Abstract

Railway ballast modeling can be performed by different approaches, through continuous or discrete models, which have their comparative advantages and disadvantages, such as excessive volumes of material for testing and calibration steps. This paper aims to adapt and propose the use of the Hybrid Lattice-Discrete Element Method for modeling railway ballast aggregates. The advantages of using this technique for this purpose are: (i) one-step calibration of the rock material from laboratory test results; (ii) simulation of fractures in rock materials; (iii) visualization of micromechanical phenomena, such as particle slippage and fracture modes; (iv) realistic representation of various geometries compared to the conventional use of the Discrete Element Method. First, parameter calibration was performed from laboratory test results on granite rock obtained from the literature. Then, particle generation, Voronoi discretization and packing algorithms were used to build models of railway ballast samples. These models were used to simulate mechanical tests, namely single particle compression, confined uniaxial compression, monotonic triaxial compression and cyclic triaxial compression. There was consistency between the results and the empirical observations reported in the literature. In addition, variations in particle size distribution were observed during the simulations, as well as the causes of failure in each specimen, either by shear or particle breakage, in addition to the fracture modes of the ballast aggregates. By analyzing these elements together, knowledge is obtained about the phenomena occurring inside the railway ballast under different loading conditions, in addition to the results of strength, failure and deformation. Finally, it is concluded that the proposed method is effective for modeling railway ballast, besides being versatile, allowing to simulate the material for different loading configurations and boundary conditions.

Similar content being viewed by others

References

Indraratna B, Salim W (2005) Mechanics of Ballasted Rail Tracks: A Geotechnical Perspective. Taylor & Francis/Balkema, London

Tutumluer E, Huang H, Hashash YMA, Ghaboussi J (2009) AREMA gradation affecting ballast performance using discrete element modeling (DEM) approach. In: Proceedings of the American Railway Engineering and Maintenance-of-Way Association Annual Conference. Chicago, IL

Chow LC, Mishra D, Tutumluer E (2014) Framework for development of an improved unbound aggregate base rutting model for mechanistic-empirical pavement design. Transp Res Rec. https://doi.org/10.3141/2401-02

Ishikawa T, Lin T, Yang J et al (2019) Application of the UIUC model for predicting ballast settlement to unsaturated ballasts under moving wheel loads. Transportation Geotech 18:149–162. https://doi.org/10.1016/j.trgeo.2018.12.003

Chen SS, Fu ZZ, Han HQ, Peng C (2011) An elastoplastic model for rockfill materials considering particle breakage. Yantu Gongcheng Xuebao/Chin J Geotech Eng. https://doi.org/10.1061/(ASCE)GM.1943-5622.0000681

Indraratna B, Thakur PK, Vinod JS, Salim W (2012) Semiempirical cyclic densification model for ballast incorporating particle breakage. Int J Geomech 12:260–271. https://doi.org/10.1061/(ASCE)GM.1943-5622.0000135

Xiao J, Zhang D, Wei K, Luo Z (2017) Shakedown behaviors of railway ballast under cyclic loading. Constr Build Mater 155:1206–1214. https://doi.org/10.1016/j.conbuildmat.2017.07.225

Desai CS (2007) Unified DSC constitutive model for pavement materials with numerical implementation. Int J Geomech 7:83–101. https://doi.org/10.1061/(ASCE)1532-3641(2007)7:2(83)

Cundall PA, Strack ODL (1979) A discrete numerical model for granular assemblies. Geotechnique 29:47–65. https://doi.org/10.1680/geot.1979.29.1.47

Ergenzinger C, Seifried R, Eberhard P (2012) A discrete element approach to model breakable railway ballast. J Comput Nonlinear Dyn doi 10(1115/1):4006731

Mahmoud E, Papagiannakis AT, Renteria D (2016) discrete element analysis of railway ballast under cycling loading. Procedia Eng 143:1068–1076. https://doi.org/10.1016/j.proeng.2016.06.221

Thakur PK, Indraratna B, Vinod JS (2009) DEM simulation of effect of confining pressure on ballast behaviour. In: Proceedings of the 17th international conference on soil mechanics and geotechnical engineering: the academia and practice of geotechnical engineering

Tutumluer E, Qian Y, Hashash YMA et al (2013) Discrete element modelling of ballasted track deformation behaviour. Int J Rail Transp 1:57–73. https://doi.org/10.1080/23248378.2013.788361

Eliáš J (2014) Simulation of railway ballast using crushable polyhedral particles. Powder Technol 264:458–465. https://doi.org/10.1016/j.powtec.2014.05.052

Gladkyy A, Kuna M (2017) DEM simulation of polyhedral particle cracking using a combined Mohr–Coulomb–Weibull failure criterion. Granul Matter 19:41. https://doi.org/10.1007/s10035-017-0731-8

Cui XH, Xiao H, Ling X (2022) Analysis of ballast breakage in ballast bed when using under sleeper pads. Geomech Geoeng 17:677–688. https://doi.org/10.1080/17486025.2020.1864030

Hossain Z, Indraratna B, Darve F, Thakur PK (2007) DEM analysis of angular ballast breakage under cyclic loading. Geomech Geoeng 2:175–181. https://doi.org/10.1080/17486020701474962

Liu G-Y, Xu W-J, Sun Q-C, Govender N (2020) Study on the particle breakage of ballast based on a GPU accelerated discrete element method. Geosci Front 11:461–471. https://doi.org/10.1016/j.gsf.2019.06.006

Yan Y, Zhao J, Ji S (2015) Discrete element analysis of breakage of irregularly shaped railway ballast. Geomech Geoeng 10:1–9. https://doi.org/10.1080/17486025.2014.933891

Rasmussen LL (2021) Hybrid lattice/discrete element method for bonded block modeling of rocks. Comput Geotech 130:103907. https://doi.org/10.1016/j.compgeo.2020.103907

Bolander J, Yoshitake K, Thomure J (1999) STRESS ANALYSIS USING ELASTICALLY HOMOGENEOUS RIGID-BODY-SPRING NETWORKS. Doboku Gakkai Ronbunshu 16:25–32. https://doi.org/10.2208/jscej.1999.633_25

Yip M, Mohle J, Bolander JE (2005) Automated modeling of three-dimensional structural components using irregular lattices. Comput-Aided Civ Infrastruct Eng 20:393–407. https://doi.org/10.1111/j.1467-8667.2005.00407.x

Rasmussen LL, de Farias MM, de Assis AP (2018) Extended Rigid Body Spring Network method for the simulation of brittle rocks. Comput Geotech 99:31–41. https://doi.org/10.1016/j.compgeo.2018.02.021

Camanho P, Davila C (2002) Mixed-Mode Decohesion Finite Elements for the Simulation of Delamination in Composite Materials. Langley

Asahina D, Ito K, Houseworth JE et al (2015) Simulating the Poisson effect in lattice models of elastic continua. Comput Geotech 70:60–67. https://doi.org/10.1016/j.compgeo.2015.07.013

Zang A, Wagner FC, Stanchits S et al (2000) Fracture process zone in granite. J Geophys Res Solid Earth 105:23651–23661. https://doi.org/10.1029/2000JB900239

Benzeggagh ML, Kenane M (1996) Measurement of mixed-mode delamination fracture toughness of unidirectional glass/epoxy composites with mixed-mode bending apparatus. Compos Sci Technol 56:439–449. https://doi.org/10.1016/0266-3538(96)00005-X

Jackson R, Gorski B, Gyenge M (1995) Geotechnical properties of rock. Minister of Supply and Services Canada, Ottawa, ON (Canada), Canada

Hoek E, Carranza C, Corkum B (2002) Hoek-brown failure criterion – 2002 edition. In: Proc. NARMS-TAC Conference. Toronto, pp 267–273

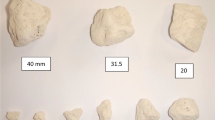

Diógenes DF (2021) Avaliação multiescala de propriedades (petrográficas, físicas e morfológicas) de agregados e empacotamento de partículas para composição de lastros ferroviários. PhD Dissertation, Universidade Federal do Ceará

Recarey C, Pérez I, Roselló R et al (2019) Advances in particle packing algorithms for generating the medium in the discrete element method. Comput Methods Appl Mech Eng 345:336–362. https://doi.org/10.1016/j.cma.2018.11.011

Recarey C, Cortés LA, de Farias MM et al (2018) Systemic characterization and evaluation of particle packings as initial sets for discrete element simulations. Comput Part Mech 5:319–334. https://doi.org/10.1007/s40571-017-0171-6

Valera RLR, González JI, de Oliveira JM et al (2023) Development and coupling of numerical techniques for modeling micromechanical discrete and continuous media using real particle morphologies. Comput Part Mech 10:121–141. https://doi.org/10.1007/s40571-022-00481-x

Rasmussen LL, de Farias MM (2019) Lattice modelling of gravity and stress-driven failures of rock tunnels. Comput Geotech 116:103183. https://doi.org/10.1016/j.compgeo.2019.103183

Jaeger JC (1967) Failure of rocks under tensile conditions. Int J Rock Mech Mining Sci Geomech Abstracts 4:219–227. https://doi.org/10.1016/0148-9062(67)90046-0

McDowell GR, Bolton MD, Robertson D (1996) The fractal crushing of granular materials. J Mech Phys Solids 44:2079–2101. https://doi.org/10.1016/S0022-5096(96)00058-0

McDowell GR, Bolton MD (1998) On the micromechanics of crushable aggregates. Géotechnique 48:667–679. https://doi.org/10.1680/geot.1998.48.5.667

Nakata AFL, Hyde M, Hyodo H, Murata, (1999) A probabilistic approach to sand particle crushing in the triaxial test. Géotechnique 49:567–583. https://doi.org/10.1680/geot.1999.49.5.567

Xiao Y, Meng M, Daouadji A et al (2020) Effects of particle size on crushing and deformation behaviors of rockfill materials. Geosci Front 11:375–388. https://doi.org/10.1016/j.gsf.2018.10.010

Weibull W (1951) A statistical distribution function of wide applicability. J Appl Mech 18:293–297. https://doi.org/10.1115/1.4010337

Indraratna B, Ionescu D, Christie D, Chowdhury R (1997) Compression and Degradation of Railway Ballast Under One-Dimensional Loading. Australian Geomechanics 48–61

Marsal RJ (1975) Mechanical properties of rockfill. Int J Rock Mech Mining Sci Geomech Abstracts 12:67. https://doi.org/10.1016/0148-9062(75)90138-2

Marschi ND, Chan CK, Seed HB (1972) Evaluation of Properties of Rockfill Materials. J Soil Mech Found Div 98:95–114. https://doi.org/10.1061/JSFEAQ.0001735

Indraratna B, Wijewardena LSS, Balasubramaniam AS (1993) Large-scale triaxial testing of grey wacke rockfill. Géotechnique 43:37–51. https://doi.org/10.1680/geot.1993.43.1.37

Zhang J, Wang X, Yin Z-Y, Liang Z (2020) DEM modeling of large-scale triaxial test of rock clasts considering realistic particle shapes and flexible membrane boundary. Eng Geol 279:105871. https://doi.org/10.1016/j.enggeo.2020.105871

Charles JA, Watts KS (1980) The influence of confining pressure on the shear strength of compacted rockfill. Geotechnique 30:353–367. https://doi.org/10.1680/geot.1980.30.4.353

Indraratna B, Ionescu D, Christie HD (1998) Shear behavior of railway ballast based on large-scale triaxial tests. J Geotech Geoenviron Eng 124:439–449. https://doi.org/10.1061/(ASCE)1090-0241(1998)124:5(439)

Werkmeister S, Dawson AR, Wellner F (2001) Permanent deformation behavior of granular materials and the shakedown concept. Transp Res Record 1757:75–81. https://doi.org/10.3141/1757-09

Sun QD, Indraratna B, Nimbalkar S (2016) Deformation and degradation mechanisms of railway ballast under high frequency cyclic loading. J Geotech Geoenviron Eng 142:04015056. https://doi.org/10.1061/(ASCE)GT.1943-5606.0001375

Acknowledgements

This work was financially supported by the Conselho Nacional de Desenvolvimento Científico e Tecnológico—CNPq. This support is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

de Almeida Torquato e Silva, S., de Farias, M.M., Rasmussen, L.L. et al. Hybrid Lattice-discrete element method for ballast modeling. Comp. Part. Mech. (2024). https://doi.org/10.1007/s40571-024-00723-0

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40571-024-00723-0