Abstract

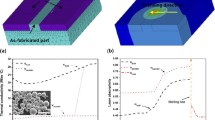

Rapid advancements in the aerospace industry necessitate the development of unified, lightweight and thermally conductive structures. Integrating complex geometries, including bionic and porous structures, is paramount in thermally conductive structures to attain improved thermal conductivity. The design of two high-porosity porous lattice structures was inspired by pomelo peel structure, using Voronoi parametric design. By combining characteristic elements of two high-porostructuressity porous lattice structures designed, a novel high-porosity porous gradient structure is created. This structure is based on gradient design. Utilizing selective laser melting (SLM), fabrication comprises three . Steady-state thermal characteristics are evaluated via finite element analysis (FEA). The experimental thermal conductivity measurements correlate well with simulation results, validating the sequence of K_L as the highest, followed by D_K_L and then D_L. Heat treatment significantly improves thermal conductivity, enhancing the base material by about 45.6% and porous structured samples by approximately 43.7%.

Similar content being viewed by others

References

Y.M. Xiao, Y.Q. Yang, S.B. Wu, J. Chen, D. Wang, C.H. Song, Acta Metall. Sin.-Engl. Lett. 35, 486 (2022)

L.E. Murr, J. Mater. Sci. Technol. 32, 987 (2016)

X.J. Wang, S.Q. Xu, S.W. Zhou, W. Xu, M. Leary, P. Choong, M. Qian, M. Brandt, Y.M. Xie, Biomaterials 83, 127 (2016)

B. Blakey-Milner, P. Gradl, G. Snedden, M. Brooks, J. Pitot, E. Lopez, M. Leary, F. Berto, A. du Plessis, Mater. Des. 209, 110008 (2021)

G. Allevi, M. Cibeca, R. Fioretti, R. Marsili, R. Montanini, G. Rossi, Measurement 126, 252 (2018)

L. Berrocal, R. Fernández, S. González, A. Periñán, S. Tudela, J. Vilanova, L. Rubio, J.M.M. Márquez, J. Guerrero, F. Lasagni, Prog. Addit. Manuf. 4, 83 (2019)

X.J. Nie, Z. Chen, Y. Qi, H. Zhang, H.H. Zhu, Acta Metall. Sin.-Engl. Lett. 36, 1454 (2023)

T. Maconachie, M. Leary, B. Lozanovski, X. Zhang, M. Qian, O. Faruque, M. Brandt, Mater. Des. 183, 108137 (2019)

A.G. Evans, J.W. Hutchinson, N.A. Fleck, M.F. Ashby, H.N.G. Wadley, Prog. Mater. Sci. 46, 309 (2001)

M.G. Rashed, M. Ashraf, R. Mines, P.J. Hazell, Mater. Des. 95, 518 (2016)

M.R. Karamooz Ravari, M. Kadkhodaei, M. Badrossamay, R. Rezaei, Int. J. Mech. Sci. 88, 154 (2014)

K.J. Lin, K.M. Hu, D.D. Gu, Opt. Laser Technol. 115, 9 (2019)

C. Dawson, J.F.V. Vincent, G. Jeronimidis, G. Rice, P. Forshaw, J. Theor. Biol. 199, 291 (1999)

F.M. Scott, Nature 210, 1015 (1966)

M. Thielen, C.N. Schmitt, S. Eckert, T. Speck, R. Seidel, Bioinspir. Biomim. 8, 025001 (2013)

A. Bührig-Polaczek, C. Fleck, T. Speck, P. Schüler, S.F. Fischer, M. Caliaro, M. Thielen, Bioinspir. Biomim. 11, 045002 (2016)

L.C. Long, Z.K. Wang, K. Chen, J. Wood Sci. 61, 569 (2015)

H. Zhao, Y. Han, C. Pan, D. Yang, H. Wang, T. Wang, X. Zeng, P. Su, Micromachines. 12 (2021)

S.J. Yue, Z.G. Xu, Int. Commun. Heat Mass Transf. 142, 106640 (2023)

F. Muzaki, J. Limanza, G.N. Surname, Numerical simulation and analysis of functionally graded materials and it’s potentials for battery application: a review. In: Paper presented at the 3rd international Symposium on Material and Electrical Engineering Conference (ISMEE), (2021), pp. 249–252

L. Zhao, L.B. Song, J.G. Santos Macías, Y.X. Zhu, M.S. Huang, A. Simar, Z.H. Li, Addit. Manuf. 56, 102914 (2022)

N. Takata, H. Kodaira, K. Sekizawa, A. Suzuki, M. Kobashi, Mater. Sci. Eng. A 704, 218 (2017)

R.R.J. Sélo, S. Catchpole-Smith, I. Maskery, I.A. Ashcroft, C.J. Tuck, Addit. Manuf. 34, 101214 (2020)

C. Butler, S. Babu, R. Lundy, R. O’Reilly Meehan, J. Punch, N. Jeffers, Mater. Charact. 173, 110945 (2021)

Y.R. Liang, T.J. Ma, T.N. Jin, B. Zhang, L. Yang, W.H. Yin, H.G. Fu, Mater. Sci. Technol. 39, 1223 (2023)

B.S. Yang, W.H. Chen, R.L. Xin, X.H. Zhou, D. Tan, C. Ding, Y. Wu, L. Yin, C.Y. Chen, S. Wang, Z.L. Yu, J.T. Pham, S. Liu, Y.F. Lei, L.J. Xue, J. Bionic Eng. 19, 448 (2022)

D. Almonti, N. Ucciardello, Materials (2019)

Y. Du, H.X. Liang, D.Q. Xie, N. Mao, J.F. Zhao, Z.J. Tian, C.J. Wang, L.D. Shen, Mater. Chem. Phys. 239, 121968 (2020)

H.J. Xu, Z.B. Xing, F.Q. Wang, Z.M. Cheng, Chem. Eng. Sci. 195, 462 (2019)

B.O. Aduda, J. Mater. Sci. 31, 6441 (1996)

M. Laleh, E. Sadeghi, R.I. Revilla, Q. Chao, N. Haghdadi, A.E. Hughes, W. Xu, I.D. Graeve, M. Qian, I. Gibson, M.Y. Tan 2023 Prog. Mater. Sci. 133

N.T. Aboulkhair, C. Tuck, I. Ashcroft, I. Maskery, N.M. Everitt, Metall. Mater. Trans. A 46, 3337 (2015)

EOS GmbH-Electro Optical Systems, EOS Aluminium AlSi10Mg. (Germany, 2014)

American Society for Testing and Materials, E1225–13. (United States, 2013)

O. Al-Ketan, R. Rowshan, R.K. Abu Al-Rub, Addit. Manuf. 19, 167 (2018)

H.X. Wang, X. Lin, N. Kang, Z.H. Qin, S.Q. Shi, J.C. Li, W.D. Huang, Acta Metall. Sin.-Engl. Lett. 35, 375 (2022)

B. Liu, B.Q. Li, Z. Li, Results Phys. 12, 982 (2019)

X.H. Gu, J.X. Zhang, X.L. Fan, L.C. Zhang, Acta Metall. Sin.-Engl. Lett. 33, 327 (2020)

T. Rubben, R.I. Revilla, I. De Graeve, Corros. Sci. 147, 406 (2019)

M. Wang, B. Song, Q. Wei, Y. Zhang, Y. Shi, Mater. Sci. Eng. A 739, 463 (2019)

J.J. Shea, I.E.E.E. Electr, Insul. Mag. 21, 56 (2005)

A. Azizi, F. Hejripour, J.A. Goodman, P.A. Kulkarni, X. Chen, G. Zhou, S.N. Schiffres, Rapid. Prototyp. J 29, 1109 (2023)

X. Zhang, M.H. Zhang, C.P. Zhang, T. Zhou, X. Wu, X.Z. Yue, Mater. (basel) 15, 8046 (2022)

Acknowledgements

The authors are grateful for funding of the Shanghai Sailing Program (No. 19YF1434300) and the Shanghai Engineering Research Center of High-Performance Medical Device Materials (No. 20DZ2255500) and the National Natural Science Foundation of China (No. 11947137).

Author information

Authors and Affiliations

Contributions

H.L. Tang was involved in conceptualization, methodology, investigation, software, writing—original draft and validation. X. Zhang was responsible for conceptualization, investigation, validation and data curation. C.P. Zhang took part in data curation, resources, and reviewing and editing. T. Zhou participated in methodology, experiments design, and reviewing and editing. S.Y. Guo contributed to validation and resources. G.P. Xu gave academic advice and guidance on experimental design. R.S. Zhao carried out statistical analysis of experimental results. B.Y. Hur was involved in data analysis. X.Z. Yue assisted with methodology, visualization, formal analysis, reviewing and editing, and data curation.

Corresponding author

Ethics declarations

Conflict of interest

The authors state that there are no conflicts of interest to disclose.

Additional information

Available online at http://link.springer.com/journal/40195

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Tang, H., Zhang, X., Zhang, C. et al. Designing High-Porosity Porous Structures with Complex Geometries for Enhanced Thermal Conductivity Using Selective Laser Melting and Heat Treatment. Acta Metall. Sin. (Engl. Lett.) (2024). https://doi.org/10.1007/s40195-024-01672-6

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40195-024-01672-6