The article provides results of experimental studies for production of hot-pressed and calibrated bars made of alloy 6082 by a method of ingotless rolling-extrusion (IRE) of long-length press products made of alloy 6082 at the experimental installation SLIP-2,5. Rational deformation regimes for processing under specified temperature and rate conditions are determined. It is established that the process is guaranteed to be implemented with the following parameters: roll rotation speed 4 rpm; melting temperature 750 °C; extension during pressing 7.3–10.0; compression during rolling 50%. The data obtained for properties of deformed semi-finished products manufactured according to the proposed technology make it possible to assert that the level of mechanical properties of calibrated bars corresponds to the thermally-strengthened state of alloy 6082 according to the specifications of standard EN 755–2. In addition, comparison of the results obtained for determining bar mechanical properties obtained using the IRE method makes it possible to conclude that it is comparable to the level of properties of bars made of this alloy manufactured under hot pressing production conditions. The technical and economic analysis carried out for factory conditions calibrated bar manufacture made of alloy 6082 showed that introduction of new technology using ingotless rolling-extrusion makes it possible to reduce production cost on an average by 15.5%.

Similar content being viewed by others

References

D. A. Chernavina, E. A. Chernavin, A. V. Faller, and M. Yu. Zdanovich, “World aluminium market: development tendencies prospects and key problems,” Molodoi Uchenyie, No. 17, 2026–210 (2018).

Yu. A. Gorbunov, “Problems and prospects of through processing of aluminium alloys,” Tekhnol. Legkikh. Splavov, No. 1, 134–136 (2016).

Yu. A. Gorbunov, G. P. Usynina, L. A. Smirnova, V. N. Kazakov, and A. S. Sgvytkov, RF patent 2241871, Method for Producing Standard Bars of Alloys of the Aluminium-Magnesium-Silicon System, Publ. 10.12.2004, Bull. No. 34.

N. Bauzer, G. Zauer, and K. Zigert, Pressing. Reference Handbook [translated from German], Alyusil MViT, Moscow (2009).

Praveen Kumar and Geeta Agnihotri, “Finite element analysis of industrial cold drawing process,” Inter. J. of Engineering Research and Applications (IJERA), 3, No. 3, 988–994 (2013).

S. B. Sidel’nikov, E. S. Lopatina, N. N. Dovzhenko, et al., Features of Metal Structure Formation and Properties with High-Speed Crystallization-Deformation and Modification of Aluminum Alloys [in Russian], Sib. Feder. Univ., Krasnoyarsk (2015).

S. B. Sidel’nikov, N. N. Dovzhenko, and N. N. Zagirov, Combined and Contemporary Methods for Treating Nonferrous Metals and Alloys: Monograph [in Russian], MAKS Press, Moscow (2005).

A. V. Sal’nikov, A. V. Strelov, and M. M. Motkov, “Production of hard aluminium alloys by combined rolling-extrusion,” Tsvet. Met. i Mineraly, Krasnoyarsk, 674–677 (2017).

R. A. Shatalov, N. Sh. Boskhamdzhiev, and V. A. Nikolaev, Contemporary Metal Casting and Deformation Processes [in Russian], Izd. MGOU, Moscow (2009).

R. L. Shatalov, “Rise of strip quality, made of nonferrous metals and alloys, in rolling,” Tsvetnye Metally, No. 5, 65–70 (200).

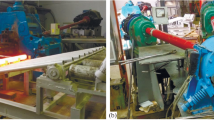

S. B. Sidle’nikov, V. N. Baranov, A. A. Startsev, T R. Gil’manshina, et al., RF Patent 2724758, Device for Metal Ingotless Rolling and Extrusion, Publ. 25.06.2020, Bull. No. 18.

Yu. V. Gorokhov, V. G. Sherkunnov, N. N. Dovzhenko, et al., Bases of Planning Continuous Metal Extrusion Processes: Monograph [in Russian], Sib. Fed. Univ., Krasnoyarsk (2013).

Yu. N. Loginov and S. P. Burkin, “Energy saving in extrusion processes,” Tsvet. Met., No. 10, 81.86 (2002).

EN 5733, Aluminum and Aliuminum Alloys. Chemical Composition and Workpiece Shape. Part 3. Chemical Composition and Object Shape (2013).

Yu. A. Gorbunov, N. A. Grishchenko, and A. S. Kuzhim, “Study of the rheological properties of aluminium alloy 6082,” Internat. Coll. Sci. Work, “Mechanics of Deformed Media in Production Processes,” Izd. IrGTU, Irkutsk (2000).

Yu. A. Gorbunov, M. M. Antonov, N. V. Okladnikova, V. P. Zhereb, et al., “Effect of modification on the structure and properties of wrought alloys of the Al–Mg–Si system,” J. of Siberian Federal University. Engineering & Technologies, 5, No. 8, 24–129 (2015).

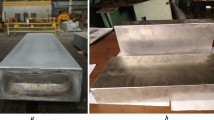

S. B. Sidel’nikov, A. S. Bersenev, N. N. Dovzhenko, E. S. Lopatina, et al., “Development of technology for preparing bars by combined casting and rolling extrusion in a SLiPP-2.5 unit from alluminum alloys of the 6XXX series and structure of their structure and properties,” Svet. Met. Mineraly, Krasnoyarsk, 306–307 (2016).

EN 755–2, Aluminum and Aluminium Alloys Extruded Bars, Pipes, and Shapes. Part 2. Mechanical Properties (2013).

N. A. Belov, Phase Composition of Industrial and Prospective Aluminum Alloys. Monograph [in Russian], MiSIS, Moscow (2011.

T. A. Orelkina, E. N. Drozdova, and A. S. Nadol’ko, Practical Metallography of Nonferrous Metals and Alloys. Teaching Aid. [in Russian], Sib. Fed. Univ., Krasnoyarsk (2013).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallurg, Vol. 67, No. 9, pp. 42–48, September, 2023, Russian DOIhttps://doi.org/10.52351/00260827_2023_09_42.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sidelnikov, S.B., Lopatina, E.S., Konstantinov, I.L. et al. Technology for the Producing Calibrated Bars Made of Aluminum Alloy 6082 Prepared Using Ingotless Rolling-Pressing. Metallurgist 67, 1293–1301 (2024). https://doi.org/10.1007/s11015-024-01621-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11015-024-01621-9