TIG) welding method is another kind of welding technology that is used very often, especially for welding of high alloyed steels, special alloys, and nonferrous metals, like aluminum or copper. This technology is considered as clean and nearly fumeless; however, recent examinations show that it also has high levels of particle emission, but in the nanoparticle (NP) size range (1–100 nm in diameter). Despite the existence of occupational exposure limits countries like Germany, studies indicate that exposure often exceeds these limits [10,11,12,13].

Several technical solutions aim to manage the fume-caused health risks. In Japan, a fume-exhaust gun system is recommended [14]. The European standard “Health and safety in welding and allied processes—Laboratory method for sampling fume and gases—Part 4: Fume data sheets” UNE EN ISO 15011–4 allows the substitution of less hazardous filler metals to reduce the possible harmful effects of the created welding fumes [15]. Also, it has been reported that even the proper droplet transfer method, or a complex arc modulation technique can significantly reduce the fume emission rate [16,17,18].

Fume extraction torches for MIG/MAG welding, also known as “fume extraction guns”, originated in the 1970s with the aim of reducing welders’ exposure to hazardous fumes. These devices have been the subject of various studies, some of which indicate that the fume extraction flow rate around 100 m3 h−1 is effective in capturing fumes. The torch’s inclination also plays a significant role in the efficiency of fume capture [19, 20]. Despite their potential advantages, these torches have not been widely adopted. Reasons include ergonomic issues such as the torch’s excessive weight and rigidity, as well as technical problems like inefficient fume capture and the suction of shielding gas that compromises the quality of the weld. Field observations also indicate that welders rarely maintain the suggested torch inclination angles, which affects the device’s efficiency in capturing fumes.

Studies by Rösemann et al. [21] and Yapp et al. [19] underline the importance of these personal protection equipment tools, emphasizing that their design, weight, and efficiency in fume extraction are key factors for their acceptance by operators [19]. Godbole et al. used computational fluid dynamics to optimize the design of extraction nozzles, eventually leading to a patented torch design that significantly increases fume reduction efficiency [3, 22]. Flynn and Susi’s review [23] show that fume extraction torches can effectively reduce fume exposure by 40–50% compared to natural ventilation, although they are not always sufficient to lower fume exposure below certain thresholds. Marconi and Bravaccini [20] reported similar findings, but also emphasized the need to consider various factors like welding position and environmental conditions for optimum use. Bonthoux [24] identifies multiple factors affecting fume extraction efficiency, such as extraction flow velocity, nozzle position, and torch inclination, and provides quantitative recommendations for optimum efficiency.

It is important to note that while on-torch fume extraction technology has been available for MIG/MAG welding methods for some time, the development of a fume extraction torch system specifically for TIG welding is a more recent advancement. Consequently, there is a relative lack of comprehensive knowledge and data regarding the effectiveness of these systems in eliminating fumes during TIG welding processes. This gap in information underscores the need for further research and evaluation to fully understand and optimize the use of fume extraction technology in TIG welding, especially given the distinct nature of fumes generated by different welding techniques.

Overall, it is considered that while fume extraction torches are important personal protection tools, their efficiency can be influenced by numerous factors that need to be carefully considered for optimal use. These challenges have led to ongoing research aimed at improving the long-term effectiveness of this fume capture system.

In summary, welding represents considerable health risks to workers, and despite various technological and regulatory efforts, many challenges remain in reducing exposure to hazardous substances effectively. Fume extraction torches offer a potential solution but are hindered by ergonomic and technical challenges. In this work, we report an experimental measurement of an on-torch fume extraction TIG welding torch’s effectivity on nanoparticle elimination during the welding.

2 Materials and methods

2.1 Welding experiments

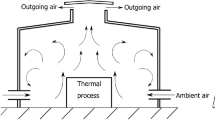

Bead on plate welding was done by trained welding personnel, using Rehm TIGER® 180DC (Rehm GmbH u. Co, Uhingen, Germany) power source, WT40 electrode (W + 4 m%ThO) in 2.4-mm diameter, and 99.996 Ar shielding gas (Linde Hungary, Répcelak, Hungary) with flow rate of 6 l/min. The base material was 1.0038 grade non-alloy structural steel plate in 3 mmthickness, with the nominal chemical composition of Cmax, 0.17%; Mnmax, 1.4%; Pmax, 0.035%; Smax, 0.035%; Cumax, 0.055%; Cmax, 0.17%; and Nmax, 0.015%, respectively. The filler material was a Ø 2.4-mm TigRod 12.64® (G4Si1/ER70S-6) with the nominal chemical composition of C, 0.08%; Si, 0.8%; and Mn, 1.28% (ESAB, Göteborg, Sveden). The welding current was set to 80A, and the welding position PA, respectively. For the experiments, an Abicor Binzel xFume® TIG torch, connected to an Abicor Binzel FEC-W3 cyclone high vacuum fume extractor (Alexander Binzel Schweisstechnik GmbH & Co. KG, Buseck, Germany) was used. The on torch air-shutter valve was set to minimal airflow. The control measurements were done using traditional Abicor Binzel Abitig Grip 26® TIG torch. One welding experiment lasted 15 min, 5 min between the test runs. The three measurements were done for both with the fume extractor torch and the control setup (conventional welding torch). The schematic diagram of the welding shop is shown in the Fig. 1. During the process, the door (2000 × 750 mm) was completely open to enhance the natural ventilation. The physical dimensions of the welding torch is shown in the Fig. 2.

Images showing the xFume® TIG torchs’ ceramic nozzle and the fume extraction pathway around the nozzle (rightmost image, black “ring” around the gas lens). The black plate on the back of the neck of the torch is an air-shutter valve to regulate extraction flow. The raster size in the background is 10 mm

2.2 Nanoparticle concentration measurement

The measurement was done using a Testo DiscMini® nanoparticle counter device (Testo SE & Co. KGaA, Titisee-Neustadt, Germany) according to the manufacturer’s instructions. The sampling head was mounted on the apron of the welder, near to the shoulder to ensure for to sample the breathing zone air.

2.3 Local fume extraction

The welding has taken place in an open welding chamber (600 × 500 × 600) connected to a Kemper SmartMaster® LEV device (Kemper GmBh, Wreden, Germany). The extraction tube of the LEV was installed to the upper-left side of the welding chamber, without the original hood unit. Otherwise, the LEV unit was utilized according to the instructions of the manufacturer; all parameters (like airflow, etc.) were considered as nominal.

2.4 Statistical analysis of the data

The measurement data were analyzed using R statistical software. The normal distribution of the datasets was tested by Shapiro–Wilk test, the datasets were compared with Kruskal–Wallis H test. The level of significance was considered as 0.05 in each cases. The Shapiro–Wilk test is a widely used statistical method for assessing the normality of a data distribution. Developed by Samuel Shapiro and Martin Wilk in 1965, it evaluates the hypothesis that a given sample comes from a normally distributed population. The test calculates a W statistic, representing the correlation between the data and the corresponding normal scores. A significant deviation of the W statistic from its expected value under normality implies non-normality of the data. This test is particularly effective for small sample sizes, making it a preferred choice in many scientific studies [25].

The Kruskal–Wallis H test is a non-parametric method used to compare three or more groups. It is an extension of the Mann–Whitney U test and is applied when the assumptions of ANOVA, such as normality, are not met. This test ranks all data across groups, comparing these ranks to determine significant differences. It is ideal for ordinal or continuous data and does not assume a normal distribution [26].

3 Results and discussion

During the welding process, the release of welding fumes is effectively mitigated through the utilization of a specialized TIG fume extraction head attached to the front end of the welding torch. This extraction head efficiently captures air directly from the source, within the welder’s breathing zone, and its effectiveness was meticulously assessed.

In Fig. 3, we can observe the average nanoparticle count and its variations measured within the breathing zone, emanating from both conventional and extraction-type TIG welding torches. In the case of the conventional TIG torch, during the initial experimental period, the device recorded an average of 237,000 nanoparticles per cubic centimeter of air. During the subsequent measurement, this count significantly escalated, reaching nearly 700,000 nanoparticles (NP)/cm3 (with a standard deviation of 195,000). In the third measurement, we consistently recorded an average of 534,000 particles (with a standard deviation of 267,000). The differences between the groups are caused by uneven torch position and by differences between the actual natural ventilation of the workshop. Conversely, when employing the fume extraction TIG torch, none of our measurements exceeded 70,000 NP/cm3. Specifically, during the first measurement, we registered an average count of 57,000, followed by 62,500 in the second, and nearly 70,000 NP/cm3 in the third measurement. Notably, the standard deviations of the measured particle counts exhibited significantly reduced values, measuring 7.814, 26.643, and 39.120, respectively. During these welding runs, we tried to ensure the same ventilation conditions, but the alterations in the torch positions were the same as above, since the welding was done by hand.

Average nanoparticle count results of different conventional (control, red) and fume extraction TIG torch (green) welding test runs. At the end of the diagram, the summarized control- and fume extraction results are shown crosshatched; the asterisk is showing the statistically significant difference between the summarized data

In Fig. 4, the particle count emitted over time by the conventional TIG welding torch can be seen. It is discernible that, despite periodic fluctuations, the particle count progressively increases with time, surpassing the threshold of 500,000 NP/cm3 by the 15-min mark in all three measurements, and even exceeding 800,000 NP/cm3 in two instances. This suggests that the natural ventilation of the workspace was insufficient, allowing the nanoparticle (NP) count to rise to such high levels. Additionally, the data implies that these values would have continued to escalate had the welding persisted beyond the 15-min mark.

Conversely, when employing the extraction-type TIG welding torch, the concentration of nanoparticles measured within the breathing zone consistently remained significantly lower throughout the 15-min welding process as shown in Fig. 5. Concentrations ranged from 50,000 to 60,000 NP/cm3 in the majority of time intervals. This figure vividly illustrates that, during the first measurement, the NP count consistently remained low, while in the second measurement, it momentarily surged to 200,000 NP/cm3 for 1-min intervals at the 6th and 13th min. In the final measurement, we encountered only one noteworthy peak, reaching 278,000 particles around the 8th min. These accidental high fume generations may be caused by burning off some unnoticed impurities during the welding process. The plot suggests that there was no accumulation of NP in the breathing area, unlike in the case of the conventional welding torch.

Based on the results obtained from both conventional and extraction-type TIG welding torches, it can be conclusively asserted that there exists a statistically significant difference in airborne nanoparticle concentration, favoring the utilization of the extraction-type TIG torch. This conclusion is supported by the result of the statistical comparison of the data, which has shown significant difference between the conventional and extraction-type measurement groups (p value < 2.2 × 10−16). This result is also demonstrated in Fig. 3, at the end of the graph.

Welder protection from fume exposure has become increasingly crucial in recent times. All welding methods, especially the TIG technique, emit ultrafine particles. Even though TIG welding produces a low amount of PM10-PM2.5 particles, deeming it almost smokeless, it is significant to note that this method also produces a considerable amount of nanoparticles [27, 28]. Despite being solid, due to the size range, the diffusibility of these particles is behaving much like gases. These nanoparticles have recently attracted significant attention due to the associated potential health risks. Especially following the International Agency for Research on Cancer (IARC) reclassification of welding fumes as a category 1, proven carcinogenic, the urge to eliminate these particles effectively from the air has surged [2].

Although fume extraction torches for MIG/MAG technology have been available for a while, their initial reception among welders was lukewarm, mainly because of the added weight and bulkiness. Thankfully, this situation is changing, and on-torch extraction is now not only available for MIG/MAG but also for TIG welding. Our research compared the nanoparticle elimination capabilities of the tested torch to traditional TIG welding under local exhaust ventilation and general ventilation conditions.

4 Conclusions

We made bead on plate welding on plain carbon steel via manual TIG welding. The employed moderate current setting (80 A) in the welding experiments, is representative of typical work conditions. Nanoparticle measurements were made in the welders breathing zone applying commercial TIG torch as control measurement and fume extraction torch as well.

The investigated fume extraction TIG system consistently showcased an effective extraction capacity. Compared to earlier control values under identical welding parameters, the on-torch extraction significantly reduced the nanoparticle levels in the welder’s breathing zone. This aligns with past measurements on MIG/MAG extraction torches as reported by Flynn, and Susi, and Marconi and Bravaccini, and later by Yapp et al. [19, 23, 29].

It is pivotal to acknowledge that while local exhaust ventilation hoods are mostly operated manually, the extraction torch’s proximity to the arc ensures optimal fume extraction at the source. It must be emphasized that for best results, nanoparticle-rich air should be entirely evacuated from the workspace, given the challenges in filtering these particles with current systems.

The TIG welding method, vital for joining metals like stainless steel, was once considered virtually fumeless. However, recent studies have highlighted its substantial ultrafine particle emissions, underscoring potential health hazards for welders and adjacent workers. While the optimal defense against these particulates has traditionally been a combination of LEV and adequate general ventilation, the advent of on-torch extraction systems like xFume® offers welders an enhanced layer of protection. Nevertheless, for maximized safety, the extracted polluted air must be completely eliminated from the workshop. Literature also indicates a potential inverse relationship between the efficiency of on-torch extraction in MIG/MAG technology and the applied current settings, suggesting potential saturation of the torch’s extraction capacity [24]. As it was mentioned in Section 2, we used the fume extraction torch with full choke setting of the air-shutter valve, so we are sure that there is considerable reserve in the extraction capabilities of the examined TIG system. We recognize the importance of further exploring the saturation phenomenon in TIG technology extraction torches.

References

Honaryar MK, Lunn RM, Luce D, Ahrens W, Tmannetje A, Hansen J, Bouaoun L, Loomis D, Byrnes G, Vilahur N, Stayner L, Guha N (2019) Welding fumes and lung cancer: a meta-analysis of case-control and cohort studies. Occup Environ Med. 76(6):422–431. https://doi.org/10.1136/oemed-2018-105447

IARC (2018) Welding, molybdenum trioxide, and indium tin oxide. International Agency for Research on Cancer, Lyon

Flynn MR, Susi P (2009) Neurological risks associated with manganese exposure from welding operations - a literature review. Int J Hyg Envir Heal 212(5):459–469. https://doi.org/10.1016/j.ijheh.2008.12.003

Pesch B, Lehnert M, Weiss T, Kendzia B, Menne E, Lotz A, Heinze E, Behrens T, Gabriel S, Schneider W, Brüning T (2018) Exposure to hexavalent chromium in welders: results of the WELDOX II field study. Ann Work Expos Heal 62(3):351–361. https://doi.org/10.1093/annweh/wxy004

Racette BA, Nielsen SS, Criswell SR, Sheppard L, Seixas N, Warden MN, Checkoway H (2017) Dose-dependent progression of Parkinsonism in manganese-exposed welders. Neurology 88(4):344–351. https://doi.org/10.1212/Wnl.0000000000003533

McMillan G (2005) Is electric arc welding linked to manganism or Parkinson’s disease? Toxicol Rev 24(4):237–257. https://doi.org/10.2165/00139709-200524040-00004

Lehnert M, Pesch B, Lotz A, Pelzer J, Kendzia B, Gawrych K, Heinze E, Van Gelder R, Punkenburg E, Weiss T, Mattenklott M, Hahn JU, Möhlmann C, Berges M, Hartwig A, Brüning T, Grp WS (2012) Exposure to inhalable, respirable, and ultrafine particles in welding fume. Ann Occup Hyg 56(5):557–567. https://doi.org/10.1093/annhyg/mes025

Jenkins NT, Eagar TW (2005) Chemical analysis of welding fume particles - airborne particle size is the most important factor in determining the accuracy of a method for chemical analysis. Weld J 84(6):87s–93s

Siew SS, Kauppinen T, Kyyrönen P, Heikkilä P, Pukkala E (2010) Occupational exposure to iron and welding fumes and the risk of lung cancer. Eur J Public Health 20:15–16

Kendzia B, Van Gelder R, Schwank T, Hagemann C, Zschiesche W, Behrens T, Weiss T, Brüning T, Pesch B (2017) Occupational exposure to inhalable manganese at German workplaces. Ann Work Expos Heal 61(9):1108–1117. https://doi.org/10.1093/annweh/wxx080

Kendzia B, Koppisch D, Van Gelder R, Gabriel S, Zschiesche W, Behrens T, Brüning T, Pesch B (2019) Modelling of exposure to respirable and inhalable welding fumes at German workplaces. J Occup Environ Hyg 16(6):400–409. https://doi.org/10.1080/15459624.2019.1566734

Pesch B, Kendzia B, Pohlabeln H, Ahrens W, Wichmann HE, Siemiatycki J, Taeger D, Zschiesche W, Behrens T, Jöckel KH, Brüning T (2019) Exposure to welding fumes, hexavalent chromium, or nickel and risk of lung cancer. Am J Epidemiol 188(11):1984–1993. https://doi.org/10.1093/aje/kwz187

Federal Institute for Occupational Safety and Health (2017) Technical rule for hazardous substances (TRGS) 561: Activities involving carcinogenic metals and their compounds. GMBI 43. 786–812. https://www.baua.de/EN/Service/Technical-rules/TRGS/TRGS-561.html

Ojima J (2006) Performance of a fume-exhaust gun system in CO arc welding. J Occup Health 48(3):207–209. https://doi.org/10.1539/Joh.48.207

ISO (2017) ISO 15011-4:2017: Health and safety in welding and allied processes. Laboratory method for sampling fume and gases Part 4: Fume data sheets. Geneva, Switzerland, pp 1–12

Costa L (2014) Correlation between the welding process and the development of fumes: characterization, analysis and risk management. Weld Int 28(9):700–707. https://doi.org/10.1080/09507116.2012.753267

Carpenter KR, Monaghan BJ, Norrish J (2009) Analysis of fume formation rate and fume particle composition for gas metal arc welding (GMAW) of plain carbon steel using different shielding gas compositions. Isij Int 49(3):416–420. https://doi.org/10.2355/isijinternational.49.416

Egerland SA, Wiesinger M, Sharma R, Ebert B (2023) Experimental study of measures preventing welders from fume exposure. Welding in the World 67(1):1–20. https://doi.org/10.1007/s40194-022-01395-1

Yapp D, Lawmon J, Castner H (2001) Development of lightweight fume extraction welding guns. National Shipbuilding ResearchProgram SP-7 Welding Panel, Naval Surface Warfare Center, Columbus, OH 1–45. https://www.researchgate.net/publication/235084222_Development_of_Lightweight_Fume_Extraction_Welding_Guns

Mario Marconi Albano, Bravaccini, (2010) Capture efficiency of integral fume extraction torches for GMA welding — Part 2. Welding in the World 54(3–4):15–33. https://doi.org/10.1007/BF03263486

Rösemann B, Dreller S, Goebel A (2009) The new TRGS 528 on welding work. Gefahrstoffe, Reinhaltung der Luft. 69:286–290

Ajit Godbole Paul, John Cooper, Norrish, (2010) Design and optimization of a novel on-torch fume extraction device using CFD and fluid simulation. Welding in the World 54(3–4):R80–R86. https://doi.org/10.1007/BF03263491

Flynn MR, Susi P (2012) Local exhaust ventilation for the control of welding fumes in the construction industry-a literature review. Ann Occup Hyg 56(7):764–776. https://doi.org/10.1093/annhyg/mes018

Bonthoux F (2016) Factors affecting the capture efficiency of a fume extraction torch for gas metal arc welding. Ann Occup Hyg 60(6):761–770. https://doi.org/10.1093/annhyg/mew016

King AP, Eckersley RJ (2019) Chapter 7 - inferential statistics IV: choosing a hypothesis test. In: King AP, Eckersley RJ (eds) Statistics for Biomedical Engineers and Scientists. Academic Press, pp 147–171. https://doi.org/10.1016/B978-0-08-102939-8.00016-5

Xia Y (2020) Chapter Eleven - correlation and association analyses in microbiome study integrating multiomics in health and disease. In: Sun J (ed) Progress in Molecular Biology and Translational Science, vol 171. Academic Press, pp 309–491. https://doi.org/10.1016/bs.pmbts.2020.04.003

Brand P, Lenz K, Reisgen U, Kraus T (2013) Number size distribution of fine and ultrafine fume particles from various welding processes. Ann Occup Hyg 57(3):305–313. https://doi.org/10.1093/annhyg/mes070

Berlinger B, Benker N, Weinbruch S, L’Vov B, Ebert M, Koch W, Ellingsen DG, Thomassen Y (2011) Physicochemical characterisation of different welding aerosols. Anal Bioanal Chem 399(5):1773–1780. https://doi.org/10.1007/s00216-010-4185-7

Meeker JD, Susi P, Flynn MR (2010) Hexavalent chromium exposure and control in welding tasks. J Occup Environ Hyg 7(11):607–615. https://doi.org/10.1080/15459624.2010.510105

Acknowledgements

The xFume fume extraction TIG torch and the FEC W3 high vacuum fume extractor were provided for the measurement by the Cooptim Weld Technology Limited, Székesfehérvár, Hungary. The authors thank the National Research, Development and Innovation Office, Budapest, Hungary, for their financial support.

Funding

Open access funding provided by University of Veterinary Medicine. This research was funded by the National Research, Development and Innovation Office under grant FK_18 ID: 129055. This study was supported by the strategic research fund of the University of Veterinary Medicine Budapest (Grant No. SRF-001).

Author information

Authors and Affiliations

Contributions

Experimental design: Csaba Kővágó and Kornél Májlinger, data evaluation, statistical analysis: Csaba Kővágó and Éva Szűcs-Somlyó, manuscript writing: Csaba Kővágó, Éva Szűcs-Somlyó, manuscript revision: Kornél Májlinger, József Lehel, graph drawing: Kornél Májlinger.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Kővágó, C., Májlinger, K., Szűcs-Somlyó, É. et al. Investigation on the effectivity of nanoparticle elimination of a fume extractor TIG torch. Weld World (2024). https://doi.org/10.1007/s40194-024-01741-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40194-024-01741-5